The Impact of Protective Gloves on Manual Dexterity in Cold Environments—A Pilot Study

Abstract

:1. Introduction

- have an appropriate level of thermal insulation,

- be made of flexible materials that are not damaged by low temperature,

- be comfortable to use,

- allow workers to manipulate their fingers, and

- be fitted to the user’s hand.

2. Materials and Methods

2.1. Subjects

2.2. Clothing

2.3. Research Equipment

2.3.1. Climatic Chamber

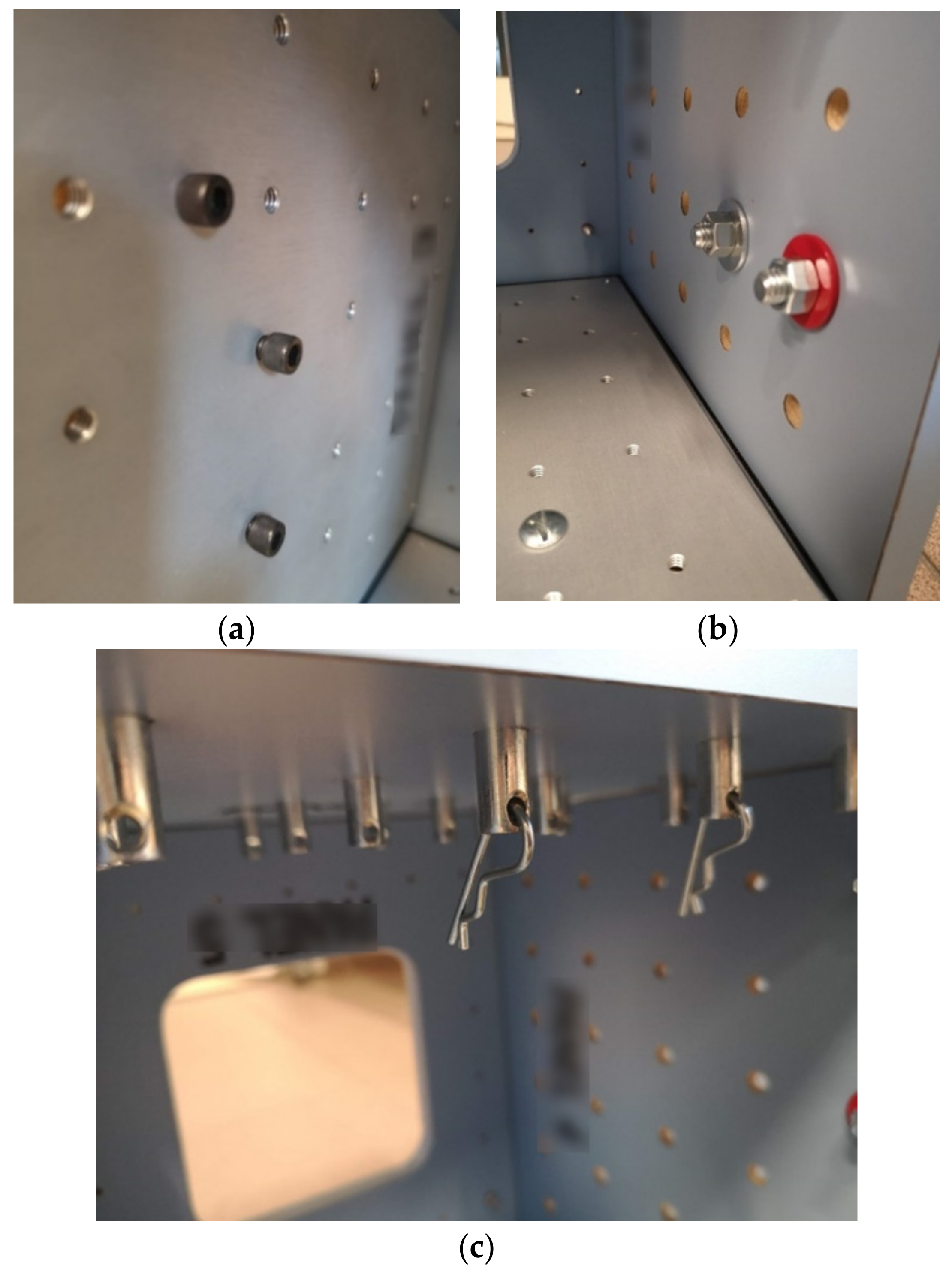

2.3.2. Manual Dexterity Determination

2.4. Methodology

2.4.1. Qualifying Tests

2.4.2. Testing the Properties of Gloves and Clothing Used in the Tests

The Gloves

The Protective Clothing for Cold Environment

2.4.3. Volunteer Studies

- Walking (2.5 km/h) on the treadmill (simulated moderate effort)—5 min;

- Sorting of small elements by shape;

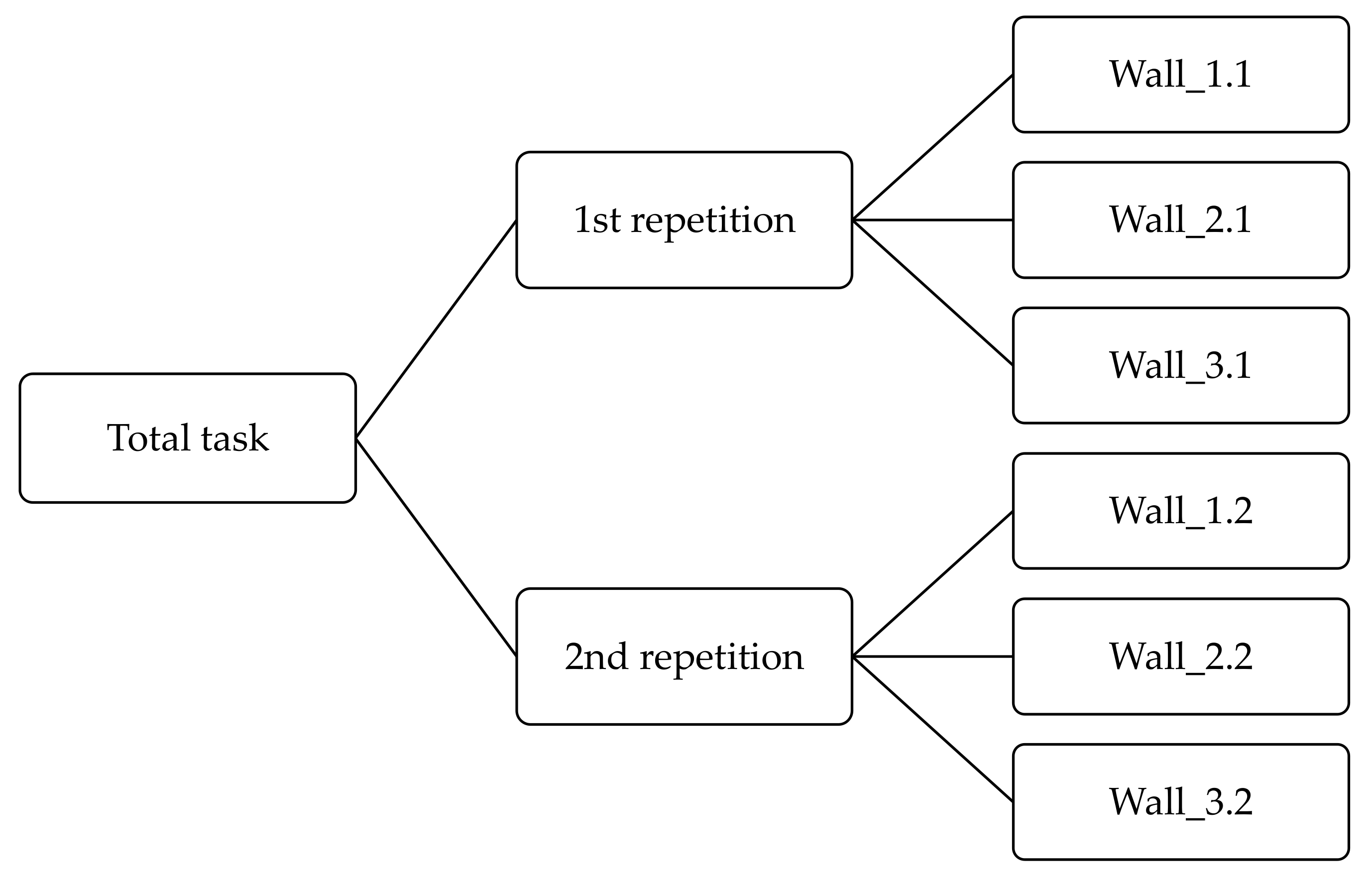

- Completing the wall 1 (time measurement)—1st repetition;

- Completing the wall 2 (time measurement)—1st repetition;

- Completing the wall 3 (time measurement)—1st repetition;

- Sorting of small elements by color;

- Sorting of small elements by shape;

- Completing the wall 1 (time measurement)—2nd repetition;

- Completing the wall 2 (time measurement)—2nd repetition;

- Completing the wall 3 (time measurement)—2nd repetition.

2.4.4. Statistical Analysis

3. Results

3.1. Tested Clothing Parametres

3.1.1. Clothing Insulation

3.1.2. Glove Parameters

3.2. Time to Complete the Tasks

3.2.1. Time to Complete the Total Tasks

3.2.2. Time to Complete the Individual Walls

3.3. Thermal Comfort Scale, Ease of Manipulation Response and Comfort of Use

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- EN ISO 11079:2008; Ergonomics of the Thermal Environment—Determination and Interpretation of Cold Stress when Using Required Clothing Insulation (IREQ) and Local Cooling Effects. ISO: Geneva, Switzerland, 2007.

- Cheung, S.S.; Lee, J.K.; Oksa, J. Thermal stress, human performance, and physical employment standards. Appl. Physiol. Nutr. Metab. 2016, 41 (Suppl. 2), S148–S164. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ray, M.; King, M.; Carnahan, H. A review of cold exposure and manual performance: Implications for safety, training and performance. Saf. Sci. 2019, 115, 1–11. [Google Scholar] [CrossRef]

- Working Conditions in 2020, Statistics Poland, Gdańsk. 2021. Available online: https://stat.gov.pl/obszary-tematyczne/rynek-pracy/warunki-pracy-wypadki-przy-pracy/warunki-pracy-w-2020-roku,1,15.html (accessed on 22 December 2021).

- Imamura, R.; Rissanen, S.; Kinnunen, M.; Rintamaki, H. Manual performance in cold conditions while wearing NBC clothing. Ergonomics 1998, 41, 1421–1432. [Google Scholar] [CrossRef]

- Makowiec-Dąbrowska, T.; Bogdan, A.; Kurczewska, A.; Stefko, A.; Kamińska, W. Safe Work in a Cold Microclimate [Bezpieczna Praca w Zimnym Mikroklimacie]; CIOP-PIB: Warsaw, Poland, 2007; pp. 23–41. (In Polish) [Google Scholar]

- Młynarczyk, M.; Orysiak, J.; Irzmańska, E. The impact of exposure to cold on manual skills of a worker using protective gloves [Wpływ ekspozycji na zimno na sprawność manualną pracownika używającego rękawic ochronnych]. Occup. Saf.—Sci. Pract. [Bezpieczeństwo Pracy. Nauka i Praktyka] 2021, 7, 22–26. (In Polish) [Google Scholar]

- Sari, H.; Gartner, M.; Hoeft, A.; Candas, V. Glove thermal insulation: Local heat transfer measures and relevance. Eur. J. Appl. Physiol. 2004, 92, 702–705. [Google Scholar] [CrossRef]

- Basak, T.; Sahin, G.; Demirtas, A. Comparison of surgical gloves: Perforation, satisfaction and manual dexterity. Int. J. Occup. Saf. Ergon. 2021, 1–7. [Google Scholar] [CrossRef]

- Tian, Y.; Ding, L.; Liu, H.; Li, Y.; Li, D.; Wang, L. Effects of EVA gloves on grip strength and fatigue under low temperature and low pressure. Appl. Ergon. 2016, 53, 17–24. [Google Scholar] [CrossRef]

- Ramadan, M.Z. The Effects of Industrial Protective Gloves and Hand Skin Temperatures on Hand Grip Strength and Discomfort Rating. Int. J. Environ. Res. Public Health 2017, 14, 1506. [Google Scholar] [CrossRef] [Green Version]

- Yu, A.; Yick, K.L.; Ng, S.P.; Yip, J. Case study on the effects of fit and material of sports gloves on hand performance. Appl. Ergon. 2019, 75, 17–26. [Google Scholar] [CrossRef]

- Zander, J.; Morrison, J. Effects of pressure, cold and gloves on hand skin temperature and manual performance of divers. Eur. J. Appl. Physiol. 2008, 104, 237–244. [Google Scholar] [CrossRef]

- Ceballos, D.; Mead, K.; Ramsey, J. Recommendations to Improve Employee Thermal Comfort When Working in 40°F Refrigerated Cold Rooms. J. Occup. Environ. Hyg. 2015, 12, D216–D221. [Google Scholar] [CrossRef] [PubMed]

- Morrison, J.; Hamilton, K.; Zander, J. Phase 1: Optimizing the Performance and Safety of Mine Countermeasures Diving; Report DCIEM-97-CR-43; Defence R&D Canada: Toronto, ON, Canada, 1997; p. 210.

- Irzmańska, E.; Wójcik, P.; Adamus-Włodarczyk, A. Manual work in cold environments and its impact on selection of materials for protective gloves based on workplace observations. Appl. Ergon. 2018, 68, 186–196. [Google Scholar] [CrossRef] [PubMed]

- Voelcker, T. Prediction of thermal comfort range of gloves in regard of individual thermal sensations. In Proceedings of the 10th International Meeting for Manikin and Modelling, Tampere, Finland, 7–9 September 2014. [Google Scholar]

- Wiggen, Ø.N.; Heen, S.; Færevik, H.; Reinertsen, R.E. Effect of cold conditions on manual performance while wearing petroleum industry protective clothing. Ind. Health. 2011, 49, 443–451. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Orysiak, J.; Młynarczyk, M. Protective clothing used in a selected fruits and vegetable processing companies-preliminary (questionnaire) research [Odzież ochronna stosowana w wybranym zakładzie przetwórstwa owocowo-warzywnego–badania wstępne (ankietowe)]. In Proceedings of the XIII Interdyscyplinarna Konferencja Naukowa TYGIEL 2021 “Interdyscyplinarność kluczem do rozwoju”, Lublin, Poland, 25–28 March 2021. (In Polish). [Google Scholar]

- Drabek, T.; Boucek, C.D.; Buffington, C.W. Wearing the wrong size latex surgical gloves impairs manual dexterity. J. Occup. Environ. Hyg. 2010, 7, 152–155. [Google Scholar] [CrossRef]

- Młynarczyk, M. Influence of Air Velocity on the Total Thermal Insulation of Different Types of Clothing. Fibres Text. East. Eur. 2019, 27, 75–80. [Google Scholar] [CrossRef]

- Heus, R.; Daanen, H.A.; Havenith, G. Physiological criteria for functioning of hands in the cold: A review. Appl. Ergon. 1995, 26, 5–13. [Google Scholar] [CrossRef]

- Dianat, I.; Haslegrave, C.M.; Stedmon, A.W. Methodology for evaluating gloves in relation to the effects on hand performance capabilities: A literature review. Ergonomics 2012, 55, 1429–1451. [Google Scholar] [CrossRef]

- VCWS 1 Small Tools. Available online: https://www.basesofva.com/vcws-1-small-tools-mechanical/ (accessed on 21 December 2021).

- EN 511:2006; Protective Gloves Against Cold. European Committee for Standardization: Brussels, Belgium, 2006.

- EN 342:2018-01; Protective Clothing—Ensembles and Garments for Protective against Cold Protection against Cold. European Committee for Standardization: Brussels, Belgium, 2017.

- EN ISO 15831:2004; Clothing. Physiological Properties. Thermal Insulation Measurement with the Use of Thermal Mannikin. ISO: Geneva, Switzerland, 2004.

- Młynarczyk, M.; Havenith, G.; Léonard, J.; Martins, R.; Hodder, S. Inter-laboratory proficiency tests in measuring thermal insulation and evaporative resistance of clothing using the Newton-type thermal manikin. Text. Res. J. 2018, 88, 453–466. [Google Scholar] [CrossRef] [Green Version]

- Młynarczyk, M. Characteristics of Specialised Firefighter Clothing Used in Poland–the Thermal Parameters. Fibres Text. East. Eur. 2020, 28, 65–70. [Google Scholar] [CrossRef]

- Dianat, I.; Haslegrave, C.M.; Stedmon, A.W. Short and longer duration effects of protective gloves on hand performance capabilities and subjective assessments in a screw-driving task. Ergonomics 2010, 53, 1468–1483. [Google Scholar] [CrossRef]

- Geng, Q.; Chen, F.; Holmer, I. The effect of protective gloves on manual dexterity in the cold environments. Int. J. Occup. Saf. Ergon. 1997, 3, 15–29. [Google Scholar] [CrossRef]

- ASHRAE Standard 55-2013; Thermal Environmental Conditions for Human Occupancy. ASHRAE: Atlanta, GA, USA, 2013.

- Preece, D.; Lewis, R.; Carré, M.J. A Critical Review of the Assessment of Medical Gloves. Tribol. Mater. Surf. Interfaces 2021, 15, 10–19. [Google Scholar] [CrossRef]

- Drabek, T.; Boucek, C.D.; Buffington, C.W. Wearing ambidextrous vinyl gloves does not impair manual dexterity. J. Occup. Environ. Hyg. 2013, 10, 307–311. [Google Scholar] [CrossRef]

- Irzmańska, E.; Tokarski, T. A new method of ergonomic testing of gloves protecting against cuts and stabs during knife use. Appl. Ergon. 2017, 61, 102–114. [Google Scholar] [CrossRef] [PubMed]

- Holmer, I. Work in the cold. Int. Arch. Occup. Environ. Health 1993, 65, 147–155. [Google Scholar] [CrossRef] [PubMed]

- Irzmańska, E.; Bacciarelli-Ulacha, A. Effects of simulated pressure of wooden, plastic, and metal materials on the thermal insulation of cold-protective gloves of various designs. Text. Res. J. 2019, 89, 4060–4070. [Google Scholar] [CrossRef]

- Matusiak, M.; Kowalczyk, S. Thermal-Insulation Properties of Multilayer Textile Packages. ARJ 2014, 14, 299–307. [Google Scholar] [CrossRef] [Green Version]

- Wells, R.; Hunt, S.; Hurley, K.; Rosati, P. Laboratory assessment of the effect of heavy rubber glove thickness and sizing on effort, performance and comfort. Int. J. Ind. Ergon. 2010, 40, 386–391. [Google Scholar] [CrossRef]

- Havenith, G.; Heus, R.; Daanen, H.A. The hand in the cold, performance and risk. Arctic. Med. Res. 1995, 54, 37–47. [Google Scholar]

- Daanen, H.A. Manual performance deterioration in the cold estimated using the wind chill equivalent temperature. Ind. Health. 2009, 47, 262–270. [Google Scholar] [CrossRef] [Green Version]

- Gaydos, H.; Dusek, E. Effects of localized hand cooling versus total body cooling on manual performance. J. Appl. Physiol. 1958, 12, 377–380. [Google Scholar] [CrossRef] [PubMed]

- Hein, J.L.; Sesno, N.N.; Armenta, R.F.; Nessler, J.A.; Asakawa, D.S. Upper limb manual dexterity, strength and blood flow after walking with backpack load. Appl. Ergon. 2021, 97, 103505. [Google Scholar] [CrossRef] [PubMed]

- Sobinov, A.R.; Bensmaia, S.J. The neural mechanisms of manual dexterity. Nat. Rev. Neurosci. 2021, 22, 741–757. [Google Scholar] [CrossRef] [PubMed]

| Glove A—Double Glove | Glove B—Single Glove |

|---|---|

| white glove: five-finger glove made of knitted, polyester fibres with increased mechanical parameters | a glove with a five-finger construction made of polyester fibres with an acrylic lining, with increased insulating properties; the outer side, dorsal and palm part of glove, was coated with polyacrylonitrile rubber with an uneven surface increasing grip in a wet environment |

| black glove: five-finger glove made of knitted fleece, polyester fibres with insulating properties | |

|  |

| Thermal Comfort Sensation | Ease of Manipulation | Comfort of Use |

|---|---|---|

| −3 cold | 1 making work impossible | 1 very uncomfortable |

| −2 cool | 2 interferes very much with work | 2 uncomfortable |

| −1 slightly cool | 3 moderately interferes with work | 3 not very comfortable |

| 0 neutral | 4 little interferes with work | 4 comfortable |

| 1 slightly warm | 5 does not interfere with work | 5 very comfortable |

| 2 warm | ||

| 3 hot |

| Gloves | Thermal Insulation ITR [m2 °C/W] | Mean Value of Thermal Insulation ITR [m2 °C/W] | Performance Level | Compliance with the Requirements |

|---|---|---|---|---|

| Gloves A | 0.098 | 0.10 | 1 | Tested gloves meet the requirements of the standard—1st performance level |

| 0.098 | ||||

| Gloves B | 0.099 | 0.10 | 1 | Tested gloves meet the requirements of the standard—1st performance level |

| 0.098 |

| Gloves | Thermal Resistance R [m2 °C/W] | Mean Value of Thermal Resistance R [m2 °C/W] | Performance Level | Compliance with the Requirements |

|---|---|---|---|---|

| Gloves A | 0.1010 | 0.097 | 2 | The tested set meets the requirements standard—2nd performance level |

| 0.0938 | ||||

| Gloves B | 0.1030 | 0.102 | 3 | The tested glove meets the requirements Standard—3rd performance level |

| 0.1000 |

| Variants | V1A | V1B | V2A | V2B | V3 |

|---|---|---|---|---|---|

| Conditions | +5 °C, gloves A | +5 °C, gloves B | −1 °C, gloves A | −1 °C, gloves B | +20 °C, bare hands |

| Time of total task (min) | 00:24:13 ± 00:01:49 | 00:24:48 ± 00:05:29 | 00:23:09 ± 00:04:24 | 00:25:00 ± 00:04:40 | 00:13:50 ± 00:01:25 * |

| Time of 1st repetition (min) | 00:12:59 ± 00:01:04 ** | 00:12:51 ± 00:02:40 | 00:11:21 ± 00:02:08 | 00:12:29 ± 00:02:19 | 00:06:50 ± 00:00:57 * |

| Time of 2nd repetition (min) | 00:11:14 ± 00:01:06 | 00:11:57 ± 00:02:55 | 00:11:48 ± 00:02:28 | 00:12:31 ± 00:02:29 | 00:06:59 ± 00:00:33 * |

| Variants | Time to Complete the Individual Walls (min) | V3 wall 1.1 | V3 wall 2.1 | V3 wall 3.1 | V3 wall 1.2 | V3 wall 2.2 | V3 wall 3.2 |

|---|---|---|---|---|---|---|---|

| Time to complete the individual walls (min) | Mean ± SD | 00:02:35 ± 00:00:23 | 00:02:48 ± 00:00:17 | 00:01:27 ± 00:00:26 | 00:02:31 ± 00:00.13 | 00:02:54 ± 00:00:30 | 00:01:34 ± 00:00:11 |

| V1A wall 1.1 | 00:05:23 ± 00:00:42 | * | - | - | - | - | - |

| V1A wall 2.1 | 00:05:21 ± 00:01:21 | - | * | - | - | - | - |

| V1A wall 3.1 | 00:02:15 ± 00:00:21 | - | - | * | - | - | - |

| V1A wall 1.2 | 00:04:34 ± 00:00:46 | - | - | - | * | - | - |

| V1A wall 2.2 | 00:04:28 ± 00:00:46 | - | - | - | - | * | - |

| V1A wall 3.2 | 00:02:11 ± 00:00:19 | - | - | - | - | - | * |

| V1B wall 1.1 | 00:05:37 ± 00:01:17 | * | - | - | - | - | - |

| V1B wall 2.1 | 00:05:06 ± 00:01:33 | - | * | - | - | - | - |

| V1B wall 3.1 | 00:02:08 ± 00:00:12 | - | - | * | - | - | - |

| V1B wall 1.2 | 00:05:17 ± 00:01:53 | - | - | - | * | - | - |

| V1B wall 2.2 | 00:04:38 ± 00:01:42 | - | - | - | - | * | - |

| V1B wall 3.2 | 00:02:02 ± 00:00:24 | - | - | - | - | - | * |

| V2A wall 1.1 | 00:05:01 ± 00:01:35 | * | - | - | - | - | - |

| V2A wall 2.1 | 00:04:29 ± 00:00:46 | - | * | - | - | - | - |

| V2A wall 3.1 | 00:01:54 ± 00:00:21 | - | - | - | - | - | - |

| V2A wall 1.2 | 00:05:34 ± 00:01:36 | - | - | - | * | - | - |

| V2A wall 2.2 | 00:04:27 ± 00:01:07 | - | - | - | - | * | - |

| V2A wall 3.2 | 00:01:47 ± 00:00:17 | - | - | - | - | - | - |

| V2B wall 1.1 | 00:05:56 ± 00:01:53 | * | - | - | - | - | - |

| V2B wall 2.1 | 00:04:28 ± 00:00:20 | - | * | - | - | - | - |

| V2B wall 3.1 | 00:02:05 ± 00:00:17 | - | - | * | - | - | - |

| V2B wall 1.2 | 00:05:44 ± 00:01:37 | - | - | - | * | - | - |

| V2B wall 2.2 | 00:04:31 ± 00:00:43 | - | - | - | - | * | - |

| V2B wall 3.2 | 00:02:16 ± 00:00:28 | - | - | - | - | - | * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orysiak, J.; Młynarczyk, M.; Irzmańska, E. The Impact of Protective Gloves on Manual Dexterity in Cold Environments—A Pilot Study. Int. J. Environ. Res. Public Health 2022, 19, 1637. https://doi.org/10.3390/ijerph19031637

Orysiak J, Młynarczyk M, Irzmańska E. The Impact of Protective Gloves on Manual Dexterity in Cold Environments—A Pilot Study. International Journal of Environmental Research and Public Health. 2022; 19(3):1637. https://doi.org/10.3390/ijerph19031637

Chicago/Turabian StyleOrysiak, Joanna, Magdalena Młynarczyk, and Emilia Irzmańska. 2022. "The Impact of Protective Gloves on Manual Dexterity in Cold Environments—A Pilot Study" International Journal of Environmental Research and Public Health 19, no. 3: 1637. https://doi.org/10.3390/ijerph19031637

APA StyleOrysiak, J., Młynarczyk, M., & Irzmańska, E. (2022). The Impact of Protective Gloves on Manual Dexterity in Cold Environments—A Pilot Study. International Journal of Environmental Research and Public Health, 19(3), 1637. https://doi.org/10.3390/ijerph19031637