Historical Asbestos Measurements in Denmark—A National Database

Abstract

:1. Introduction

2. Methodology

2.1. Data Collection

- The National Research Centre for Work Environment (NRCWE) and National archives: 79 asbestos measurements from 1982 to 1986 from various industries collected from [30].

- Aalborg University Hospital: 3068 asbestos measurements from 1971 to 1985 in an asbestos cement factory and in a facility which manufactured insulation materials with and without asbestos.

- Department of Public Health, Aarhus University: 132 measurements of asbestos from 1987 to 1989 during dismantling activities in schools and hospitals.

- Odense University Hospital: 5957 measurements from a facility manufacturing asbestos-containing materials such as transport equipment and friction materials (e.g., brakes) in the period of 1980–1997.

2.2. Asbestos Database Structure

- (i).

- Premises: Filling reference number of the archive, company sector;

- (ii).

- Identification of material: name and CAS number;

- (iii).

- (Industrial sector, job and task codes according to the national classifications, as explained below;

- (iv).

- Purpose of the measurement: either random sampling, sampling due to disease in an employee, sampling requested by the company, regulatory check, research purposes or other;

- (v).

- Determinants—exposure scenario: description of working tasks, environmental conditions such as temperature and humidity, number of people working in the same working area (potentially exposed group of people);

- (vi).

- Determinants—technical conditions and measures to control worker exposure: automation level, processes designed aiming to prevent release, type of local exhaust ventilation, type of general ventilation (mechanical or natural), and personal protective measures;

- (vii).

- Exposure metrics: worker experience in years, exposure duration, exposure frequency;

- (viii).

- Sampling characteristics: sampling position (stationary or personal), original sample track number, anonymous subject identifier, sample date and time, pump flow, sampled volume; sampling and fibres counting method used;

- (ix).

- Exposure data: asbestos concentration in fibres cm−3.

2.3. Data Analysis

3. Results

3.1. Measurement of Asbestos Concentrations

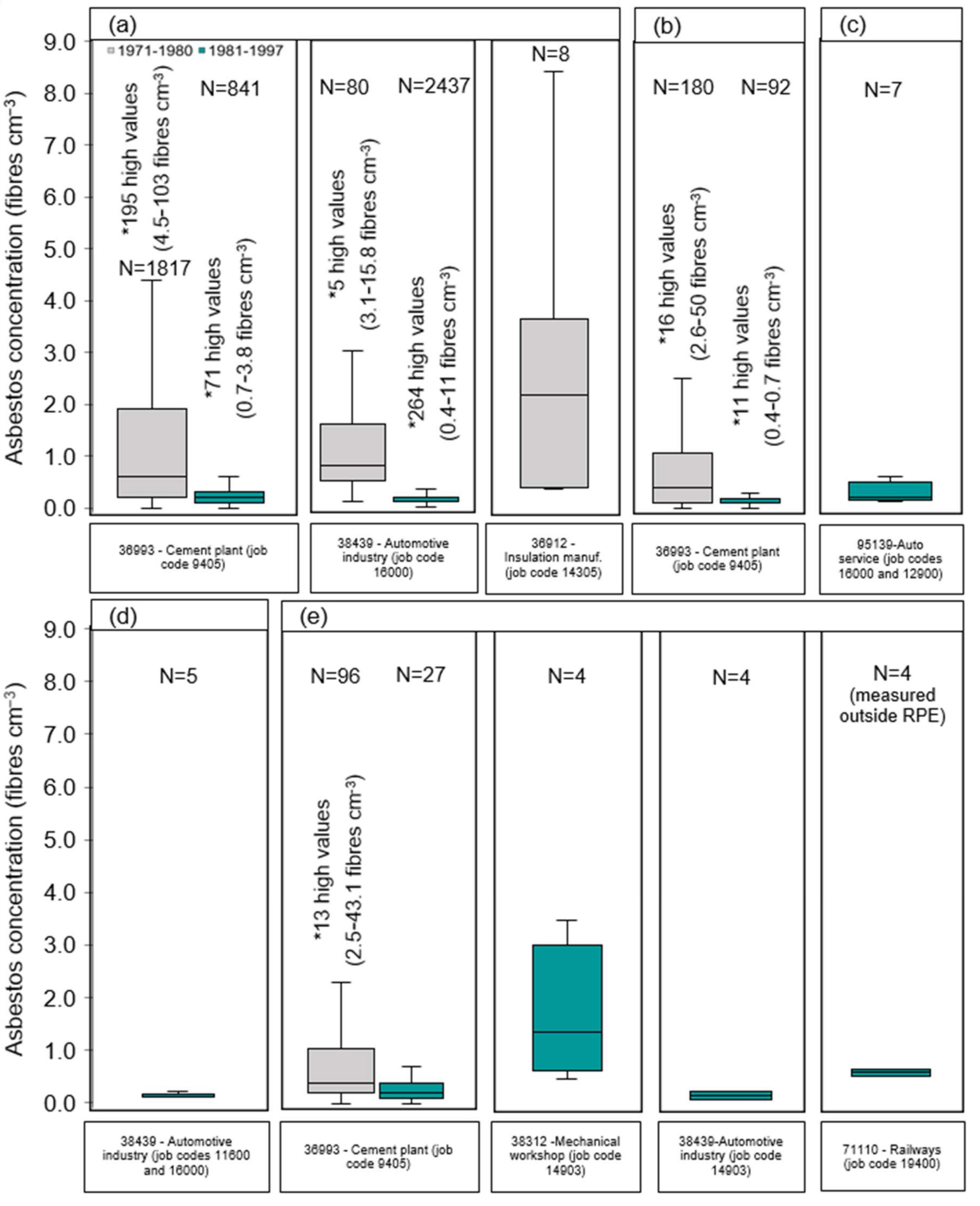

3.1.1. Manufacturing of Asbestos Products

3.1.2. Active Handling of Asbestos Products

3.1.3. Transport, Storage, and Package of Asbestos Products

3.1.4. Maintenance Jobs

3.1.5. General Supervision of Work Processes and Inspection Tasks

3.1.6. Cleaning Activities

3.2. Time Evolution of Exposure Patterns

4. Discussion

4.1. Asbestos Exposure Levels Found in Danish Industries

4.2. Comparison of Asbestos Exposure Concentrations with Health Guideline Values

4.3. Database Limitations

- Most of the inventoried datasets did not provide comprehensive details with respect to their study approach or design to be able to fully understand the type or duration of exposure. Even though some of the archives and reports provided general insight about the working conditions in the workplaces, most of them lacked essential information regarding the corresponding industry, work situation, determinants of exposure (e.g., personal RPE, encapsulation of the process, exhaust ventilation), and duration of measurements. From several exposure scenarios, it was unclear whether the data was based on stationary or personal sampling and sampling year was not reported. In case of personal sampling, it was also not stated in 44.6% of the cases whether such measurement was with RPE and if it was measured inside or outside the respiratory mask. Prior to 1980, exposure scenarios were scarce with only 2189 measurements, corresponding to 37% of the inventoried situations measured in which asbestos concentrations, sampling position, industry and job codes were available (5869 measurements). The lack of these type of descriptions and the scattered quantitative exposure information over time consequently introduced uncertainties in the identification and modelling of clear temporal trends in asbestos exposure levels due to changes in the measurement strategy, exposure control practices and process characteristics [33,41,42].

- Even though, it is very likely that majority of the inventoried asbestos exposure concentrations were determined by using appropriate methodologies, and analysed by using phase contrast microscope (PCM) method, 5817 (out of 5869) datasets lacked information about sampling techniques and counting procedures. One of the PCM method limitations is that it cannot differentiate between asbestos and non-asbestos fibres, while scanning electron microscope (SEM) or transmission electron microscope (TEM), which is approximately 100 times more sensitive, is capable of distinguishing different fibre types. It is therefore likely that PCM method overestimated the asbestos fibre concentration in the air in occupational settings where large proportions of other fibres (e.g., wool, cotton, glass) are present [43,44]. On the other hand, due to the low resolution of the PCM method, it is also probable that most of samples did not account for thin fibres (width less than 0.25 µm) and potentially underestimated asbestos exposures [24,45]. There have been, however, numerous attempts to convert total fibre counts to specific fibre counts with fibre type, length, and diameter [24].

- Most quantitative information describing exposure patterns among industries and jobs was available for the largest Danish industries which manufactured automotive and asbestos cement products (5677 measurements, 96.7%). All the asbestos samplings in these industries were conducted as part of a regulatory check. It is likely that they correspond to the dustiest tasks and would result in an overestimation of personal exposure concentrations if applied to the entire work force in these industries. The detailed information about tasks performed does, however, allow for estimation of the exposure associated with these tasks, which would most likely be close to the typical exposure levels between 1971 and 1985. In almost all the other occupational categories and industries, the number of available measurements was limited to a few samples. It is probable that larger industries registered lower fibre levels if compared to smaller workplaces or less controlled facilities where the awareness of occupational hazards and health problems may have been lower and where safety measures were less sophisticated or even non-existent. The measurements on an asbestos cement factory operating in Denmark were performed quarterly by the factory, systematically covering relevant tasks and analysed at NRCWE (at the time called SIFA) in agreement with the Danish Working Authorities. The insulation materials manufacturer, by far the largest facility of its type in Denmark, performed measurements in a similar way. In principle, these datasets should be highly representative for these workplaces, but evidently, these companies would have been able to affect the results by optimizing tasks, cleaning and ventilation settings on days of measurements. However, the authors believe that if further asbestos exposure concentrations exist, inclusion of these would not significantly affect the key findings reported here.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hendry, N.W. The geology, occurrences, and major uses of abestos. Ann. N. Y. Acad. Sci. 1965, 132, 12–21. [Google Scholar] [CrossRef]

- IARC Asbestos (Chrysotile, Amosite, Crocidolite, Tremolite, Actinolite, and Anthophyllite). IARC Work. Gr. Eval. Carcinog. Risks to Humans. Arsenic, Met. Fibres Dusts. Lyon Int. Agency Res. Cancer; 2012. (IARC Monogr. Eval. Carcinog. Risks to Humans, No. 100C.); 2012; No. 100C. Available online: https://www.ncbi.nlm.nih.gov/books/NBK304374/ (accessed on 26 November 2020).

- National Toxicology Program. NTP Toxicology and Carcinogenesis Studies of Crocidolite Asbestos (CAS No. 12001-28-4) in F344/N Rats (Feed Studies). Nat. Toxicol. Prog. Tech. Rep. Ser. 1988, 280, 1–178. Available online: https://pubmed.ncbi.nlm.nih.gov/12748699/ (accessed on 26 November 2020). [PubMed]

- National Toxicology Program. NTP Lifetime Carcinogenesis Studies of Chrysotile Asbestos (CAS No. 12001-29-5) in Syrian Golden Hamsters (Feed Studies). Natl. Toxicol. Program Tech. Rep. Ser. 1990, 246, 1–192. Available online: https://pubmed.ncbi.nlm.nih.gov/12750747/ (accessed on 26 November 2020). [PubMed]

- National Toxicology Program. NTP Toxicology and Carcinogenesis Studies of Amosite Asbestos (CAS No. 12172-73-5) in F344/N Rats (Feed Studies) . Natl. Toxicol. Program Tech. Rep. Ser. 1990, 279, 1–341. Available online: https://pubmed.ncbi.nlm.nih.gov/12748700/ (accessed on 26 November 2020). [PubMed]

- WHO Asbestos: Elimination of Asbestos-Related Diseases. World Health Organization. Available online: http://www.who.int/news-room/fact-sheets/detail/asbestos-elimination-of-asbestos-related-diseases (accessed on 27 July 2020).

- WHO. Determination of Airborne Fibre Number Concentrations; WHO: Geneva, Switzerland, 1997; pp. 1–53. [Google Scholar]

- Matsuzaki, H.; Maeda, M.; Lee, S.; Nishimura, Y.; Kumagai-Takei, N.; Hayashi, H.; Yamamoto, S.; Hatayama, T.; Kojima, Y.; Tabata, R.; et al. Asbestos-induced cellular and molecular alteration of immunocompetent cells and their relationship with chronic inflammation and carcinogenesis. J. Biomed. Biotechnol. 2012, 492608. [Google Scholar] [CrossRef]

- Lanphear, B.P.; Buncher, C.R. Latent period for malignant mesothelioma of occupational origin. J. Occup. Med. 1992, 34, 718–721. [Google Scholar] [PubMed]

- AT At-Vejledning Stoffer of Materialer C.2.2-2: Asbest. Arbejdstilsynet, Denmark. July 2005–Updated June 2019. Available online: https://at.dk/media/5675/c-2-2-2-asbest-t.pdf (accessed on 20 November 2020).

- Stayner, L.; Smith, R.; Bailer, J.; Gilbert, S.; Steenland, K.; Dement, J.; Brown, D.; Lemen, R. Exposure-response analysis of risk of respiratory disease associated with occupational exposure to chrysotile asbestos. Occup. Environ. Med. 1997, 54, 646–652. [Google Scholar] [CrossRef] [Green Version]

- Hein, M.J.; Stayner, L.T.; Lehman, E.; Dement, J.M. Follow-up study of chrysotile textile workers: Cohort mortality and exposure-response. Occup. Environ. Med. 2007, 64, 616––625. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gualtieri, A.F. Mineral Fibres: Crystal Chemistry, Chemical-Physical Properties, Biological Interaction and Toxicity, 2017. Eur. Mineral. Union Notes Mineral. 2017, 18, 7–9. [Google Scholar]

- Røe, O.D. Asbest, malignt mesoteliom og lungekræft. Ugeskr. Laeger 2018, 180, 2–5. [Google Scholar]

- AT BEK nr 660 af 24/09/1986. The Ministry of Employment. Executive Order on Asbestos (Asbestos Order). Available online: https://www.retsinformation.dk/eli/lta/1986/660 (accessed on 20 November 2020). (In Danish).

- AT BEK nr 1502 af 21/12/2004. The Ministry of Employment. Executive Order on Asbestos (Asbestos Order). Available online: https://www.retsinformation.dk/eli/lta/2004/1502 (accessed on 20 November 2020). (In Danish).

- Raffn, E.; Lynge, E.; Juel, K.; Korsgaard, B. Incidence of cancer and mortality among employees in the asbestos cement industry in Denmark. Br. J. Ind. Med. 1989, 46, 90–96. [Google Scholar] [CrossRef] [Green Version]

- Sherson, L. Low-Dose Occupational Asbestos Exposure and Lung Cancer: A Scientific Reference Document on behalf of the Danish Working Environment Research Fund; Arbejds- og Miljømedicinsk Klinik; Department of Occupational and Environmental M edicine, Odense University Hospital: Odense, Denmark, 2013. [Google Scholar]

- Brauer, C.; Baandrup, U.; Jacobsen, P.; Krasnik, M.; Olsen, J.H.; Pedersen, J.H.; Rasmussen, T.R.; Schlünssen, V.; Sherson, D.; Svolgaard, B.; et al. Screening for asbestbetingede sygdomme? Ugeskr. Laeger 2009, 171, 433–436. [Google Scholar]

- Skammeritz, E.; Omland, L.H.; Johansen, J.P. Omland Asbestos exposure and survival in malignant mesothelioma: A description of 122 consecutive cases at an occupational clinic. Int. J. Occup. Environ. Med. 2011, 2, 224–236. [Google Scholar]

- Greenberg, M.; Lloyd Davies, T.A. Mesothelioma Register 1967–68. Br. J. Ind. Med. 1974. [Google Scholar] [CrossRef] [Green Version]

- Burdorf, A.; Swuste, P. An expert system for the evaluation of historical asbestos exposure as diagnostic criterion in asbestos-related diseases. Ann. Occup. Hyg. 1999. [Google Scholar] [CrossRef]

- Rice, C.; Heineman, E.F. An asbestos job exposure matrix to characterize fiber type, length, and relative exposure intensity. Appl. Occup. Environ. Hyg. 2003, 18, 506–512. [Google Scholar] [CrossRef]

- Nielsen, L.S.; Bælum, J.; Rasmussen, J.; Dahl, S.; Olsen, K.E.; Albin, M.; Hansen, N.C.; Sherson, D. Occupational asbestos exposure and lung cancer—A systematic review of the literature. Arch. Environ. Occup. Heal. 2014, 69, 191–206. [Google Scholar] [CrossRef] [PubMed]

- Peters, S.; Vermeulen, R.; Portengen, L.; Olsson, A.; Kendzia, B.; Vincent, R.; Savary, B.; Lavoué, J.; Cavallo, D.; Cattaneo, A.; et al. SYN-JEM: A Quantitative Job-Exposure Matrix for Five Lung Carcinogens. Ann. Occup. Hyg. 2016, 60, 795–811. [Google Scholar] [CrossRef] [Green Version]

- The Medical Research Council Pneumoconiosis Unit (Mrcpu). A survey of pleural thickening: Its relation to asbestos exposure and previous pleural disease. Environ. Res. 1972, 5, 142–151. [Google Scholar] [CrossRef]

- Nielsen, A. Asbestos in the indoor atmosphere and environment. Ugeskr. Laeger 1986, 148, 3323–3328. [Google Scholar] [PubMed]

- Raffn, E. Kræft og dødsfald i asbestcementindustrien. En kohorteundersøgelse af cancerincidensen og mortaliteten blandt ansatte på Dansk Eternit Fabrik A/S 1928-1984. Ph.D. Thesis, Copenhagen University, Copenhagen, Denmark, 1990. [Google Scholar]

- Brauer, C.; Jacobsen, P. Report on Health Risks and Clinical Examiantions of DSB Employees Exposed to Asbestos; Occupational and Environmental Department, Bispebjerg Hospital: Copenhagen, Denmark, 2007. (In Danish) [Google Scholar]

- ATABAS Arbejdstilsynets Database for Arbejdspladsmålinger. ATABAS. Opgørelser for Perioden January 1983–December 1985 Arbejdsmiljøinstituttet January 1986. 1986; Not published. [Google Scholar]

- ECHA. Guidance on Information Requirements and Chemical Safety Assessment Chapter R. 14: Occupational Exposure Assessment; European Chemicals Agency: Helsinki, Finland, 2016; ISBN 9789294950819. [Google Scholar]

- Franken, R.; Shandilya, N.; Marquart, H.; McNally, K.; Fransman, W. Extrapolating the Applicability of Measurement Data on Worker Inhalation Exposure to Chemical Substances. Ann. Work Expo. Health 2020, 64, 250–269. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Swuste, P.; Dahhan, M.; Burdorf, A. Linking Expert Judgement and Trends in Occupational Exposure into a Job-Exposure Matrix for Historical Exposure to Asbestos in The Netherlands. Ann. Occup. Hyg. 2008, 52, 397–403. [Google Scholar] [CrossRef] [Green Version]

- Health Effects Institute. Asbestos Research (HEI-AR) Asbestos in Public and Commercial Buildings: A Literature Review and Synthesis of Current Knowledge; Report Number 1991-01-01; Health Effects Institute-Asbestos Research: Cambridge, MA, USA, 1991. [Google Scholar]

- Mlynarek, S.; Corn, M.; Blake, C. Asbestos exposure of building maintenance personnel. Regul. Toxicol. Pharmacol. 1996. [Google Scholar] [CrossRef]

- Akkersdijk, H. Asbestos in Occupational Groups in The Netherlands; Scheikundige Dienst Directoraat-Generaal van de Arbeid: Voorburg, The Netherlands, 1984. [Google Scholar]

- Boman, N.; Christensson, B. Asbest på våra Arbetsplatser. Undersökningsrapport AMT 102/74; Arbetarskyddsstyrelsen: Stockholm, Sweden, 1974. [Google Scholar]

- Price, B.; Crump, K.S.; Baird, E.C. Airborne asbestos levels in buildings: Maintenance worker and occupant exposures. J. Expo. Anal. Environ. Epidemiol. 1992, 2, 357–374. [Google Scholar]

- Kinney, P.L.; Satterfield, M.H.; Shaikh, R.A. Airborne fiber levels during asbestos operations and maintenance work in a large office building. Appl. Occup. Environ. Hyg. 1994, 9, 825–835. [Google Scholar] [CrossRef]

- BAI Bygge/Anlæg & Industri (BAI) Ministry of Children and Education. Safety When Working with Asbestos-Containing Materials. Available online: https://materialeplatformen.dk/bookpage/99585528 (accessed on 6 December 2021). (In Danish).

- Cherrie, J.; Addison, J.; Dodgson, J. Comparative Studies of Airborne Asbestos in Occupational and Non-Occupational Environments Using Optical and Electron Microscope Techniques; IARC Scientific Publications: Lyon, France, 1989; Volume 90, pp. 304–309. [Google Scholar] [PubMed]

- Burdett, G. A comparison of historic asbestos measurements using a thermal precipitator with the membrane filter-phase contrast microscopy method. Ann. Occup. Hyg. 1998, 42, 21–31. [Google Scholar] [CrossRef]

- Moldoveanu, M. Air Pollution with Asbestos in Several Cities in Romania. In Advanced Topics in Environmental Health and Air Pollution Case Studies; InTech: Rijeka, Croatia, 2011. [Google Scholar] [CrossRef] [Green Version]

- Harper, M.; Butler, C.; Berry, D.; Wroble, J. Where occupation and environment overlap: US forest service worker exposure to libby amphibole fibers. J. Occup. Environ. Hyg. 2015, 12, D47–D53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eypert-Blaison, C.; Romero-Hariot, A.; Clerc, F.; Vincent, R. Assessment of occupational exposure to asbestos fibers: Contribution of analytical transmission electron microscopy analysis and comparison with phase-contrast microscopy. J. Occup. Environ. Hyg. 2018, 15, 263–274. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fonseca, A.S.; Jørgensen, A.K.; Larsen, B.X.; Moser-Johansen, M.; Flachs, E.M.; Ebbehøj, N.E.; Bønløkke, J.H.; Østergaard, T.O.; Bælum, J.; Sherson, D.L.; et al. Historical Asbestos Measurements in Denmark—A National Database. Int. J. Environ. Res. Public Health 2022, 19, 643. https://doi.org/10.3390/ijerph19020643

Fonseca AS, Jørgensen AK, Larsen BX, Moser-Johansen M, Flachs EM, Ebbehøj NE, Bønløkke JH, Østergaard TO, Bælum J, Sherson DL, et al. Historical Asbestos Measurements in Denmark—A National Database. International Journal of Environmental Research and Public Health. 2022; 19(2):643. https://doi.org/10.3390/ijerph19020643

Chicago/Turabian StyleFonseca, Ana Sofia, Amalie Kofoed Jørgensen, Bianca Xuan Larsen, Marina Moser-Johansen, Esben Meulengracht Flachs, Niels Erik Ebbehøj, Jakob Hjort Bønløkke, Trine Olesen Østergaard, Jesper Bælum, David Lee Sherson, and et al. 2022. "Historical Asbestos Measurements in Denmark—A National Database" International Journal of Environmental Research and Public Health 19, no. 2: 643. https://doi.org/10.3390/ijerph19020643