Research on Coal Mine Building Compliance Inspection System Based on Accident Causation and BIM in China

Abstract

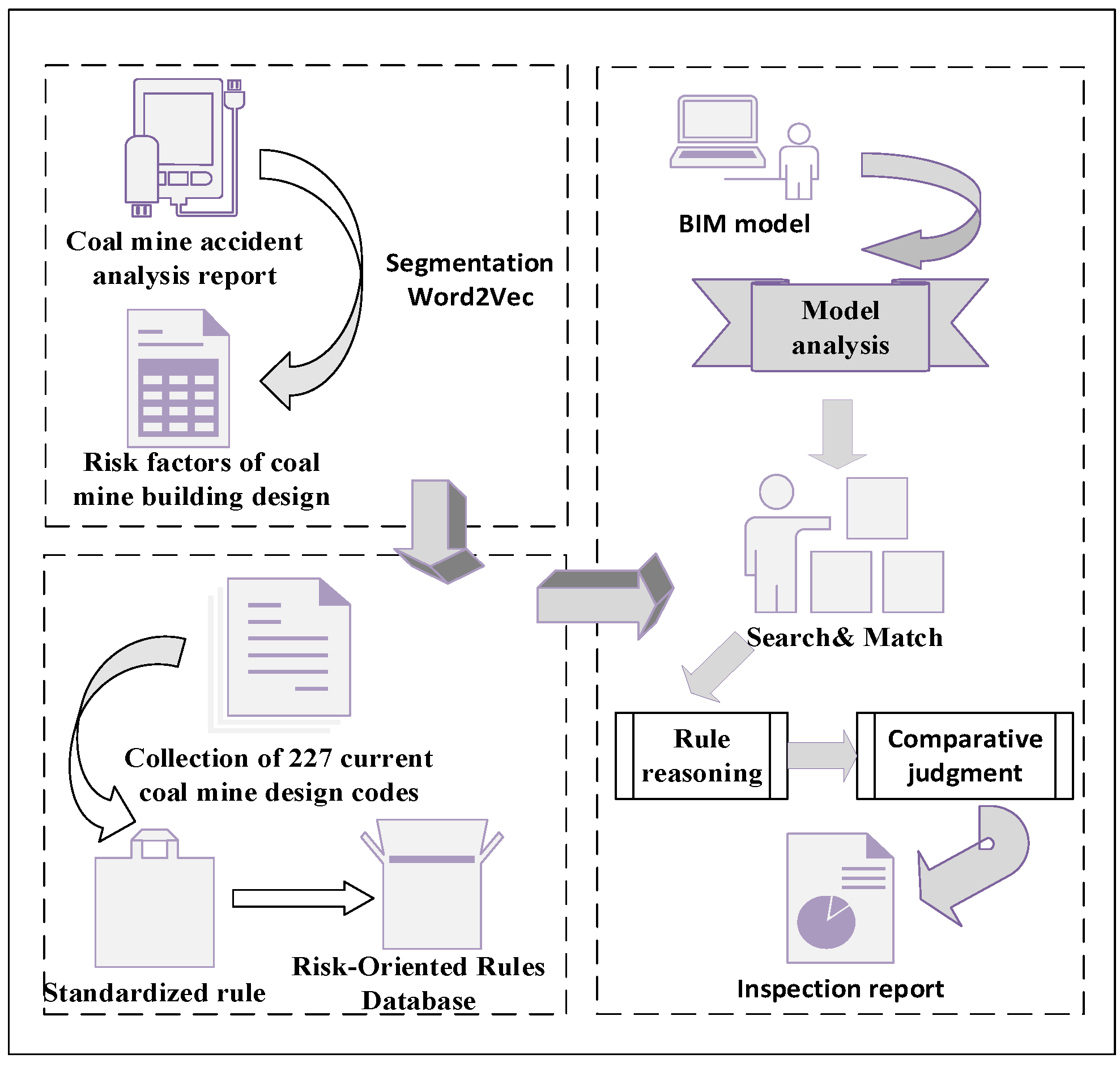

:1. Introduction

2. Extraction of Risk Factors for Coal Mine Building Design

2.1. Data Sources

2.2. Extraction of Risk Factors for Coal Mine Building Design Based on Word2Vec

3. Establishment of the SQL Rule Database

3.1. Standardization of Building Information

3.2. SQL Rule Database Establishment

4. Development of Compliance Inspection System Based on BIM

4.1. Compliance Inspection Reasoning Mechanism Design

- (1)

- Select components that need to be checked for compliance in the inspection system interface.

- (2)

- Query all relevant rules in the rule library according to the components selected.

- (3)

- Select the environment or prerequisite for the components.

- (4)

- Select the component properties of the inspection. If the property is a single component, check whether the attribute parameters of the component are complied with. If the selected attribute is determined using two or more components, such as the distance between components, the first component is selected as the center, a coordinate axis is established, the distance between the related components is measured, and then compliance is evaluated.

- (5)

- Noncompliance declaration and output of inspection report.

4.2. Compliance Inspection System Creation and Testing

4.2.1. Development Software Selection and System Construction Process

4.2.2. System Test

- (1)

- Test model testing

- (2)

- Instance model testing

4.2.3. System Assessment

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, X.J.; Li, Y.; Wang, F.; Shi, X.M.; Yang, Y.C.; Xu, X.C.; Huang, Y.L.; Wei, D.W. Experimental study on the mechanical properties and consolidation mechanism of microbial grouted backfill. Int. J. Min. Sci. Technol. 2022, 32, 271–282. [Google Scholar] [CrossRef]

- Fa, Z.W.; Li, X.C.; Qiu, Z.X.; Liu, Q.L.; Zhai, Z.Y. From correlation to causality: Path analysis of accident-causing factors in coal mines from the perspective of human, machinery, environment and management. Resour. Policy. 2021, 73, 102157. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Wang, S.J. Research on Safety Production System Integration Model of Coal Mine Construction Project. Product. Res. 2011, 11, 89–92. (In Chinese) [Google Scholar] [CrossRef]

- Bangwal, D.; Suyal, J.; Kumar, R. Hotel building design, occupants’ health and performance in response to COVID 19. Int. J. Hosp. Manag. 2022, 103, 103212. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.Y.; Ji, H.G.; Wang, T.; Pei, F.; Quan, D. Mechanism of country rock damage and failure in deep shaft excavation under high pore pressure and asymmetric geostress. Chin. J. Eng. 2020, 42, 715–722. (In Chinese) [Google Scholar] [CrossRef]

- NBIMS-US; National BIM Standard-United States Version 3. The National Academies Press: Washington, DC, USA, 2015.

- Malekitabar, H.; Ardeshir, A.; Sebt, M.H.; Stouffs, R. Construction safety risk drivers: A BIM approach. Saf. Sci. 2016, 82, 445–455. [Google Scholar] [CrossRef]

- Zhang, S.J.; Teizer, J.; Lee, J.K.; Eastman, C.M.; Venugopal, M. Building Information Modeling (BIM) and Safety: Automatic Safety Checking of Construction Models and Schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Zhong, B.T.; Gan, C.; Luo, H.B.; Xing, X.J. Ontology-based framework for building environmental monitoring and compliance checking under BIM environment. Build. Environ. 2018, 141, 127–142. [Google Scholar] [CrossRef]

- Li, M.; Yu, H.L.; Liu, P. An automated safety risk recognition mechanism for underground construction at the pre-construction stage based on BIM. Autom. Constr. 2018, 91, 284–292. [Google Scholar] [CrossRef]

- Afzal, M.; Shafiq, M.T. Evaluating 4D-BIM and VR for Effective Safety Communication and Training: A Case Study of Multilingual Construction Job-Site Crew. Buildings 2021, 11, 319. [Google Scholar] [CrossRef]

- Getuli, V.; Capone, P.; Bruttini, A. Planning, management and administration of HS contents with BIM and VR in construction: An implementation protocol. Eng. Constr. Archit. Manag. 2021, 28, 603–623. [Google Scholar] [CrossRef]

- Bangwal, D.; Tiwari, P.; Chamola, P. Workplace design features, job satisfaction, and organization commitment. Sage Open 2017, 7, 2158244017716708. [Google Scholar] [CrossRef] [Green Version]

- Succar, B.; Kassem, M. Macro-BIM adoption: Conceptual structures. Autom. Constr. 2015, 57, 64–79. [Google Scholar] [CrossRef] [Green Version]

- Ma, J. Constraints of coal mining safety management efficiency. Work 2020, 65, 869–880. [Google Scholar] [CrossRef] [PubMed]

- Ghaffarianhoseini, A.; Tookey, J.; Ghaffarianhoseini, A.; Naismith, N.; Azhar, S.; Efimova, O.; Raahemifar, K. Building Information Modelling (BIM) uptake: Clear benefits, understanding its implementation, risks and challenges. Renew. Sust. Energ. Rev. 2017, 75, 1046–1053. [Google Scholar] [CrossRef]

- Min, S.-N.; Subramaniyam, M.; Park, S.J.; Lee, K.S. Development of the fall prevention index on the movable scaffold for construction workers. Work 2020, 65, 167–173. [Google Scholar] [CrossRef]

- Fenves, S.J. Tabular decision logic for structural design. Am. Soc. Civ. Eng. 1966, 92, 473–490. [Google Scholar] [CrossRef]

- Pauwels, P.; Van Deursen, D.; Verstraeten, R.; De Roo, J.; De Meyer, R.; Van de Walle, R.; Van Campenhout, J. A semantic rule checking environment for building performance checking. Autom. Constr. 2011, 20, 506–518. [Google Scholar] [CrossRef]

- Luo, H.B.; Gong, P.S. A BIM-based Code Compliance Checking Process of Deep Foundation Construction Plans. J. Intell. Robot. Syst. 2015, 79, 549–576. [Google Scholar] [CrossRef]

- Kincelova, K.; Boton, C.; Blanchet, P.; Dagenais, C. Fire Safety in Tall Timber Building: A BIM-Based Automated Code-Checking Approach. Buildings 2020, 10, 121. [Google Scholar] [CrossRef]

- Kamkarhaghighi, M.; Makrehchi, M. Content Tree Word Embedding for document representation. Expert Syst. Appl. 2017, 90, 241–249. [Google Scholar] [CrossRef]

- Jing, S.F.; Liu, X.W.; Gong, X.Y.; Tang, Y.; Xiong, G.; Liu, S.; Xiang, S.G.; Bi, R.S. Correlation analysis and text classification of chemical accident cases based on word embedding. Process Saf. Environ. 2022, 158, 698–710. [Google Scholar] [CrossRef]

- Huang, J.Y.; Li, J.J.; Chen, Y.Y.; Sun, J.K.; Shi, P. Burst Hotspots Dynamic Detection and Tracking on Large-Scale Text Stream. IEEE Access 2019, 7, 30913–30924. [Google Scholar] [CrossRef]

- Zhang, D.W.; Xu, H.; Su, Z.C.; Xu, Y.F. Chinese comments sentiment classification based on word2vec and SVMperf. Expert Syst. Appl. 2015, 42, 1857–1863. [Google Scholar] [CrossRef]

- Tan, Z.L.; Chen, X.C. Research on management of hidden danger in coal mine based on text mining. J. Saf. Sci. Technol. 2020, 16, 43–48. (In Chinese) [Google Scholar] [CrossRef]

- An, L.; Han, Y.X.; Yi, X.Y.; Li, G.; Yu, C.M. Prediction and Evolution of the Influence of Microblog Entries in the Context of Terrorist Events. Soc. Sci. Comput. Rev. 2021, 42, 715–722. [Google Scholar] [CrossRef]

- Brown, D.E. Text mining the contributors to rail accidents. IEEE Trans. Intell. Transp. Syst. 2015, 17, 346–355. [Google Scholar] [CrossRef]

- Luo, X.X.; Liu, Q.L.; Qiu, Z.X. A Correlation Analysis of Construction Site Fall Accidents Based on Text Mining. Front. Built Environ. 2021, 7, 690071. [Google Scholar] [CrossRef]

- Fa, Z.W.; Li, X.C.; Liu, Q.L.; Qiu, Z.X.; Zhai, Z.Y. Correlation in causality: A progressive study of hierarchical relations within human and organizational factors in coal mine accidents. Int. J. Environ. Res. Public Health. 2021, 18, 5020. [Google Scholar] [CrossRef]

- Qiu, Z.X.; Liu, Q.L.; Li, X.C.; Zhang, J.J.; Zhang, Y.Q. Construction and analysis of a coal mine accident causation network based on text mining. Process Saf. Environ. Prot. 2021, 153, 320–328. [Google Scholar] [CrossRef]

- Chen, D.H.; Wang, Y.N.; Zhou, Z.L.; Zhao, X.H.; Li, T.Y.; Wang, K.L. Research on WordNet Word Similarity Calculation Based on Word2Vec. Comput. Eng. Appl. 2022, 58, 222–229. (In Chinese) [Google Scholar] [CrossRef]

- Bangwal, D.; Tiwari, P. Environmental design and awareness impact on organization image. Eng. Constr. Archit. Manag. 2019, 26, 29–45. [Google Scholar] [CrossRef]

- Solihin, W.; Eastman, C. Classification of rules for automated BIM rule checking development. Autom. Constr. 2015, 53, 69–82. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Kang, H. Research on knowledge-based BIM for automated compliance checking system in architectural design. J. Graph. 2020, 41, 490–499. (In Chinese) [Google Scholar] [CrossRef]

- Zhu, K. Application of STAMP modal in coal mine accident analysis. Syst. Eng. Theory Pract. 2018, 38, 1069–1081. (In Chinese) [Google Scholar] [CrossRef]

- He, L. Application of BIM technology in coal mine roadway design. Coal Eng. 2021, 53, 18–20. (In Chinese) [Google Scholar] [CrossRef]

| Accident Type | Risk Factors for Coal Mine Building Design | ||||

|---|---|---|---|---|---|

| Roof | Working surface (0.9788) | Stoping workface (0.9778) | Coal rock pillar (0.9771) | Return laneway (0.9680) | Repairing roadway (0.9450) |

| Flood | coal rock pillar (0.9859) | Water detection points (0.9744) | Drainage system (0.9699) | Internal warehouse (0.9465) | Water inflow (0.9372) |

| Gas | Return laneway (0.9723) | Ventilation system (0.9709) | Coal rock pillar (0.9690) | Working surface (0.9655) | Stoping workface (0.9480) |

| Transport | Transporter (0.9778) | Buffer (0.9773) | Power system (0.9754) | Strand (0.9659) | Point pillar (0.9631) |

| Electromechanical | Power system (0.9728) | Filter (0.9701) | Transporter (0.9683) | Sensor (0.9624) | Ventilator (0.9598) |

| Other | Overhead lines (0.5782) | Ventilator (0.5695) | Tape dispenser (0.5688) | Intake airway (0.5656) | Steel strand (0.5652) |

| Number | Type Name | Example |

|---|---|---|

| 1 | One-to-one constraints on component properties without preconditions | Coring rate of inspection hole should not be less than 75% |

| 2 | One-to-one constraints on component properties with preconditions | Cast-in-place concrete support, concrete slump should not be less than 150 mm |

| 3 | One-to-many constraints on component properties without preconditions | The height of the working surface pre-grouting should be 30–50 m |

| 4 | One-to-many constraints on component properties with preconditions | The height of the temporary anchor spray support in Class II rock formation should be 50–80 m |

| 5 | A single property constraint involving multiple components without preconditions | The final depth of the inspection hole should be 10 m greater than the design depth of the wellbore |

| 6 | A single property constraint involving multiple components with preconditions | When pouring tremie pipe, the distance between the pipe and the end face of the slot should be 1.5 m |

| 7 | Multi-attribute constraints involving multiple components without preconditions | The depth of the sleepers buried in the ballast shall be 1/2 to 2/3 of the thickness of the sleepers |

| 8 | Multi-attribute constraints involving multiple components with preconditions | During smooth blasting, the distance of surrounding apertures should be controlled within 0.4–0.6 m; |

| Source | Premise | Name | Related | Property | Degree Word | Compara-tive Word | Value | Description |

|---|---|---|---|---|---|---|---|---|

| GB50511 -2010 | Null | Inspection hole | Null | Core rate | Should not | Less than | 75% | Coring rate of inspection hole should not be less than 75%. |

| GB50511 -2010 | Concrete support | Concrete | Null | Slump | Should not | Less than | 150 mm | Cast-in-place concrete support, concrete slump should not be less than 150 mm. |

| GB50511 -2010 | Null | Pregrouting | Null | Height | Should | Greater than or equal to | 30 m | The height of the working surface pregrouting should be 30–50 m. |

| GB50511 -2010 | Null | Pregrouting | Null | Height | Should | Less than or equal to | 50 m | The height of the working surface pregrouting should be 30–50 m. |

| GB50511 -2010 | In class II rock | Temporary support | Null | Height | Should | Greater than or equal to | 50 m | The height of the temporary anchor spray support in Class II rock formation should be 50–80 m. |

| GB50511 -2010 | In class II rock | Temporary support | Null | Height | Should | Less than or equal to | 80 m | The height of the temporary anchor spray support in Class II rock formation should be 50–80 m. |

| GB50511 -2010 | Null | Inspection hole depth | Wellbore depth | Distance | Should | Greater than | 10 m | The final depth of the inspection hole should be 10 m greater than the design depth of the wellbore. |

| GB50511 -2010 | Tremie pipe | Blanking conduit | Slotted end | Distance | Should | Equal to | 1.5 m | When pouring tremie pipe, the distance between the pipe and the end face of the slot should be 1.5 m. |

| GB50511 -2010 | Null | Sleeper | Sleeper thickness | Depth | Shall | Greater than or equal to | 1/2 | The depth of the sleepers buried in the ballast shall be 1/2 to 2/3 of the thickness of the sleepers. |

| GB50511 -2010 | Null | Sleeper | Sleeper thickness | Depth | Shall | Less than or equal to | 2/3 | The depth of the sleepers buried in the ballast shall be 1/2 to 2/3 of the thickness of the sleepers. |

| GB50215-2015 | Smooth blasting | Surrounding aperture | Other aperture | Distance | Should | Greater than or equal to | 0.4 m | During smooth blasting, the distance of surrounding apertures should be controlled within 0.4–0.6 m; |

| GB50215-2015 | Smooth blasting | Surrounding aperture | Other aperture | Distance | Should | Less than or equal to | 0.6 m | During smooth blasting, the distance of surrounding apertures should be controlled within 0.4–0.6 m; |

| Degree of Noncompliance | Degree Words | ||||

|---|---|---|---|---|---|

| Serious | Ought not | Shall not | Forbidden | Must | Shall |

| Medium | Should | Should not | |||

| General | Can | ||||

| Sections | Number of Components | Number of Detections | Correct Number of Checks |

|---|---|---|---|

| Construction preparation | 4 | 4 | 4 |

| Common method of construction of vertical shafts | 77 | 73 | 71 |

| Special method of vertical shaft construction | 262 | 243 | 238 |

| Extension and Rehabilitation of Vertical Shafts | 6 | 5 | 5 |

| Inclined shaft and flat cavern construction | 6 | 6 | 5 |

| Roadway construction | 79 | 72 | 71 |

| Concealed shafts and chambers | 6 | 5 | 5 |

| Ancillary work | 108 | 99 | 98 |

| Working Environment and Occupational Hazards | 9 | 8 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhang, X.; Liu, Q.; Zhang, Y.; Gu, X.; Qiu, Z. Research on Coal Mine Building Compliance Inspection System Based on Accident Causation and BIM in China. Int. J. Environ. Res. Public Health 2022, 19, 16466. https://doi.org/10.3390/ijerph192416466

Li X, Zhang X, Liu Q, Zhang Y, Gu X, Qiu Z. Research on Coal Mine Building Compliance Inspection System Based on Accident Causation and BIM in China. International Journal of Environmental Research and Public Health. 2022; 19(24):16466. https://doi.org/10.3390/ijerph192416466

Chicago/Turabian StyleLi, Xinchun, Xiaolin Zhang, Quanlong Liu, Yueqian Zhang, Xiao Gu, and Zunxiang Qiu. 2022. "Research on Coal Mine Building Compliance Inspection System Based on Accident Causation and BIM in China" International Journal of Environmental Research and Public Health 19, no. 24: 16466. https://doi.org/10.3390/ijerph192416466