Effect of Adding De-Oiled Kitchen Water on the Bioconversion of Kitchen Waste Treatment Residue by Black Soldier Fly Larvae

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Design

2.3. Measurement Indicators

2.4. Analytical Methods

2.4.1. Formulas Involved in the Experiment

2.4.2. Index Measurement Method

2.5. Data Processing

3. Results and Discussion

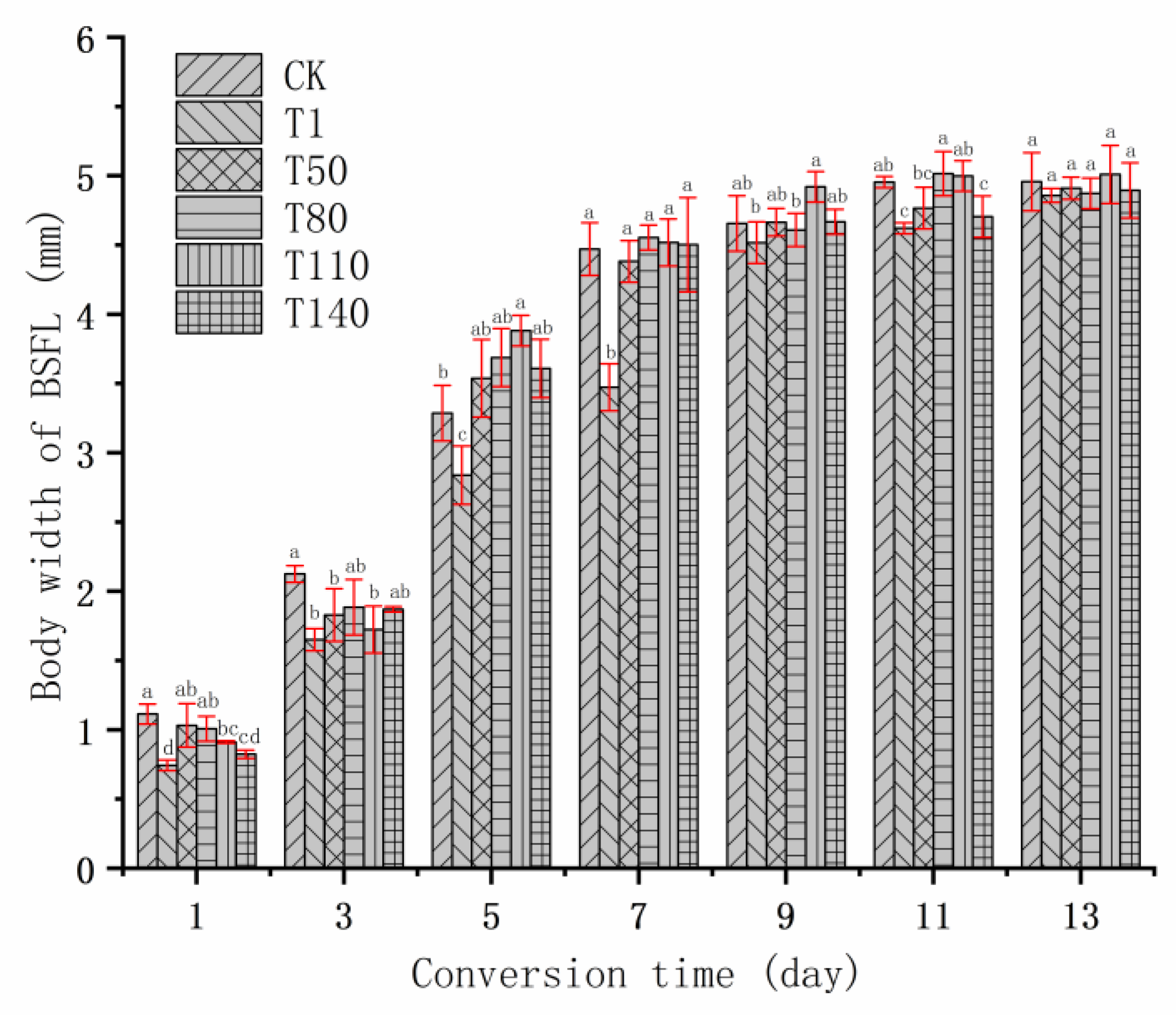

3.1. Effect of Adding DKW on Growth, Development and Body Composition of BSFL

3.2. The Effect of Adding DKW on the Nutrient Content of BR

3.3. The Effect of Adding DKW on the Bioconversion Effect of KWTR

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, H.Z.; Yue, S.Y.; Li, H.A.; Wang, Q.H.; Tu, M.B. Recovery of lactic acid and other organic acids from food waste ethanol fermentation stillage: Feasibility and effects of substrates. Sep. Purif. Technol. 2019, 209, 223–228. [Google Scholar] [CrossRef]

- Luo, L.W.; Wong, J.W.C. Enhanced food waste degradation in integrated two-phase anaerobic digestion: Effect of leachate recirculation ratio. Bioresour. Technol. 2019, 291, 121831. [Google Scholar] [CrossRef] [PubMed]

- FAO. Food Wastage Footprint Full-Cost Accounting; FAO, Food and Agricultural Organization of the United Nations: Rome, Italy, 2014. [Google Scholar]

- FAO. Food Wastage Footprint: Impacts on Natural Resources; FAO, Food and Agricultural Organization of the United Nations: Rome, Italy, 2013. [Google Scholar]

- Liang, J.R.; Yan, C.; Wang, D.Z.; Xiong, Y.W.; Zhou, L.X. A pilot study on bio-conversion of restaurant food waste by fly maggots and the related equipments. Environ. Eng. 2021, 39, 166–171. [Google Scholar] [CrossRef]

- Bing, J.Y.; Luo, E.H.; Jin, Y.Y.; Li, Y.Y.; Liu, D.D. Current Situation of Food Waste Recycling in China. Environ. Sci. Manag. 2018, 43, 39–43. [Google Scholar]

- Wang, S.J.; Xu, C.M.; Song, L.Y.; Zhang, J. Anaerobic Digestion of Food Waste and Its Microbial Consortia: A Historical Review and Future Perspectives. Int. J. Environ. Res. Public Health 2022, 19, 9519. [Google Scholar] [CrossRef]

- Peng, W.; Wang, Z.; Shu, Y.; Lü, F.; Zhang, H.; Shao, L.; He, P. Fate of a biobased polymer via high-solid anaerobic co-digestion with food waste and following aerobic treatment: Insights on changes of polymer physicochemical properties and the role of microbial and fungal communities. Bioresour. Technol. 2022, 343, 126079. [Google Scholar] [CrossRef]

- Cudjoe, D.; Zhu, B.; Wang, H. Towards the realization of sustainable development goals: Benefits of hydrogen from biogas using food waste in China. J. Clean. Prod. 2022, 360, 132161. [Google Scholar] [CrossRef]

- Meng, Q.C.; Liu, H.B.; Zhang, H.D.; Xu, S.Y.; Lichtfouse, E.; Yun, Y.B. Anaerobic digestion and recycling of kitchen waste: A review. Environ. Chem. Lett. 2022, 20, 1745–1762. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Wang, J.; Luo, Z.M. A Review: Recent Advances in Oily Wastewater Treatment. Recent Innov. Chem. Eng. 2015, 7, 17–24. [Google Scholar] [CrossRef]

- Grau, T.; Vilcinskas, A.; Joop, G. Sustainable farming of the mealwormTenebrio molitor for the production of food and feed. Zeitschrift für Naturforschung C 2017, 72, 337–349. [Google Scholar] [CrossRef]

- Kwon, O. Future prospects and development strategies of insect industry for food and feed in Korea. Entomol. Res. 2022, 52, 341–344. [Google Scholar] [CrossRef]

- Belluco, S.; Halloran, A.; Ricci, A. New protein sources and food legislation: The case of edible insects and EU law. Food Secur. 2017, 9, 803–814. [Google Scholar] [CrossRef]

- Kutty, S.; Yoong, L.S.; Khun, T.C. Growth performance, waste reduction and efficiency of conversion of digested food waste by Hermetia illucens larvae via bioconversion. J. Pure Appl. Microbiol. 2015, 9, 533–537. [Google Scholar]

- Bordiean, A.; Krzyżaniak, M.; Stolarski, M.J. Bioconversion Potential of Agro-Industrial Byproducts by Tenebrio molitor—Long-Term Results. Insects 2022, 13, 810. [Google Scholar] [CrossRef]

- van Zanten, H.H.E.; Mollenhorst, H.; Oonincx, D.G.A.B.; Bikker, P.; Meerburg, B.G.; de Boer, I.J.M. From environmental nuisance to environmental opportunity: Housefly larvae convert waste to livestock feed. J. Clean. Prod. 2015, 102, 362–369. [Google Scholar] [CrossRef]

- Callan, E. Hermetia illucens (L.) (Diptera, Stratiomyidae), a cosmopolitan American species long established in Australia and New Zealand. Entomol. Mon. Mag. 1974, 109, 232–234. [Google Scholar]

- Bradley, S.W.; Sheppard, D.C. House fly oviposition inhibition by larvae ofHermetia illucens, the black soldier fly. J. Chem. Ecol. 1984, 10, 853–859. [Google Scholar] [CrossRef]

- Beskin, K.V.; Holcomb, C.D.; Cammack, J.A.; Crippen, T.L.; Knap, A.H.; Sweet, S.T.; Tomberlin, J.K. Larval digestion of different manure types by the black soldier fly (Diptera: Stratiomyidae) impacts associated volatile emissions. Waste Manag. 2018, 74, 213–220. [Google Scholar] [CrossRef]

- Yang, Y.; Yan, H.; Zhao, Z.Y.; Chen, J.H.; Xin, A.G. Safety test of treating pigs killed by two kinds of epidemic diseases with black soldier flies. Swine Prod. 2016, 147, 85–86. [Google Scholar] [CrossRef]

- Hardouin, J.; Mahoux, G. Zootechnie d’Insectes-Elevage et Utilisation au Bénéfice de l’homme et de Certains Animaux; Bureau pour l’Echange et la Distribution de l’Information sur le Mini-élevage (BEDIM) 45 bis avenue de la Belle Gabrielle: Nogent sur Marne Cedex, France, 2003; 164p. [Google Scholar]

- Singh, A.; Srikanth, B.H.; Kumari, K. Determining the Black Soldier fly larvae performance for plant-based food waste reduction and the effect on Biomass yield. Waste Manag. 2021, 130, 147–154. [Google Scholar] [CrossRef]

- Somroo, A.A.; Ur Rehman, K.; Zheng, L.; Cai, M.; Xiao, X.; Hu, S.; Mathys, A.; Gold, M.; Yu, Z.; Zhang, J. Influence of Lactobacillus buchneri on soybean curd residue co-conversion by black soldier fly larvae (Hermetia illucens) for food and feedstock production. Waste Manag. 2019, 86, 114–122. [Google Scholar] [CrossRef] [PubMed]

- Klüber, P.; Müller, S.; Schmidt, J.; Zorn, H.; Rühl, M. Isolation of Bacterial and Fungal Microbiota Associated with Hermetia illucens Larvae Reveals Novel Insights into Entomopathogenicity. Microorganisms 2022, 10, 319. [Google Scholar] [CrossRef] [PubMed]

- Harnden, L.M.; Tomberlin, J.K. Effects of temperature and diet on black soldier fly, Hermetia illucens (L.) (Diptera: Stratiomyidae), development. Forensic Sci. Int. 2016, 266, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Ratti, S.; Zarantoniello, M.; Chemello, G.; Giammarino, M.; Palermo, F.A.; Cocci, P.; Mosconi, G.; Tignani, M.V.; Pascon, G.; Cardinaletti, G.; et al. Spirulina-enriched Substrate to Rear Black Soldier Fly (Hermetia illucens) Prepupae as Alternative Aquafeed Ingredient for Rainbow Trout (Oncorhynchus mykiss) Diets: Possible Effects on Zootechnical Performances, Gut and Liver Health Status, and Fillet Quality. Animals 2023, 13, 173. [Google Scholar] [CrossRef] [PubMed]

- Finke, M.D. Estimate of chitin in raw whole insects. Zoo Biol. 2007, 26, 105–115. [Google Scholar] [CrossRef]

- ISO 6492:1999; Animal Feeding Stuffs: Determination of Fat Content. ISO: Geneva, Switzerland, 1999.

- Halligan, J.E. Determination of Crude Fiber. J. Am. Chem. Soc. 1907, 29, 1515–1516. [Google Scholar] [CrossRef] [Green Version]

- John, J.L.S. Report on Ash. J. Aoac. Int. 1943, 26, 220–226. [Google Scholar] [CrossRef]

- Walldey, A.; Black, I.A. Estimation of soil organic carbon by the chromic acid titration method. Soil Sci. 1934, 47, 29–38. [Google Scholar]

- ISO 7485:2000; Animal Feeding Stuffs-Determination of Potassium and Sodium Contents-Methods Using Flame-Emission Spectrometry. ISO: Geneva, Switzerland, 2000.

- ISO 6496:1999; Animal and Vegetable Fats and Oils—Determination of Moisture and Volatile Matter Content. ISO: Geneva, Switzerland, 1999.

- Block, J. Interference of the ammoniiun ion in Mohr’s method for the determination of chloride. Talanta 1967, 14, 1130–1131. [Google Scholar] [CrossRef]

- Russell, C.; Wessnitzer, J.; Young, J.M.; Armstrong, J.D.; Webb, B. Dietary Salt Levels Affect Salt Preference and Learning in Larval Drosophila. PLoS ONE 2011, 6, e20100. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.L.; Jin, W.Z.; Tao, X.H.; Zhang, Q.; Zhu, J.; Feng, S.Y.; Xu, X.H.; Li, H.Y.; Wang, Z.H.; Zhang, Z.J. Black soldier fly larvae (Hermetia illucens) strengthen the metabolic function of food waste biodegradation by gut microbiome. Microb. Biotechnol. 2019, 12, 528–543. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abraham, M.; Kurien, E.K.; Bhindhu, P.S.; Gilsha Bai, E.B. Suitability of Kitchen Waste Water in Agriculture. Int. J. Econ. Plants 2018, 5, 181–183. [Google Scholar] [CrossRef]

- Makkar, H.P.S.; Tran, G.; Heuzé, V.; Ankers, P. State-of-the-art on use of insects as animal feed. Anim. Feed Sci. Technol. 2014, 197, 1–33. [Google Scholar] [CrossRef]

- Wu, N.; Wang, X.; Mao, Z.; Liang, J.; Liu, X.; Xu, X. Bioconversion of chicken meat and bone meal by black soldier fly larvae: Effects of straw addition on the quality and microbial profile of larval frass. J. Environ. Manag. 2022, 307, 114579. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Hou, Y.; Li, W.; Yang, S.; Li, Q.; Yu, Z. Biodiesel production from rice straw and restaurant waste employing black soldier fly assisted by microbes. Energy 2012, 47, 225–229. [Google Scholar] [CrossRef]

- Liu, K. Effects of sample size, dry ashing temperature and duration on determination of ash content in algae and other biomass. Algal Res. 2019, 40, 101486. [Google Scholar] [CrossRef]

- Liu, X.Y. Study on Characteristics and Anaerobic Digestion Digestion Performance of Kitchen Waste. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2011. [Google Scholar]

- Wang, J.F.; Wang, B.F.; Zhang, C.X.; Nie, L.H. Preparation of Nano-SiO2 Modified PA66 Microfiltration Membrane and Treatment of Oily Wastewater. J. Phys. Conf. Ser. 2022, 2324, 12010. [Google Scholar] [CrossRef]

- Napitupulu, A.M.M.; Suhendra, L.; Gunam, I.B.W. Effect of Saccharomyces cerevisiae ATCC 9763 concentration and fermentation time on bioethanol content from corn stover crude cellulose substrate. IOP Conf. Ser. Earth Environ. Sci. 2021, 913, 12026. [Google Scholar] [CrossRef]

- Zhou, Y.H. Determination of crude fiber content in 6 common vegetables. Contemp. Hortic. 2019, 373, 13–14. [Google Scholar] [CrossRef]

- Taiwo, A.E.; Tom-James, A.; Falowo, O.A.; Okoji, A.; Adeyi, O.; Olalere, A.O.; Eloka-Eboka, A. Techno-economic analysis of Cellulase Production by Trichoderma reesei in Submerged Fermentation Processes using a Process Simulator. S. Afr. J. Chem. Eng. 2022, 42, 98–105. [Google Scholar] [CrossRef]

- Borkent, S.; Hodge, S. Glasshouse Evaluation of the Black Soldier Fly Waste Product HexaFrass™ as an Organic Fertilizer. Insects 2021, 12, 977. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Awasthi, S.K.; Qin, S.Y.; Liu, H.; Awasthi, M.K.; Zhou, Y.; Jiao, M.; Pandey, A.; Varjani, S.; Zhang, Z. Conversion food waste and sawdust into compost employing black soldier fly larvae (diptera: Stratiomyidae) under the optimized condition. Chemosphere 2021, 272, 129931. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Selvam, A.; Lai, K.M.; Wong, J.W.C. Critical evaluation of post-consumption food waste composting employing thermophilic bacterial consortium. Bioresour. Technol. 2017, 245, 665–672. [Google Scholar] [CrossRef] [PubMed]

- Bertinetti, C.; Samayoa, A.C.; Hwang, S. Effects of Feeding Adults ofHermetia illucens (Diptera: Stratiomyidae) on Longevity, Oviposition, and Egg Hatchability: Insights Into Optimizing Egg Production. J. Insect Sci. 2019, 19. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bosch, G.; van Zanten, H.H.E.; Zamprogna, A.; Veenenbos, M.; Meijer, N.P.; van der Fels-Klerx, H.J.; van Loon, J.J.A. Conversion of organic resources by black soldier fly larvae: Legislation, efficiency and environmental impact. J. Clean. Prod. 2019, 222, 355–363. [Google Scholar] [CrossRef]

- Wen, M.; Zhang, J.; Zheng, Y.; Yi, S. Effects of Combined Potassium and Organic Fertilizer Application on Newhall Navel Orange Nutrient Uptake, Yield, and Quality. Agronomy 2021, 11, 1990. [Google Scholar] [CrossRef]

- Yang, X.; Wang, D.M.; Mai, L.W. Growth and development and utilizing transformation characteristics with diet under different moisture content of black soldier fly (Hermetia illucens). J. Environ. Entomol. 2020, 42, 1183–1190. [Google Scholar]

- Li, M.Q.; Chen, L.J. Analysis of composition in kitchen waste fermentation wastewater. Chin. J. Environ. Eng. 2016, 10, 683–688. [Google Scholar]

- Kozlov, A.N.; Shamansky, V.A.; Donskoy, I.G.; Penzik, M.V.; Keiko, A.V. A DSC signal for studying kinetics of moisture evaporation from lignocellulosic fuels. Thermochim. Acta 2021, 698, 178887. [Google Scholar] [CrossRef]

| Items | Content |

|---|---|

| Moisture | 74.29% |

| pH | 3.92 |

| Crude protein | 20.83% |

| Ether extract | 18.30% |

| Salinity | 1.54% |

| Oil | 0.57% |

| Items | Content |

|---|---|

| pH | 3.79 |

| NH3-N | 42.76 mg/L |

| Total suspended solids | 8331.84 mg/L |

| Salinity | 2.85% |

| Organic matter | 5350.47 mg/L |

| Oil | 0.24% |

| Item | CK | T1 | T50 | T80 | T110 | T140 |

|---|---|---|---|---|---|---|

| ADWG/(g/d) | 79.74 ± 1.70 c | 74.81 ± 0.62 d | 76.14 ± 0.43 d | 82.18 ± 0.02 b | 87.21 ± 1.38 a | 79.23 ± 0.96 c |

| Output (wet basis)/(g) | 1036.63 ± 22.06 b | 972.59 ± 8.00 a | 989.85 ± 5.54 a | 1068.36 ± 0.29 c | 1133.74 ± 17.91 d | 1030.03 ± 12.50 b |

| Output (dry basis)/(g) | 191.53 ± 1.19 c | 169.87 ± 2.85 d | 200.50 ± 6.93 c | 229.20 ± 7.01 b | 248.03 ± 6.51 a | 200.90 ± 9.69 c |

| Item/% | CK | T1 | T50 | T80 | T110 | T140 |

|---|---|---|---|---|---|---|

| CP | 41.32 ± 1.78 bc | 33.24 ± 1.22 a | 39.55 ± 1.50 b | 44.26 ± 0.78 cd | 44.86 ± 0.49 d | 43.98 ± 1.57 cd |

| EE | 32.89 ± 0.77 a | 32.38 ± 0.53 a | 29.16 ± 0.65 c | 30.30 ± 0.83 bc | 33.63 ± 0.32 a | 30.69 ± 0.24 b |

| CA | 26.84 ± 0.58 a | 23.67 ± 0.43 b | 23.05 ± 1.29 bc | 21.99 ± 0.10 c | 19.99 ± 0.25 d | 22.55 ± 0.49 bc |

| SAL | 1.74 ± 0.042 d | 2.43 ± 0.037 c | 2.57 ± 0.023 c | 2.57 ± 0.006 bc | 2.72 ± 0.033 b | 2.94 ± 0.046 a |

| TP | 0.87 ± 0.05 a | 0.89 ± 0.02 ab | 0.91 ± 0.01 ab | 0.94 ± 0.01 ab | 0.94 ± 0.01 b | 0.88 ± 0.00 a |

| Ca | 4.51 ± 0.16 a | 4.61 ± 0.24 a | 4.81 ± 0.12 a | 4.66 ± 0.02 a | 4.67 ± 0.1 a | 4.76 ± 0.64 a |

| DM | 18.47 ± 0.49 cd | 17.47 ± 0.46 d | 20.26 ± 0.22 ab | 21.45 ± 0.82 a | 21.88 ± 0.50 a | 19.50 ± 0.47 bc |

| Item | CK | T1 | T50 | T80 | T110 | T140 |

|---|---|---|---|---|---|---|

| CP/% | 24.25 ± 0.81 c | 25.82 ± 0.91 bc | 27.22 ± 0.46 ab | 26.09 ± 0.98 bc | 25.84 ± 1.18 bc | 28.81 ± 1.30 a |

| EE/% | 20.23 ± 1.23 b | 23.30 ± 0.37 a | 23.03 ± 0.61 a | 24.67 ± 0.60 a | 23.10 ± 1.09 a | 23.86 ± 1.11 a |

| CF/% | 28.50 ± 2.57 b | 23.60 ± 0.91 a | 22.77 ± 1.50 a | 21.75 ± 1.78 a | 22.07 ± 2.40 a | 23.03 ± 1.73 a |

| OM/% | 69.40 ± 2.05 c | 71.27 ± 1.27 c | 72.53 ± 0.90 bc | 72.98 ± 0.50 ab | 73.40 ± 0.61 ab | 74.54 ± 2.33 a |

| pH | 6.77 ± 0.06 a | 6.95 ± 0.12 a | 6.89 ± 0.02 a | 6.82 ± 0.15 a | 6.91 ± 0.01 a | 6.80 ± 0.36 a |

| TN/% | 3.88 ± 0.13 c | 4.13 ± 0.15 bc | 4.36 ± 0.07 ab | 4.17 ± 0.16 bc | 4.13 ± 0.19 bc | 4.61 ± 0.21 a |

| TP/% | 1.13 ± 0.05 d | 1.14 ± 0.04 d | 1.22 ± 0.03 d | 1.47 ± 0.11 c | 1.69 ± 0.06 b | 1.88 ± 0.03 a |

| TK/% | 0.20 ± 0.010 d | 0.22 ± 0.016 d | 0.31 ± 0.004 c | 0.37 ± 0.011 c | 0.51 ± 0.035 b | 0.72 ± 0.056 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Yang, C.; Peng, Y.; Liu, T.; Wang, Z.; Xiong, C. Effect of Adding De-Oiled Kitchen Water on the Bioconversion of Kitchen Waste Treatment Residue by Black Soldier Fly Larvae. Int. J. Environ. Res. Public Health 2023, 20, 2577. https://doi.org/10.3390/ijerph20032577

He Z, Yang C, Peng Y, Liu T, Wang Z, Xiong C. Effect of Adding De-Oiled Kitchen Water on the Bioconversion of Kitchen Waste Treatment Residue by Black Soldier Fly Larvae. International Journal of Environmental Research and Public Health. 2023; 20(3):2577. https://doi.org/10.3390/ijerph20032577

Chicago/Turabian StyleHe, Zhuojun, Cheng Yang, Yan Peng, Taoze Liu, Zhanghong Wang, and Chengcai Xiong. 2023. "Effect of Adding De-Oiled Kitchen Water on the Bioconversion of Kitchen Waste Treatment Residue by Black Soldier Fly Larvae" International Journal of Environmental Research and Public Health 20, no. 3: 2577. https://doi.org/10.3390/ijerph20032577