Understanding Hazardous Materials Transportation Accidents Based on Higher-Order Network Theory

Abstract

1. Introduction

2. Methodology

2.1. Data and Data Analysis

2.2. Construction of HMTACN

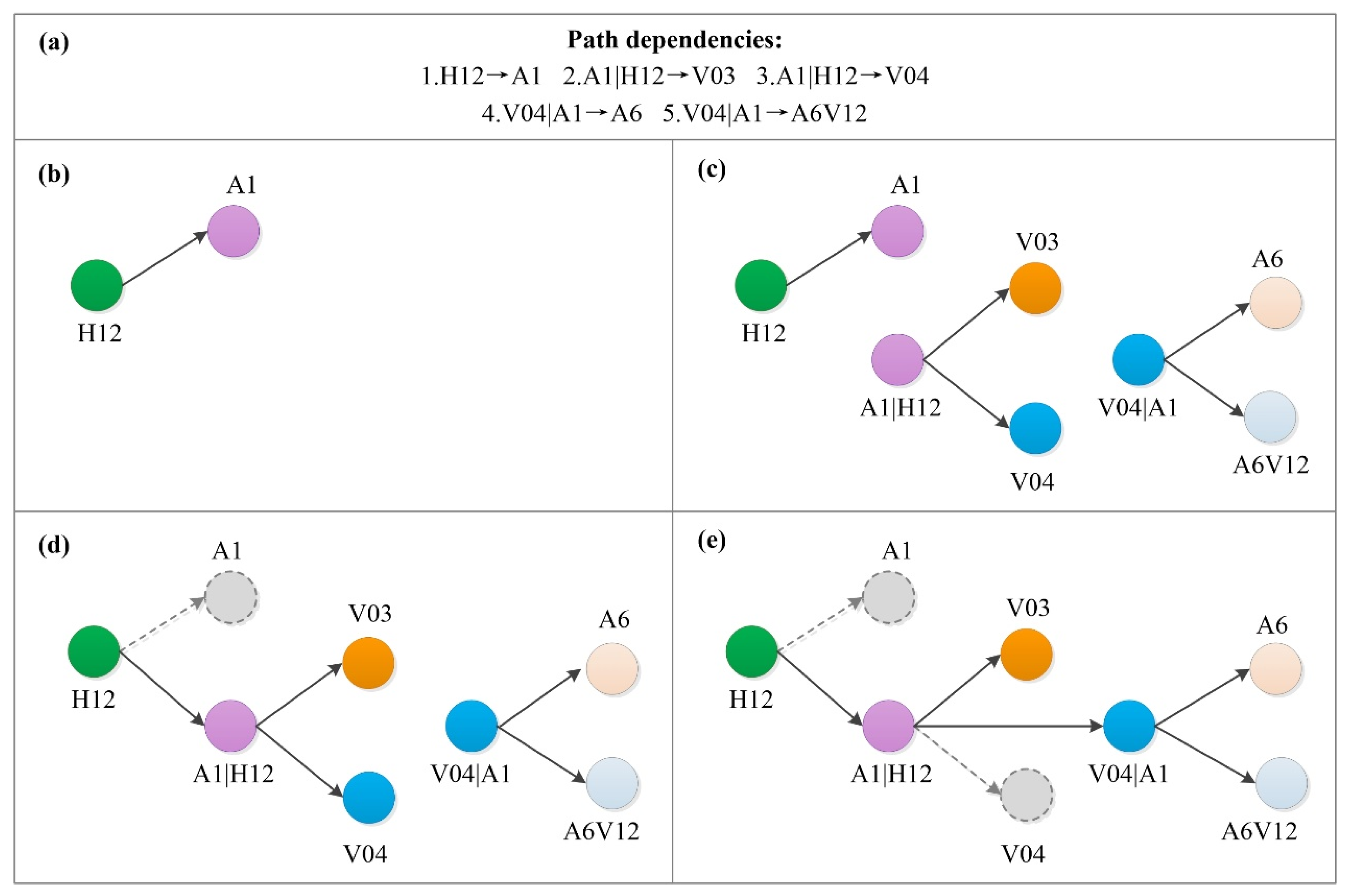

2.2.1. Extraction of Path Dependency

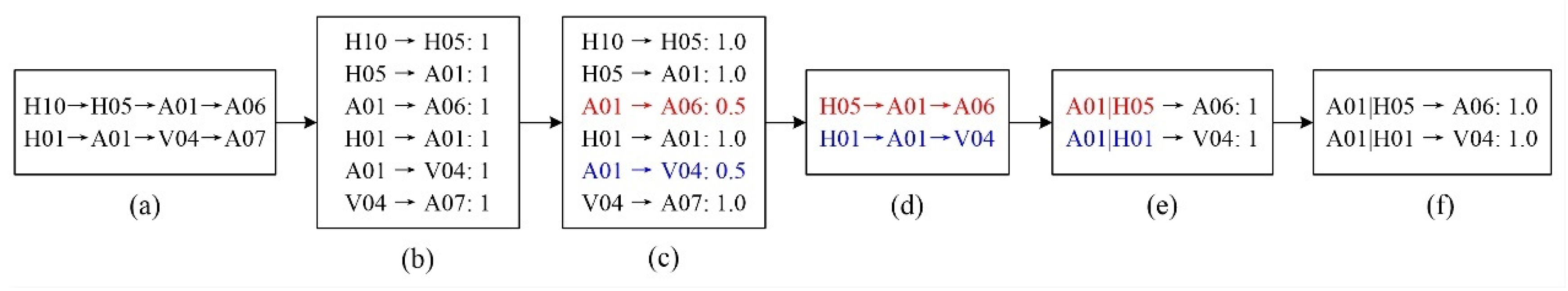

2.2.2. Process of Network Construction

3. Results and Discussion

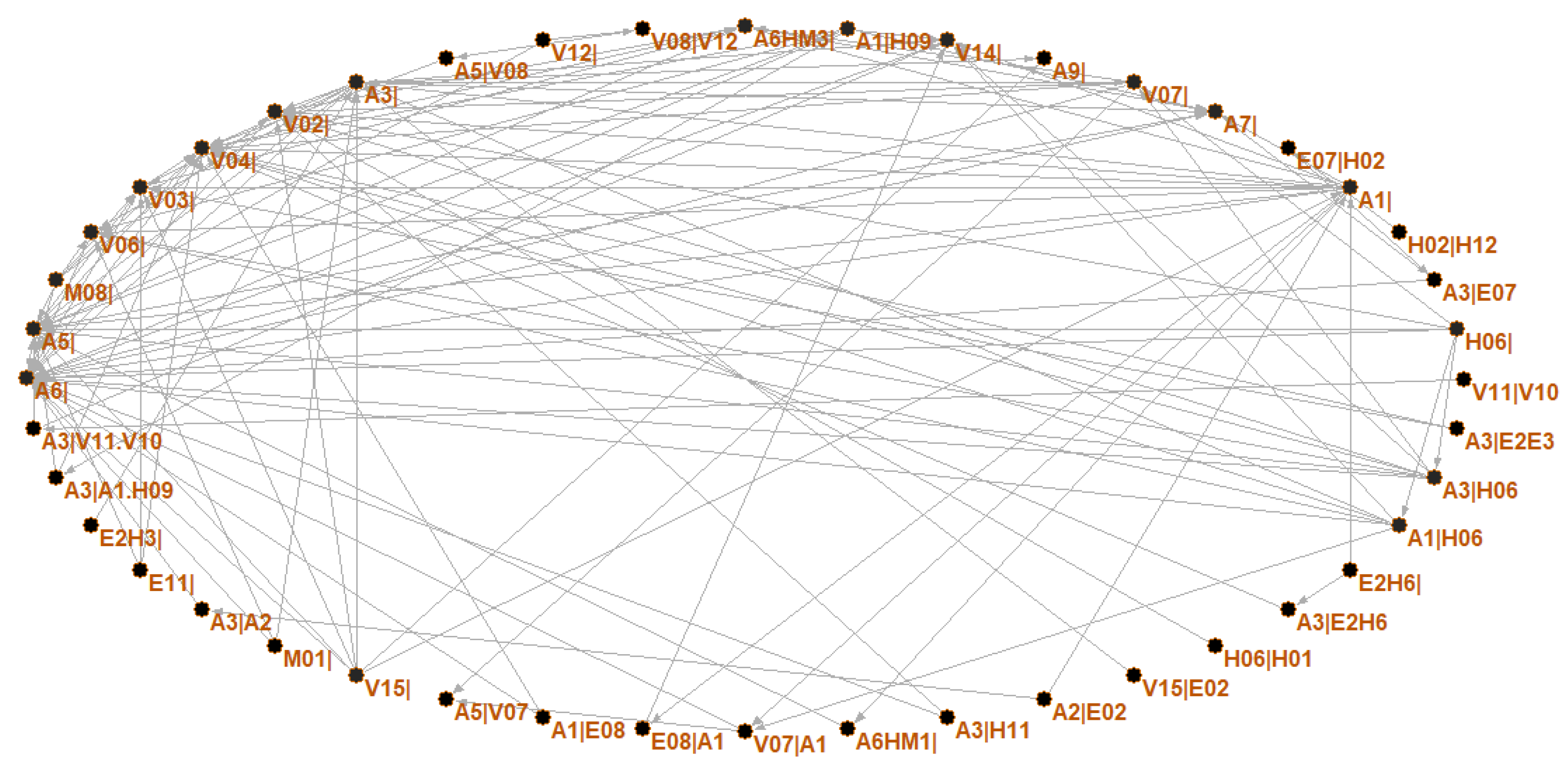

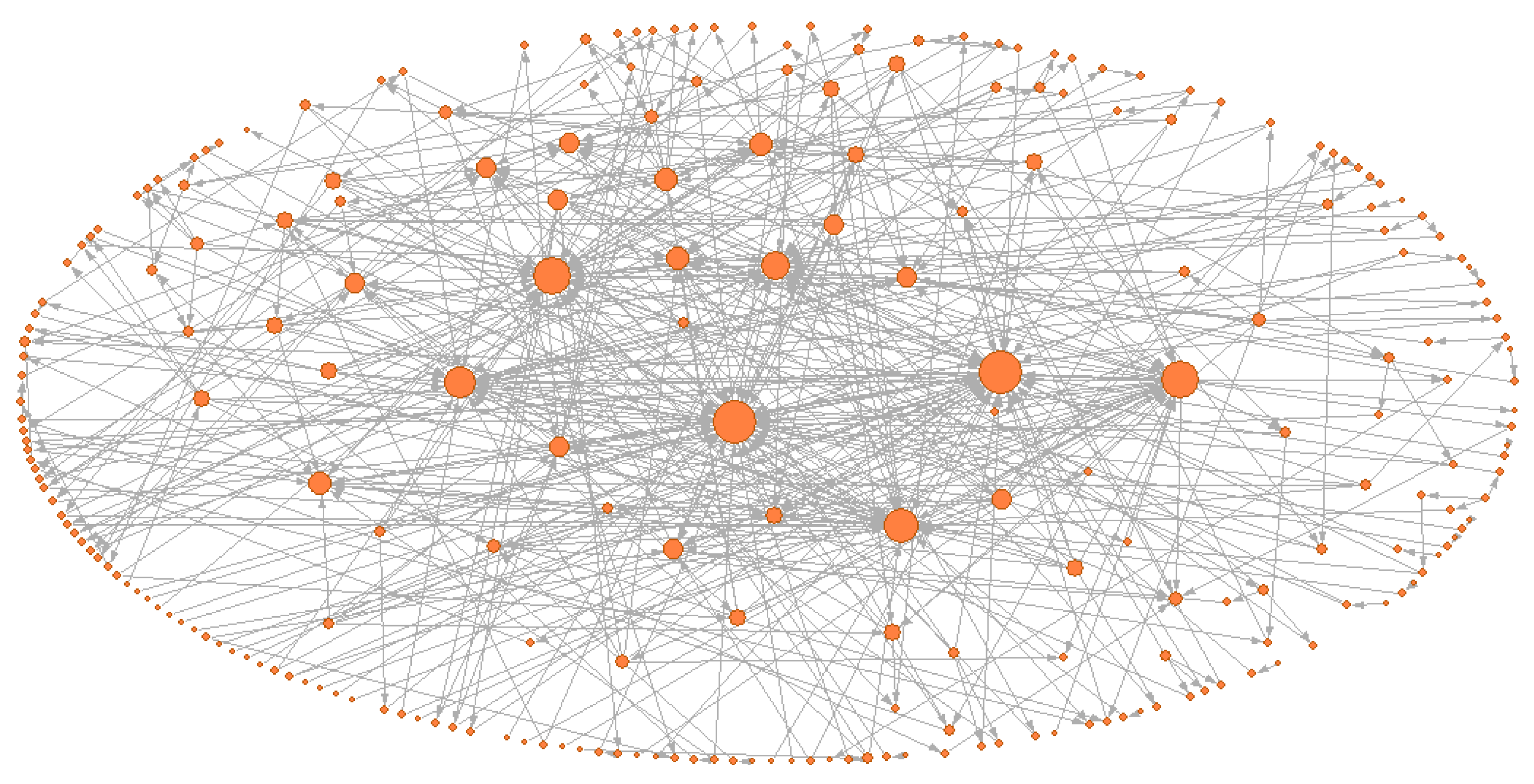

3.1. Overall Description of the HMTACN

3.2. Topological Properties

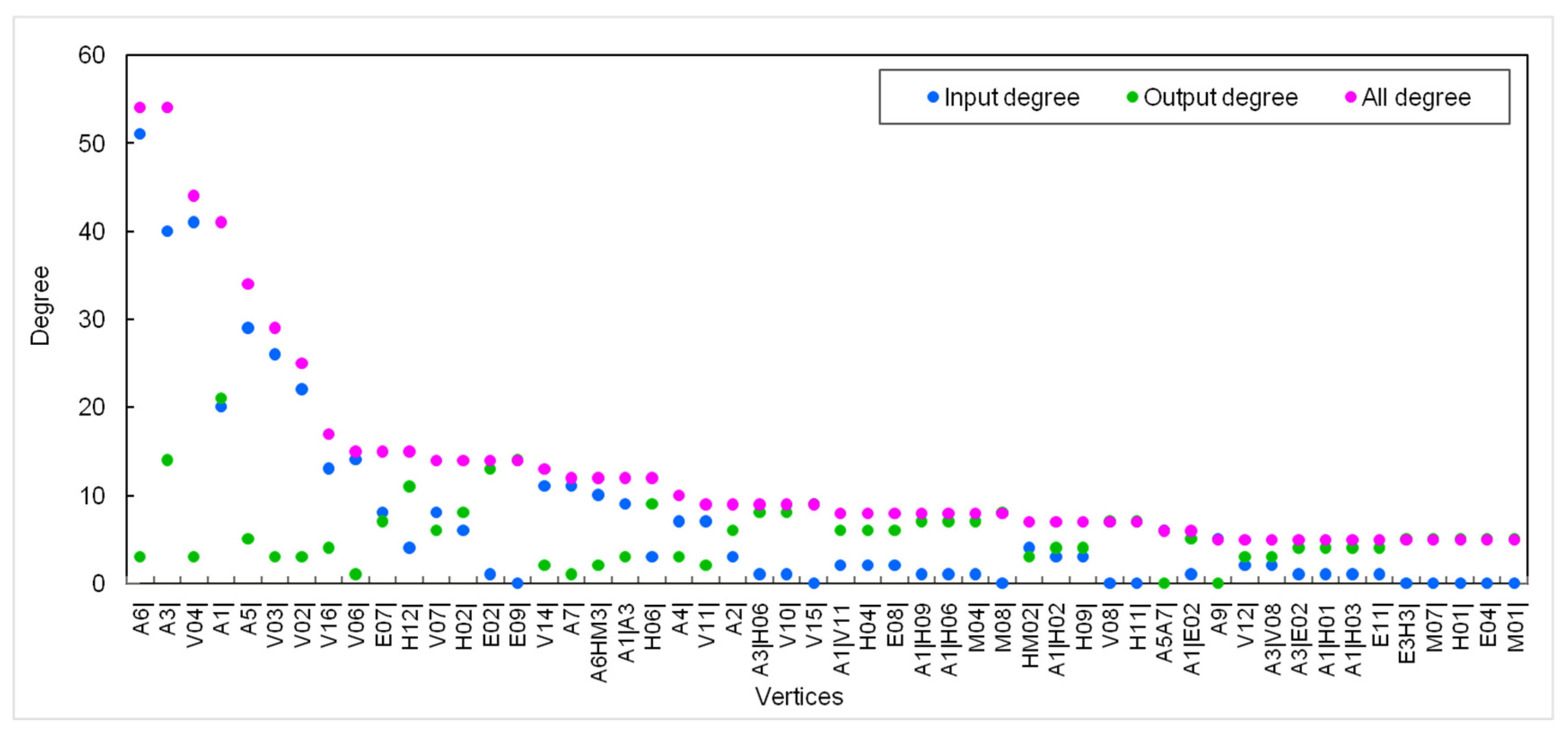

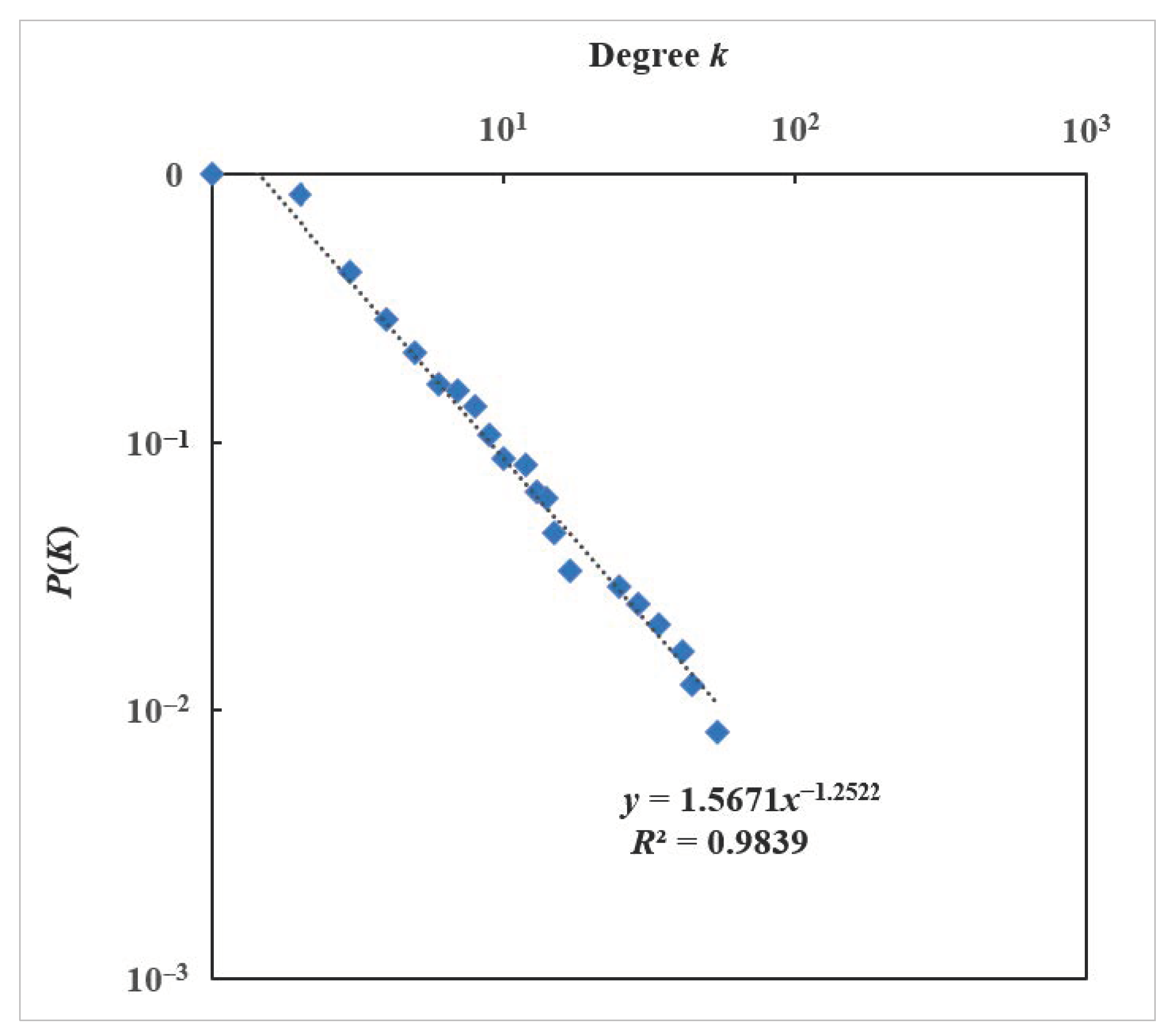

3.2.1. Degree Distribution

3.2.2. Average Path Length and Diameter

3.2.3. Clustering Coefficient

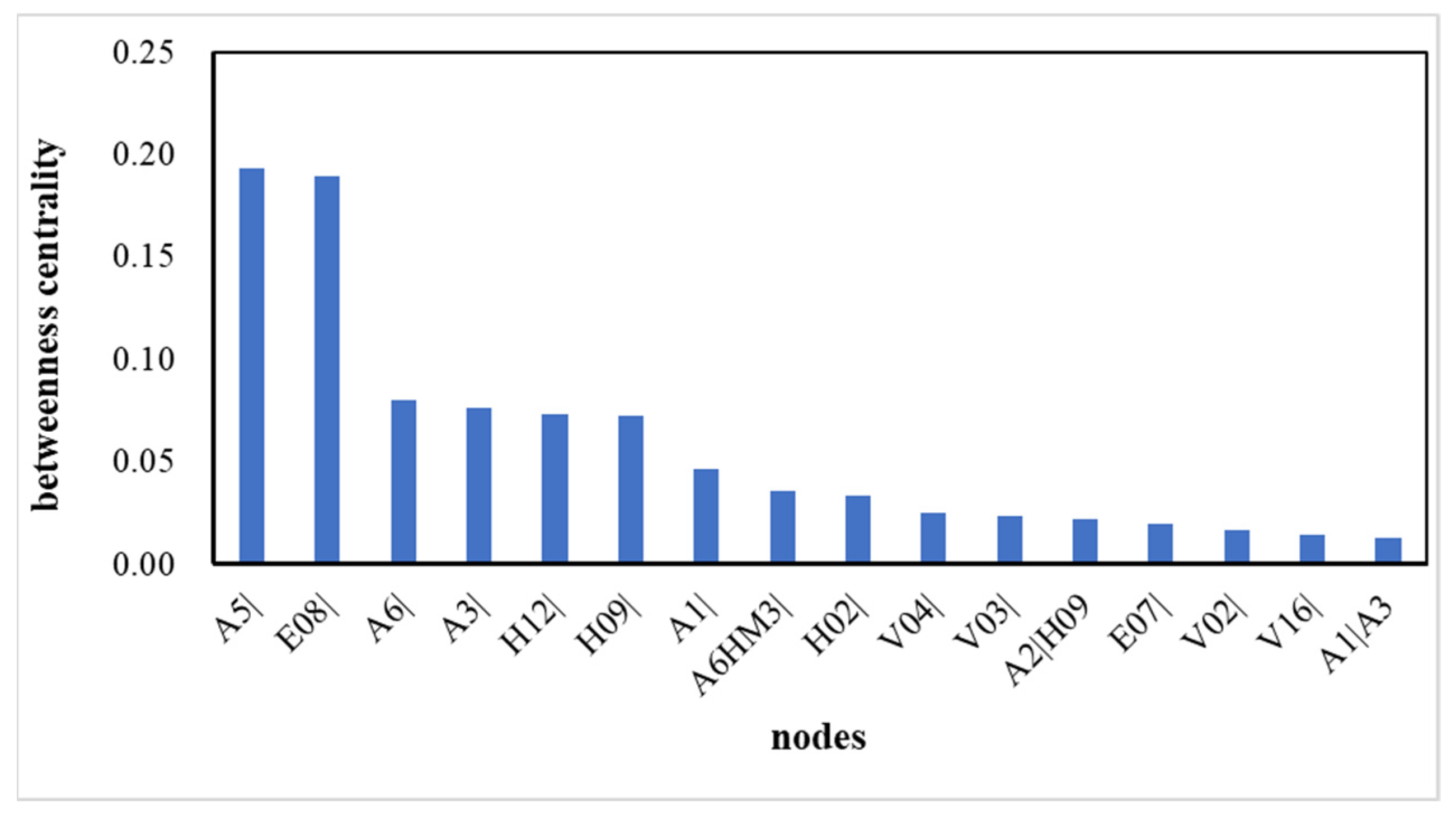

3.2.4. Betweenness Centrality

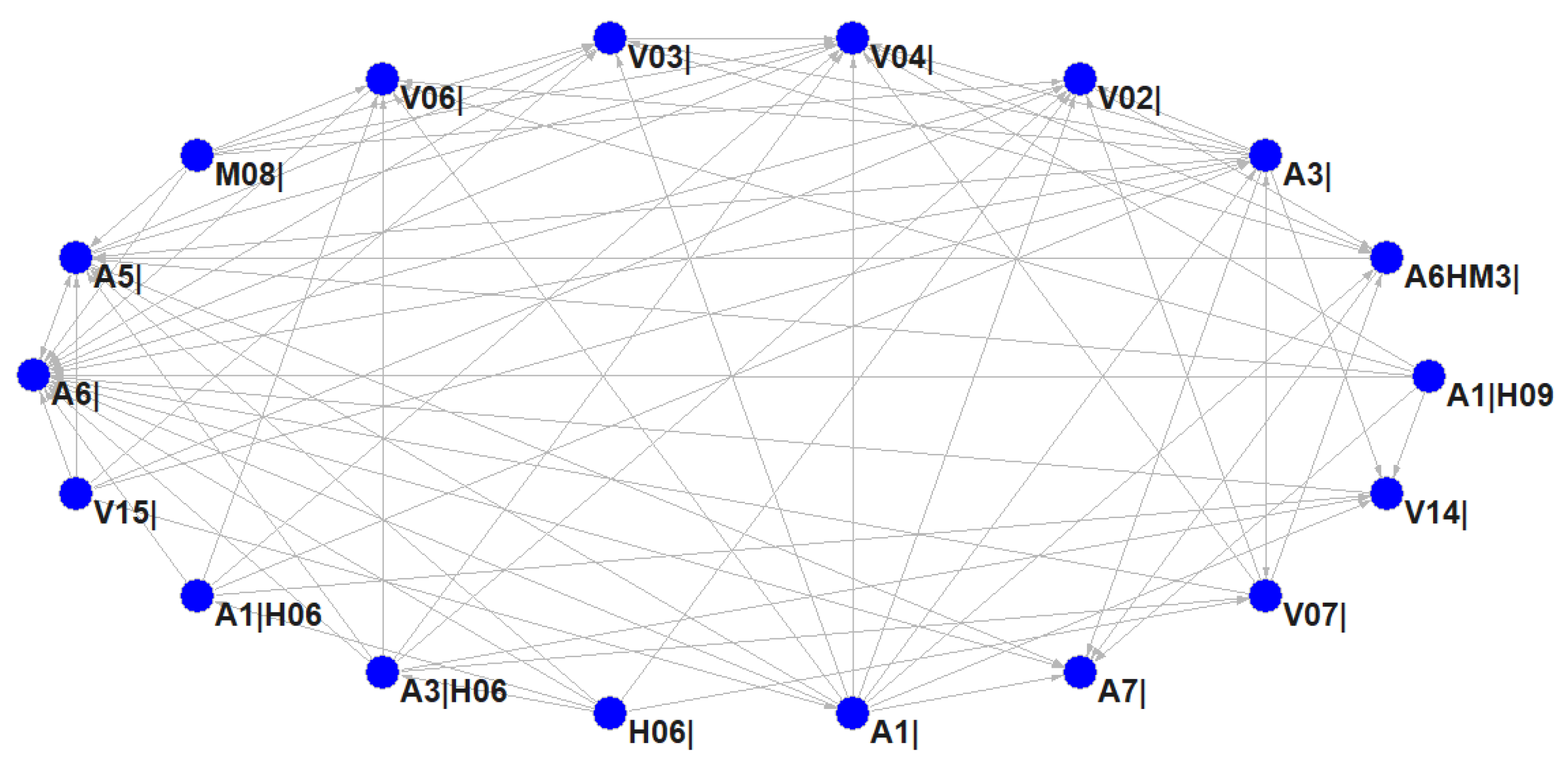

3.2.5. K-Core

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, X.; Yan, Y.; Li, X.; Xie, C.; Wang, L. Analysis on tank truck accidents involved in road hazardous materials transportation in China. Traffic Inj. Prev. 2014, 15, 762–768. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.; Shi, S.; Lu, Y.; Liu, Y.; Wang, Y.; Peng, J. Analysis on tank transportation accidents of hazardous chemicals from 2103 to 2018. China Saf. Sci. J. 2020, 30, 119–126. [Google Scholar]

- Zhejiang Provincial Emergency Management Department. Investigation Report on “6·13” LPG Transportation Tank Car Major Explosion Accident at Wenling Section of Shenhai Expressway. 2020. Available online: https://yjt.zj.gov.cn/art/2020/12/31/art_1228978417_59031875.html (accessed on 31 December 2021).

- Ren, C.; Wu, Q.; Zhang, C.; Zhang, S. A normal distribution-based methodology for analysis of fatal accidents in land hazardous material transportation. Int. J. Environ. Res. Public Health 2018, 15, 1437. [Google Scholar] [CrossRef] [PubMed]

- Oggero, A.; Darbra, R.M.; Munoz, M.; Planas, E.; Casal, J. A survey of accidents occurring during the transport of hazardous substances by road and rail. J. Hazard. Mater. 2006, 133, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Pompone, E.C.; de Oliveira Neto, G.C. A Survey on Accidents in the Road Transportation of Hazardous Materials in São Paulo, Brazil, from 1983 to 2015. Transp. Res. Rec. 2019, 2673, 285–293. [Google Scholar] [CrossRef]

- Zhang, H.D.; Zheng, X.P. Characteristics of hazardous chemical accidents in China: A statistical investigation. J. Loss Prev. Process Ind. 2012, 25, 686–693. [Google Scholar] [CrossRef]

- Montiel, H.; Vilchez, J.A.; Arnaldos, J.; Casal, J. Historical analysis of accidents in the transportation of natural gas. J. Hazard. Mater. 1996, 51, 77–92. [Google Scholar] [CrossRef]

- Yang, J.; Li, F.; Zhou, J.; Zhang, L.; Huang, L.; Bi, J. A survey on hazardous materials accidents during road transport in China from 2000 to 2008. J. Hazard. Mater. 2010, 184, 647–653. [Google Scholar] [CrossRef]

- Li, X.W.; Liu, T.Z.; Liu, Y.K. Cause analysis of unsafe behaviors in hazardous chemical accidents: Combined with HFACs and Bayesian network. Int. J. Environ. Res. Public Health 2020, 17, 11. [Google Scholar] [CrossRef]

- Fu, G.; Suo, X.; Jia, Q.; Fu, M. Comparative study on ten accident causation models. J. Saf. Sci. Technol. 2018, 14, 58–63. [Google Scholar]

- Wang, W.; Cai, K.; Du, W.; Wu, X.; Tong, L.C.; Zhu, X.; Cao, X. Analysis of the Chinese railway system as a complex network. Chaos Solitons Fractals 2020, 130, 109408. [Google Scholar] [CrossRef]

- Li, K.P.; Wang, S.S. A network accident causation model for monitoring railway safety. Saf. Sci. 2018, 109, 398–402. [Google Scholar] [CrossRef]

- Liu, J.; Schmid, F.; Zheng, W.; Zhu, J. Understanding railway operational accidents using network theory. Reliab. Eng. Syst. Saf. 2019, 189, 218–231. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, W.; Guo, X.; Ding, J. A method for modeling and analysis of directed weighted accident causation network (DWACN). Phys. A Stat. Mech. Its Appl. 2015, 437, 263–277. [Google Scholar] [CrossRef]

- Zhou, Z.P.; Irizarry, J.; Li, Q.M. Using network theory to explore the complexity of subway construction accident network (SCAN) for safety management. Saf. Sci. 2014, 64, 127–136. [Google Scholar] [CrossRef]

- Zhou, Z.P.; Irizarry, J. Integrated framework of modified accident energy release model and network theory to explore the full complexity of Hangzhou subway construction collapse. J. Manag. Eng. 2016, 32, 05016013. [Google Scholar] [CrossRef]

- Xu, J.; Wickramarathne, T.L.; Chawla, N.V. Representing higher-order dependencies in networks. Sci. Adv. 2016, 2, e1600028. [Google Scholar] [CrossRef]

- Markov, A.A. Theory of Algorithms; Schorr-Kon, J.J.; PST staff, Translators; Academy of Sciences of the USSR: Moscow, Russia, 1954. [Google Scholar]

- Lambiotte, R.; Rosvall, M.; Scholtes, I. From networks to optimal higher-order models of complex systems. Nat. Phys. 2019, 15, 313–320. [Google Scholar] [CrossRef]

- Wei, W.; Carley, K.M. Measuring temporal patterns in dynamic social networks. ACM Trans. Knowl. Discov. Data TKDD 2015, 10, 1–27. [Google Scholar] [CrossRef]

- Rosvall, M.; Esquivel, A.V.; Lancichinetti, A.; West, J.D.; Lambiotte, R. Memory in network flows and its effects on spreading dynamics and community detection. Nat. Commun. 2014, 5, 4630. [Google Scholar] [CrossRef]

- Pfitzner, R.; Scholtes, I.; Garas, A.; Tessone, C.J.; Schweitzer, F. Betweenness preference: Quantifying correlations in the topological dynamics of temporal networks. Phys. Rev. Lett. 2013, 110, 198701. [Google Scholar] [CrossRef] [PubMed]

- Matamalas, J.T.; De Domenico, M.; Arenas, A. Assessing reliable human mobility patterns from higher order memory in mobile communications. J. R. Soc. Interface 2016, 13, 20160203. [Google Scholar] [CrossRef] [PubMed]

- Belth, C.; Kamran, F.; Tjandra, D.; Koutra, D. When to remember where you came from: Node representation learning in higher-order networks. In Proceedings of the 2019 IEEE/ACM International Conference on Advances in Social Networks Analysis and Mining (ASONAM), Vancouver, BC, Canada, 27–30 August 2019; pp. 222–225. [Google Scholar]

- Scholtes, I.; Wider, N.; Pfitzner, R.; Garas, A.; Tessone, C.J.; Schweitzer, F. Causality-driven slow-down and speed-up of diffusion in non-Markovian temporal networks. Nat. Commun. 2014, 5, 5024. [Google Scholar] [CrossRef] [PubMed]

- Iacopini, I.; Petri, G.; Barrat, A.; Latora, V. Simplicial models of social contagion. Nat. Commun. 2019, 10, 2485. [Google Scholar] [CrossRef]

- Scholtes, I.; Wider, N.; Garas, A. Higher-order aggregate networks in the analysis of temporal networks: Path structures and centralities. Eur. Phys. J. B 2016, 89, 61. [Google Scholar] [CrossRef]

- Benson, A.R. Three hypergraph eigenvector centralities. arXiv 2018, arXiv:1807.09644. [Google Scholar] [CrossRef]

- Benson, A.R.; Gleich, D.F.; Leskovec, J. Higher-order organization of complex networks. Science 2016, 353, 163–166. [Google Scholar] [CrossRef]

- Peixoto, T.P.; Rosvall, M. Modelling sequences and temporal networks with dynamic community structures. Nat. Commun. 2017, 8, 582. [Google Scholar] [CrossRef]

- Scholtes, I. When is a network a network? Multi-order graphical model selection in pathways and temporal networks. In Proceedings of the 23rd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Online, 13 August 2017; pp. 1037–1046. [Google Scholar]

- Schaub, M.T.; Benson, A.R.; Horn, P.; Lippner, G.; Jadbabaie, A. Random walks on simplicial complexes and the normalized Hodge 1-Laplacian. SIAM Rev. 2020, 62, 353–391. [Google Scholar] [CrossRef]

- Saebi, M.; Xu, J.; Kaplan, L.M.; Ribeiro, B.; Chawla, N.V. Efficient modeling of higher-order dependencies in networks: From algorithm to application for anomaly detection. EPJ Data Sci. 2020, 9, 15. [Google Scholar] [CrossRef]

- Lotito, Q.F.; Musciotto, F.; Montresor, A.; Battiston, F. Higher-order motif analysis in hypergraphs. Commun. Phys. 2022, 5, 79. [Google Scholar] [CrossRef]

- Aktas, M.E.; Nguyen, T.; Jawaid, S.; Riza, R.; Akbas, E. Identifying critical higher-order interactions in complex networks. Sci. Rep. 2021, 11, 21288. [Google Scholar] [CrossRef] [PubMed]

- Vasilyeva, E.; Kozlov, A.; Alfaro-Bittner, K.; Musatov, D.; Raigorodskii, A.M.; Perc, M.; Boccaletti, S. Multilayer representation of collaboration networks with higher-order interactions. Sci. Rep. 2021, 11, 5666. [Google Scholar] [CrossRef] [PubMed]

- Xie, F.J.; Ma, M.D.; Ren, C.P. Research on multilayer network structure characteristics from a higher-order model: The case of a Chinese high-speed railway system. Phys. A Stat. Mech. Its Appl. 2022, 586, 126473. [Google Scholar] [CrossRef]

- National Highway Traffic Safety Administration. Traffic Safety Facts: Motorcycles, DOT HS; National Highway Traffic Safety Administration: Washington, DC, USA, 2009; Volume 811, p. 159. [Google Scholar]

- Blincoe, L.J.; Seay, A.G.; Zaloshnja, E.; Miller, T.R.; Romano, E.O.; Luchter, S.; Spicer, R.S. The Economic Impact of Motor Vehicle Crashes; Technical Report; NHTSA: Washington, DC, USA, 2002. [Google Scholar]

- Newman, M.E.J. The structure and function of complex networks. SIAM Rev. 2003, 45, 167–256. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, S.; Lang, H.; Jiang, C.; Xing, Y. The Situation of Hazardous Materials Accidents during Road Transportation in China from 2013 to 2019. Int. J. Environ. Res. Public Health 2022, 19, 9632. [Google Scholar] [CrossRef]

- Watts, D.J.; Strogatz, S.H. Collective dynamics of ‘small-world’ networks. Nature 1998, 393, 440–442. [Google Scholar] [CrossRef]

| General Cause | Specific Cause (Code) | General Cause | Specific Cause (Code) |

|---|---|---|---|

| Human (H) | Fatigue driving (H01) Improper avoidance (H02) Fast driving (H03) Improper braking (H04) Improper overtaking (H05) Improper operation (H06) Overload transportation (H07) Distracted driving (H08) Unsafe distance (H09) Unfamiliar with the road (H10) Other hazmat personnel reasons (H11) Non-hazmat personnel reasons (H12) | Vehicle (V) | Tank equipment failure (V01) Valve loose (V02) Valve damaged (V03) Tank damaged (V04) Tank/valve aging (V05) Pipe rupture (V06) Other tank reasons (V07) Blow-out (V08) Transmission shaft fracture (V09) Brake system fault (V10) Vehicle out of control (V11) Tire overheating (V12) Equipment aging (V13) Oil tank damaged (V14) Other vehicle reasons (V15) Packaging issues (V16) |

| Hazardous Materials (HM) | Explosive materials (HM01) Gas (HM02) Flammable liquid (HM03) Flammable solid (HM04) Oxidizing materials (HM05) Toxic and infectious materials (HM06) Radioactive materials (HM07) Corrosive and irritant materials (HM08) Miscellaneous hazmat (HM09) | Management (M) | Illegally refitting vehicles (M01) No supercargo (M02) Failure to clean tank as required (M03) Illegal transportation (M04) No hazmat qualification certificate (M05) No hazmat transportation license (M06) Inadequate safety check (M07) Other management reasons (M08) |

| Environment (E) | Downhill road (E01) Slippery road (E02) Turning road (E03) Poor road (E04) Other road reasons (E05) Traffic jam (E06) Multi-car collision (E07) Other traffic reasons (E08) Rain or snow weather (E09) Foggy weather (E10) High temperature (E11) Poor visibility (E12) Other environment reasons (E13) | Accident type (A) | Collision (A1) Scrape (A2) Roll-over (A3) Fall-over (A4) Fire (A5) Leakage (A6) Explosion (A7) Poisoning (A8) Others (A9) |

| Cluster | Freq | Freq% | CumFreq | CumFreq% |

|---|---|---|---|---|

| 1 | 58 | 23.87 | 58 | 23.87 |

| 2 | 109 | 44.86 | 167 | 68.72 |

| 3 | 26 | 10.70 | 193 | 79.42 |

| 4 | 18 | 7.41 | 211 | 86.83 |

| 5 | 14 | 5.76 | 225 | 92.59 |

| 6 | 18 | 7.41 | 243 | 100.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, C.; Chen, B.; Xie, F.; Zhao, X.; Zhang, J.; Zhou, X. Understanding Hazardous Materials Transportation Accidents Based on Higher-Order Network Theory. Int. J. Environ. Res. Public Health 2022, 19, 13337. https://doi.org/10.3390/ijerph192013337

Ren C, Chen B, Xie F, Zhao X, Zhang J, Zhou X. Understanding Hazardous Materials Transportation Accidents Based on Higher-Order Network Theory. International Journal of Environmental Research and Public Health. 2022; 19(20):13337. https://doi.org/10.3390/ijerph192013337

Chicago/Turabian StyleRen, Cuiping, Bianbian Chen, Fengjie Xie, Xuan Zhao, Jiaqian Zhang, and Xueyan Zhou. 2022. "Understanding Hazardous Materials Transportation Accidents Based on Higher-Order Network Theory" International Journal of Environmental Research and Public Health 19, no. 20: 13337. https://doi.org/10.3390/ijerph192013337

APA StyleRen, C., Chen, B., Xie, F., Zhao, X., Zhang, J., & Zhou, X. (2022). Understanding Hazardous Materials Transportation Accidents Based on Higher-Order Network Theory. International Journal of Environmental Research and Public Health, 19(20), 13337. https://doi.org/10.3390/ijerph192013337