An Investigation on the Impact of Unloading Rate on Coal Mechanical Properties and Energy Evolution Law

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Preparation

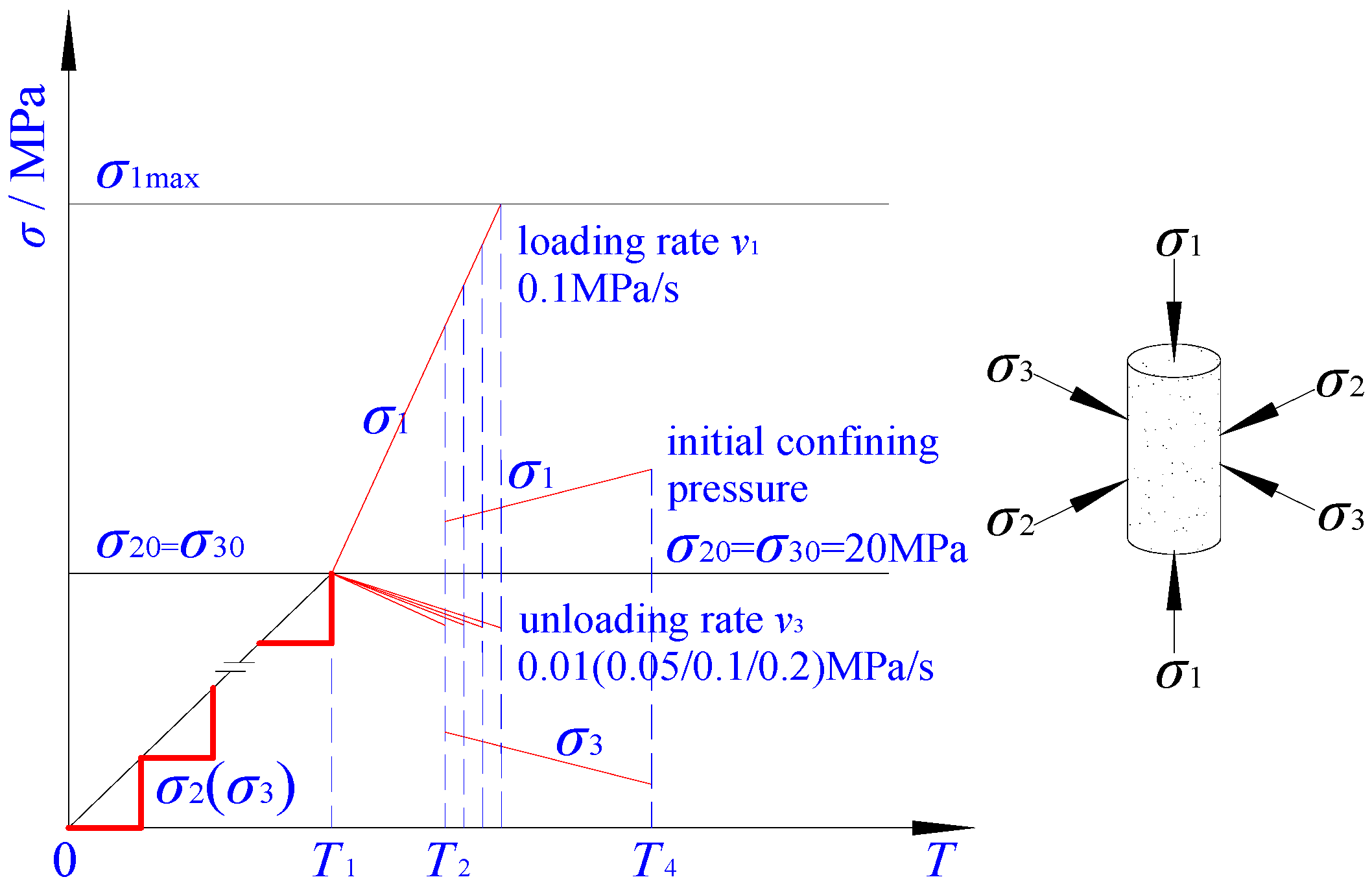

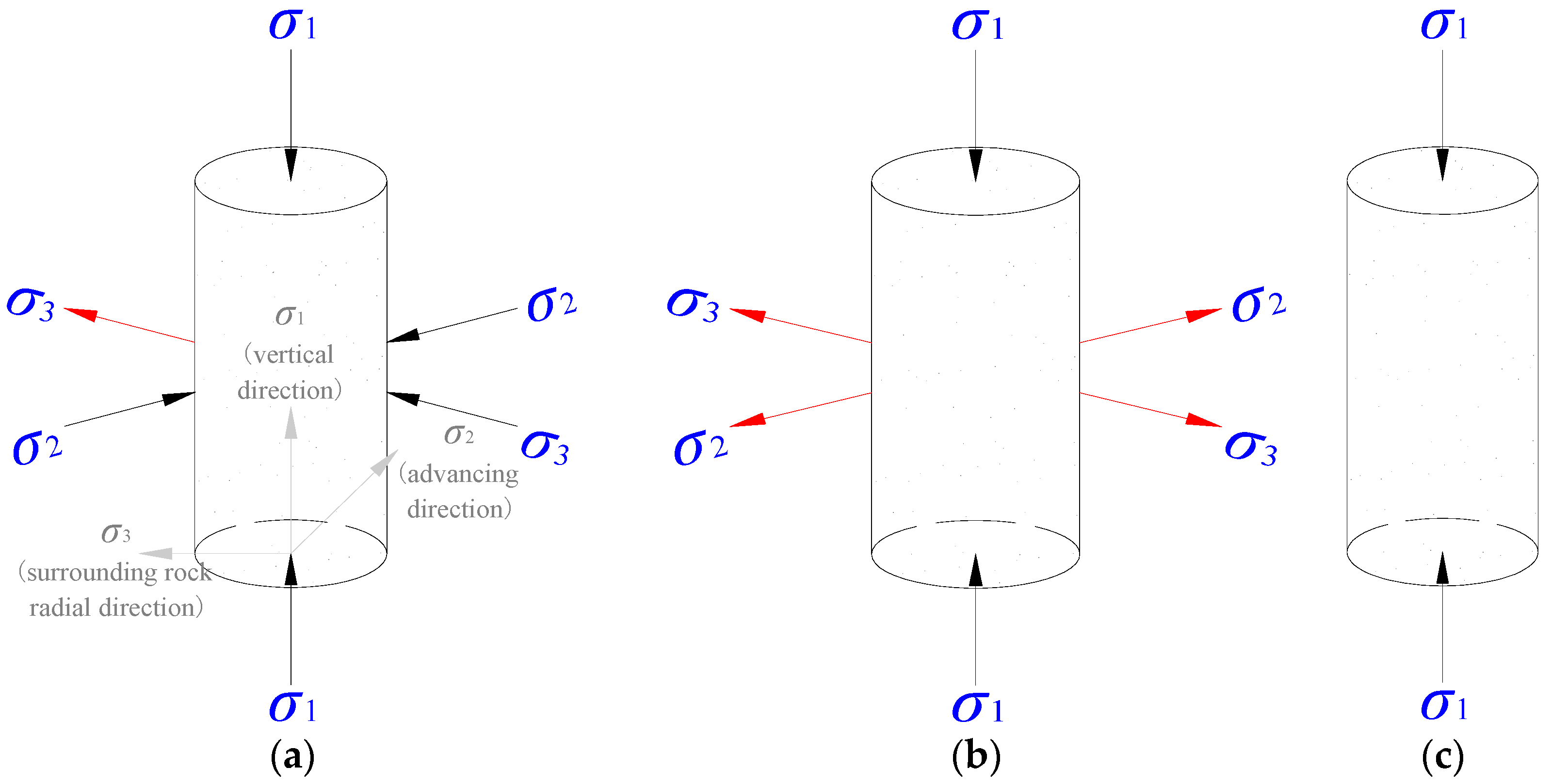

2.2. Test Method

- (1)

- Stress was controlled by increasing the load at a rate of 0.05 MPa/s, following the principle of σ2 = σ3 = 5 → σ1 = 5 → σ2 = σ3 = 10 → σ1 = 10 MPa, …. The confining pressure and shaft pressure were increased alternatively until both reached 20 MPa.

- (2)

- In order to control the stress, the shaft pressure, σ1, was increased at a constant rate of v1 = 0.1 MPa/s; meanwhile, the confining pressure in sample σ3 was decreased at the rate of v3, following the rate setpoint of 0.01, 0.05, 0.1, and 0.2 MPa/s until the failure of the test sample.

3. Result Analysis and Discussion

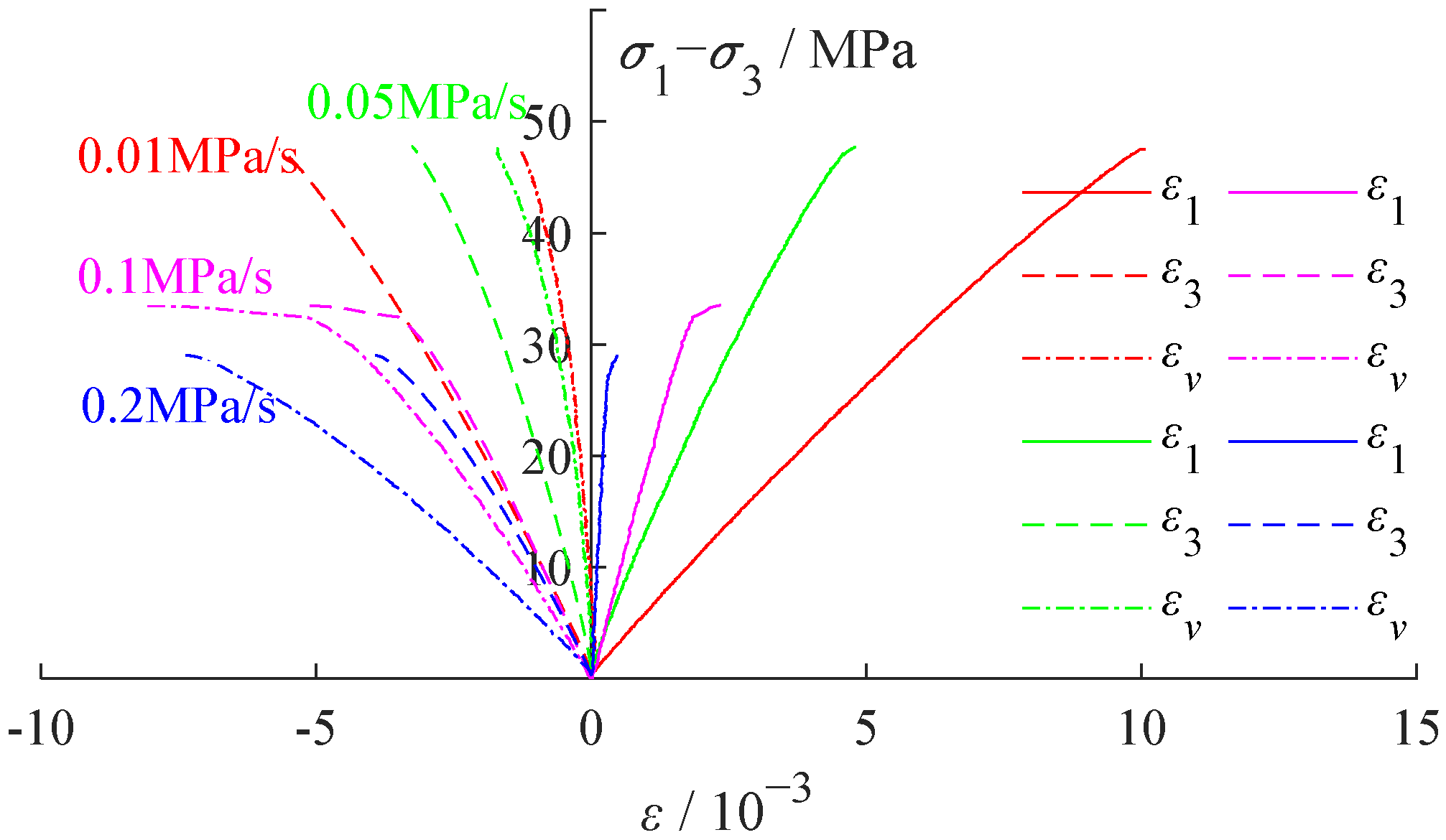

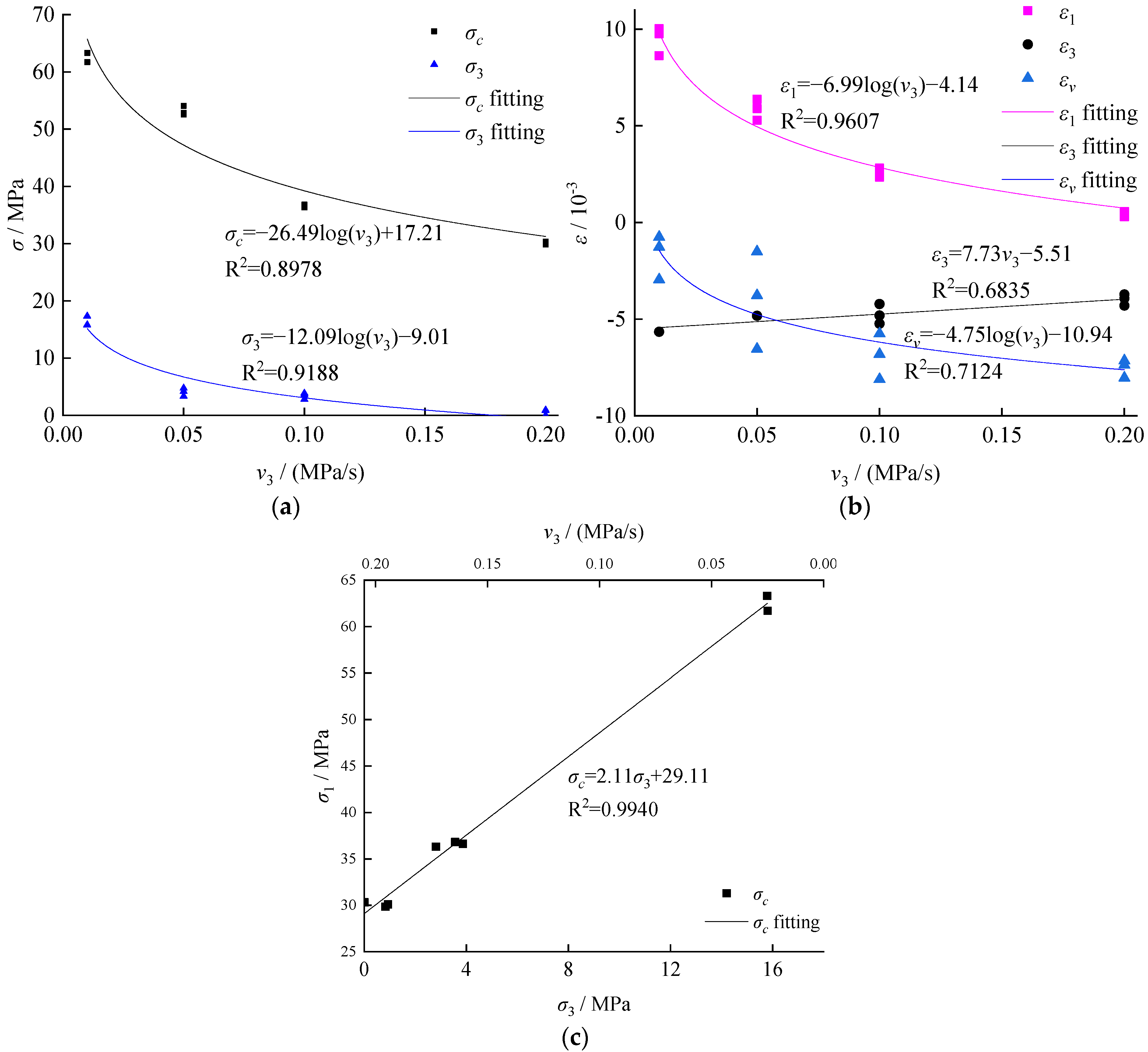

3.1. The Relationship between the Unloading Rate and Mechanical Properties of the Coal Body

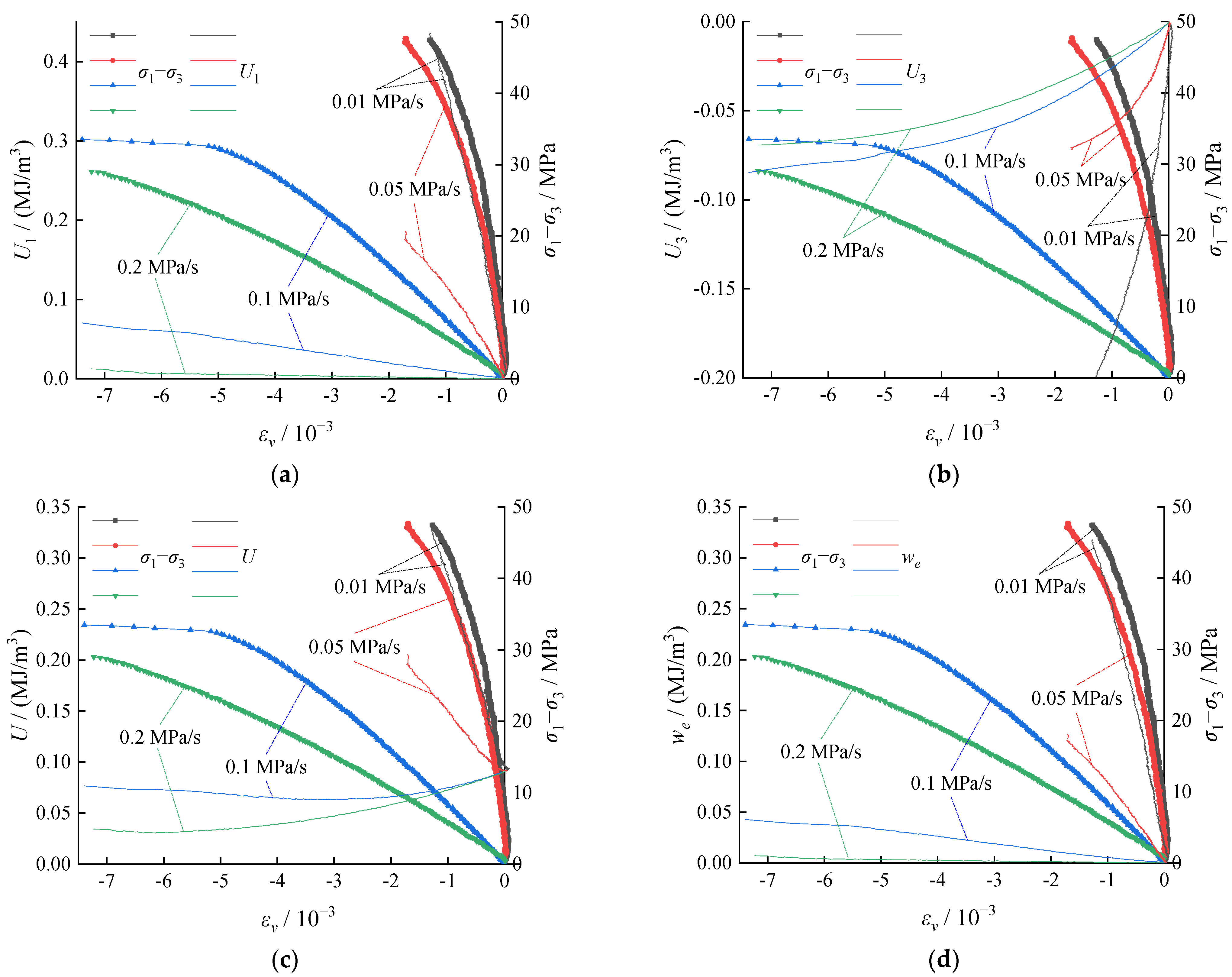

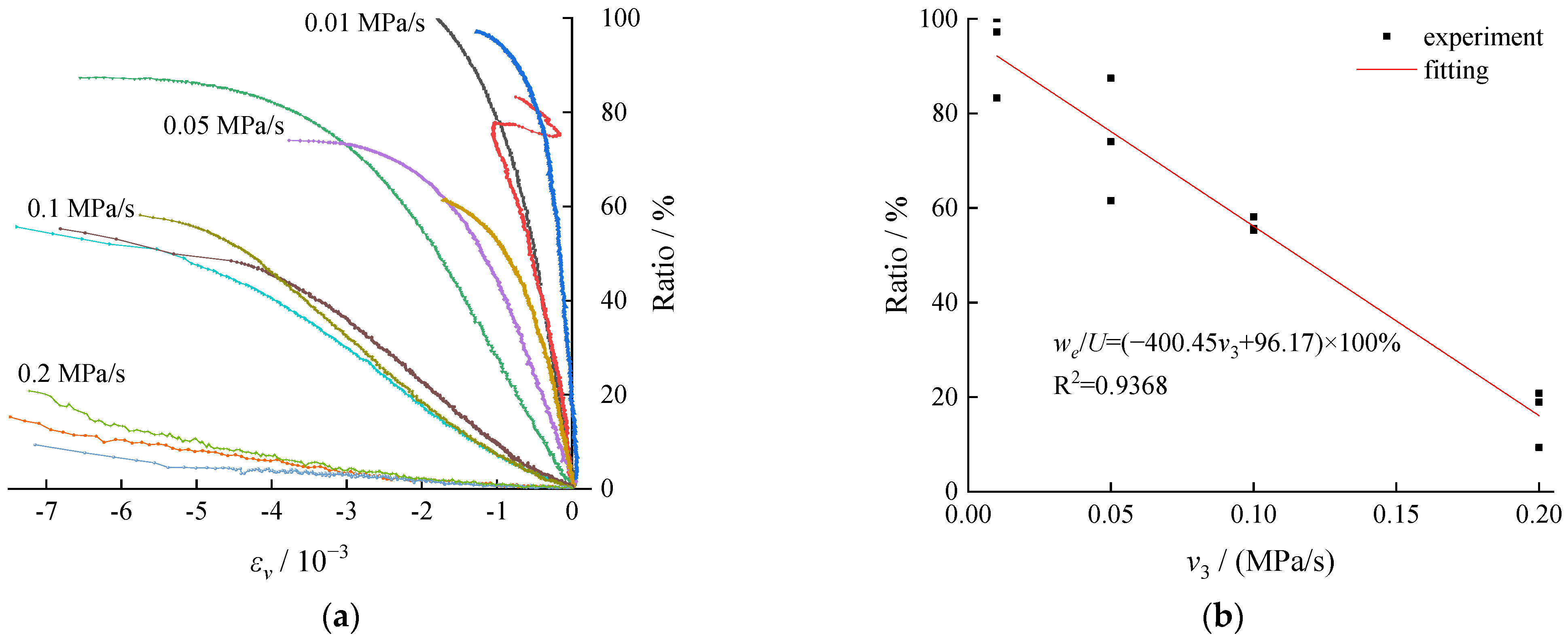

3.2. The Evolvement between the Unloading Rate and Energy Evolution of the Coal Body

3.3. Discussion

4. Conclusions

- (1)

- As the unloading rate increased, a series of mechanical properties of the coal body, including the peak strength, the confining pressure, the axial strain, and horizontal strain, tended to decrease at the rupture stage while the volume strain and the elastic modulus increased, indicating that the rupture form evolved from the ductile failure to brittle failure.

- (2)

- Regarding the energy, the axial pressure did positive work while the surrounding pressure did negative work, with decrease in the total work and the stored elastic strain energy. In addition, the dissipation energy increased, and the elastic strain energy conversion rate decreased linearly, indicating that the high unloading rate increased the possibility of dynamic disasters induced by the instantaneous brittle rupture of the coal body. Due to the low releasable elastic strain energy stored in the coal body and the low unloading rate, the strength and probability of subsequent dynamic manifestations of coal body destruction were reduced.

- (3)

- Some differences were noticed between the actual excavation and the three axial tests. During the actual excavation, the risk and intensity of the instantaneous failure and the consequent dynamic disasters were higher. However, increasing the excavation speed in a controlled way was beneficial to the safe and efficient construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Swanson, S.R.; Brown, W.S. An observation of loading path independence of failure in rock. Int. J. Rock Mech. Min. Sci. 1971, 8, 277–281. [Google Scholar] [CrossRef]

- Crouch, S.L. A note on post-failure stress-strain path dependence in norite. Int. J. Rock Mech. Min. Sci. 1972, 9, 197–204. [Google Scholar] [CrossRef]

- Jose, S.O.L.; Chandler, N.A. Innovative laboratory testing. Int. J. Rock Mech. Min. Sci. 2004, 41, 1427–1445. [Google Scholar]

- Guo, H.J.; Ji, M.; Liu, D.P.; Liu, M.X.; Li, G.F.; Chen, J.J. An experimental research on surrounding rock unloading during solid coal roadway excavation. Geofluids 2021, 2021, 5604642. [Google Scholar] [CrossRef]

- Zhao, Y.; Bi, J.; Wang, C.L.; Liu, P.F. Effect of unloading rate on the mechanical behavior and fracture characteristics of sandstones under complex triaxial stress conditions. Rock Mech. Rock Eng. 2021, 54, 4851–4866. [Google Scholar] [CrossRef]

- Ji, Y.L.; Wu, W.; Zhao, Z.H. Unloading-induced rock fracture activation and maximum seismic moment prediction. Eng. Geol. 2019, 262, 105352. [Google Scholar] [CrossRef]

- Cong, Y.; Feng, X.T.; Zheng, Y.R.; Wang, Z.Q.; Qiu, S.L. Study on effects of unloading rate on macro-meso failure mechanism of brittle rock. Chin. J. Rock Mech. Eng. 2016, 35, 3696–3705. [Google Scholar]

- Zheng, Q.D. Study on the Influence of Different Unloading-Confining Pressure Rates on Marble Fracture Process; Qingdao University of Technology: Qingdao, China, 2016. [Google Scholar]

- Li, X.B.; Wang, S.M.; Weng, L.; Huang, L.Q.; Zhou, T.; Zhou, J. Damage constitutive model of different age concretes under impact load. J. Cent. South Univ. 2015, 22, 693–700. [Google Scholar] [CrossRef]

- Li, X.B.; Zou, Y.; Zhou, Z.L. Numerical simulation of the rock SHPB test with a special shape striker based on the discrete element method. Rock Mech. Rock Eng. 2014, 47, 1693–1709. [Google Scholar] [CrossRef]

- Zhang, M.B.; Cui, L.; Hu, W.J.; Du, J.L.; Zhang, Z.; Wang, C.L. Acoustic emission experimental research of the damage characteristics of raw coal under different loading and unloading rates. Shock Vib. 2020, 2020, 9063929. [Google Scholar] [CrossRef]

- Li, D.Y.; Sun, Z.; Li, X.B.; Xie, T. Mechanical response and failure characteristics of granite under different stress paths in triaxial loading and unloading conditions. Chin. J. Rock Mech. Eng. 2016, 35, 3449–3457. [Google Scholar]

- Zhao, G.Y.; Dai, B.; Dong, L.J.; Yang, C. Experimental research on mechanical characteristics and strength criterion of rock of triaxial unloading tests under different stress paths. Rock Soil Mech. 2015, 36, 3121–3127, 3149. [Google Scholar]

- Guo, J.Q.; Liu, P.F.; Fan, J.Q.; Shi, X.Y.; Huang, X.; Hao, X.J. Influence of confining pressure unloading rate on the strength characteristics and fracture process of granite using lab tests. Adv. Mater. Sci. Eng. 2021, 2021, 7925608. [Google Scholar] [CrossRef]

- Qian, Y.J.; Wu, Y.L.; Pei, W.W.; Zhu, Y.Y. Rock strength and deformation characteristics under different unloading rates. Hydro-Sci. Eng. 2020, 6, 48–54. [Google Scholar]

- Li, T. Siltstone’s Mechanical Properties in Different Stress Paths and Research of Unloading Constitutive Model; China University of Mining & Technology: Xuzhou, China, 2015. [Google Scholar]

- Guo, H.J.; Ji, M.; Cao, L. Effect of unloading rate on the mechanical properties of siltstone. J. Xi’an Univ. Archit. Technol. 2020, 52, 860–868. [Google Scholar]

- Yin, G.Z.; Ma, B.; Liu, C.; Li, M.H.; Lu, J.; Yin, S.Y. Effect of loading and unloading rates on mechanical properties and energy characteristics of sandstone under true triaxial stress. J. China Coal Soc. 2019, 44, 454–462. [Google Scholar]

- Zhao, H.G.; Liu, C.; Huang, G. Dilatancy behavior and permeability evolution of sandstone subjected to initial confining pressures and unloading rates. R. Soc. Open Sci. 2021, 8, 201792. [Google Scholar] [CrossRef]

- Ma, D.P.; Zhou, Y.; Liu, C.X.; Shang, Y.D. Energy evolution characteristics of coal failure in triaxial tests under different unloading confining pressure rates. Rock Soil Mech. 2019, 40, 2645–2652. [Google Scholar]

- Peng, K.; Zhang, J.; Zou, Q.L.; Song, X. Deformation characteristics of granites at different unloading rates after high-temperature treatment. Environ. Earth Sci. 2020, 79, 25–42. [Google Scholar]

- Hou, G.Y.; Liang, J.P.; Hu, T.; Jing, H.Y.; Zhang, G.D.; Tan, J.X.; Yang, X.; Zhang, Y.K. Effects of the unloading rate on the deformation and damage of the surrounding rock under different confining pressures. Chin. J. Rock Mech. Eng. 2019, 38, 433–444. [Google Scholar]

- Hou, G.Y.; Jing, H.Y.; Liang, J.P.; Tan, J.X.; Zhang, Y.K.; Yang, X.; Xie, X. Experimental study on surrounding rock deformation and acoustic emission characteristics of rectangular roadway under different loads. Rock Soil Mech. 2020, 41, 1818–1828. [Google Scholar]

- Fang, Q.C.; Shang, L.; Shang, Y.H.; Chen, Z.F. Mechanical and energy characteristics of granites under unloading test. J. Cent. South Univ. 2016, 47, 4148–4153. [Google Scholar]

- Song, Y.D. Study on Macroscopic and Microscopic Failure Mechanism of Marble under Constant Axial Stress Unloading Confining Pressure; Qingdao University of Technology: Qingdao, China, 2020. [Google Scholar]

- Zhao, H.G.; Song, Z.L.; Zhang, D.M.; Liu, C.; Yu, B.C. True triaxial experimental study on mechanical characteristics and energy evolution of sandstone under various loading and unloading rates. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 22. [Google Scholar] [CrossRef]

- Shen, W.; Dou, L.M.; He, H.; Gong, S.Y.; Ji, X.J. Study on mechanism and prevention of rock burst under loading and unloading path in solid coal driving. J. Min. Saf. Eng. 2019, 36, 768–776. [Google Scholar]

- Chen, Z.Q.; He, C.; Hu, X.-Y.; Chun-Chi, M.A. Effect of stress paths on failure mechanism and progressive damage of hard-brittle rock. J. Mt. Sci. 2021, 18, 2486–2502. [Google Scholar] [CrossRef]

| Number | Unloading Rate/(MPa/s) | Horizontal Strain ε3/10−3 | Volume Strain εv/10−3 | Confining Pressure σ3/MPa | Axial Strain ε1/10−3 | Failure Strength σc/MPa | |

|---|---|---|---|---|---|---|---|

| 1 | 0.01 | −6.364 | −2.953 | 15.808 | 9.775 | 61.704 | 57.658 |

| 2 | 0.01 | −4.693 | −0.749 | 17.327 | 8.636 | 47.965 | |

| 3 | 0.01 | −5.652 | −1.271 | 15.793 | 10.033 | 63.306 | |

| 4 | 0.05 | −6.458 | −6.549 | 4.155 | 6.367 | 52.851 | 53.159 |

| 5 | 0.05 | −4.830 | −3.769 | 3.358 | 5.892 | 54.071 | |

| 6 | 0.05 | −3.398 | −1.507 | 4.765 | 5.289 | 52.554 | |

| 7 | 0.1 | −5.233 | −8.112 | 2.810 | 2.354 | 36.312 | 36.585 |

| 8 | 0.1 | −4.812 | −6.812 | 3.865 | 2.811 | 36.629 | |

| 9 | 0.1 | −4.215 | −5.750 | 3.561 | 2.681 | 36.814 | |

| 10 | 0.2 | −4.302 | −9.351 | 0.009 | 0.565 | 30.335 | 30.094 |

| 11 | 0.2 | −3.722 | −7.149 | 0.937 | 0.295 | 30.090 | |

| 12 | 0.2 | −3.923 | −7.368 | 0.835 | 0.478 | 29.856 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, H.; Sun, Z.; Ji, M.; Wu, Y.; Nian, L. An Investigation on the Impact of Unloading Rate on Coal Mechanical Properties and Energy Evolution Law. Int. J. Environ. Res. Public Health 2022, 19, 4546. https://doi.org/10.3390/ijerph19084546

Guo H, Sun Z, Ji M, Wu Y, Nian L. An Investigation on the Impact of Unloading Rate on Coal Mechanical Properties and Energy Evolution Law. International Journal of Environmental Research and Public Health. 2022; 19(8):4546. https://doi.org/10.3390/ijerph19084546

Chicago/Turabian StyleGuo, Hongjun, Zhongguang Sun, Ming Ji, Yongfeng Wu, and Lihui Nian. 2022. "An Investigation on the Impact of Unloading Rate on Coal Mechanical Properties and Energy Evolution Law" International Journal of Environmental Research and Public Health 19, no. 8: 4546. https://doi.org/10.3390/ijerph19084546

APA StyleGuo, H., Sun, Z., Ji, M., Wu, Y., & Nian, L. (2022). An Investigation on the Impact of Unloading Rate on Coal Mechanical Properties and Energy Evolution Law. International Journal of Environmental Research and Public Health, 19(8), 4546. https://doi.org/10.3390/ijerph19084546