Occurrence Location and Propagation Inconformity Characteristics of Vibration Events in a Heading Face ofa Coal Mine

Abstract

:1. Introduction

2. Methods

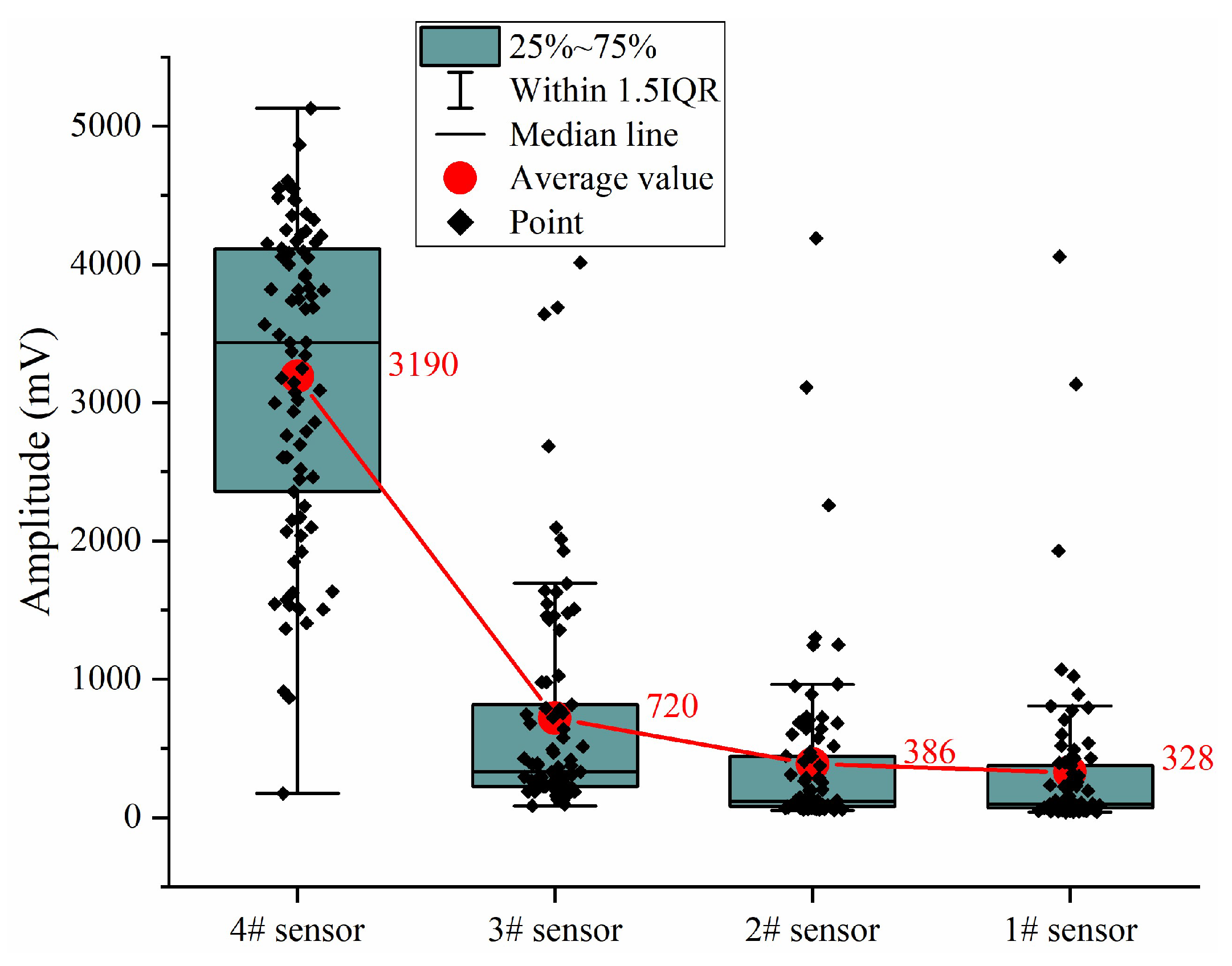

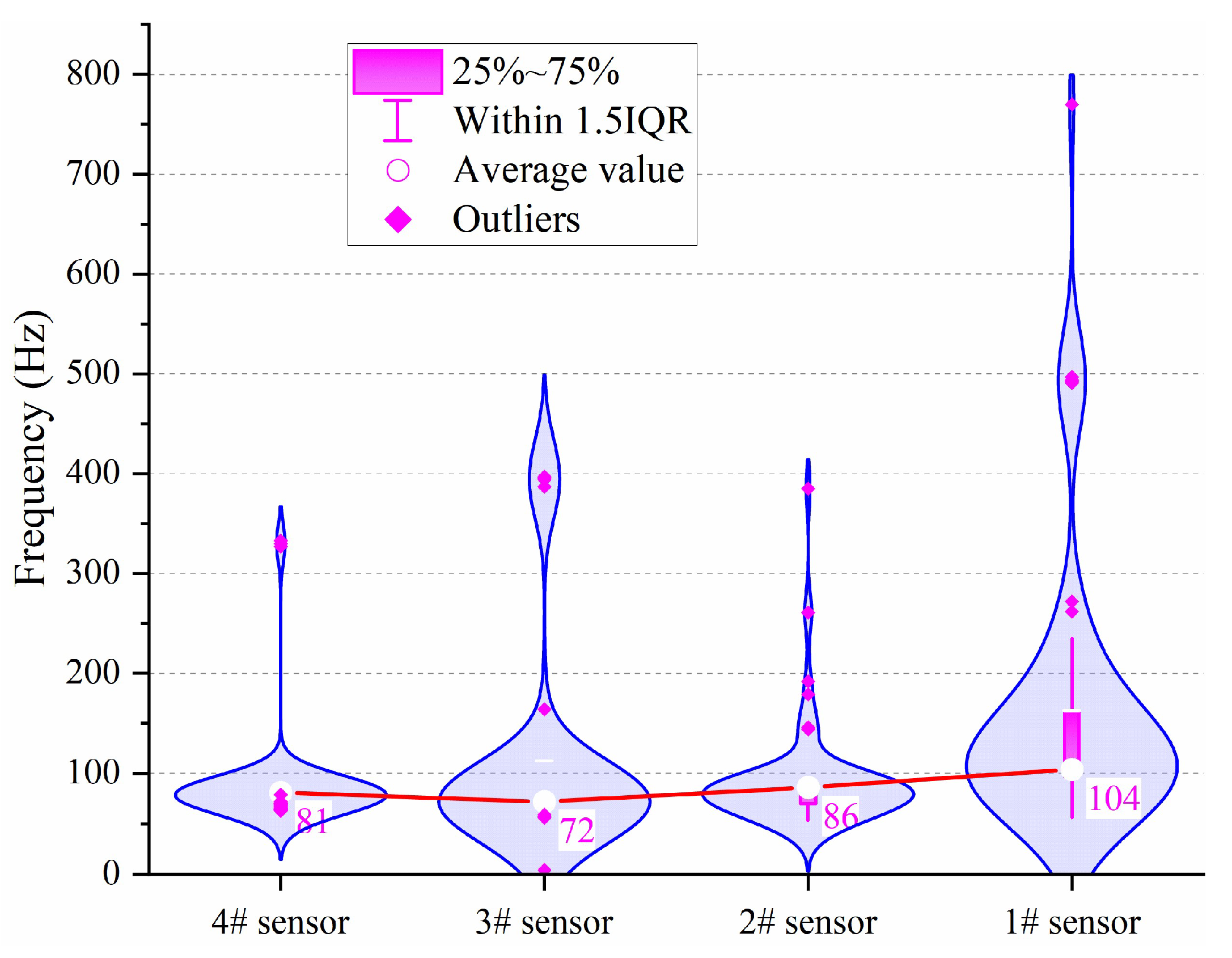

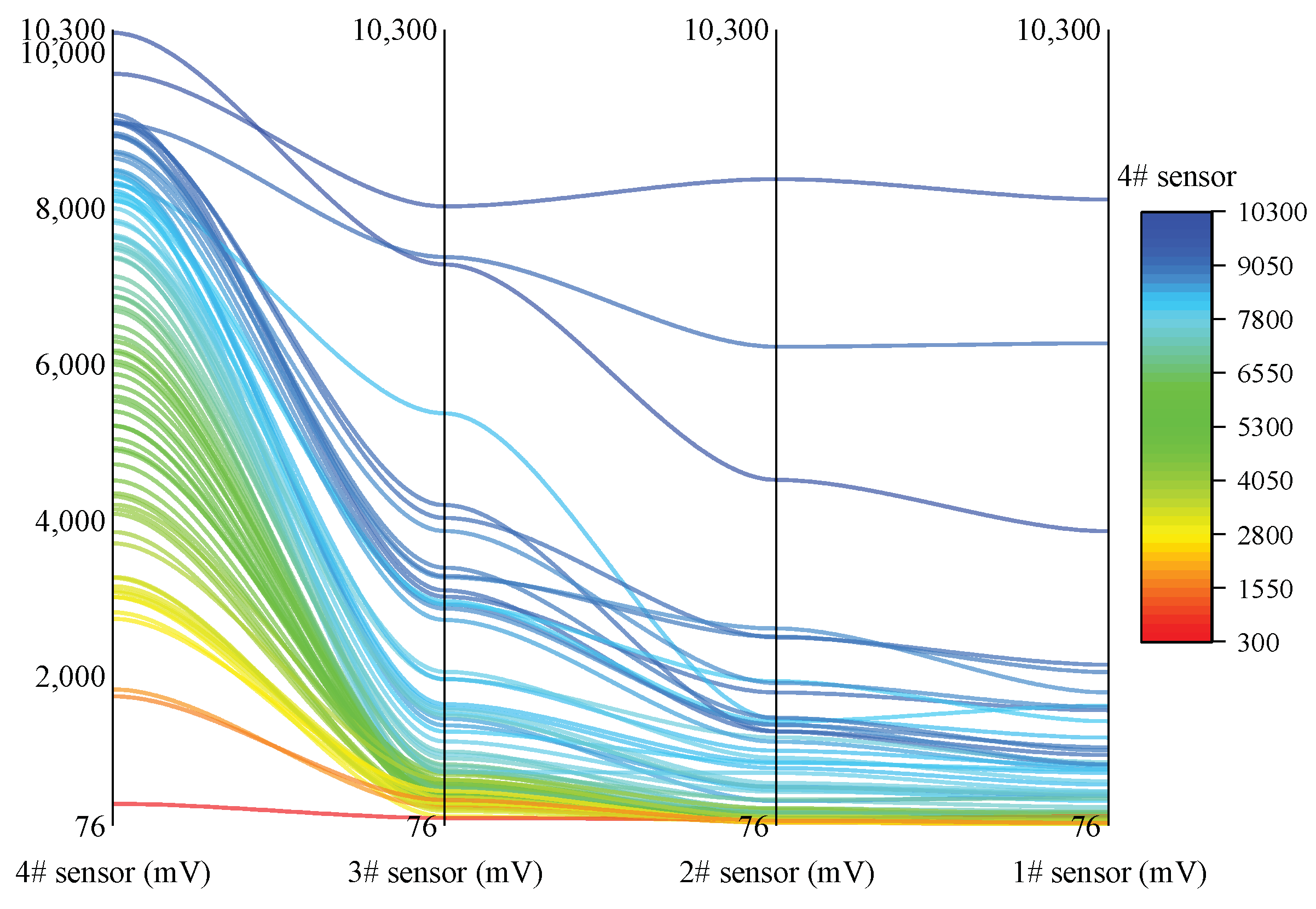

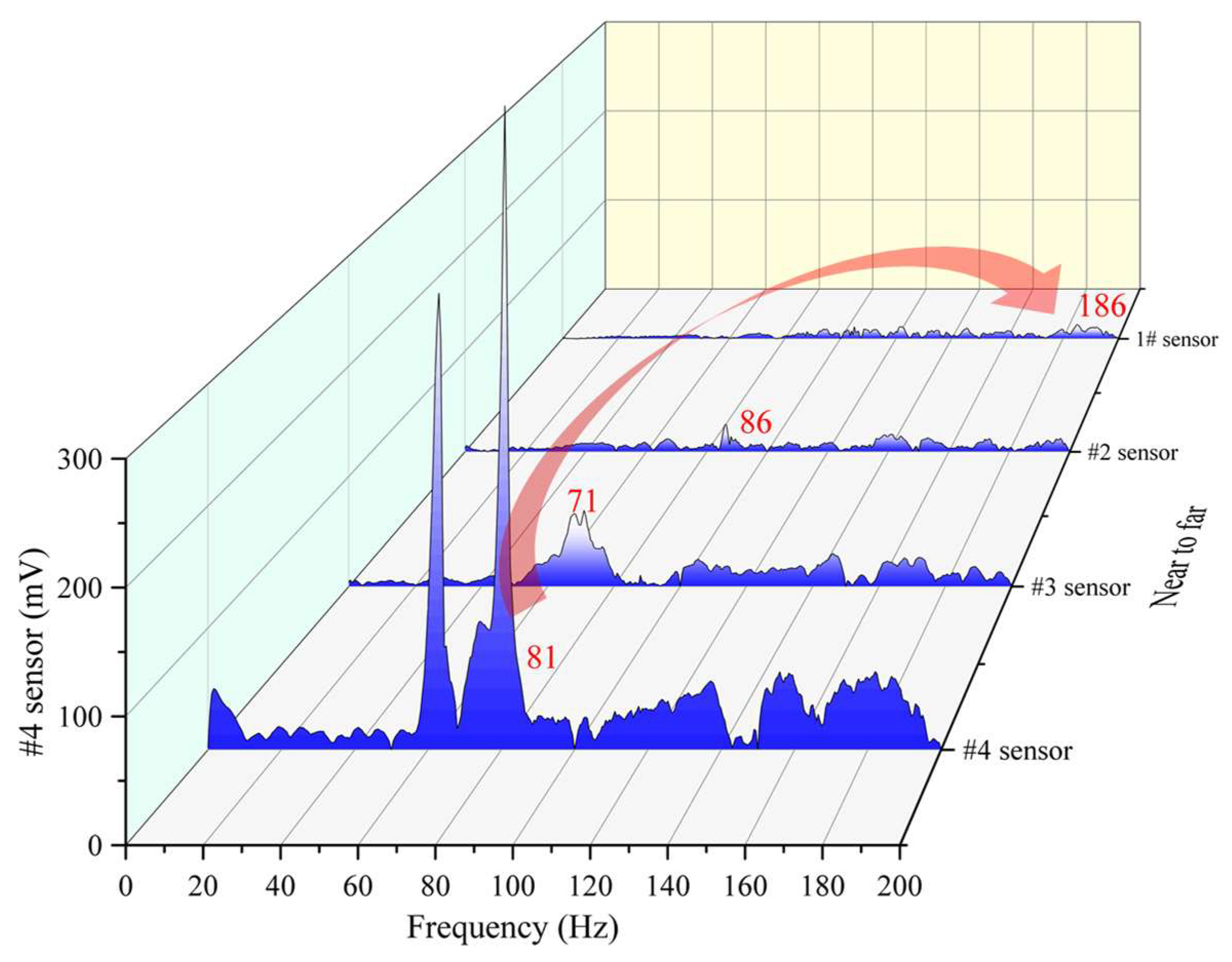

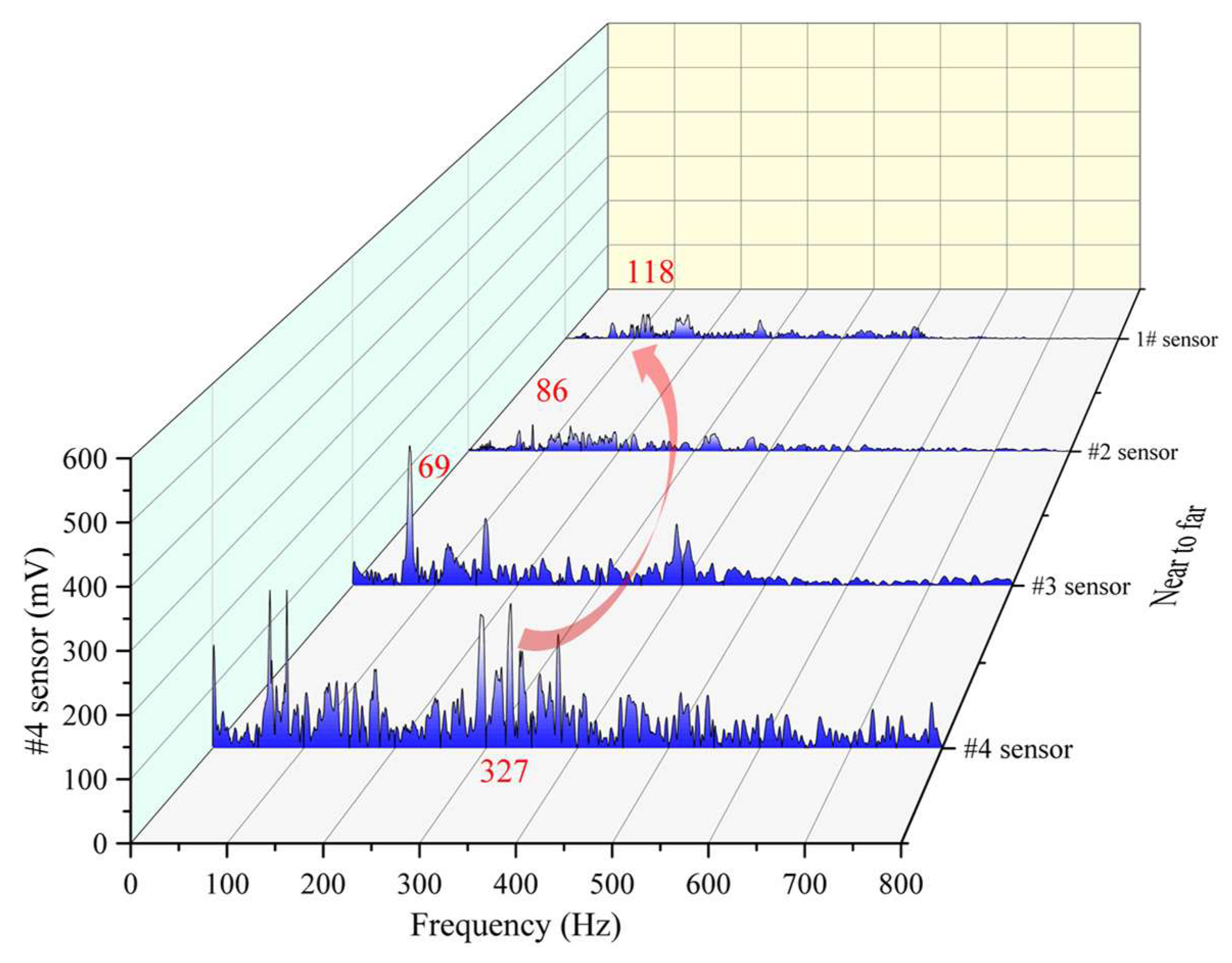

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Meifeng, C. Key theories and technonogies for surrounding rock stability and ground control in deep mining. J. Min. Strat. Control. Eng. 2020, 2, 033037. [Google Scholar]

- Guo, W.-Y.; Zhao, T.-B.; Tan, Y.-L.; Yu, F.-H.; Hu, S.-C.; Yang, F.-Q. Progressive mitigation method of rock bursts under complicated geological conditions. Int. J. Rock Mech. Min. Sci. 2017, 96, 11–22. [Google Scholar] [CrossRef]

- Zhao, T.-B.; Guo, W.-Y.; Tan, Y.-L.; Yin, Y.-C.; Cai, L.-S.; Pan, J.-F. Case Studies of Rock Bursts Under Complicated Geological Conditions During Multi-seam Mining at a Depth of 800 m. Rock Mech. Rock Eng. 2018, 51, 1539–1564. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Yao, J.; Gong, F.; Li, X.; Du, K.; Tao, M.; Huang, L.; Du, S. Experimental investigation of rock breakage by a conical pick and its application to non-explosive mechanized mining in deep hard rock. Int. J. Rock Mech. Min. Sci. 2019, 122, 104063. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, N.; Ma, J.; Li, C.; Ren, J.; Jiang, B. Mechanism of Rock Burst Revealed by Numerical Simulation and Energy Calculation. Shock. Vib. 2020, 2020, 1–15. [Google Scholar] [CrossRef]

- Xiufeng, Z.; Xiaocheng, Q.; Quande, W. Development and application of multi-dimension multi-parameter monitoring and early warning platform of coal bursts. J. Min. Strat. Control. Eng. 2021, 3, 69–78. [Google Scholar]

- Ziyi, F.; Yongliang, L.; Hao, S.; Xiaolei, C. Characteristics and control measures of unsymmetric deformation of roadways within weakly-cemented soft rock. J. Min. Strat. Control Eng. 2022, 4. [Google Scholar]

- Shichang, S.; Yongzheng, W.; Yukai, F.; Penghao, Z. Experimental study on shear mechanical properties of anchored rock mass under impact load. J. Min. Strat. Control. Eng. 2021, 3. [Google Scholar]

- Cai, W.; Dou, L.; Zhang, M.; Cao, W.; Shi, J.-Q.; Feng, L. A fuzzy comprehensive evaluation methodology for rock burst forecasting using microseismic monitoring. Tunn. Undergr. Space Technol. 2018, 80, 232–245. [Google Scholar] [CrossRef]

- Mark, C. Coal bursts that occur during development: A rock mechanics enigma. Int. J. Min. Sci. Technol. 2018, 28, 35–42. [Google Scholar] [CrossRef]

- Hebblewhite, B.; Galvin, J. A review of the geomechanics aspects of a double fatality coal burst at Austar Colliery in NSW, Australia in April 2014. Int. J. Min. Sci. Technol. 2017, 27, 3–7. [Google Scholar] [CrossRef]

- Zhen, H. Evolution Law of Plastic Zone and Burst Failure Mechanism of Gateway in Yima Coalfield; China University of mining and Technology (Beijing): Beijing, China, 2018. [Google Scholar]

- Zhu, S.; Jiang, F.; Liu, J.; Wang, G.; Wang, X.; Jiang, Y.; Qu, X.; Xu, H.; Ning, Y. Mechanism and monitoring and early warning technology of rock burst in the heading face of compound thick coal seam. J. China Coal Soc. 2020, 45, 1659–1670. [Google Scholar]

- Hao, S.; Huilin, Z.; Guansheng, Q.; Wei, L.; Mingjun, W. Preparation and CO2 adsorption properties of TEPA-functionalized multi-level porous particles based on solid waste. Colloids Surf. A Physicochem. Eng. Asp. 2022, 653, 130004. [Google Scholar]

- Li, B. Research on Evolution Mechanism and Prevention of Rock Burst in Deep Coal Seam Excavation Roadway; Shandong University of Science and Technology: Qingdao, China, 2019. [Google Scholar]

- Zhu, S.; Jiang, F.; Wang, X.; Jiang, Y.; Ning, T.; Sun, S. Energy accumulation characteristics and rockburst mechanism of surrounding rock at heading face of extra-thick coal seam. Chin. J. Geotech. Eng. 2019, 41, 2071–2078. [Google Scholar]

- Cao, A.-Y.; Dou, L.-M.; Wang, C.-B.; Yao, X.-X.; Dong, J.-Y.; Gu, Y. Microseismic Precursory Characteristics of Rock Burst Hazard in Mining Areas Near a Large Residual Coal Pillar: A Case Study from Xuzhuang Coal Mine, Xuzhou, China. Rock Mech. Rock Eng. 2016, 49, 4407–4422. [Google Scholar] [CrossRef]

- Wang, S.; Huang, L.; Li, X. Analysis of rockburst triggered by hard rock fragmentation using a conical pick under high uniaxial stress. Tunn. Undergr. Space Technol. 2020, 96, 103195. [Google Scholar] [CrossRef]

- Yang, G.; Jiang, F.; Qu, X.; Li, L.; Wei, Q.; Li, N. Comprehensive monitoring and early warning technology for rock burst of tunneling face with thick coal seams. Chin. J. Geotech. Eng. 2019, 41, 1949–1958. [Google Scholar]

- Yuanjie, W.; Gang, X.; Fabing, C.; Yangpo, L. Mining pressure weakening mechanism by ground fracturing and fracturing evaluation of hard rock strata. J. Min. Strat. Control Eng. 2022, 4, 023027. [Google Scholar]

- Tiedong, C.; Zhizhao, Z.; Qiwen, Y.; Baoyong, Y. Denoising method of rock acoustic emission signal based on improved VMD. J. Min. Strat. Control Eng. 2022, 4, 023011. [Google Scholar]

- Li, Q.-Y.; Dong, L.-J.; Li, X.-B.; Yin, Z.-Q.; Liu, X.-L. Effects of sonic speed on location accuracy of acoustic emission source in rocks. Trans. Nonferr. Met. Soc. China 2011, 21, 2719–2726. [Google Scholar] [CrossRef]

- Feng, J.; Wang, E.; Ding, H.; Huang, Q.; Chen, X. Deterministic seismic hazard assessment of coal fractures in underground coal mine: A case study. Soil Dyn. Earthq. Eng. 2020, 129, 105921. [Google Scholar] [CrossRef]

- Lu, C.-P.; Liu, G.-J.; Liu, Y.; Zhang, N.; Xue, J.-H.; Zhang, L. Microseismic multi-parameter characteristics of rockburst hazard induced by hard roof fall and high stress concentration. Int. J. Rock Mech. Min. Sci. 2015, 76, 18–32. [Google Scholar] [CrossRef]

- Bukowska, M. The Rockbursts in the Upper Silesian Coal Basin in Poland. J. Min. Sci. 2012, 48, 445–456. [Google Scholar] [CrossRef]

- Lu, C.-P.; Liu, Y.; Wang, H.-Y.; Liu, P.-F. Microseismic signals of double-layer hard and thick igneous strata separation and fracturing. Int. J. Coal Geol. 2016, 160–161, 28–41. [Google Scholar] [CrossRef]

- Wang, P.; Jiang, L.; Jiang, J.; Zheng, P.; Li, W. Strata Behaviors and Rock Burst–Inducing Mechanism under the Coupling Effect of a Hard, Thick Stratum and a Normal Fault. Int. J. Geomech. 2018, 18, 04017135. [Google Scholar] [CrossRef]

- Ding, X.; Xiao, X.-C.; Wu, D.; Lv, X.-F. Mechanical properties and charge signal characteristics in coal material failure under different loading paths. Int. J. Coal Sci. Technol. 2019, 6, 138–149. [Google Scholar] [CrossRef]

- Dou, L.; Yang, K.; Chi, X. Fracture behavior and acoustic emission characteristics of sandstone samples with inclined precracks. Int. J. Coal Sci. Technol. 2020, 8, 77–87. [Google Scholar] [CrossRef]

- Kong, P.; Jiang, L.; Wu, Y.; Chen, L.; Ning, J. Numerical Analysis of Roadway Rock-Burst Hazard Under Superposed Dynamic and Static Loads. Energies 2019, 12, 3761. [Google Scholar] [CrossRef] [Green Version]

- Lu, C.-P.; Dou, L.-M.; Zhang, N.; Xue, J.-H.; Wang, X.-N.; Liu, H.; Zhang, J.-W. Microseismic frequency-spectrum evolutionary rule of rockburst triggered by roof fall. Int. J. Rock Mech. Min. Sci. 2013, 64, 6–16. [Google Scholar] [CrossRef]

- Yao, M.; Ma, W.; Cao, L.; Zhang, G.; Jiang, F. Application research on rock sound monitoring technology in early warning of rock burst in Coal Mine. Coal Sci. Technol. 2020, 49, 57–62. [Google Scholar]

- Li, C.; Liu, J.; Wang, C.; Li, J.; Zhang, H. Spectrum characteristics analysis of microseismic signals transmitting between coal bedding. Saf. Sci. 2012, 50, 761–767. [Google Scholar] [CrossRef]

- Yu, D.; Wang, P. An improved empirical green function method to extract microseismic signals. Geod. Geodyn. 2019, 10, 42–48. [Google Scholar] [CrossRef]

- Yuan, S.; Liu, J.; Wang, S.; Wang, T.; Shi, P. Seismic Waveform Classification and First-Break Picking Using Convolution Neural Networks. IEEE Geosci. Remote Sens. Lett. 2018, 15, 272–276. [Google Scholar] [CrossRef] [Green Version]

- Thirumalaiselvi, A.; Sasmal, S. Acoustic emission monitoring and classification of signals in cement composites during early-age hydration. Constr. Build. Mater. 2019, 196, 411–427. [Google Scholar] [CrossRef]

- Kong, B.; Wang, E.; Li, Z.; Wang, X.; Niu, Y.; Kong, X. Acoustic emission signals frequency-amplitude characteristics of sandstone after thermal treated under uniaxial compression. J. Appl. Geophys. 2017, 136, 190–197. [Google Scholar] [CrossRef]

- Liu, J.; Yang, M.; Wang, D.; Zhang, J. Different bedding loaded coal mechanics properties and acoustic emission. Environ. Earth Sci. 2018, 77, 322. [Google Scholar] [CrossRef]

- Dexing, L.; Enyuan, W.; Xiangguo, K.; Xiaoran, W.; Chong, Z.; Haishan, J.; Hao, W.; Jifa, Q. Fractal characteristics of acoustic emissions from coal under multi-stage true-triaxial compression. J. Geophys. Eng. 2018, 15, 2021–2032. [Google Scholar] [CrossRef] [Green Version]

- Peng, P.; He, Z.; Wang, L. Automatic Classification of Microseismic Signals Based on MFCC and GMM-HMM in Underground Mines. Shock. Vib. 2019, 2019, 1–9. [Google Scholar] [CrossRef]

- Zhao, G.-Y.; Ma, J.; Dong, L.-J.; Li, X.-B.; Chen, G.-H.; Zhang, C.-X. Classification of mine blasts and microseismic events using starting-up features in seismograms. Trans. Nonferr. Met. Soc. China 2015, 25, 3410–3420. [Google Scholar] [CrossRef]

- Leake, M.R.; Conrad, W.J.; Westman, E.C.; Ghaychi Afrouz, S.; Molka, R.J. Microseismic monitoring and analysis of induced seismicity source mechanisms in a retreating room and pillar coal mine in the Eastern United States. Undergr. Space 2017, 2, 115–124. [Google Scholar] [CrossRef]

- Wang, J.; Ning, J.; Qiu, P.; Yang, S.; Shang, H. Microseismic monitoring and its precursory parameter of hard roof collapse in longwall faces: A case study. Geomech. Eng. 2019, 17, 375–383. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Accornero, F.; Mpalaskas, A.C.; Matikas, T.E.; Aggelis, D.G. Influence of damage in the acoustic emission parameters. Cem. Concr. Compos. 2013, 44, 9–16. [Google Scholar] [CrossRef]

- Yongchuan, Z.; Tianhong, Y.; Fukun, X.; Penghai, Z.; Qinglei, Y. Study on the Attenuation of Elastic Wave Propagating in Medium-grained Sandstone. J. Vib. Meas. Diagn. 2018, 38, 285–291. [Google Scholar]

- Li, X.; Li, Z.; Wang, E.; Feng, J.; Chen, L.; Li, N.; Zou, Q. Microseismic Signal Spectra, Energy Characteristics, and Fractal Features Prior to Rock Burst: A Case Study from the Qianqiu Coal Mine, China. J. Earthq. Eng. 2016, 21, 891–911. [Google Scholar] [CrossRef]

- Liang, Z.; Xue, R.; Xu, N.; Li, W. Characterizing rockbursts and analysis on frequency-spectrum evolutionary law of rockburst precursor based on microseismic monitoring. Tunn. Undergr. Space Technol. 2020, 105, 103564. [Google Scholar] [CrossRef]

- Xu, X.; Dou, L.; Lu, C.; Zhang, Y. Frequency spectrum analysis on micro-seismic signal of rock bursts induced by dynamic disturbance. Min. Sci. Technol. 2010, 20, 682–685. [Google Scholar] [CrossRef]

- Zhang, R.; Dai, F.; Gao, M.Z.; Xu, N.W.; Zhang, C.P. Fractal analysis of acoustic emission during uniaxial and triaxial loading of rock. Int. J. Rock Mech. Min. Sci. 2015, 79, 241–249. [Google Scholar] [CrossRef]

- Chicco, D. Siamese Neural Networks: An Overview. Methods Mol. Biol. 2021, 2190, 73–94. [Google Scholar] [CrossRef]

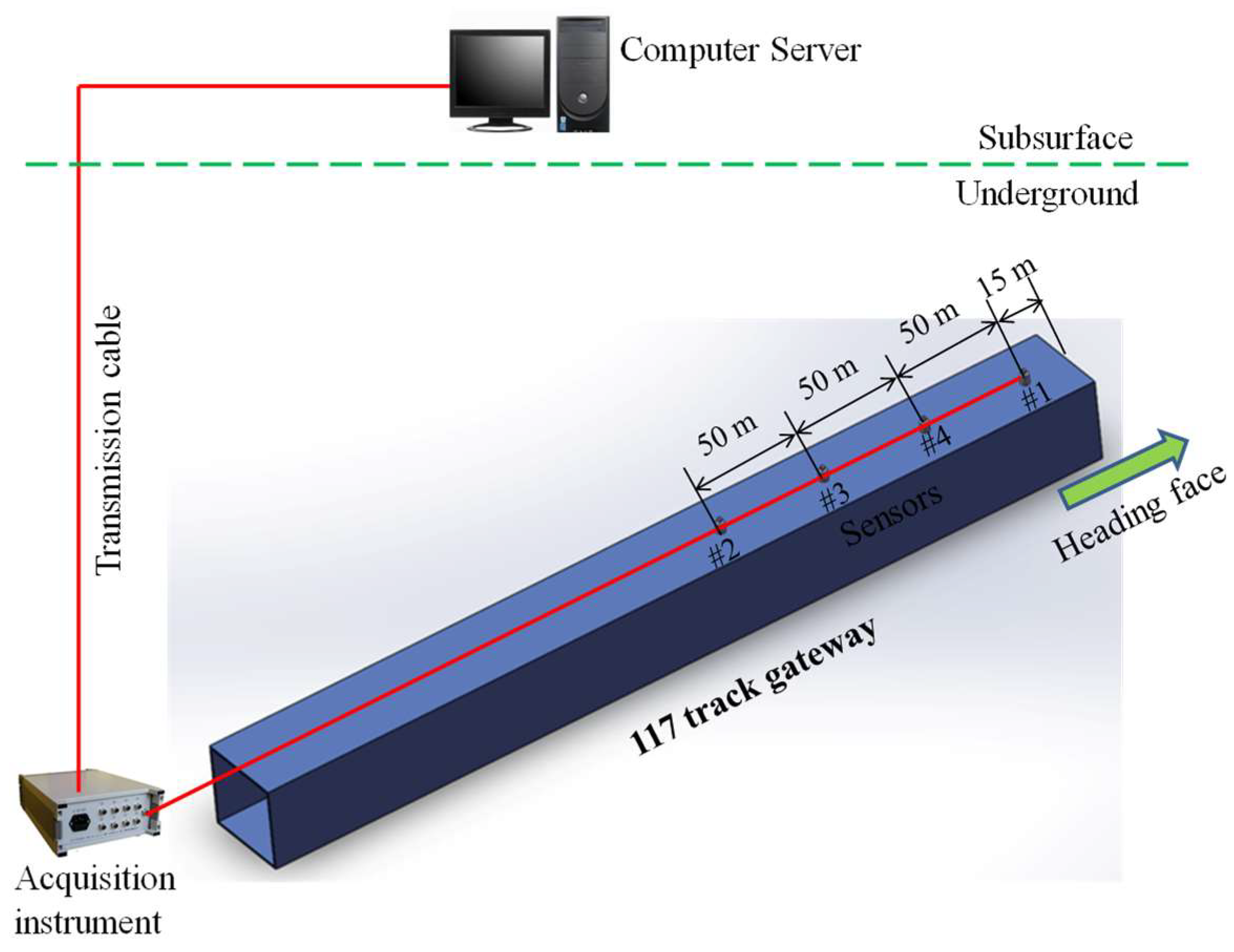

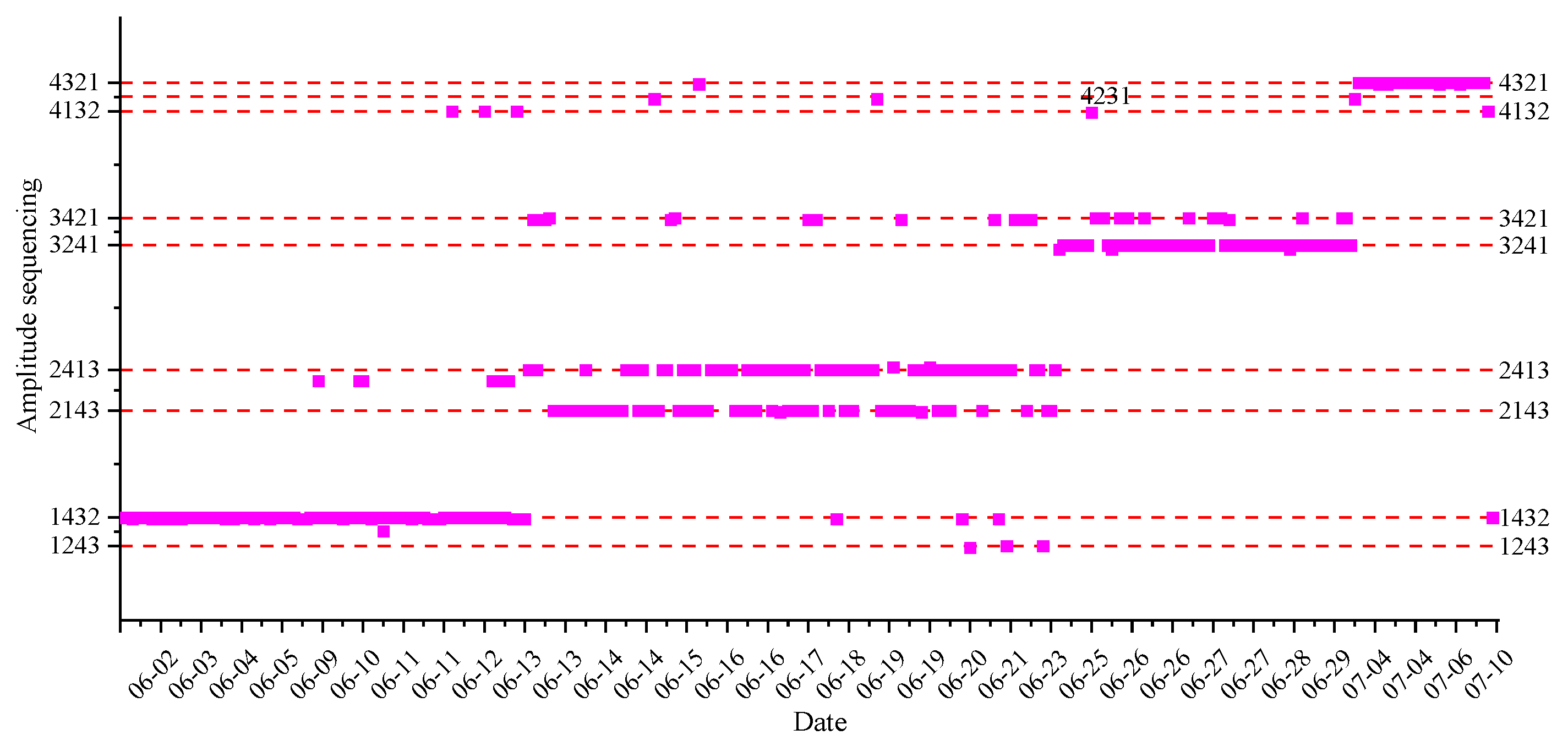

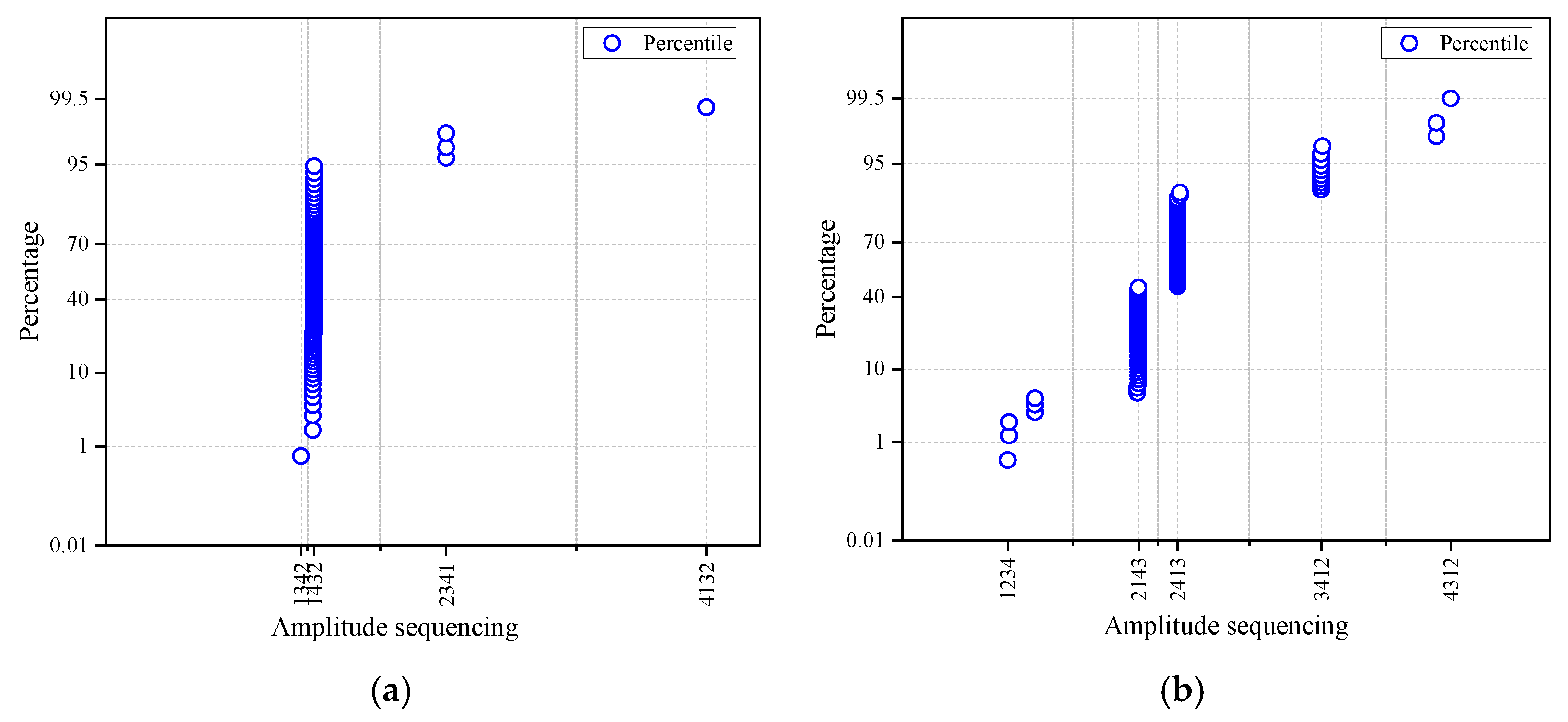

| Periods | Sensor Arrangement | Shifting Sensor |

|---|---|---|

| June 1~June 12 | 1432 | |

| June 13~June 23 | 2143 | #2 |

| June 23~June 30 | 3214 | #3 |

| July 1~July 9 | 4321 | #4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, J.; Zhang, W.; Zhang, H.; Kou, H. Occurrence Location and Propagation Inconformity Characteristics of Vibration Events in a Heading Face ofa Coal Mine. Int. J. Environ. Res. Public Health 2022, 19, 15169. https://doi.org/10.3390/ijerph192215169

Ren J, Zhang W, Zhang H, Kou H. Occurrence Location and Propagation Inconformity Characteristics of Vibration Events in a Heading Face ofa Coal Mine. International Journal of Environmental Research and Public Health. 2022; 19(22):15169. https://doi.org/10.3390/ijerph192215169

Chicago/Turabian StyleRen, Jianju, Wenlong Zhang, Hongmei Zhang, and Honggang Kou. 2022. "Occurrence Location and Propagation Inconformity Characteristics of Vibration Events in a Heading Face ofa Coal Mine" International Journal of Environmental Research and Public Health 19, no. 22: 15169. https://doi.org/10.3390/ijerph192215169