Multi-Criterial Algorithm for the Efficient and Ergonomic Manual Assembly Process

Abstract

:1. Introduction

2. Materials and Methods

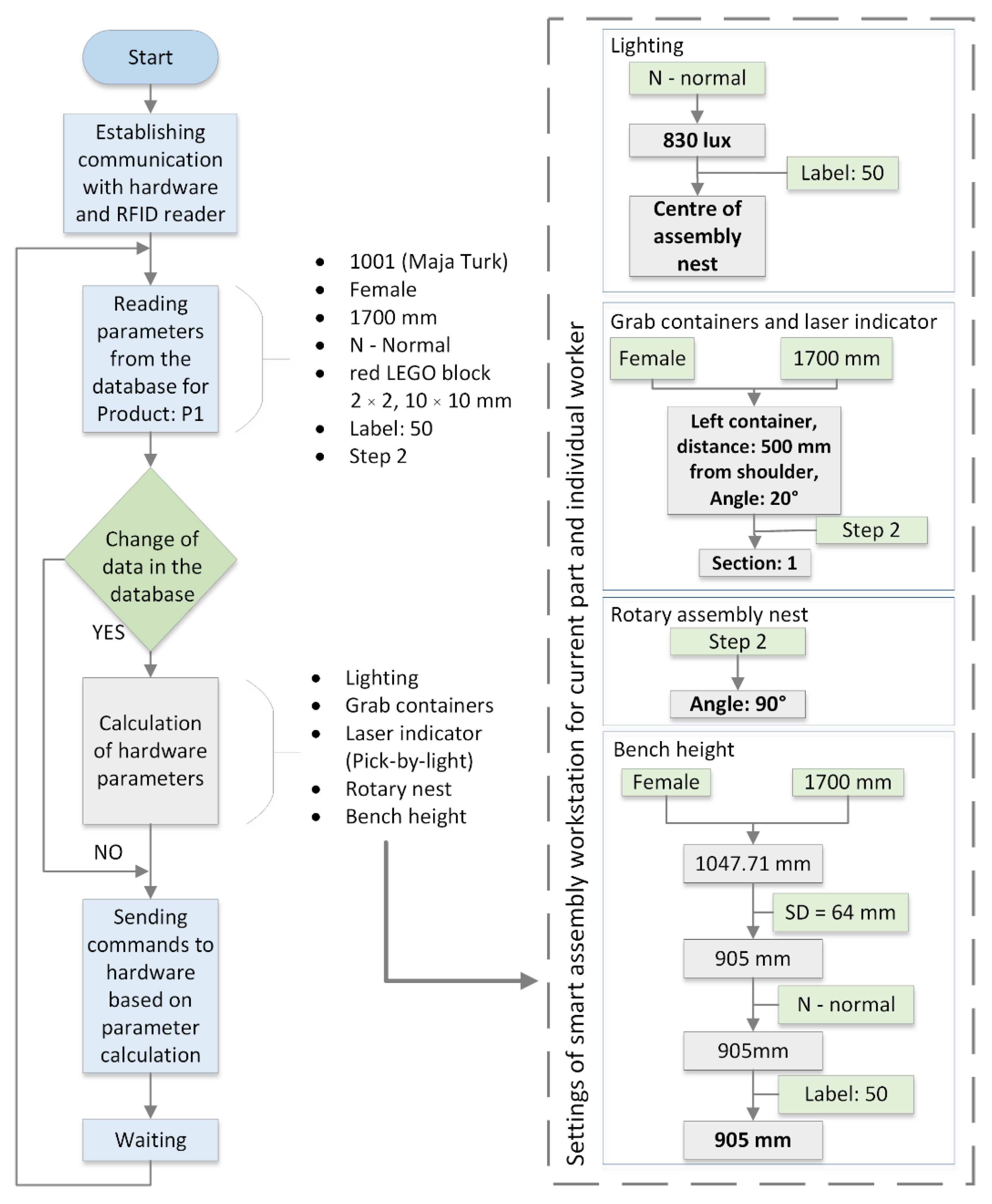

2.1. Multi-Criterial Algorithm

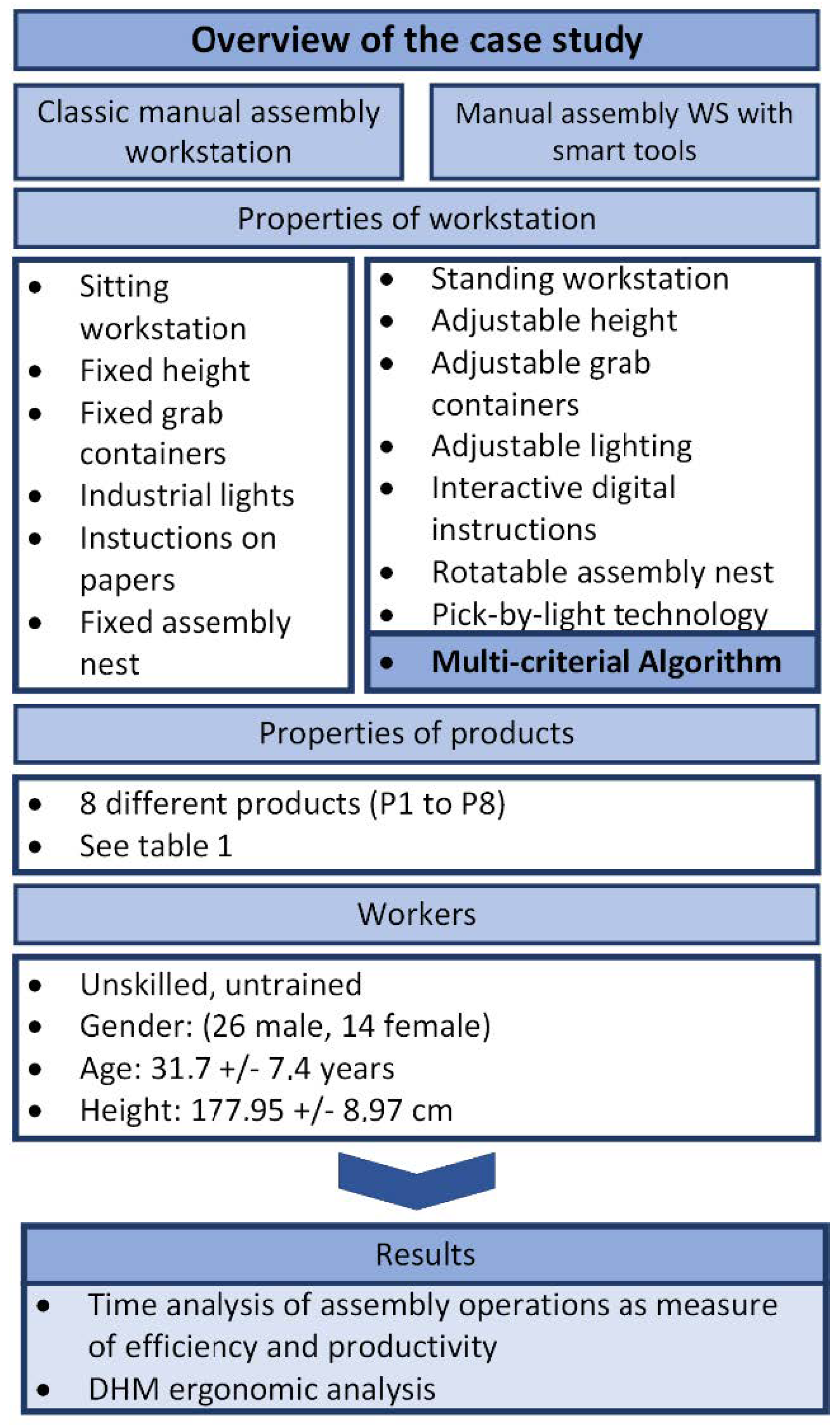

2.2. Overview of the Case Study

2.2.1. The Course of the Experiment

2.2.2. Functionality of a Classic and Smart Manual Assembly Workstation

2.2.3. Characteristics of Products and Workers

2.2.4. Evaluation Process

3. Results and Discussion

3.1. Multi-Criterial Algorithm

3.2. Laboratory Case Study Experiment

3.2.1. Time Analysis

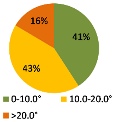

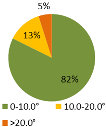

3.2.2. Ergonomic Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Koren, Y.; Shpitalni, M. Design of reconfigurable manufacturing systems. J. Manuf. Syst. 2016, 29, 130–141. [Google Scholar] [CrossRef]

- Ahmed, S.; Gawand, M.S.; Irshad, L.; Demirel, H.O. Exploring the Design Space Using a Surrogate Model Approach with Digital Human Modeling Simulations. In Proceedings of the 38th Computers and Information in Engineering Conference, Quebec City, QC, Canada, 26–29 August 2018. [Google Scholar] [CrossRef]

- Weyer, S.; Schmitt, M.; Ohmer, M.; Gorecky, D. Towards Industry 4.0—Standardization as the crucial challenge for highly modular, multi-vendor production systems. IFAC-PapersOnLine 2015, 48, 579–584. [Google Scholar] [CrossRef]

- Zupan, H.; Herakovic, N.; Zerovnik, J.; Berlec, T. Layout Optimization of a Production Cell. Int. J. Simul. Model. 2016, 16, 603–616. [Google Scholar] [CrossRef]

- Liu, M.; Ma, J.; Lin, L.; Ge, M.; Wang, Q.; Liu, C. Intelligent assembly system for mechanical products and key technology based on internet of things. J. Int. Manuf. 2017, 28, 271–299. [Google Scholar] [CrossRef]

- Sanjog, J.; Karmakar, S.; Patel, T.; Chowdhury, A. DHM an Aid for Virtual Ergonomics of Manufacturing Shop Floor: A Re-view with Reference to Industrially Developing Countries. Int. J. Comput. Appl. 2012, 54, 18–23. [Google Scholar] [CrossRef]

- Attaran, M.; Attaran, S.; Kirkland, D. The need for digital workplace: Increasing workforce productivity in the information age. Int. J. Enterp. Inf. Syst. 2019, 15, 1–23. [Google Scholar] [CrossRef]

- Selimović, J.; Pilav-Velić, A.; Krndžija, L. Digital workplace Digital workplace transformation in the financial service sector: Investigating the relationship between employees’ expectations and intentions. Technol. Soc. 2021, 66, 101640. [Google Scholar] [CrossRef]

- Richter, A.; Heinrich, P.; Stocker, A.; Schwabe, G. Digital Work Design. Bus. Inf. Syst. Eng. 2018, 60, 259–264. [Google Scholar] [CrossRef] [Green Version]

- Borgs, S.P.; La Delfa, N.J.; Dickerson, C.R. An evaluation of off-axis manual forces and upper extremity joint moments during unilateral pushing and pulling exertions. Ergonomics 2019, 62, 52–64. [Google Scholar] [CrossRef]

- Mali, S.C.; Vyavahare, R.T. An Ergonomic Evaluation of an Industrial Workstation: A Review. Int. J. Curr. Eng. Technol. 2015, 5, 1820–1826. [Google Scholar]

- Gorecky, D.; Khamis, M.; Mura, K. Introduction and establishment of virtual training in the factory of the future. Int. J. Comput. Integr. Manuf. 2015, 30, 182–190. [Google Scholar] [CrossRef]

- Bertram, P.; Birtel, M.; Quint, F.; Ruskowski, M. Intelligent Manual Working Station through Assistive Systems. IFAC-PapersOnLine 2018, 51, 170–175. [Google Scholar] [CrossRef]

- Saidi-Mehrabad, M.; Paydar, M.M.; Aalaei, A. Production planning and worker training in dynamic manufacturing systems. J. Manuf. Syst. 2013, 32, 308–314. [Google Scholar] [CrossRef]

- Lai, Z.-H.; Tao, W.; Leu, M.C.; Yin, Z. Smart augmented reality instructional system for mechanical assembly towards worker-centered intelligent manufacturing. J. Manuf. Syst. 2020, 55, 69–81. [Google Scholar] [CrossRef]

- Rodriguez, L.; Quint, F.; Gorecky, D.; Romero, D.; Siller, H.R. Developing a Mixed Reality Assistance System Based on Projection Mapping Technology for Manual Operations at Assembly Workstations. Procedia Comput. Sci. 2015, 75, 327–333. [Google Scholar] [CrossRef] [Green Version]

- Hoedt, S.; Claeys, A.; Van Landeghem, H.; Cottyn, J. The evaluation of an elementary virtual training system for manual assembly. Int. J. Prod. Res. 2017, 55, 7496–7508. [Google Scholar] [CrossRef]

- Tao, W.; Lai, Z.-H.; Leu, M.C.; Yin, Z.; Qin, R. A self-aware and active-guiding training & assistant system for worker-centered intelligent manufacturing. Manuf. Lett. 2019, 21, 45–49. [Google Scholar] [CrossRef]

- Leber, M.; Bastic, M.; Moody, L.; Schmidt Krajnc, M. A study of the impact of ergonomically designed workplaces on employee productivity. Adv. Prod. Eng. Manag. 2018, 13, 107–117. [Google Scholar] [CrossRef] [Green Version]

- Chaffin, D. Improving digital human modelling for proactive ergonomics in design. Ergonomics 2005, 48, 478–491. [Google Scholar] [CrossRef]

- Bauters, K.; Cottyn, J.; Claeys, D.; Slembrouck, M.; Veelaert, P.; van Landeghem, H. Automated work cycle classification and performance measurement for manual workstations. Robot. Comput. Manuf. 2018, 51, 139–157. [Google Scholar] [CrossRef]

- Laudante, E.; Greco, A.; Caterino, M.; Fera, M. Human–Robot Interaction for Improving Fuselage Assembly Tasks: A Case Study. Appl. Sci. 2020, 10, 5757. [Google Scholar] [CrossRef]

- Colim, A.; Faria, C.; Braga, A.C.; Sousa, N.; Rocha, L.; Carneiro, P.; Costa, N.; Arezes, P. Towards an Ergonomic Assessment Framework for Industrial Assembly Workstations—A Case Study. Appl. Sci. 2020, 10, 3048. [Google Scholar] [CrossRef]

- Cohen, Y.; Faccio, M.; Galizia, F.G.; Mora, C.; Pilati, F. Assembly system configuration through Industry 4.0 principles: The expected change in the actual paradigms. IFAC-PapersOnLine 2017, 50, 14958–14963. [Google Scholar] [CrossRef]

- Bortolini, M.; Ferrari, E.; Gamberi, M.; Pilati, F.; Faccio, M. Assembly system design in the Industry 4.0 era: A general framework. IFAC-PapersOnLine 2017, 50, 5700–5705. [Google Scholar] [CrossRef]

- Papetti, A.; Rossi, M.; Menghi, R.; Germani, M. Human-centered design for improving the workplace in the footwear sector. Procedia CIRP 2020, 91, 295–300. [Google Scholar] [CrossRef]

- Zamfirescu, C.-B.; Pirvu, B.-C.; Gorecky, D.; Chakravarthy, H. Human-centred Assembly: A Case Study for an Anthropocentric Cyber-physical System. Procedia Technol. 2014, 15, 90–98. [Google Scholar] [CrossRef] [Green Version]

- Sand, O.; Büttner, S.; Paelke, V.; Röcker, C. smARt.Assembly—Projection-Based Augmented Reality for Supporting Assembly Workers. In Virtual, Augmented and Mixed Reality; Lecture Notes in Computer, Science; Lackey, S., Shumaker, R., Eds.; Springer: Cham, Switzerland, 2016; Volume 9740, pp. 643–652. [Google Scholar] [CrossRef]

- Meske, C.; Junglas, I. Investigating the elicitation of employees’ support towards digital workplace transformation. Behav. Inf. Technol. 2021, 40, 1120–1136. [Google Scholar] [CrossRef]

- Deprag Schulz GmbHu.co: Deprag: Manual Workstations. Available online: https://www.deprag.com/en/automation/products/manual-workstations.html (accessed on 21 January 2022).

- Item Industrietechnik GmbH: Item: Work Bench System. Available online: https://www.item24.de/en/productworld/work-bench-system.html (accessed on 21 January 2022).

- Qu, Y.J.; Ming, X.G.; Liu, Z.W.; Zhang, X.Y.; Hou, Z.T. Smart manufacturing systems: State of the art and future trends. Int. J. Adv. Manuf. Technol. 2019, 18, 3751–3768. [Google Scholar] [CrossRef]

- Turk, M.; Pipan, M.; Simic, M.; Herakovic, N. A Smart Algorithm for Personalizing the Workstation in the Assembly Process. Appl. Sci. 2020, 10, 8624. [Google Scholar] [CrossRef]

| Product Name | Figure of Product | Number of Parts | Number of Different Parts | Assembly Complexity | Dimension of Part | Dimension along Z-axis |

|---|---|---|---|---|---|---|

| P1 |  | 34 | 12 | N 1 | 60 × 30 mm | 50 mm |

| P2 |  | 25 | 6 | N | 60 × 30 mm | 50 mm |

| P3 |  | 31 | 6 | N | 60 × 30 mm | 50 mm |

| P4 |  | 23 | 8 | N | 60 × 30 mm | 50 mm |

| P5 |  | 27 | 10 | N | 60 × 30 mm | 50 mm |

| P6 |  | 61 | 18 | N | 75 × 30 mm | 150 mm |

| P7 |  | 65 | 14 | N | 75 × 60 mm | 50 mm |

| P8 |  | 121 | 29 | N | 60 × 60 mm | 150 mm |

| Product Name | Final Time (SD) (s) | Time Saving [%] | |

|---|---|---|---|

| Classic Workstation | Smart Workstation | ||

| P1 | 216.41 (41.5) | 185.3 (23.5) | 14.4 |

| P2 | 163.7 (21.6) | 142.5 (18.3) | 13.0 |

| P3 | 187.4 (39.2) | 159.7 (31.6) | 14.8 |

| P4 | 154.8 (25.7) | 131.8 (15.9) | 14.9 |

| P5 | 160.7 (36.2) | 139.2 (28.4) | 13.4 |

| P6 | 405.1 (63.7) | 345.7 (49.7) | 14.7 |

| P7 | 457.6 (98.1) | 401.2 (56.8) | 12.3 |

| P8 | 1082.3 (121.4) | 959.8 (87.1) | 11.3 |

| Joint Name | Basic Version | Improved Version | |

|---|---|---|---|

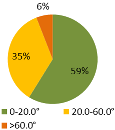

| Joint: Neck | |||

| Flexion |  |  |  |

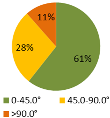

| Joint: Back | |||

| Flexion |  |  |  |

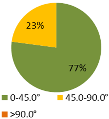

| Joint: Left Shoulder | |||

| Flexion |  |  |  |

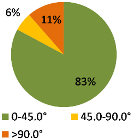

| Abduction |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turk, M.; Šimic, M.; Pipan, M.; Herakovič, N. Multi-Criterial Algorithm for the Efficient and Ergonomic Manual Assembly Process. Int. J. Environ. Res. Public Health 2022, 19, 3496. https://doi.org/10.3390/ijerph19063496

Turk M, Šimic M, Pipan M, Herakovič N. Multi-Criterial Algorithm for the Efficient and Ergonomic Manual Assembly Process. International Journal of Environmental Research and Public Health. 2022; 19(6):3496. https://doi.org/10.3390/ijerph19063496

Chicago/Turabian StyleTurk, Maja, Marko Šimic, Miha Pipan, and Niko Herakovič. 2022. "Multi-Criterial Algorithm for the Efficient and Ergonomic Manual Assembly Process" International Journal of Environmental Research and Public Health 19, no. 6: 3496. https://doi.org/10.3390/ijerph19063496

APA StyleTurk, M., Šimic, M., Pipan, M., & Herakovič, N. (2022). Multi-Criterial Algorithm for the Efficient and Ergonomic Manual Assembly Process. International Journal of Environmental Research and Public Health, 19(6), 3496. https://doi.org/10.3390/ijerph19063496