Investigating the Barriers to Applying the Internet-of-Things-Based Technologies to Construction Site Safety Management

Abstract

:1. Introduction

- (1)

- To identify the barriers to applying IoT-based technologies to CSSM;

- (2)

- To prioritize the identified barriers using a fuzzy-based algorithm.

2. Literature Review

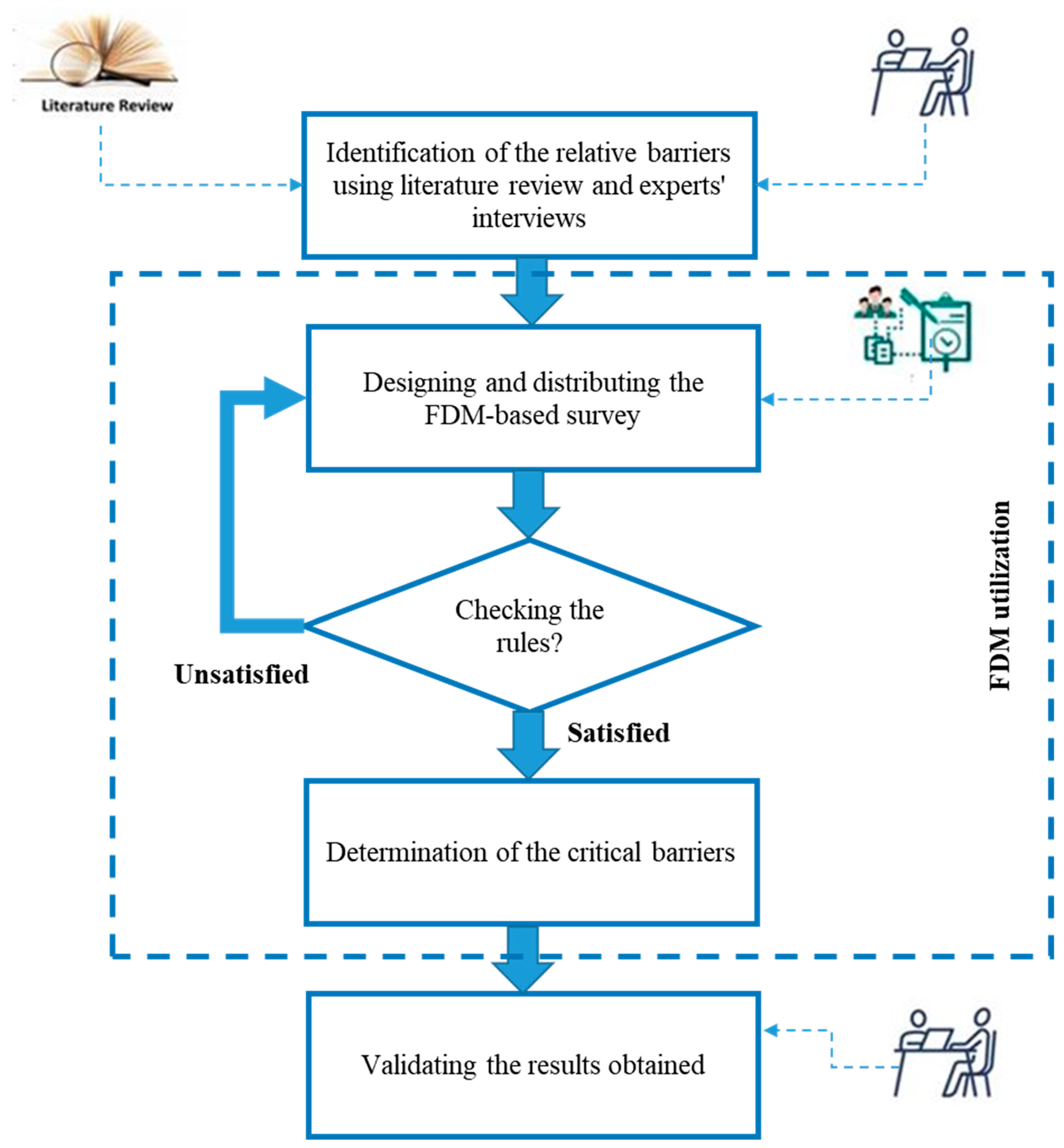

3. Methodology

3.1. Data Collection

3.2. Identification of Barriers

3.3. Prioritization of the Identified Barriers Using the Fuzzy Delphi Method

- (a)

- If the standard deviation to mean ratio ( for each barrier is less than 30%, then a good level of consensus among the pool of experts for that specific barrier is deemed reached. On the other hand, if the for each barrier is equal to or more than 30%, then the level of consensus among the pool of experts for that specific barrier is considered poor. Accordingly, the respective experts need to adjust their responses. It is notable that the SDMR needs to be calculated for each barrier separately, based on all of the questionnaires filled out by the pool of experts.

- (b)

- If the Cronbach reliability test corresponding to the responses of an expert is less than 0.7, then the answers provided are not prudent and, consequently, need to be done again; otherwise, the provided responses are concluded to be sagacious and consistent. It is worth mentioning that the Cronbach reliability test needs to be calculated for checking the consistency of the responses of an expert in filling out the respective survey.

3.4. Validation Stage

4. Results and Discussion

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Questionnaire Survey

| Barrier | Importance of Barriers | ||||

| Very Low | Low | Medium | High | Very High | |

| Lack of integration b/w technologies | ☐ | ☐ | ☐ | ☐ | ☐ |

| Limited scale technology implementation | ☐ | ☐ | ☐ | ☐ | ☐ |

| Lack of publicly available large datasets | ☐ | ☐ | ☐ | ☐ | ☐ |

| Deficiencies in onsite data recording | ☐ | ☐ | ☐ | ☐ | ☐ |

| The need for technical training | ☐ | ☐ | ☐ | ☐ | ☐ |

| The need for high computational efficiency | ☐ | ☐ | ☐ | ☐ | ☐ |

| The need for heavy batteries | ☐ | ☐ | ☐ | ☐ | ☐ |

| False alarms | ☐ | ☐ | ☐ | ☐ | ☐ |

| Off-line sensor network also needed | ☐ | ☐ | ☐ | ☐ | ☐ |

| The need for proper light for smooth functionality | ☐ | ☐ | ☐ | ☐ | ☐ |

| Data privacy issues | ☐ | ☐ | ☐ | ☐ | ☐ |

| Physical interaction is challenging | ☐ | ☐ | ☐ | ☐ | ☐ |

| The need for continuous monitoring | ☐ | ☐ | ☐ | ☐ | ☐ |

| Wearable sensors reduce productivity | ☐ | ☐ | ☐ | ☐ | ☐ |

| Safety hazards | ☐ | ☐ | ☐ | ☐ | ☐ |

| Limitations on hardware and software and lack of standardization in efforts | ☐ | ☐ | ☐ | ☐ | ☐ |

| Low reliance on the technology | ☐ | ☐ | ☐ | ☐ | ☐ |

| Poor governmental policies and incentives | ☐ | ☐ | ☐ | ☐ | ☐ |

References

- Bavafa, A.; Mahdiyar, A.; Marsono, A.K. Identifying and Assessing the Critical Factors for Effective Implementation of Safety Programs in Construction Projects. Saf. Sci. 2018, 106, 47–56. [Google Scholar] [CrossRef]

- Mohandes, S.R.; Sadeghi, H.; Mahdiyar, A.; Durdyev, S.; Banaitis, A.; Yahya, K.; Ismail, S. Assessing Construction Labours’ Safety Level: A Fuzzy MCDM Approach. J. Civ. Eng. Manag. 2020, 26, 175–188. [Google Scholar] [CrossRef] [Green Version]

- Sadeghi, H.; Mohandes, S.R.; Hosseini, M.R.; Banihashemi, S.; Mahdiyar, A.; Abdullah, A. Developing an Ensemble Predictive Safety Risk Assessment Model: Case of Malaysian Construction Projects. Int. J. Environ. Res. Public Health 2020, 17, 8395. [Google Scholar] [CrossRef]

- Shafique, M.; Rafiq, M. An Overview of Construction Occupational Accidents in Hong Kong: A Recent Trend and Future Perspectives. Appl. Sci. 2019, 9, 2069. [Google Scholar] [CrossRef] [Green Version]

- Luo, F.; Li, R.Y.M.; Crabbe, M.J.C.; Pu, R. Economic Development and Construction Safety Research: A Bibliometrics Approach. Saf. Sci. 2022, 145, 105519. [Google Scholar] [CrossRef]

- Jin, R.; Zhang, H.; Liu, D.; Yan, X. IoT-Based Detecting, Locating and Alarming of Unauthorized Intrusion on Construction Sites. Autom. Constr. 2020, 118, 103278. [Google Scholar] [CrossRef]

- Zhou, C.; Ding, L.Y. Safety Barrier Warning System for Underground Construction Sites Using Internet-of-Things Technologies. Autom. Constr. 2017, 83, 372–389. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Yu, Y.; Kong, L. Wearable Insole Pressure System for Automated Detection and Classification of Awkward Working Postures in Construction Workers. Autom. Constr. 2018, 96, 433–441. [Google Scholar] [CrossRef]

- Sigcha, L.; Pavón, I.; Arezes, P.; Costa, N.; de Arcas, G.; López, J.M. Occupational Risk Prevention through Smartwatches: Precision and Uncertainty Effects of the Built-in Accelerometer. Sensors 2018, 18, 3805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soltanmohammadlou, N.; Sadeghi, S.; Hon, C.K.H.; Mokhtarpour-Khanghah, F. Real-Time Locating Systems and Safety in Construction Sites: A Literature Review. Saf. Sci. 2019, 117, 229–242. [Google Scholar] [CrossRef]

- Costin, A.; Wehle, A.; Adibfar, A. Leading Indicators—A Conceptual IoT-Based Framework to Produce Active Leading Indicators for Construction Safety. Safety 2019, 5, 86. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Cao, T.; Zhao, X. Using Smartphones to Detect and Identify Construction Workers’ Near-Miss Falls Based on ANN. J. Constr. Eng. Manag. 2019, 145, 04018120. [Google Scholar] [CrossRef]

- Zhou, C.; Luo, H.; Fang, W.; Wei, R.; Ding, L. Cyber-Physical-System-Based Safety Monitoring for Blind Hoisting with the Internet of Things: A Case Study. Autom. Constr. 2019, 97, 138–150. [Google Scholar] [CrossRef]

- Chung, W.W.S.; Tariq, S.; Mohandes, S.R.; Zayed, T. IoT-Based Application for Construction Site Safety Monitoring. Int. J. Constr. Manag. 2020, 1–17. [Google Scholar] [CrossRef]

- Okpala, I.; Parajuli, A.; Nnaji, C.; Awolusi, I.; Student, P.D. Assessing the Feasibility of Integrating the Internet of Things into Safety Management Systems: A Focus on Wearable Sensing Devices. In Construction Research Congress 2020: Computer Applications; American Society of Civil Engineers: Reston, VA, USA, 2020; pp. 236–245. [Google Scholar]

- Asadzadeh, A.; Arashpour, M.; Li, H.; Ngo, T.; Bab-Hadiashar, A.; Rashidi, A. Sensor-Based Safety Management. Autom. Constr. 2020, 113, 103128. [Google Scholar] [CrossRef]

- Yang, X.; Yu, Y.; Shirowzhan, S.; Sepasgozer, S.; Li, H. Automated PPE-Tool Pair Check System for Construction Safety Using Smart IoT. J. Build. Eng. 2020, 32, 101721. [Google Scholar] [CrossRef]

- Häikiö, J.; Kallio, J.; Mäkelä, S.-M.; Keränen, J. IoT-Based Safety Monitoring from the Perspective of Construction Site Workers. Int. J. Occup. Environ. Saf. 2020, 4, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Rey-Merchán, M.D.C.; Gómez-de-Gabriel, J.M.; López-Arquillos, A.; Fernández-Madrigal, J.A. Virtual Fence System Based on IoT Paradigm to Prevent Occupational Accidents in the Construction Sector. Int. J. Environ. Res. Public Health 2021, 18, 6839. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and Trends in Internet of Things (IoT) Research: Future Applications in the Construction Industry. Eng. Constr. Archit. Manag. 2021, 28, 457–481. [Google Scholar] [CrossRef]

- Huang, Y.; Trinh, M.T.; Le, T. Critical Factors Affecting Intention OfUse of Augmented Hearing Protection Technology in Construction. J. Constr. Eng. Manag. 2021, 147. [Google Scholar] [CrossRef]

- Jin, R.; Zou, P.X.W.; Piroozfar, P.; Wood, H.; Yang, Y.; Yan, L.; Han, Y. A Science Mapping Approach Based Review of Construction Safety Research. Saf. Sci. 2019, 113, 285–297. [Google Scholar] [CrossRef]

- Tabatabaee, S.; Ashour, M.; Mohandes, S.R.; Sadeghi, H.; Mahdiyar, A.; Hosseini, M.R.; Ismail, S. Deterrents to the Adoption of Green Walls: A Hybrid Fuzzy-Based Approach. Eng. Constr. Archit. Manag. 2021. ahead of print. [Google Scholar] [CrossRef]

- Durdyev, S.; Mohandes, S.R.; Mahdiyar, A.; Ismail, S. What Drives Clients to Purchase Green Building?: The Cybernetic Fuzzy Analytic Hierarchy Process Approach. Eng. Constr. Archit. Manag. 2021. [Google Scholar] [CrossRef]

- Mohandes, S.R.; Zhang, X. Developing a Holistic Occupational Health and Safety Risk Assessment Model: An Application to a Case of Sustainable Construction Project. J. Clean. Prod. 2021, 291, 125934. [Google Scholar] [CrossRef]

- Zhang, X.; Mohandes, S.R. Occupational Health and Safety in Green Building Construction Projects: A Holistic Z-Numbers-Based Risk Management Framework. J. Clean. Prod. 2020, 275, 122788. [Google Scholar] [CrossRef]

- Mahdiyar, A.; Mohandes, S.R.; Durdyev, S.; Tabatabaee, S.; Ismail, S. Barriers to Green Roof Installation: An Integrated Fuzzy-Based MCDM Approach. J. Clean. Prod. 2020, 269, 122365. [Google Scholar] [CrossRef]

- Tabatabaee, S.; Mahdiyar, A.; Durdyev, S.; Mohandes, S.R.; Ismail, S. An Assessment Model of Benefits, Opportunities, Costs, and Risks of Green Roof Installation: A Multi Criteria Decision Making Approach. J. Clean. Prod. 2019, 238, 117956. [Google Scholar] [CrossRef]

- Mohandes, S.R.; Zhang, X. Towards the Development of a Comprehensive Hybrid Fuzzy-Based Occupational Risk Assessment Model for Construction Workers. Saf. Sci. 2019, 115, 294–309. [Google Scholar] [CrossRef]

- Tabatabaee, S.; Mahdiyar, A.; Mohandes, S.R.; Ismail, S. Towards the Development of a Comprehensive Lifecycle Risk Assessment Model for Green Roof Implementation. Sustain. Cities Soc. 2022, 76, 103404. [Google Scholar] [CrossRef]

- Gunduz, M.; Elsherbeny, H.A. Operational Framework for Managing Construction-Contract Administration Practitioners’ Perspective through Modified Delphi Method. J. Constr. Eng. Manag. 2020, 146, 4019110. [Google Scholar] [CrossRef]

- Bouzon, M.; Govindan, K.; Rodriguez, C.M.T.; Campos, L.M.S. Identification and Analysis of Reverse Logistics Barriers Using Fuzzy Delphi Method and AHP. Resour. Conserv. Recycl. 2016, 108, 182–197. [Google Scholar] [CrossRef]

- Rajendran, S.; Gambatese, J.A. Development and Initial Validation of Sustainable Construction Safety and Health Rating System. J. Constr. Eng. Manag. 2009, 135, 1067–1075. [Google Scholar] [CrossRef]

- Tabatabaee, S.; Mahdiyar, A.; Ismail, S. Towards the Success of Building Information Modelling Implementation: A Fuzzy-Based MCDM Risk Assessment Tool. J. Build. Eng. 2021, 43, 103117. [Google Scholar] [CrossRef]

| Barrier | Description | Reference |

|---|---|---|

| Lack of integration between technologies (B1) | Solutions that combine different technologies (e.g., BIM) with vision-based monitoring systems have not been sufficiently explored. | [9,16,22] |

| Limited scale of technology implementation (B2) | Most of these technologies tested their proposed algorithms on datasets that are proprietary to specific projects, which are bound by specific project constraints. | [7,16,22] |

| Lack of publicly available large datasets (B3) | Lack of publicly available large datasets for construction safety monitoring causes difficulties when comparing the performance of various algorithms. | [16] |

| Deficiencies in onsite data recording (B4) | Data, e.g., in the form of photos taken by workers on site, are mostly unorganized and stored locally. | [7,14,15,16] |

| The need for technical training (B5) | Proper technical training for workers and owner involvement are essential to prudently work with sensors functionalities (both workers and supervisors). | [15,16] |

| The need for high computational efficiency (B6) | For smooth functionality and effective data synchronization, high computational efficiency is critical. | [17] |

| The need for heavy batteries (B7) | Wi-Fi module is not an energy-saving solution for such technologies, thus requires high capacity and heavyweight batteries. | [11,17] |

| False alarms (B8) | Due to technological glitches and device registration issues, false alarms are quite common. | [7] |

| The need for off-line sensor network (B9) | For situations such as underground construction sites or isolated construction sites, neither the Wi-Fi nor general packet radio service (GPRS) are available, and the system would fail to upload data and receive orders. To address the communication coverage issue, an off-line sensor network is needed. | [7,10,17] |

| The need for proper light for smooth functionality (B10) | Systems might stop working or fail to detect wearing motions due to the constantly low illumination. | [17] |

| Data privacy issues (B11) | Workers are hesitant to adopt technology due to identity disclosure and related data privacy issues. | [7,18,19] |

| Challenges arising from physical interactions (B12) | Due to the wearable technological gadgets and involvement of high-tech solutions, physical interaction between workers is quite challenging. | [7] |

| The need for continuous monitoring (B13) | To achieve enhanced durability of the technological advancements, continuous monitoring and debugging of devices are essential. | [7,15] |

| Productivity reduction due to wearable sensors (B14) | Such technological methods require sensors to be attached to the workers’ skin, which makes them feel uncomfortable and is inconvenient when performing a given task, eventually reducing productivity. | [8] |

| Safety hazards (B15) | Workers may exhibit high-risk behavior by ignoring prompts from the devices. | [15] |

| Limitations on hardware and software and lack of standardization in efforts (B16) | Since the field of study is emerging, there is still a lack of standardization efforts; therefore, there are limitations on both hardware and software. | [11,15] |

| Low reliance on the technology (B17) | Due to fear of the unknown and lack of concrete examples, users have low reliance on the technology and still believe in ‘old school’ solutions. | [15,18,21] |

| Poor governmental policies and incentives (B18) | Despite governments having invested significantly in research and development for technological advancements, the policies and related incentives have not been well defined, thereby resulting in low adoption. | [21] |

| Experts’ ID | Educational Level | Title | Experience (Year) | Experience (Year) in Using IoT-Based Technologies | FDM Stage | Validation Stage |

|---|---|---|---|---|---|---|

| 1 | Bachelor’s in civil engineering | Contractor | 14 | 6 | * | — |

| 2 | Site supervisor | 6 | 3 | * | — | |

| 3 | Contractor | 22 | 3 | * | — | |

| 4 | Project manager | 25 | 5 | * | — | |

| 5 | OHS officer | 22 | 2 | * | — | |

| 6 | Site supervisor | 10 | 2 | * | — | |

| 7 | Master’s in construction management | Project manager | 14 | 4 | * | — |

| 8 | OHS officer | 16 | 4 | * | — | |

| 9 | Master’s in building services | Site supervisor | 17 | 4 | * | — |

| 10 | Bachelor’s in civil engineering | Contractor | 19 | 3 | — | * |

| 11 | Site supervisor | 14 | 5 | — | * | |

| 12 | Master’s in construction management | Safety manager | 12 | 2 | — | * |

| 13 | Facility manager | 13 | 5 | — | * | |

| 14 | Project manager | 18 | 2 | — | * |

| Variables | Fuzzy Numbers |

|---|---|

| Very low importance | |

| Low importance | |

| Medium importance | |

| High importance | |

| Very high importance |

| Barrier | Min | Most Likely Value | Max | Defuzzification | Rank | SDMR % (1st Round) | SDMR % (2nd Round) |

|---|---|---|---|---|---|---|---|

| B1 | 1.50 | 3.0000 | 4.50 | 6.0000 | 14 | 35 | 18 |

| B2 | 1.50 | 3.3684 | 5.00 | 6.6579 | 11 | 24 | 24 |

| B3 | 1.50 | 3.2105 | 5.00 | 6.4474 | 12 | 18 | 18 |

| B4 | 2.50 | 4.0526 | 5.00 | 7.9035 | 7 | 7 | 7 |

| B5 | 3.50 | 4.5263 | 5.00 | 8.8684 | 2 | 9 | 9 |

| B6 | 2.50 | 3.9474 | 5.00 | 7.7632 | 8 | 11 | 11 |

| B7 | 1.50 | 3.0000 | 5.00 | 6.1667 | 13 | 26 | 26 |

| B8 | 1.50 | 2.4211 | 4.50 | 5.2281 | 15 | 33 | 24 |

| B9 | 1.50 | 3.4737 | 5.00 | 6.7982 | 9 | 37 | 16 |

| B10 | 1.00 | 2.4737 | 4.50 | 5.1316 | 17 | 25 | 25 |

| B11 | 2.50 | 4.4211 | 5.00 | 8.3947 | 4 | 13 | 13 |

| B12 | 1.50 | 3.4211 | 5.00 | 6.7281 | 10 | 15 | 15 |

| B13 | 2.50 | 4.5263 | 5.00 | 8.5351 | 3 | 26 | 26 |

| B14 | 3.50 | 4.7895 | 5.00 | 9.2193 | 1 | 39 | 24 |

| B15 | 1.00 | 2.5263 | 4.50 | 5.2018 | 16 | 33 | 16 |

| B16 | 1.00 | 2.3158 | 4.50 | 4.9211 | 18 | 27 | 27 |

| B17 | 2.50 | 4.3158 | 5.00 | 8.2544 | 6 | 13 | 13 |

| B18 | 2.50 | 4.3684 | 5.00 | 8.3246 | 5 | 11 | 11 |

| Agg. Reliability Tests (1st round) | 0.5359 | ||||||

| Agg. Reliability Tests (2nd round) | 0.7884 | ||||||

| Barrier | Rank (Validation) | Rank (Main Results) | Barrier | Rank (Validation) | Rank (Main Results) |

| B1 | 15 | 14 | B10 | 16 | 17 |

| B2 | 12 | 11 | B11 | 4 | 4 |

| B3 | 11 | 12 | B12 | 10 | 10 |

| B4 | 9 | 7 | B13 | 3 | 3 |

| B5 | 1 | 2 | B14 | 1 | 1 |

| B6 | 7 | 8 | B15 | 18 | 16 |

| B7 | 13 | 13 | B16 | 16 | 18 |

| B8 | 13 | 15 | B17 | 6 | 6 |

| B9 | 9 | 9 | B18 | 4 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tabatabaee, S.; Mohandes, S.R.; Ahmed, R.R.; Mahdiyar, A.; Arashpour, M.; Zayed, T.; Ismail, S. Investigating the Barriers to Applying the Internet-of-Things-Based Technologies to Construction Site Safety Management. Int. J. Environ. Res. Public Health 2022, 19, 868. https://doi.org/10.3390/ijerph19020868

Tabatabaee S, Mohandes SR, Ahmed RR, Mahdiyar A, Arashpour M, Zayed T, Ismail S. Investigating the Barriers to Applying the Internet-of-Things-Based Technologies to Construction Site Safety Management. International Journal of Environmental Research and Public Health. 2022; 19(2):868. https://doi.org/10.3390/ijerph19020868

Chicago/Turabian StyleTabatabaee, Sanaz, Saeed Reza Mohandes, Rana Rabnawaz Ahmed, Amir Mahdiyar, Mehrdad Arashpour, Tarek Zayed, and Syuhaida Ismail. 2022. "Investigating the Barriers to Applying the Internet-of-Things-Based Technologies to Construction Site Safety Management" International Journal of Environmental Research and Public Health 19, no. 2: 868. https://doi.org/10.3390/ijerph19020868

APA StyleTabatabaee, S., Mohandes, S. R., Ahmed, R. R., Mahdiyar, A., Arashpour, M., Zayed, T., & Ismail, S. (2022). Investigating the Barriers to Applying the Internet-of-Things-Based Technologies to Construction Site Safety Management. International Journal of Environmental Research and Public Health, 19(2), 868. https://doi.org/10.3390/ijerph19020868