Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland

Abstract

:1. Introduction

2. Materials and Methods

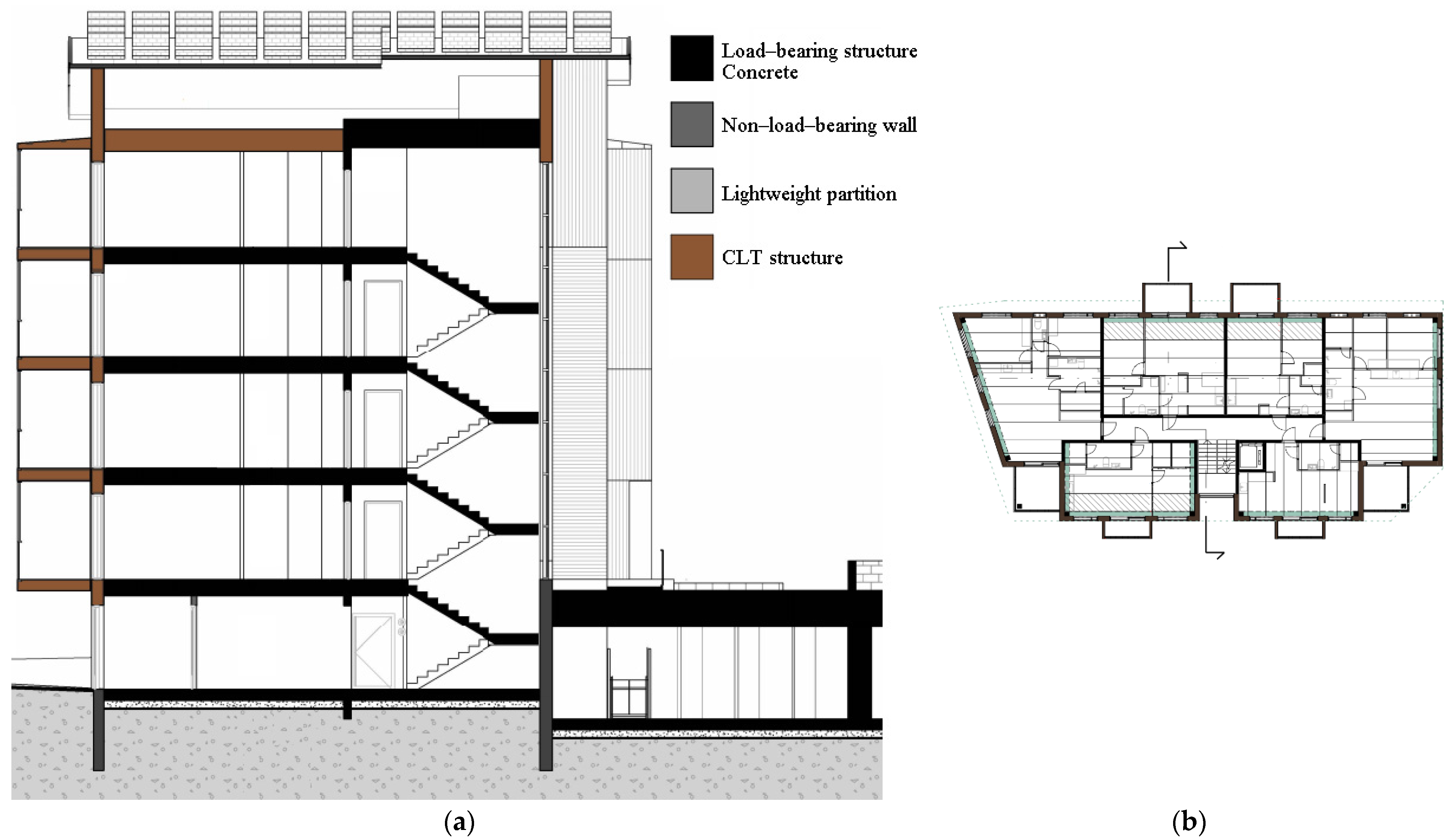

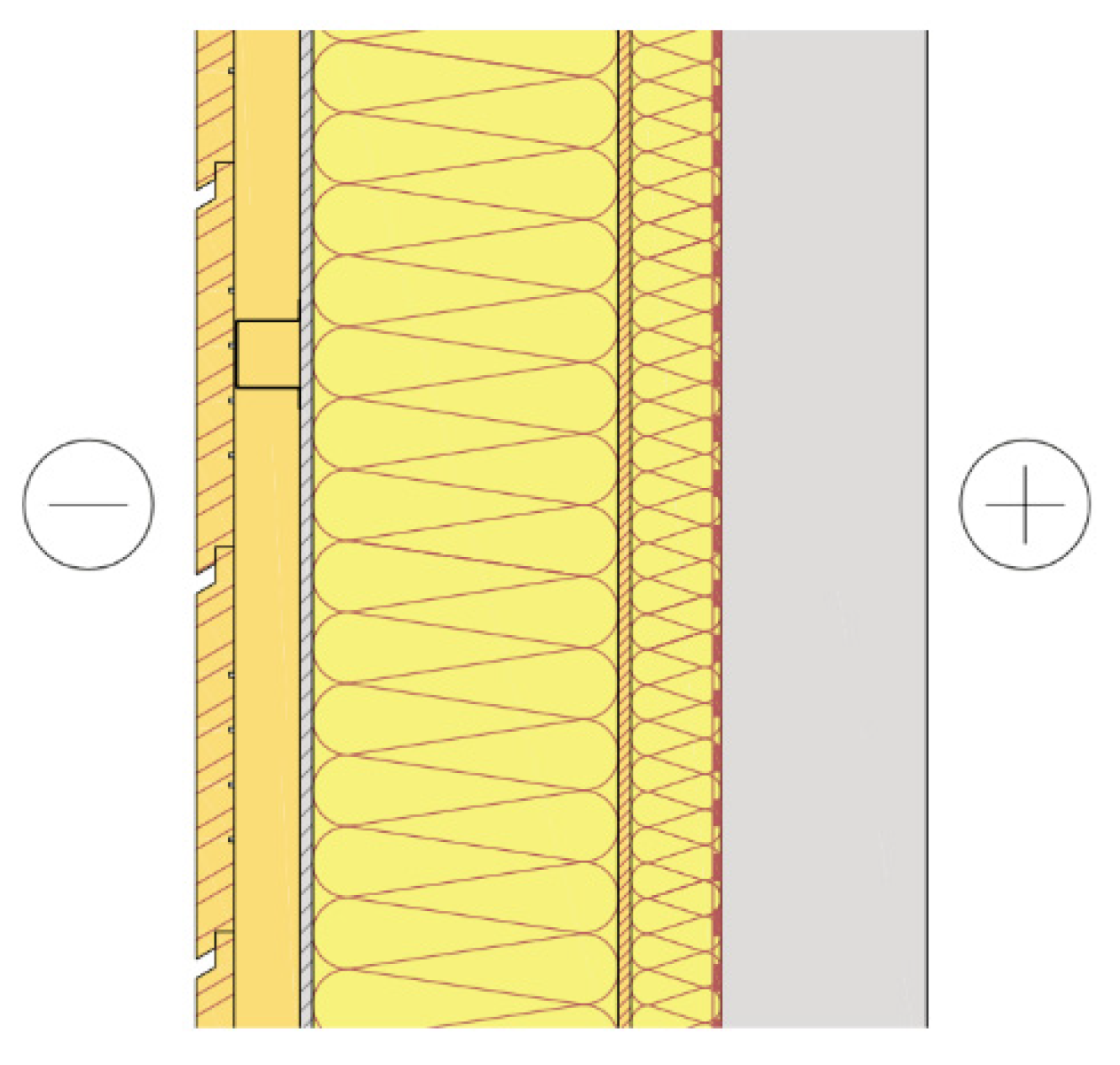

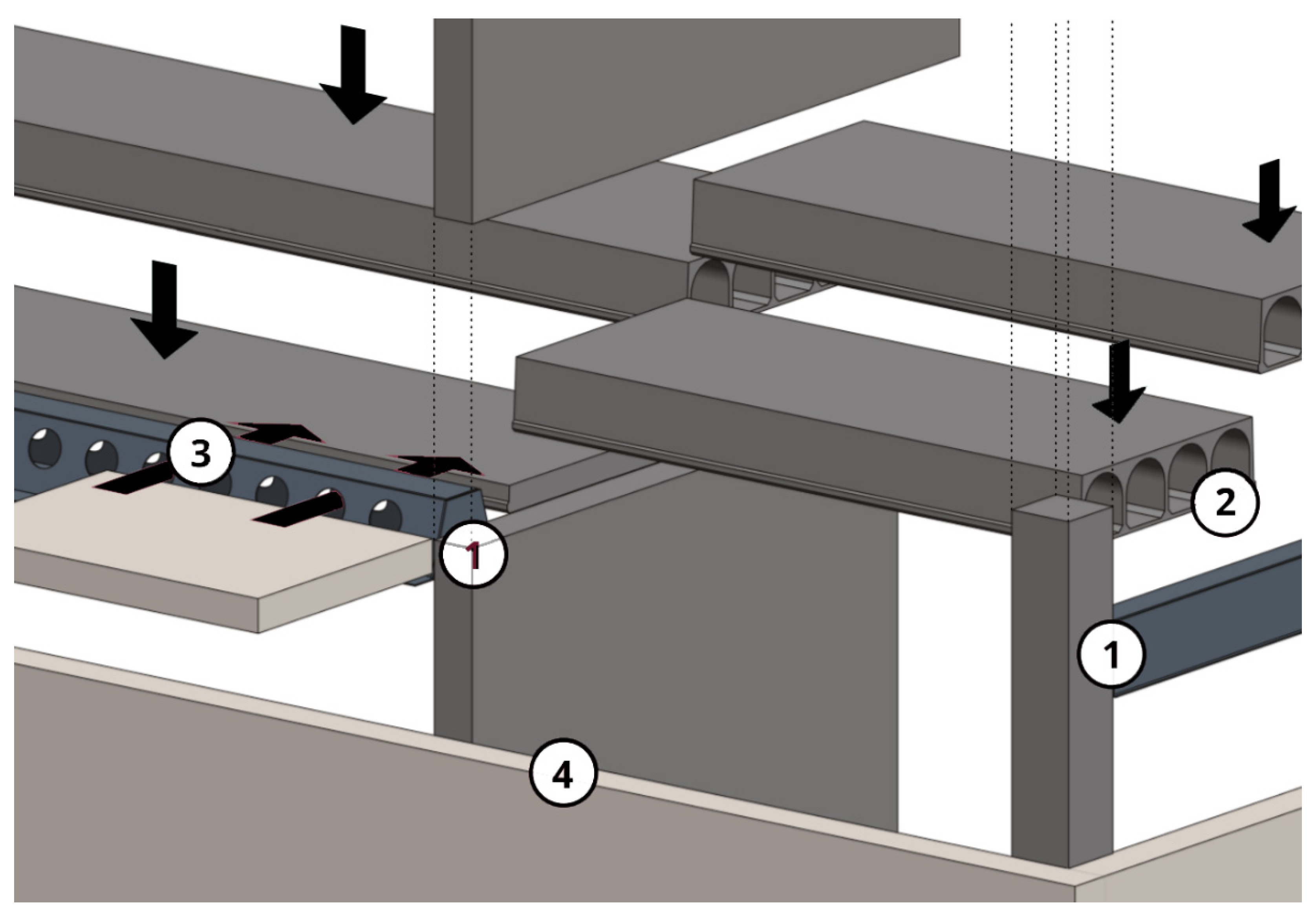

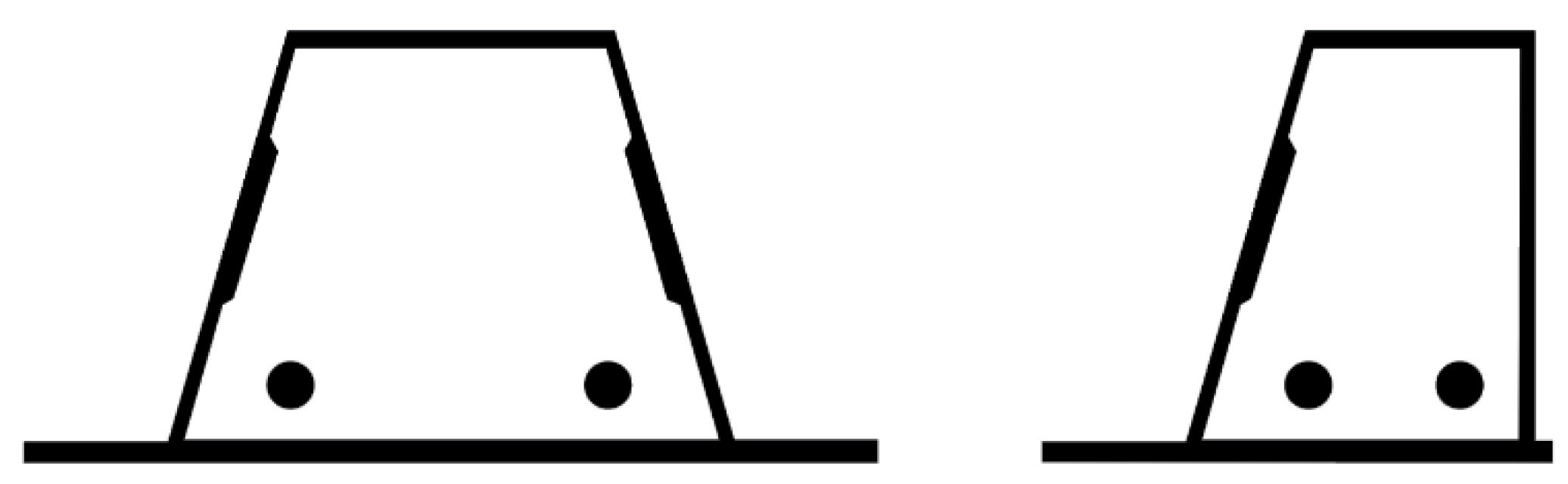

2.1. Hybrid Building Design

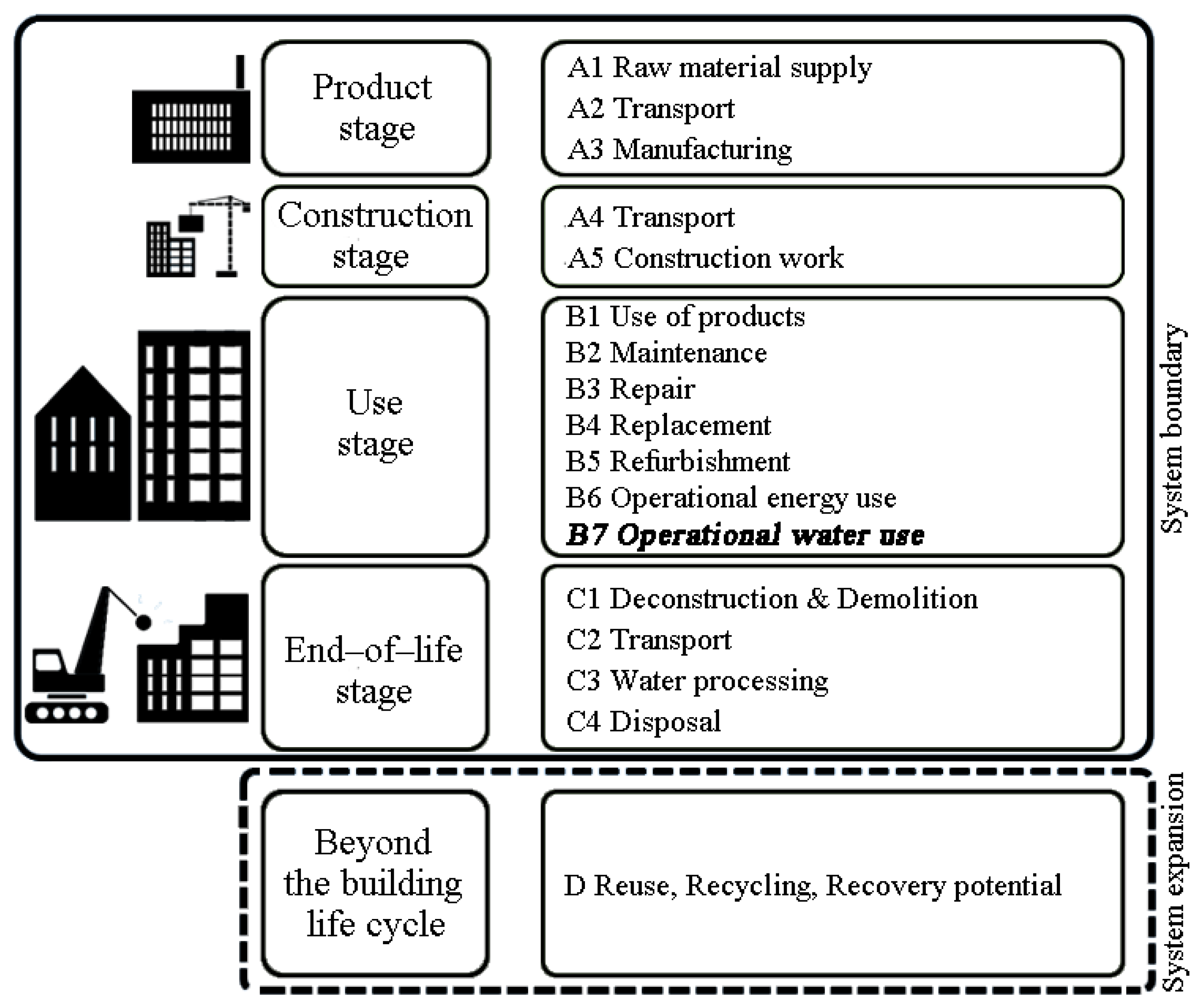

2.2. Goal and Scope

- The outer walls were load-bearing concrete sandwich elements. The intermediate floor structure was the same as in that of the hybrid apartment.

- Concrete tiles were used instead of CLT volume elements on the balconies.

- The street facade had a brick tile surface, making zoning requirements more flexible as in the hybrid apartment. The courtyard facade was made of lightweight concrete.

- The framework was designed based on the CLT element technology. LVL-ribbed tiles were used on the mid floors.

- It was the entire ground layer of the concrete structure to prevent the building from settlement differently.

- A sprinkler system was added.

- Balconies were the same CLT volume elements as in the hybrid apartment.

2.3. Software Tool

3. Results

3.1. Initial Values and Assumptions

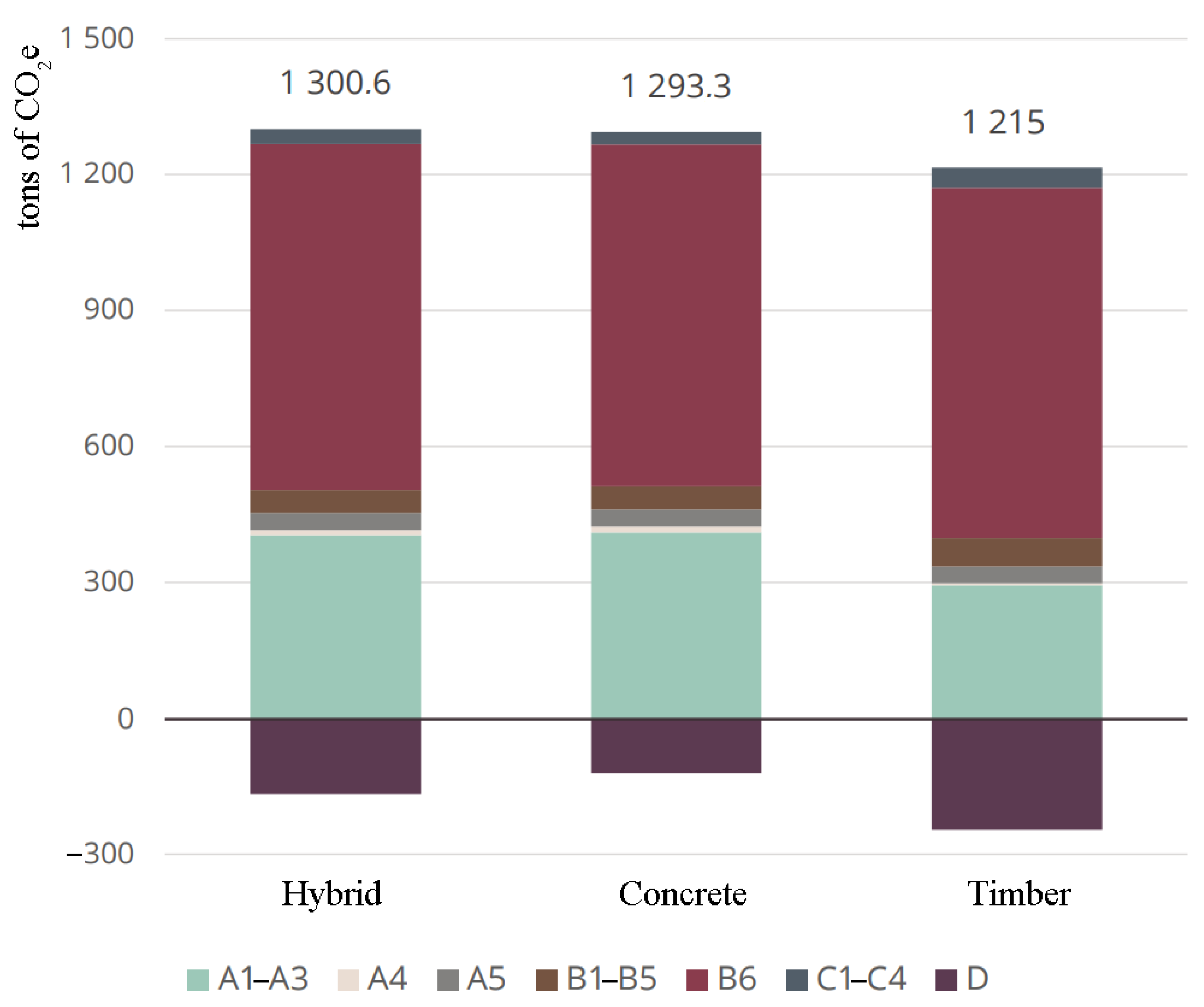

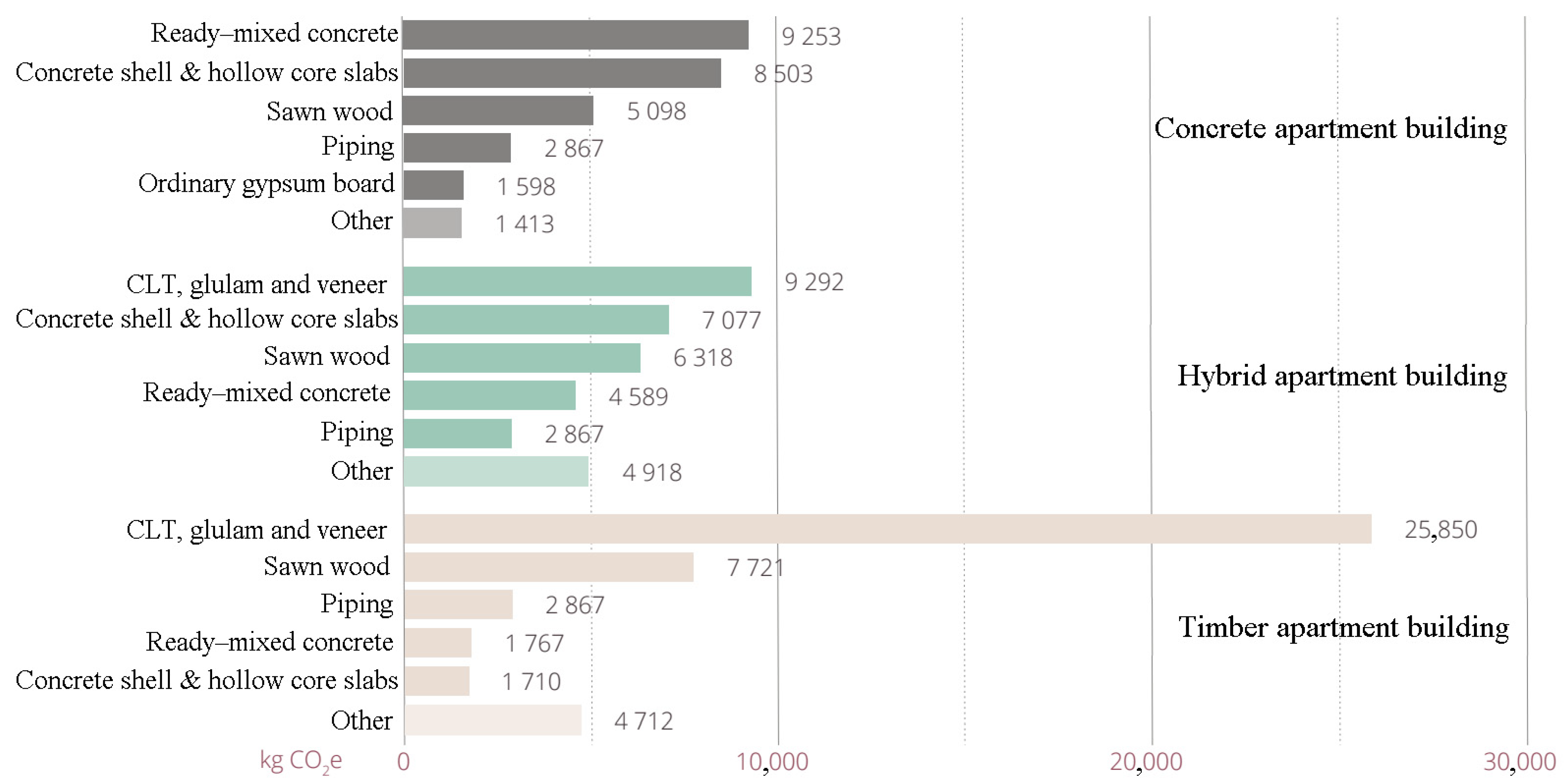

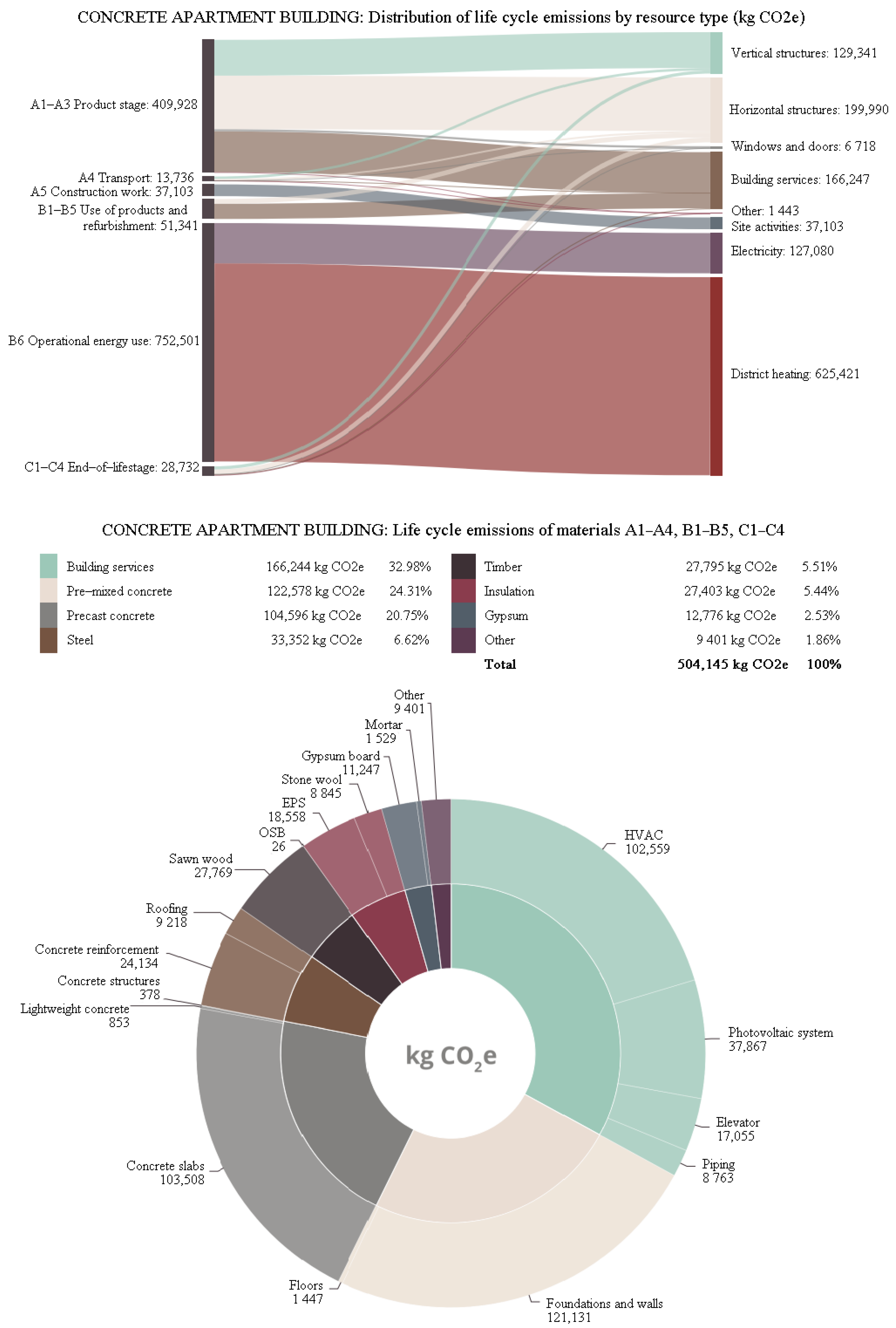

3.2. Results of Comparison

4. Discussion

Reducing Carbon Footprint

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sandanayake, M.; Lokuge, W.; Zhang, G.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef] [Green Version]

- Brussels Energy, European Commission. New Rules for Greener and Smarter Buildings Will Increase Quality of Life for All Europeans. NEWS. 15 April 2019. Available online: https://ec.europa.eu/info/news/new-rules-greener-and-smarter-buildings-will-increase-quality-life-alleuropeans-2019-apr-15_en (accessed on 6 January 2022).

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Yan, H.; Shen, Q.; Fan, L.C.H.; Wang, Y.; Zhang, L. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef] [Green Version]

- Abergel, T.; Dean, B.; Dulac, J. Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector: Global Status Report 2017; UN Environment and International Energy Agency: Paris, France, 2017. [Google Scholar]

- Solís-Guzmán, J.; Martínez-Rocamora, A.; Marrero, M. Methodology for determining the carbon footprint of the construction of residential buildings. In Assessment of Carbon Footprint in Different Industrial Sectors; Springer: Singapore, 2014; Volume 1, pp. 49–83. [Google Scholar]

- Chen, Z.; Gu, H.; Bergman, R.D.; Liang, S. Comparative Life-Cycle Assessment of a High-Rise Mass Timber Building with an Equivalent Reinforced Concrete Alternative Using the Athena Impact Estimator for Buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Panteli, C.; Kylili, A.; Stasiuliene, L.; Seduikyte, L.; Fokaides, P.A. A framework for building overhang design using Building Information Modeling and Life Cycle Assessment. J. Build. Eng. 2018, 20, 248–255. [Google Scholar] [CrossRef]

- Mahmoudkelaye, S.; Azari, K.T.; Pourvaziri, M.; Asadian, E. Sustainable material selection for building enclosure through ANP method. Case Stud. Constr. Mater. 2018, 9, e00200. [Google Scholar] [CrossRef]

- Zabalza Bribián, I.; Valero Capilla, A.; Aranda Usón, A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Uson, A.A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Carreras, J.; Boer, D.; Cabeza, L.F.; Medrano, M.; Jiménez, L.; Guillén-Gosálbez, G. Reducing the Life Cycle Environmental Impact of Buildings Following a Simulation—Optimization Approach. In Advances in Energy Systems Engineering; Springer International Publishing: Cham, Switzerland, 2016; pp. 823–839. [Google Scholar]

- Hafner, A. Contribution of timber buildings on sustainability issues. In Proceedings of the World Sustainable Building 2014, Barcelona, Spain, 28–30 October 2014. [Google Scholar]

- Sizirici, B.; Fseha, Y.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A Review of Carbon Footprint Reduction in Construction Industry, from Design to Operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef]

- Worldsteel Position Paper, Steel’s Contribution to a Low Carbon Future and Climate Resilient Societies. Available online: https://www.worldsteel.org/publications/position-papers/steel-s-contribution-to-a-lowcarbon-future.html (accessed on 6 January 2022).

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef] [Green Version]

- Smedley, T. Timber Structures Would Allow Us to Draw Carbon from the Air and Store It in Our Homes and Offices—Leading Some to Believe That Wooden Buildings Are the Future of Architecture. Available online: http://www.bbc.com/future/story/20190717-climate-change-wooden-architecture-concrete-globalwarming (accessed on 6 January 2022).

- Oladazimi, A.; Mansour, S.; Hosseinijou, S.A. Comparative Life Cycle Assessment of Steel and Concrete Construction Frames: A Case Study of Two Residential Buildings in Iran. Buildings 2020, 10, 54. [Google Scholar] [CrossRef] [Green Version]

- Svensson, E.; Panojevic, D. A Life Cycle Assessment of the Environmental Impacts of Cross-Laminated Timber. Master’s Thesis, Lund University, Lund, Sweden, January 2019. [Google Scholar]

- Ritter, M.; Skog, K.; Bergman, R. Science Supporting the Economic and Environmental Benefits of Using Wood and Wood Products in Green Building Construction; General Technical Report FPL-GTR-206; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2011; pp. 1–9. [Google Scholar]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA based comparative case study in the U.S. Pacific Northwest. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Dong, Y.; Qin, T.; Zhou, S.; Huang, L.; Bo, R.; Guo, H.; Yin, X. Comparative Whole Building Life Cycle Assessment of Energy Saving and Carbon Reduction Performance of Reinforced Concrete and Timber Stadiums—A Case Study in China. Sustainability 2020, 12, 1566. [Google Scholar] [CrossRef] [Green Version]

- Lolli, N.; Fufa, M.S.; Wiik, M.K. An assessment of greenhouse gas emissions from CLT and glulam in two residential nearly zero energy buildings. Wood Mater. Sci. Eng. 2019, 14, 342–354. [Google Scholar] [CrossRef] [Green Version]

- Lukić, I.; Premrov, M.; Leskovar, Ž.V.; Passer, A. Assessment of the environmental impact of timber and its potential to mitigate embodied GHG emissions. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 1.01–1.05. [Google Scholar] [CrossRef]

- Wang, L.; Toppinen, A.; Juslin, H. Use of wood in green building: A study of expert perspectives from the UK. J. Clean. Prod. 2014, 65, 350–361. [Google Scholar] [CrossRef]

- Kazulis, V.; Muizniece, I.; Zihare, L.; Blumberga, D. Carbon storage in wood products. Energy Procedia 2017, 128, 558–563. [Google Scholar] [CrossRef]

- Green, M.C.; Karsh, J.E. The Case for Tall Wood Buildings—How Mass Timber Offers a Safe, Economical, and Environmentally Friendly Alternative for Tall Building Structures; Mgb ARCHITECTURE + DESIGN, Equilibrium Consulting, LMDG Ltd., Eds.; BTY Group: Vancouver, BC, Canada, 2012. [Google Scholar]

- Werner, F.; Taverna, R.; Hofer, P.; Richter, K. Carbon pool and substitution effects of an increased use of wood in buildings in Switzerland: First estimates. Ann. For. Sci. 2005, 62, 889–902. [Google Scholar] [CrossRef] [Green Version]

- Kutnar, A.; Hill, C. Life Cycle Assessment—Opportunities for Forest Products Sector. Bioprod. Bus. 2017, 2, 52–64. [Google Scholar]

- Bergman, R.D.; Falk, R.H.; Gu, H.; Napier, T.R.; Meil, J. Life-Cycle Energy and GHG Emissions for New and Recovered Softwood Framing Lumber and Hardwood Flooring Considering End-of-Life Scenarios; Res. Pap. FPL-RP-672; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2013; p. 35. [Google Scholar]

- Karacabeyli, E.; Douglas, B. CLT Handbook: Cross-Laminated Timber, US ed.; FP Innovations: Quebec, QC, Canada, 2013. [Google Scholar]

- Lukacs, I.; Björnfot, A.; Tomasi, R. Strength and Stiffness of Cross-laminated Timber (CLT) Shear Walls: State-of-the-Art of Analytical Approaches. Eng. Struct. 2019, 178, 136–147. [Google Scholar] [CrossRef]

- Ramage, M.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Dagenais, C.; White, R.H.; Sumathipala, K. Fire: Fire Performance of Cross-Laminated Timber Assemblies. In CLT Handbook: Cross-Laminated Timber, US ed.; Karacabeyli, E., Douglas, B., Eds.; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA; Binational Softwood Lumber Council: Surrey, BC, Canada, 2012; Chapter 8; p. 55. ISBN 978-0-86488-553-1. [Google Scholar]

- Shahnewaz, M.; Tannert, T.; Alam, M.S.; Popovski, M. In-Plane Stiffness of Cross-Laminated Timber Panels with Openings. Struct. Eng. Int. 2017, 27, 217–223. [Google Scholar] [CrossRef]

- Zwerger, K. Recognizing the Similar and Thus Accepting the Other: The European and Japanese Traditions of Building with Wood. J. Tradit. Build. Archit. Urban. 2021, 2, 305–317. [Google Scholar] [CrossRef]

- Van Damme, B.; Schoenwald, S.; Zemp, A. Modeling the bending vibration of cross-laminated timber beams. Eur. J. Wood Wood Prod. 2017, 75, 985–994. [Google Scholar] [CrossRef]

- Chiniforush, A.A.; Akbarnezhad, A.; Valipour, H.; Xiao, J. Energy implications of using steel-timber composite (STC) elements in buildings. Energy Build. 2018, 176, 203–215. [Google Scholar] [CrossRef]

- Toivonen, R.; Lähtinen, K. Sustainability—A Literature Review on Concealed Opportunities for Global Market Diffusion for the Cross-Laminated Timber (CLT) in the Urbanizing Society; The Manuscript for Bioproducts Business; IUFRO: Curitiba, Brazil, 2019. [Google Scholar]

- Yusof, N.M.; Tahir, P.M.; Lee, S.H.; Khan, M.A.; James, R.M.S. Mechanical and physical properties of Cross-Laminated Timber made from Acacia mangium wood as function of adhesive types. J. Wood Sci. 2019, 65, 20. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Zhang, S.; Gong, Y.; Tian, Z.; Ren, H. Gluing Techniques on Bond Performance and Mechanical Properties of Cross-Laminated Timber (CLT) Made from Larix kaempferi. Polymers 2021, 13, 733. [Google Scholar] [CrossRef]

- Bahrami, A.; Nexén, O.; Jonsson, J. Comparing Performance of Cross-Laminated Timber and Reinforced Concrete Walls. Int. J. Appl. Mech. Eng. 2021, 26, 28–43. [Google Scholar] [CrossRef]

- Sun, Z.; Chang, Z.; Bai, Y.; Gao, Z. Effects of working time on properties of a soybean meal-based adhesive for engineered wood flooring. J. Adhes. 2021, 1–20. [Google Scholar] [CrossRef]

- Karjalainen, M.; Ilgın, H.E. A Statistical Study on Multi-Story Timber Residential Buildings (1995–2020) in Finland. In Proceedings of the LIVENARCH VII Livable Environments & Architecture 7th International Congress OTHER ARCHITECT/URE(S), Trabzon, Turkey, 28–30 September 2021; Volume I, pp. 82–94. [Google Scholar]

- Ilgın, H.E.; Karjalainen, M.; Koponen, O. Review of the Current State-of-the-Art of Dovetail Massive Wood Elements; IntechOpen: London, UK, 2021. [Google Scholar]

- Ilgın, H.E.; Karjalainen, M.; Koponen, O. Various Geometric Configuration Proposals for Dovetail Wooden Horizontal Structural Members in Multistory Building Construction; IntechOpen: London, UK, 2022. [Google Scholar]

- Ilgın, H.E.; Karjalainen, M. Preliminary Design Proposals for Dovetail Wood Board Elements in Multi-Story Building Construction. Architecture 2021, 1, 56–68. [Google Scholar] [CrossRef]

- Ilgın, H.E.; Karjalainen, M.; Koponen, O. Dovetailed Massive Wood Board Elements for Multi-Story Buildings. In Proceedings of the LIVENARCH VII Livable Environments & Architecture 7th International Congress OTHER ARCHITECT/URE(S), Trabzon, Turkey, 28–30 September 2021; Volume I, pp. 47–60. [Google Scholar]

- Karjalainen, M.; Ilgın, H.E.; Yli-Äyhö, M.; Soikkeli, A. Complementary Building Concept: Wooden Apartment Building: The Noppa toward Zero Energy Building Approach; IntechOpen: London, UK, 2021. [Google Scholar]

- Tulonen, L.; Karjalainen, M.; Ilgın, H.E. Tall Wooden Residential Buildings in Finland: What Are the Key Factors for Design and Implementation? IntechOpen: London, UK, 2021. [Google Scholar]

- Ilgın, H.E.; Karjalainen, M. Perceptions, Attitudes, and Interest of Architects in the Use of Engineered Wood Products for Construction: A Review; IntechOpen: London, UK, 2021. [Google Scholar]

- Roos, A.; Woxblom, L.; McCluskey, D. The influence of architects and structural engineers on timber in construction—Perceptions and roles. Silva Fenn. 2010, 44, 871–884. [Google Scholar] [CrossRef] [Green Version]

- Karjalainen, M.; Ilgın, H.; Tulonen, L. Main Design Considerations and Prospects of Contemporary Tall Timber Apartment Buildings: Views of Key Professionals from Finland. Sustainability 2021, 13, 6593. [Google Scholar] [CrossRef]

- Aaltonen, A.; Hurmekoski, E.; Korhonen, J. What About Wood?—“Nonwood” Construction Experts’ Perceptions of Environmental Regulation, Business Environment, and Future Trends in Residential Multistory Building in Finland. For. Prod. J. 2021, 71, 342–351. [Google Scholar] [CrossRef]

- Hemström, K.; Gustavsson, L.; Mahapatra, K. The sociotechnical regime and Swedish contractor perceptions of structural frames. Constr. Manag. Econ. 2017, 35, 184–195. [Google Scholar] [CrossRef] [Green Version]

- Markström, E.; Kuzman, M.K.; Bystedt, A.; Sandberg, D.; Fredriksson, M. Swedish architects view of engineered wood products in buildings. J. Clean. Prod. 2018, 181, 33–41. [Google Scholar] [CrossRef]

- Karjalainen, M.; Ilgın, H.E.; Somelar, D. Wooden Additional Floors in old Apartment Buildings: Perspectives of Housing and Real Estate Companies from Finland. Buildings 2021, 11, 316. [Google Scholar] [CrossRef]

- Karjalainen, M.; Ilgın, H.E.; Metsäranta, L.; Norvasuo, M. Wooden Facade Renovation and Additional Floor Construction for Suburban Development in Finland; IntechOpen: London, UK, 2022. [Google Scholar]

- Karjalainen, M.; Ilgın, H.E.; Metsäranta, L.; Norvasuo, M. Suburban Residents’ Preferences for Livable Residential Area in Finland. Sustainability 2021, 13, 11841. [Google Scholar] [CrossRef]

- Karjalainen, M.; Ilgın, H.E.; Somelar, D. Wooden Extra Stories in Concrete Block of Flats in Finland as an Ecologically Sensitive Engineering Solution, Ecological Engineering—Addressing Climate Challenges and Risks; IntechOpen: London, UK, 2021. [Google Scholar]

- Karjalainen, M. The Finnish Multi-Story Timber Apartment Building as a Pioneer in the Development of Timber Construction; University of Oulu: Oulu, Finland, 2002. (In Finnish) [Google Scholar]

- Gold, S.; Rubik, F. Consumer attitudes towards timber as a construction material and towards timber frame houses—Selected findings of a representative survey among the German population. J. Clean. Prod. 2009, 17, 303–309. [Google Scholar] [CrossRef]

- Lähtinen, K.; Harju, C.; Toppinen, A. Consumers’ perceptions on the properties of wood affecting their willingness to live in and prejudices against houses made of timber. Wood Mater. Sci. Eng. 2019, 14, 325–331. [Google Scholar] [CrossRef]

- Kylkilahti, E.; Berghäll, S.; Autio, M.; Nurminen, J.; Toivonen, R.; Lähtinen, K.; Vihemäki, H.; Franzini, F.; Toppinen, A. A consumer-driven bioeconomy in housing? Combining consumption style with students’ perceptions of the use of wood in multi-story buildings. Ambio 2020, 49, 1943–1957. [Google Scholar] [CrossRef]

- Karjalainen, M.; Ilgın, H.E.; Metsäranta, L.; Norvasuo, M. Residents’ Attitudes towards Wooden Facade Renovation and Additional Floor Construction in Finland. Int. J. Environ. Res. Public Health 2021, 18, 12316. [Google Scholar] [CrossRef] [PubMed]

- Zelinka, S.L.; Williamson, T.; Martinson, K.L.; Ritter, M.A. Research Needs Assessment for the Mass Timber Industry: Proceedings of the 2nd North American Mass Timber Research Needs Workshop; Gen. Tech. Rep. FPL-GTR-273; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2019; p. 41. [Google Scholar]

- Williamson, T.; Ross, R. Proceedings: Mass Timber Research Workshop 2015; General Technical Report FPL-GTR-241; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2016; pp. 1–364. [Google Scholar]

- Robertson, A.B. A Comparative Life Cycle Assessment of Mid-Rise Office Building Construction Alternatives: Laminated Timber or Reinforced Concrete. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2011. [Google Scholar]

- Darby, H.; Elmualim, A.A.; Kelly, F. A Case Study to Investigate the Life Cycle Carbon Emissions and Carbon Storage Capacity of a cross Laminated Timber, Multi-Storey Residential Building; SB13: Munich, Germany, 2013. [Google Scholar]

- Skullestad, J.L.; Bohne, R.A.; Lohne, J. High-Rise Timber Buildings as a Climate Change Mitigation Measure—A Comparative LCA of Structural System Alternatives. Energy Procedia 2016, 96, 112–123. [Google Scholar] [CrossRef] [Green Version]

- Milaj, K.; Sinha, A.; Miller, T.H.; Tokarczyk, J.A. Environmental utility of wood substitution in commercial buildings using life-cycle analysis. Wood Fiber Sci. 2017, 49, 338–358. [Google Scholar]

- Gu, H.; Bergman, R. Life Cycle Assessment and Environmental Building Declaration for the Design Building at the University of Massachusetts; General Technical Report FPL-GTR-255; USA Forest Service, Forest Products Laboratory: Madison, WI, USA, 2018; p. 71. [Google Scholar]

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S.S. Comparative Life-Cycle Assessment of a Mass Timber Building and Concrete Alternative. Wood Fiber Sci. 2020, 52, 217–229. [Google Scholar] [CrossRef]

- Ryberg, M.W.; Ohms, P.K.; Møller, E.; Lading, T. Comparative life cycle assessment of four buildings in Greenland. Build. Environ. 2021, 204, 108130. [Google Scholar] [CrossRef]

- Liang, S.; Gu, H.; Bergman, R. Environmental Life-Cycle Assessment and Life-Cycle Cost Analysis of a High-Rise Mass Timber Building: A Case Study in Pacific Northwestern United States. Sustainability 2021, 13, 7831. [Google Scholar] [CrossRef]

- Kuzman, M.K.; Lähtinen, K.; Sandberg, D. Initiatives Supporting Timber Constructions in Finland, Slovenia and Sweden. In Proceedings of the IUFRO 2017 Division 5 Conference “Forest Sector Innovations for a Greener Future”, Vancouver, BC, Canada, 12–16 June 2017; p. 18. [Google Scholar]

- Riala, M.; Ilola, L. Multi-storey timber construction and bioeconomy—Barriers and opportunities. Scand. J. For. Res. 2014, 29, 367–377. [Google Scholar] [CrossRef]

- Jussila, J.; Lähtinen, K. Effects of institutional practices on delays in construction—Views of Finnish homebuilder families. Hous. Stud. 2019, 35, 1167–1193. [Google Scholar] [CrossRef]

- Toppinen, A.; Röhr, A.; Pätäri, S.; Lähtinen, K.; Toivonen, R. The future of wooden multistory construction in the forest bioeconomy—A Delphi study from Finland and Sweden. J. For. Econ. 2018, 31, 3–10. [Google Scholar] [CrossRef]

- Toivonen, R.; Vihemäki, H.; Toppinen, A. Policy narratives on wooden multi-storey construction and implications for technology innovation system governance. For. Policy Econ. 2021, 125, 102409. [Google Scholar] [CrossRef]

- Hurmekoski, E.; Jonsson, R.; Nord, T. Context, drivers, and future potential for wood-frame multi-story construction in Europe. Technol. Forecast. Soc. Chang. 2015, 99, 181–196. [Google Scholar] [CrossRef]

- Bohner, E.; Vehmas, T.; Okkonen, M.; Kiviniemi, M.; Lahdenperä, P.; Laikari, A.; Ferreira, M. Quality Management of Concrete Construction by Digitalizing the Process Chain from Batching Plant to Building. In ASNT Digital Library American Society for Nondestructive Testing; 2018; Available online: https://ndtlibrary.asnt.org/2018/QualityManagementofConcreteConstructionbyDigitalizingtheProcessChainfromBatchingPlanttoBuilding (accessed on 6 January 2022).

- Ilgın, H.E.; Karjalainen, M.; Pelsmakers, S. Finnish architects’ attitudes towards multi-storey timber-residential buildings. Int. J. Build. Pathol. Adapt. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Karjalainen, M.; Ilgın, H.E. The Change over Time in Finnish Residents’ Attitudes towards Multi-Story Timber Apartment Buildings. Sustainability 2021, 13, 5501. [Google Scholar] [CrossRef]

- Strategic Programme to Promote a Circular Economy. The Finnish Ministry of Environment. Available online: https://ym.fi/en/strategic-programme-to-promote-a-circular-economy (accessed on 6 January 2022).

- Vatanen, M.; Sirkka, A.; Pirttinen, V.; Ahoranta, T. Current State and Future of CLT Construction in Finland, LAPLAND UAS PUBLICATIONS Series B. Research Reports and Compilations, Interview Study 2016; Lapland University of Applied Sciences: Rovaniemi, Finland, 2017. [Google Scholar]

- Zaccaro, V.L. Timber-Concrete Hybrid Innovations: A framework to Evaluate Economical and Technical Factors for the Construction Market. Master’s Thesis, KTH Royal Institute of Technology School of Architecture and the Built Environment, Stockholm, Sweden, 2017. [Google Scholar]

- Hein, C. Developing Hybrid Timber Construction for Sustainable Tall Buildings. CTBUH J. 2014, III, 40–45. [Google Scholar]

- Anttonen, N.; DASOS. Review of Wood-Based Construction and Architecture—Technology, Status and Trends. November 2015. Available online: https://www.dasos.fi/wp-content/uploads/2019/10/Dasos-report-Wood-based-Construction-and-Architecture-2015.pdf (accessed on 6 January 2022).

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. Overview of environmental footprints. In Assessing and Measuring Environmental Impact and Sustainability; Klemeš, J.J., Ed.; Butterworth-Heinemann: Oxford, UK, 2015; Chapter 5; pp. 131–193. [Google Scholar]

- Cohen, M.A. Habitat II: A critical assessment. Environ. Impact Assess. Rev. 1996, 16, 429–433. [Google Scholar] [CrossRef]

- Cohen, M.A. From Habitat II to Pachamama: A growing agenda and diminishing expectations for Habitat III. Environ. Urban. 2016, 28, 35–48. [Google Scholar] [CrossRef]

- Wiedmann, T.; Barrett, J. A Review of the Ecological Footprint Indicator—Perceptions and Methods. Sustainability 2010, 2, 1645–1693. [Google Scholar] [CrossRef] [Green Version]

- Best, A.; Giljum, S.; Simmons, C.; Blobel, D.; Lewis, K.; Hammer, M.; Cavalieri, S.; Lutter, S.; Maguire, C. Potential of the Ecological Footprint for Monitoring Environmental Impacts from Natural Resource Use: Analysis of the Potential of the Ecological Footprint and Related Assessment Tools for Use in the EU’s Thematic Strategy on the Sustainable Use of Natural Resources. Report to the European Commission, DG Environment. 2008. Available online: https://ec.europa.eu/environment/archives/natres/pdf/footprint.pdf (accessed on 6 January 2022).

- Hoekstra, A.Y. Water Neutral: Reducing and Offsetting the Impacts of Water Footprints; Value of Water Research Report Series No 28; UNESCO-IHE Institute for Water Education: Delft, The Netherlands, 2008; Available online: https://research.utwente.nl/en/publications/water-neutral-reducing-and-ofsetting-water-footprints (accessed on 6 January 2022).

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. A review of footprint analysis tools for monitoring impacts on sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- Rees, W.E. Ecological footprints and appropriated carrying capacity: What urban economics leaves out. Environ. Urban. 1992, 4, 121–130. [Google Scholar] [CrossRef]

- Fang, K.; Heijungs, R.; de Snoo, G.R. Theoretical exploration for the combination of the ecological, energy, carbon, and water footprints: Overview of a footprint family. Ecol. Indic. 2014, 36, 508–518. [Google Scholar] [CrossRef]

- Auger, C.; Hilloulin, B.; Boisserie, B.; Thomas, M.; Guignard, Q.; Rozière, E. Open-Source Carbon Footprint Estimator: Development and University Declination. Sustainability 2021, 13, 4315. [Google Scholar] [CrossRef]

- Kanafani, K.; Kjær Zimmermann, R.; Nygaard Rasmussen, F.; Birgisdóttir, H. Learnings from Developing a Context-Specific LCA Tool for Buildings—The Case of LCAbyg 4. Sustainability 2021, 13, 1508. [Google Scholar] [CrossRef]

- Wang, J.; Lin, P.-C. Should the Same Products Consumed in Different Retail Channels Have an Identical Carbon Footprint? An Environmental Assessment of Consumer Preference of Retail Channels and Mode of Transport. Sustainability 2021, 13, 615. [Google Scholar] [CrossRef]

- Šerešová, M.; Kočí, V. Proposal of Package-to-Product Indicator for Carbon Footprint Assessment with Focus on the Czech Republic. Sustainability 2020, 12, 3034. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Yin, T. Cross-Laminated Timber: A Review on Its Characteristics and an Introduction to Chinese Practices; IntechOpen: London, UK, 2021. [Google Scholar]

- Rahman, T.; Ashraf, M.; Ghabraie, K.; Subhani, M. Evaluating Timoshenko Method for Analyzing CLT under Out-of-Plane Loading. Buildings 2020, 10, 184. [Google Scholar] [CrossRef]

- The National Building Code of Finland—Structural Fire Safety, Decree of the Ministry of the Environment. 2017. Available online: https://ym.fi/en/the-national-building-code-of-finland (accessed on 6 January 2022).

- Ministry of the Environment. Department of Housing and Building the National Building Code of Finland. 2005. Available online: https://www.edilex.fi/data/rakentamismaaraykset/g1e.pdf (accessed on 6 January 2022). (In Finnish).

- E-Value Calculator, Puuinfo (The Finnish Timber Council). Available online: https://puuinfo.fi/suunnittelu/mitoitustyokalu/e-lukulaskuri-2-0/ (accessed on 6 January 2022). (In Finnish).

- Kuittinen, M. (Ed.) Method for the Whole Life Carbon Assessment of Buildings, Publications of The Ministry of The Environment|2019:23; Finnish Ministry of the Environment: Helsinki, Finland, 2019; Available online: https://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/161796/YM_2019_23_Method_for_the_whole_life_carbon_assessment_of_buildings.pdf?sequence=1&isAllowed=y (accessed on 6 January 2022).

- EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Committee for Standardisation: Brussels, Belgium, 2011.

- One Click LCA Ltd. Headquarters: Suvilahdenkatu 10 B, 00500 Helsinki, Finland. Available online: https://www.oneclicklca.com2021 (accessed on 6 January 2022).

- Mora, T.D.; Bolzonello, E.; Peron, F.; Carbonari, A. Integration of LCA tools in BIM toward a regenerative design. In Proceedings of the PLEA 2018 Hong Kong Smart and Healthy within the 2-Degree Limit, Hong Kong, China, 10–12 December 2018. [Google Scholar]

- Veselka, J.; Nehasilová, M.; Dvořáková, K.; Ryklová, P.; Volf, M.; Růžička, J.; Lupíšek, A. Recommendations for Developing a BIM for the Purpose of LCA in Green Building Certifications. Sustainability 2020, 12, 6151. [Google Scholar] [CrossRef]

- Petrovic, B.; Myhren, J.A.; Zhang, X.; Wallhagen, M.; Eriksson, O. Life Cycle Assessment of Building Materials for a Single-Family House in Sweden. Energy Procedia 2019, 158, 3547–3552. [Google Scholar] [CrossRef]

- Rustad, V. One Click LCA Som Verktøy for Sammenlignbare Klimagassberegninger Av Nybygg-Og Rehabiliteringsprosjekt. Master’s Thesis, Faculty of Science and Technology, Norwegian University of Life Sciences, Ås, Norway, 2021. (In Norwegian). [Google Scholar]

- United States: Trimble and One Click LCA Collaborate to Provide Embodied Carbon Calculations for Different Phases of Construction Projects. MENA Report. 2021. Available online: https://libproxy.tuni.fi/login?url=https://www.proquest.com/trade-journals/united-states-trimble-one-click-lca-collaborate/docview/2581095573/se-2?accountid=14242 (accessed on 6 January 2022).

- Köseci, F.C. Integrated Life Cycle Assessment (LCA) to Building Information Modelling (BIM) Interoperability in the BIM-Based LCA Processes and Analysis of BIM-Based LCA Results and Tools. Master’s Thesis, Real Estate and Construction Management Architectural Design and Construction Project Management, KTH Royal Institute of Technology, Stockholm, Sweden, 2018. [Google Scholar]

- Obrecht, T.P.; Röck, M.; Hoxha, E.; Passer, A. The challenge of integrating Life Cycle Assessment in the building design process—A systematic literature review of BIM-LCA workflows. IOP Conference Series. Earth Environ. Sci. 2020, 588, 32024. [Google Scholar] [CrossRef]

- Heralova, R.S. Life Cycle Costing as an Important Contribution to Feasibility Study in Construction Projects. Procedia Eng. 2017, 196, 565–570. [Google Scholar] [CrossRef]

- Dong, Y.H.; Ng, S.T. A social life cycle assessment model for building construction in Hong Kong. Int. J. Life Cycle Assess. 2015, 20, 1166–1180. [Google Scholar] [CrossRef]

| Integration | Notes |

|---|---|

| Industry foundation classes (IFCs) | ISO 16739/IFC 2 × 3 & IFC4 |

| Autodesk Revit Architectural/Structural Model | v.2016, 2017, 2018 as native plug-ins |

| IES-VE | v.2017 Feature Pack 4 or higher |

| Graphisoft ArchiCAD | v.18, 19 as native plug-ins |

| Tekla Structures | v.2016 as a native plug-in |

| Simplebim and Naviate Simple BIM 5.0 | BIM v.5.0 or higher |

| DesignBuilder 5.1 | v.5.1 or higher |

| Excel and CSV formats | quantity take-off or costing import |

| gbXML | Supported, e.g., by IES-VE |

| Custom integrations from XML, JSON, web services, and other sources |

| Form of Energy | Hybrid | Concrete | Timber |

|---|---|---|---|

| District heating (kWh/a) | 178,200 | 175,680 (−1.4%) | 181,440 (+1.8%) |

| Electricity (kWh/a) | 52,590 | 52,590 | 52,590 |

| Module | Hybrid | Concrete | Timber |

|---|---|---|---|

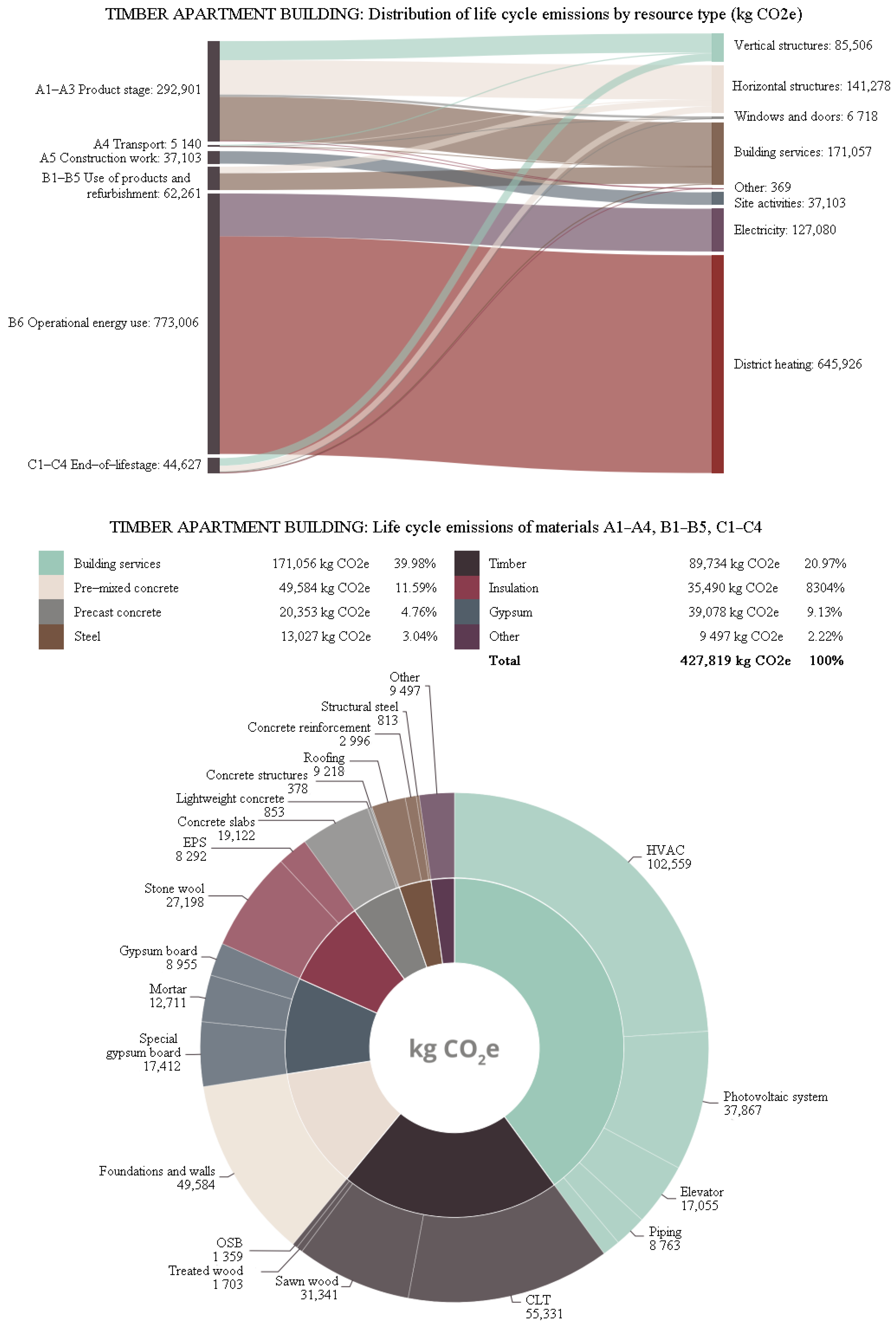

| A1–A3 Product stage | 403,951 | 409,932 (+1.5%) | 292,901 (–27.5%) |

| A4 Transport | 11,529 | 13,736 (+19.1%) | 5140 (–55.4%) |

| A5 Construction work | 37,103 | 37,103 | 37,103 |

| B1–B5 Use of products and Refurbishment | 51,457 | 51,341 (–0.2%) | 62,261 (+21.0%) |

| B6 Operational energy use | 761,472 | 752,501 (–1.2%) | 773,006 (+1.5%) |

| C1–C4 End-of-life stage | 35,061 | 28,732 (–18.1%) | 44,627 (+27.3%) |

| In total | 1,300,573 | 1,293,345 (–0.6%) | 1,215,038 (−6.6%) |

| D Beyond the building life cycle | –167,572 | –121,058 (–27.8%) | –245,590 (+47.2%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rinne, R.; Ilgın, H.E.; Karjalainen, M. Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland. Int. J. Environ. Res. Public Health 2022, 19, 774. https://doi.org/10.3390/ijerph19020774

Rinne R, Ilgın HE, Karjalainen M. Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland. International Journal of Environmental Research and Public Health. 2022; 19(2):774. https://doi.org/10.3390/ijerph19020774

Chicago/Turabian StyleRinne, Roni, Hüseyin Emre Ilgın, and Markku Karjalainen. 2022. "Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland" International Journal of Environmental Research and Public Health 19, no. 2: 774. https://doi.org/10.3390/ijerph19020774

APA StyleRinne, R., Ilgın, H. E., & Karjalainen, M. (2022). Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland. International Journal of Environmental Research and Public Health, 19(2), 774. https://doi.org/10.3390/ijerph19020774