Procedure for Determining Dimensional Allowances for PPE Using 3D Scanning Methods

Abstract

:1. Introduction

- -

- identification of the main anthropometric landmarks needed for the determination of the external dimensions of the human body;

- -

- development of an optimum method for automated sizing, involving geometric solids for the description of the human silhouette, i.e., solids with the lowest volume that can circumscribe the human body wearing underwear and PPE, in order to establish the difference in their dimensions, referred to as a dimensional allowance;

- -

- the systematization of terminology and making a distinction between dimensional allowances that affect PPE fit and those that affect human-workspace interactions.

2. Materials and Methods

- -

- Subject preparation for scanning: model repair and cleaning–artifact removal (Edit/Segment); model positioning with respect to the software coordinate system (Edit/(Translate/Rotate)); generating a point cloud after processing (Navigation bar/Sample points on a mesh);

- -

- Preliminary sizing to identify landmarks for collecting information about maximum dimensions (Tools/Segmentation/Cross-section);

- -

- Generating a geometric solid–cylinder/cuboid (File/Primitive Factory);

- -

- Superimposing the solid on 3D models of subjects wearing underwear and PPE (Edit/Translate/Rotate);

- -

- A comparison of the dimensions of the solids and calculating differences in size between subjects wearing underwear and PPE, known as dimensional allowances.

3. Results

- the radius and height of the cylinder circumscribing the silhouette of the subject in underwear (ru, hu);

- the radius and height of the cylinder circumscribing the silhouette of the subject wearing PPE (rPPE, hPPE);

- the length of the edges of the cuboid circumscribing the silhouette of the subject in underwear (xu, yu, zu);

- the length of the edges of the cuboid circumscribing the silhouette of the subject wearing PPE (xPPE, yPPE, zPPE).

- volumes of the cylinders circumscribing the silhouette of the subject wearing underwear and PPE (VC_u,VC_PPE);

- volumes of the cuboids circumscribing the silhouette of the subject wearing underwear and PPE (VQ_u,VQ_PPE);

- base areas of the cylinders circumscribing the silhouette of the subject wearing underwear and PPE (AC_u, AC_PPE);

- base areas of the cuboids circumscribing the silhouette of the subject wearing underwear and PPE (AQ_u, AQ_PPE);

- differences and relative differences between all dimensions obtained for the silhouettes of the subject wearing underwear and PPE.

4. Discussion

- -

- an increase in cylinder radius (r) by 0.0513 m, reflecting an increase in the maximum distance between the shoulders by 2r = 0.1026 m, is the width allowance for PPE;

- -

- an increase in cylinder height (h) by 0.0802 m, which is the height allowance for protective footwear and head protection devices.

- -

- an increase in cuboid height (y) by 0.774 m, which is the height allowance added to the height of persons wearing PPE;

- -

- an increase in cuboid width (z) by 0.1046 m, which is the width allowance;

- -

- an increase in cuboid depth (x) by 0.1042 m.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gordon, C.C.; Churchill, T.; Clauser, C.E.; Mcconville, J.T.; Tebbetts, I.; Walker, R.A. Technical Raport Natick/TR—89/044, Anthropometric Survey of US Army Personnel Methods and Summary Statistics. 1989. Available online: http://mreed.umtri.umich.edu/mreed/downloads/anthro/ansur/Gordon_1989.pdf (accessed on 20 December 2021).

- PeopleSize. Available online: https://www.openerg.com/psz/ (accessed on 20 December 2021).

- Jürgens, H.W.; Aune, I.A.; Pieper, U. International anthropometrischer Datenatlas. Schriftenreihe der Bundesanstalt für Arbeitsschutz Fb 587. Dortmund, Germany. 1998. Available online: https://www.baua.de/DE/Angebote/Publikationen/AWE/AWE108e.pdf?__blob=publicationFile&v=2 (accessed on 20 December 2021).

- Sizegermany. Available online: https://portal.i-size.net/SizeWeb/pages/home.seam (accessed on 20 December 2021).

- Central Web Portal World Engineering Anthropometry Resource (WEAR). Available online: http://wear2.io.tudelft.nl/ (accessed on 20 December 2021).

- Blackwell, S.; Robinette, K.; Boehmer, M.; Fleming, S. Civilian American and European Surface Anthropometry Resource (CAESAR). Volume 2: Descriptions, Final Report 2002. Available online: https://www.researchgate.net/publication/235099289 (accessed on 20 December 2021).

- Harrison, C.R.; Robinette, K.M. CAESAR: Summary Statistics for the Adult Population (Ages 18–65) of the United States of America, AFRL-HE-WP-TR-2002-0170, United States Air Force Research Laboratory, Human Effectiveness Directorate, Crew System Interface Division, 2255 H Street, Wright Patterson AFB OH 45433-7022. Available online: https://www.researchgate.net/publication/235145489_CAESAR_Summary_Statistics_for_the_Adult_Population_Ages_18-65_of_the_United_States_of_America (accessed on 20 December 2021).

- UK National Sizing Survey Database (SizeUK). Available online: https://www.humanics-es.com/uk_natl_anthro_sizing_info.pdf (accessed on 20 December 2021).

- Sizing Up Australia, Raport 2013. Available online: https://www.safeworkaustralia.gov.au/system/files/documents/1702/sizing-up-australia-chapter1-report-summary.pdf (accessed on 20 December 2021).

- Jarosz, E. Dane Antropometryczne Populacji osób Dorosłych Wybranych Krajów Unii Europejskiej i Polski dla Potrzeb Projektowania; Prace i Materiały; Instytut Wzornictwa Przemysłowego: Warszawa, Poland, 2003; Volume 6, pp. 1–63. [Google Scholar]

- Nowak, E. Atlas Antropometryczny Populacji Polskiej; Dane do projektowania; Instytut Wzornictwa Przemysłowego: Warszawa, Poland, 2000; p. 27. ISBN 83-909358-1-3. [Google Scholar]

- Kupiszewski, M. The Role of International Migration in the Modeling of Population Dynamics; Polish Academy of Sciences Institute of Geography and Spatial Organisation: Warszawa, Poland, 2002. [Google Scholar]

- Gedliczka, A.; Atlas Miar Człowieka. Dane do Projektowania i Oceny Ergonomicznej; CIOP, Warszawa 2001. Available online: Atlas%20Miar%20Człowieka.pdf (accessed on 20 December 2021).

- Griffin, L.; Sokolowski, S.L.; Seifert, E. Process Considerations in 3D Hand Anthropometric Data Collection. In Proceedings of the 3DBODY.TECH 2018 9th International Conference and Exhibition on 3D Body Scanning and Processing Technologies, Lugano, Switzerland, 16 October 2018; Volume 18, p. 123. [Google Scholar]

- Griffin, L.; Kim, N.; Carufel, R.; Sokolowski, S.; Lee, H.; Seifert, E. Dimensions of the Dynamic Hand: Implications for Glove Design, Fit, and Sizing. In International Conference on Applied Human Factors and Ergonomics AHFE 2018, Advances in Interdisciplinary Practice in Industrial Design; book series (AISC); Springer: Cham, Switzerland, 2018; Volume 790, pp. 38–48. Available online: https://link.springer.com/chapter/10.1007%2F978-3-319-94601-6_6 (accessed on 20 December 2021).

- Irzmańska, E.; Okrasa, M. Evaluation of protective footwear fit for older workers (60+): A case study using 3D scanning technique methods. Int. J. Ind. Ergon. 2018, 67, 27–31. [Google Scholar] [CrossRef]

- Morlock, S.; Schenk, A.; Klepser, A.; Schmidt, A. Using 3D Scanning for Improved Helmet Design, Conference. In Proceedings of the 7th International Conference on 3D Body Scanning Technologies, Lugano, Switzerland, 30 November–1 December 2016; Available online: https://www.researchgate.net/publication/311104590 (accessed on 20 December 2021).

- Lee, W.; Park, J.; Jeong, J.; Jeon, E.; Kim, H.-E.; Park, S.; You, H. Analysis of the Facial Anthropometric Data of Korean Pilots for Oxygen Mask Design. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, Baltimore, MD, USA, 1 September 2012; Volume 56, pp. 1927–1931. [Google Scholar] [CrossRef]

- Lee, W.; Lee, B.; Yang, X.; Yang, H.; Bok, I.; Kim, O.; Kwon, O.; You, H. A 3D anthropometric sizing analysis system based on North American CAESAR 3D scan data for design of head wearable products. Comput. Ind. Eng. 2018, 117, 121–130. [Google Scholar] [CrossRef]

- WNP. Available online: https://www.wnp.pl/budownictwo/komory-rury-piwnice-jak-bezpiecznie-pracowac-w-ograniczonej-przestrzeni,291995.html (accessed on 20 December 2021).

- VEOLIA, Standard Zarządzania Pracami o Wysokim Ryzyku. Prace w Przestrzeniach Zamkniętych. Available online: https://energiadlapoznania.pl/wp-content/uploads/sites/6/2021/02/PRACE-W-PRZESTRZENIACH-ZAMKNI%C4%98TYCH_PL.pdf (accessed on 20 December 2021).

- Gralewicz, G. Bezpieczna Praca w Przestrzeniach Zamkniętych, Konferencja 3M Poland. Atest, 2019; Volume 10. Available online: https://www.atest.com.pl/teksty,aa1910_1 (accessed on 20 December 2021).

- European Standard EN 547-1:1996+A1:2008; Safety of Machinery—Human Body Measurements—Part 1: Principles for Determining the Dimensions Required for Openings for Whole Body Access into Machinery. European Committee for Standardization: Brussels, Belgium, 2008.

- European Standard EN 547-2:1996+A1:2008; Safety of machinery—Human Body Measurements—Part 2: Pinciples for Determining the Dimensions Required for Access Openings. European Committee for Standardization: Brussels, Belgium, 2008.

- European Standard EN 349+A1:2008; Safety of Machinery—Minimum Gaps to Avoid Crushing of Parts of the Human Body. European Committee for Standardization: Brussels, Belgium, 2008.

- European Standard EN 547-3:1996+A1:2008; Safety of Machinery—Human Body Measurements—Part 3: Anthropometric Data. European Committee for Standardization: Brussels, Belgium, 2008.

- J.E. Spear Consulting, LP. Available online: https://www.jespear.com/health-effects-manganese-welding-fumes/ (accessed on 20 December 2021).

- Health and Safety Executive (HSE). Available online: https://www.hse.gov.uk/welding/health-risks-welding.htm (accessed on 20 December 2021).

- Szkudlarek, J.; Owczarek, G. Naddatki wymiarowe i naddatki do miar antropometrycznych, wynikające ze stosowania środków ochrony indywidualnej (i odzieży roboczej) a ergonomiczne środowisko pracy, Bezpieczeństwo Pracy. Nauka I Prakt. 2021, 2, 20–23. [Google Scholar]

- European Standard EN ISO 11612:2015; Protective Clothing—Clothing to Protect against Heat and Flame—Minimum Performance Requirements. European Committee for Standardization: Brussels, Belgium, 2015.

- European Standard EN 1149-5:2018; Protective Clothing. Electrostatic Properties. European Committee for Standardization: Brussels, Belgium, 2018.

- European Standard EN 61482-2:2020; Live Working—Protective Clothing against the Thermal Hazards of an Lelctric arc—Part 2: Requirements. European Committee for Standardization: Brussels, Belgium, 2020.

- European Standard EN 11611:2015; Protective Clothing for Use in Welding and Allied Processes. European Committee for Standardization: Brussels, Belgium, 2015.

- European Standard EN ISO 20471:2013/A1:2016; High Visibility Clothing. Test methods and Requirements. European Committee for Standardization: Brussels, Belgium, 2016.

- European Standard EN 166:2001; Personal Eye Protection. European Committee for Standardization: Brussels, Belgium, 2001.

- European Standard EN 175:1997; Personal Protection—Equipment for Eye and Face Protection during Welding and Allied Processes. European Committee for Standardization: Brussels, Belgium, 1997.

- European Standard EN 379:2003+A1:2009; Personal Eye Protection. Automatic Welding Filters. European Committee for Standardization: Brussels, Belgium, 2009.

- European Standard EN 388:2016+A1:2018; Protective Gloves against Mechanical Risk. European Committee for Standardization: Brussels, Belgium, 2018.

- European Standard EN 407:2004; Protective Gloves against Thermal Risks (Heat and/or Fire). European Committee for Standardization: Brussels, Belgium, 2004.

- European Standard EN 12477:2001; Protective Gloves for Welders. European Committee for Standardization: Brussels, Belgium, 2001.

- European Standard EN ISO 20349-2:2017; Personal Protective Equipment—Footwear Protecting against Risks in Foundries and Welding—Part 2: Requirements and Test Methods for Protection against Risks in Welding and Allied Processes. European Committee for Standardization: Brussels, Belgium, 2017.

- European Standard EN ISO 20345:2011; Personal Protective Equipment—Safety Footwear. European Committee for Standardization: Brussels, Belgium, 2011.

- Artec Group. Available online: https://www.artec3d.com/ (accessed on 20 December 2021).

- MeshLab. Available online: https://www.meshlab.net/ (accessed on 20 December 2021).

- CloudCompare. Available online: https://www.danielgm.net/cc/ (accessed on 20 December 2021).

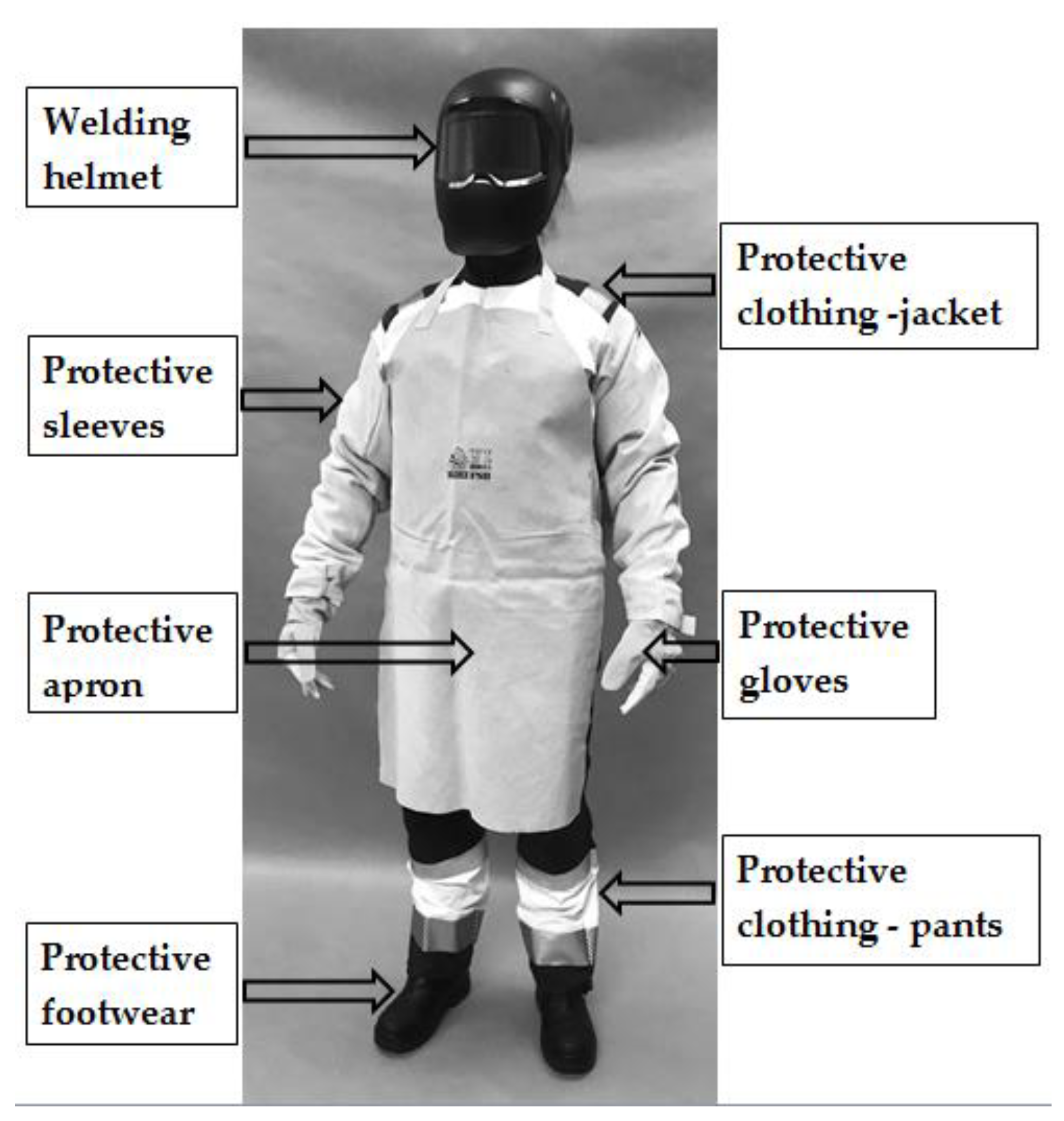

| PPE Element | PPE Characteristics |

|---|---|

| Protective clothing (jacket and overalls) |

|

| Welding helmet with automatic welding filter |

|

| Protective gloves | |

| Safety footwear S3 class |

|

| Protective apron and sleeves |

|

| Subject in Underwear | Subject Wearing PPE | |||

|---|---|---|---|---|

| ru | hu | rPPE | hPPE | |

| Cylinder radius and height (m) | 0.2991 ± 0.0008 | 1.7142 ± 0.0048 | 0.3504 ± 0.0022 | 1.7944 ± 0.0044 |

| rPPE–ru | hPPE–hu | |||

| Differences between the subject in underwear and PPE (m) | 0.0513 ± 0.0026 | 0.0802 ± 0.0034 | ||

| Δr | Δh | |||

| Relative differences between the subject in underwear and PPE (%) | 14.64 ± 0.66 | 4.47 ± 0.18 | ||

| Subject in Underwear | Subject Wearing PPE | |||||

|---|---|---|---|---|---|---|

| xu | yu | zu | xPPE | yPPE | zPPE | |

| Length of cuboid edges (m) | 0.3588 ± 0.0099 | 1.7163 ± 0.0012 | 0.5977 ± 0.0013 | 0.4707 ± 0.0280 | 1.7936 ± 0.0017 | 0.7019 ± 0.0030 |

| xPPE–xu | yPPE–yu | zPPE–zu | ||||

| Differences between the subject in underwear and PPE (m) | 0.1125 ± 0.0184 | 0.0774 ± 0.0016 | 0.1042 ± 0.0025 | |||

| Δx | Δy | Δz | ||||

| Relative differences between the subject in underwear and PPE (%) | 23.78 ± 2.58 | 4.31 ± 0.09 | 14.85 ± 0.31 | |||

| Subject in Underwear | Subject Wearing PPE | |||

|---|---|---|---|---|

| AC_u | VC_u | AC_PPE | VC_PPE | |

| Cylinder base area (m2) and volume (m3) | 0.2809 ± 0.016 | 0.4814 ± 0.036 | 0.3855 ± 0.044 | 0.6917 ± 0.070 |

| AC_PPE–AC_u | VC_PPE–VC_u | |||

| Differences in cylinder base area (m2) and volume (m3) between subject in underwear and PPE | 0.1046 ± 0.055 | 0.2102 ± 0.093 | ||

| ΔAw | ΔVw | |||

| Relative differences in cylinder base area and volume between subject in underwear and PPE (%) | 37.25 ± 2.10 | 43.67 ± 2.17 | ||

| Subject in Underwear | Subject Wearing PPE | |||

|---|---|---|---|---|

| AQ_u | VQ_u | AQ_PPE | VQ_PPE | |

| Cuboid base area (m2) and volume (m3) | 0.2141 ± 0.0057 | 0.3675 ± 0.0098 | 0.3303 ± 0.0184 | 0.5925 ± 0.0335 |

| AQ_PPE–AQ_u | VQ_PPE–VQ_u | |||

| Absolute differences in cuboid base area (m2) and volume (m3) between subject in underwear and PPE | 0.1162 ± 0.0129 | 0.2250 ± 0.0240 | ||

| ΔAQ | ΔVQ | |||

| Relative differences in cuboid base area and volume between subject in underwear and PPE (%) | 54.19 ± 4.70 | 61.14 ± 5.04 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szkudlarek, J.; Owczarek, G.; Jachowicz, M.; Zagrodny, B. Procedure for Determining Dimensional Allowances for PPE Using 3D Scanning Methods. Int. J. Environ. Res. Public Health 2022, 19, 2397. https://doi.org/10.3390/ijerph19042397

Szkudlarek J, Owczarek G, Jachowicz M, Zagrodny B. Procedure for Determining Dimensional Allowances for PPE Using 3D Scanning Methods. International Journal of Environmental Research and Public Health. 2022; 19(4):2397. https://doi.org/10.3390/ijerph19042397

Chicago/Turabian StyleSzkudlarek, Joanna, Grzegorz Owczarek, Marcin Jachowicz, and Bartłomiej Zagrodny. 2022. "Procedure for Determining Dimensional Allowances for PPE Using 3D Scanning Methods" International Journal of Environmental Research and Public Health 19, no. 4: 2397. https://doi.org/10.3390/ijerph19042397

APA StyleSzkudlarek, J., Owczarek, G., Jachowicz, M., & Zagrodny, B. (2022). Procedure for Determining Dimensional Allowances for PPE Using 3D Scanning Methods. International Journal of Environmental Research and Public Health, 19(4), 2397. https://doi.org/10.3390/ijerph19042397