Characterization of Three Types of Recycled Aggregates from Different Construction and Demolition Waste: An Experimental Study for Waste Management

Abstract

1. Introduction

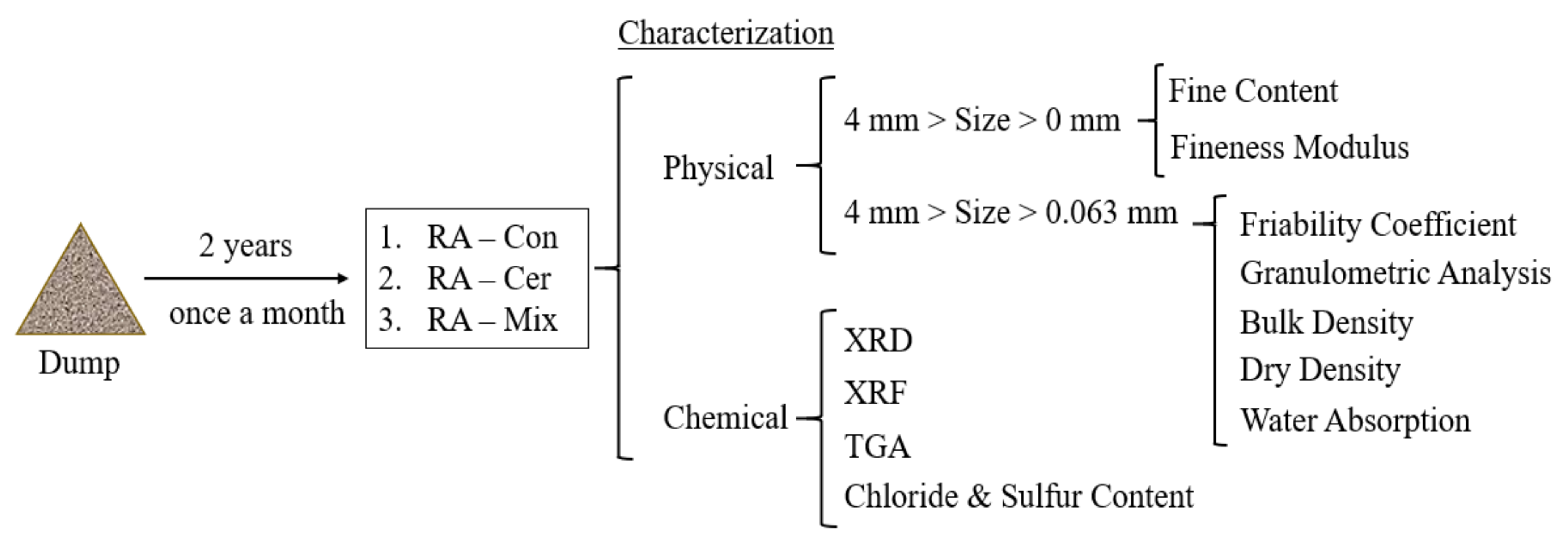

2. Methodology

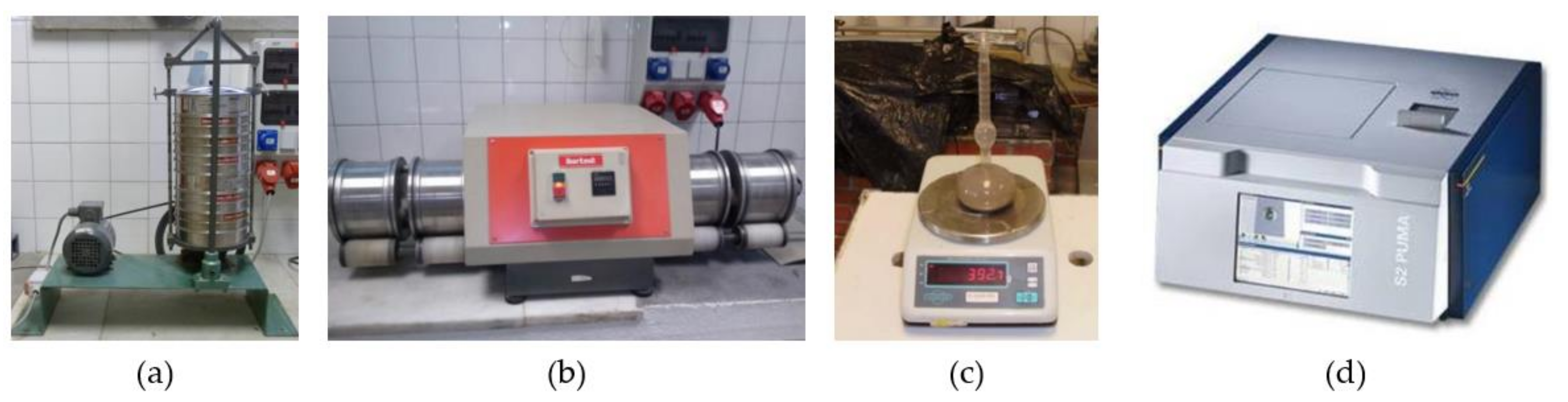

2.1. Physical Characterization

2.2. Chemical Characterization

3. Analysis of Results

3.1. Study of the Physical Properties of Recycled Aggregates

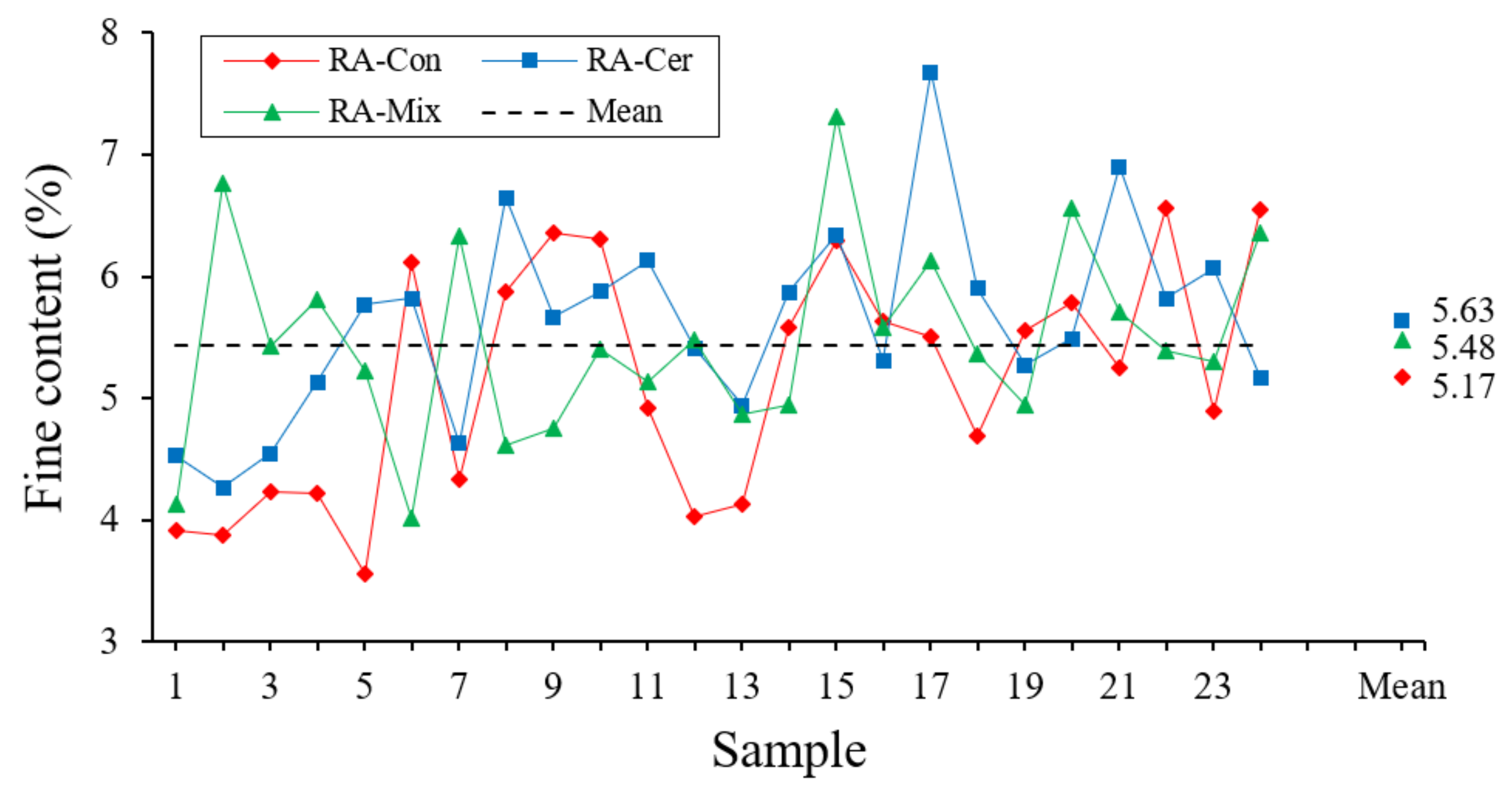

3.1.1. Fine Content

3.1.2. Fineness Modulus

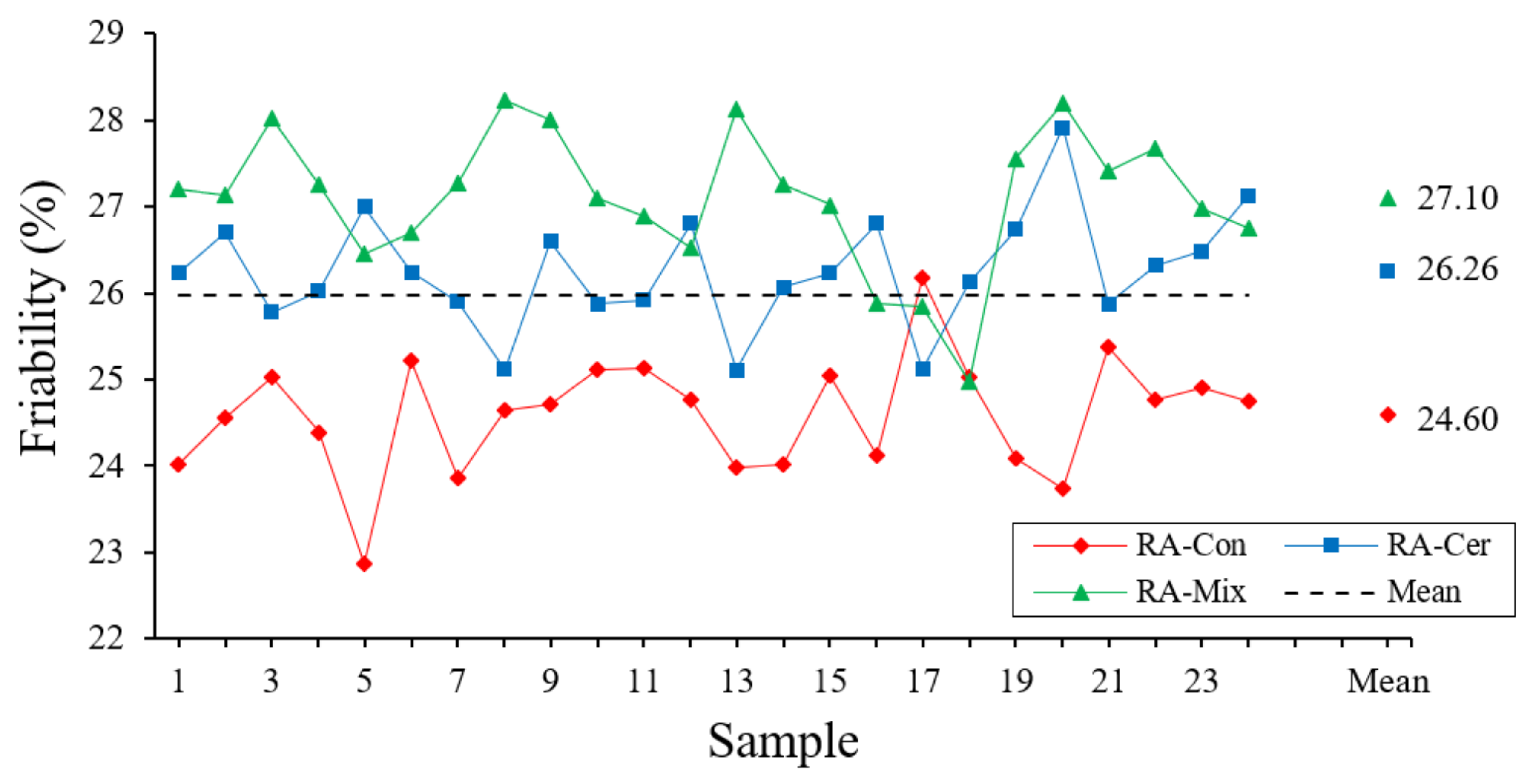

3.1.3. Friability Coefficient

3.1.4. Set Density

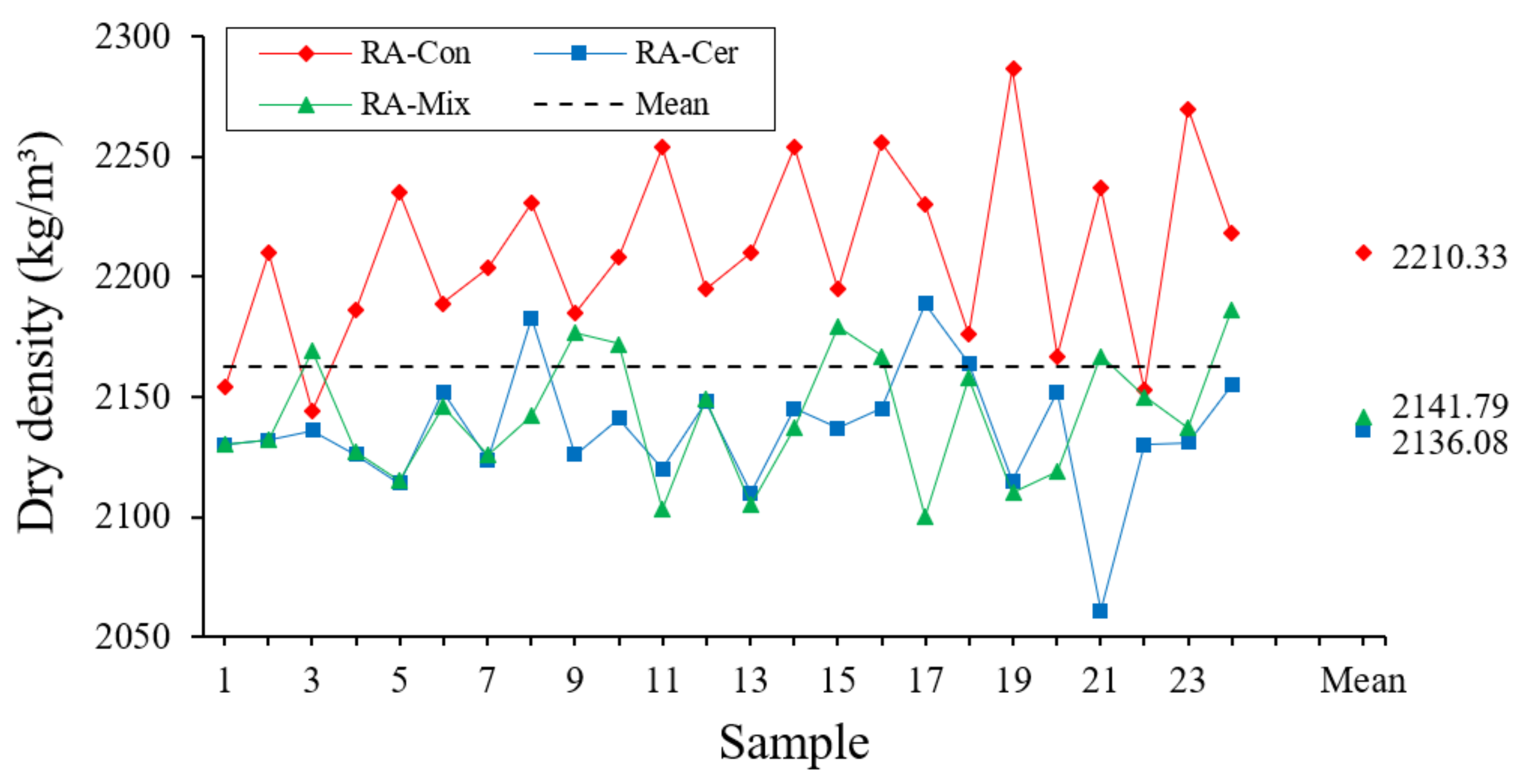

3.1.5. Relative Density

3.1.6. Water Absorption

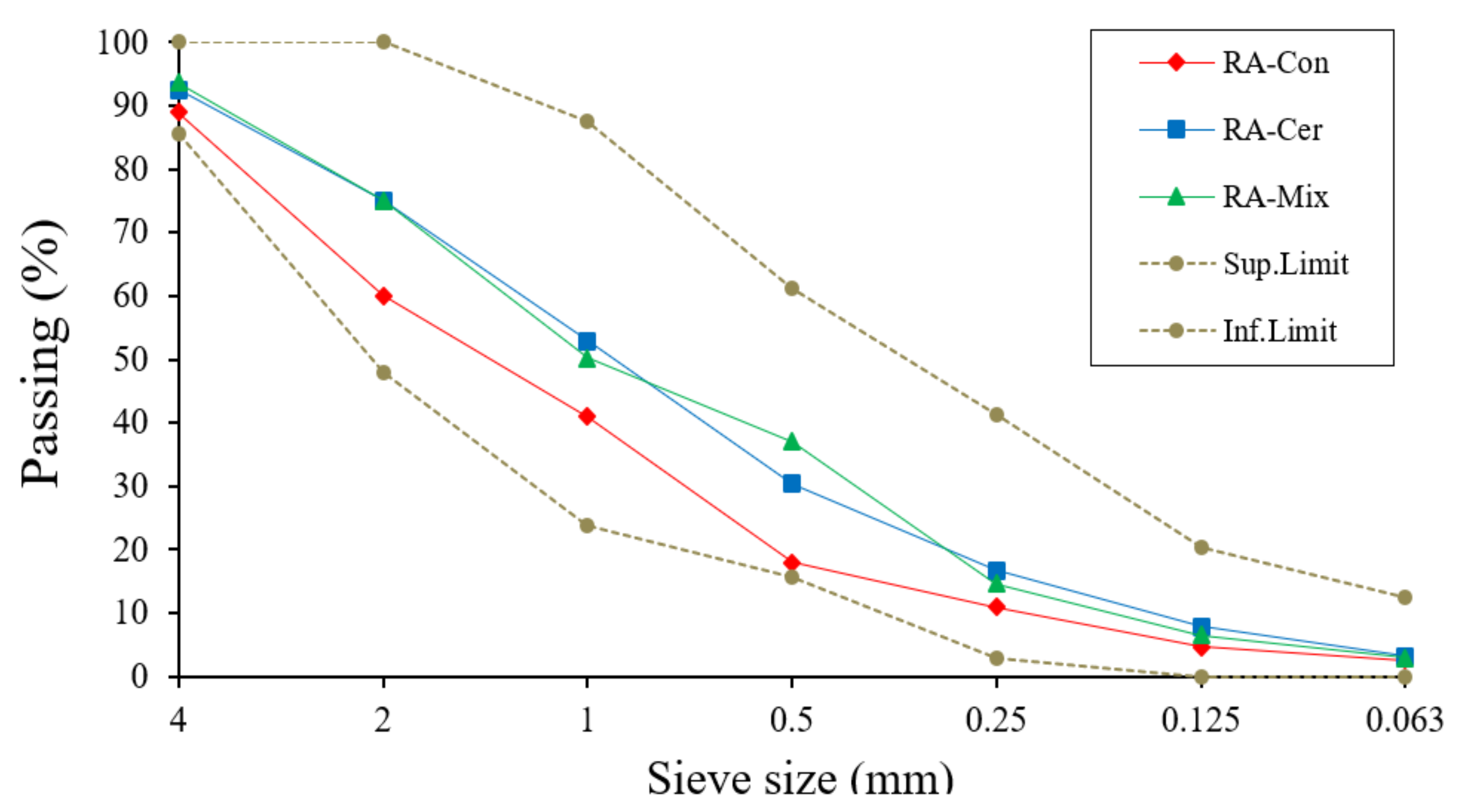

3.1.7. Granulometric Analysis

3.2. Chemical Characterization of Recycled Aggregates

3.2.1. X-ray Diffraction

3.2.2. Thermogravimetric Analysis (TGA)

3.2.3. X-ray Fluorescence

3.2.4. Chloride and Total Sulfur Content

4. Discussion

- It has been possible to corroborate that a high content of fines is produced during the process of elaboration of recycled aggregates, and, as these aggregates reach a high modulus of fineness. Regarding the performed statistical analysis, it can be observed that there are no significant differences in terms of the content in fines for three types of recycled aggregates. The fineness modulus of the RA–Mix presents significantly higher values for this property compared to the rest of tested aggregates at 99.7% confidence.

- The coefficient of friability of the aggregates is also impaired because of the recycling process. Once the statistical analysis has been conducted, it has been observed that there are significant differences for three types of analyzed aggregates, being the recycled concrete aggregate the one that shows the best properties.

- Regarding the relative density and overall density values obtained, it has been possible to verify that RA–Con has obtained significantly higher values compared to the other two recycled aggregates. These higher density values make it the optimal aggregate for the preparation of masonry mortars and concrete if higher mechanical resistance is to be achieved.

- Regarding the water absorption, all the aggregates have presented statistically significant differences, being the RA–Cer the recycled aggregate that has presented a higher percentage for this property, and the RA–Con is one which shows the lowest values. However, despite their high absorption, these recycled aggregates can be used as raw material for the manufacture of mortars and concrete.

- Lastly, it has been verified that three types of recycled aggregates used in this research present a continuous granulometry within the limits established by the reference regulations for the preparation of masonry mortars. This continuous granulometry favors the workability of the binder material mixture and has a positive effect on its mechanical properties.

- From the analysis of X-ray diffraction for three types of recycled aggregates, it has been observed that the predominant crystalline phases are quartz and calcite, as they have higher relative abundance. Although other secondary crystalline phases such as albite, sanidine, phlogopite, gypsum, and baseite have been found.

- Regarding the thermogravimetric analysis, it has been observed that the content of calcite and gypsum compounds is higher in the aggregate samples from ceramic waste. These results show that RA–Cer is the least suitable recycled aggregate for the fabrication of structural concretes.

- With the quantitative and qualitative analysis of the composition of the aggregates conducted by employing X-ray fluorescence, it has been possible to verify that these recycled aggregates are mainly composed of calcium and aluminum silicates.

- Finally, the content of water-soluble chlorides and total sulfur presented percentages are lower than 0.06% and 1%, respectively, values set as maximum admissible in construction aggregates.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bontempi, E.; Sorrentino, G.P.; Zanoletti, A.; Alessandri, I.; Depero, L.E.; Caneschi, A. Sustainable Materials and their Contribution to the Sustainable Development Goals (SDGs): A Critical Review Based on an Italian Example. Molecules 2021, 26, 1407. [Google Scholar] [CrossRef]

- Walsh, P.P.; Murphy, E.; Horan, D. The role of science, technology and innovation in the UN 2030 agenda. Technol. Forecast. Soc. Change 2020, 154, 119957. [Google Scholar] [CrossRef]

- Bao, Z.; Lu, W. Developing efficient circularity for construction and demolition waste management in fast emerging economies: Lessons learned from Shenzhen, China. Sci. Total Environ. 2020, 724, 138–264. [Google Scholar] [CrossRef]

- Del Rio, M.; Villoria, P.; Longobardi, L.; Santa Cruz, J.; Porras, C. Redesigning lightweight gypsum with mixes of polystyrene waste from construction and demolition waste. J. Clean. Prod. 2019, 220, 144–151. [Google Scholar] [CrossRef]

- Uzzal, M.; Thomas, S. Influence of waste materials on buildings’ life cycle environmental impacts: Adopting resource recovery principle. Resour. Conserv. Recycl. 2019, 142, 10–23. [Google Scholar]

- Villoria, P. Sistema de Gestión de Residuos de Construcción y Demolición en obras de Edificación Residencia. Buenas Prácticas en la Ejecución de obra. Ph.D. Thesis, Escuela Técnica Superior de Edificación, Universidad Politécnica de Madrid, Madrid, Spain, 2014. [Google Scholar]

- Eurostat. Recovery Rate of Construction and Demolition Waste (Code: CEI_WM040); Eurostat: Brussels, Belgium, 2020. [Google Scholar]

- Bao, Z.; Lu, W.; Chi, B.; Yuan, H.; Hao, J. Procurement innovation for a circular economy of construction and demolition waste: Lessons learnt from Suzhou, China. J. Waste Manag. 2019, 99, 12–21. [Google Scholar] [CrossRef]

- Saiz, P.; González, M.; Fernández, F.; Rodríguez, A. Comparative study of three types of fine recycled aggregates from construction and demolition waste (CDW), and their use in masonry mortar fabrication. J. Clean. Prod. 2016, 118, 162–169. [Google Scholar] [CrossRef]

- Blengini, G.A.; Garbarino, E. Resources and waste management in Turin (Italy): The role of recycled aggregates in the sustainable supply mix. J. Clean. Prod. 2010, 18, 1021–1030. [Google Scholar] [CrossRef]

- Ma, M.; Tam, V.W.Y.; Le, K.N.; Li, W. Challenges in current construction and demolition waste recycling: A China study. J. Waste Manag. 2020, 118, 610–625. [Google Scholar] [CrossRef]

- Zanelotti, A.; Cornelio, A.; Bontempi, E. A post-pandemic sustainable scenario: What actions can be pursued to increase the raw materials availability? Environ. Res. 2021, 202, 111–681. [Google Scholar] [CrossRef]

- Vegas, I.; Ibáñez, J.A.; Lisbona, A.; Sáez de Cortázar, A.; Frías, M. Pre-normative research on the use of mixed recycled aggregates in unbound road sections. Constr. Build Mater. 2011, 25, 2674–2682. [Google Scholar] [CrossRef]

- Rodríguez, C.; Parra, C.; Casado, G.; Miñano, I.; Albaladejo, F.; Benito, F.; Sánchez, I. The incorporation of construction and demolition wastes as recycled mixed aggregates in non-structural concrete precast pieces. J. Clean. Prod. 2016, 127, 152–161. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, L.; Li, F.; Peng, J. Recycled aggregates from construction and demolition wastes as alternative filling materials for highway subgrades in China. J. Clean. Prod. 2020, 255, 120–223. [Google Scholar] [CrossRef]

- Khoury, E.; Ambrós, W.; Cazacliu, B.; Hoffman, C.; Remond, S. Heterogeneity of recycled concrete aggregates, an intrinsic variability. Constr. Build Mater. 2018, 175, 705–713. [Google Scholar] [CrossRef]

- Raman, J.V.M.; Ramasamy, V. Various treatment techniques involved to enhance the recycled coarse aggregate in concrete: A review. Mater. Today Proc. 2021, 45, 6356–6363. [Google Scholar] [CrossRef]

- Lam, P.; Yu, A.; Wu, Z.; Su Poon, C. Methodology for upstream estimation of construction waste for new building projects. J. Clean. Prod. 2019, 230, 1003–1012. [Google Scholar] [CrossRef]

- Sánchez de Juan, M. Estudio Sobre la Utilización de Árido Reciclado Para la Fabricación de Hormigón Estructural. Ph.D. Thesis, Escuela Técnica Superior de Ingenieros de Caminos, Canales y Puertos, Universidad Politécnica de Madrid, Madrid, Spain, 2007. [Google Scholar]

- Seo, D.S.; Choi, H.B. Effects of the old cement mortar attached to the recycled aggregate surface on the bond characteristics between aggregate and cement mortar. Constr. Build Mater. 2014, 59, 72–77. [Google Scholar] [CrossRef]

- Pin Verian, K.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Chaitanya, M.; Ramakrishna, G. Enhancing the mechanical properties of pervious recycled aggregate concrete using silicafumes. Mater. Today Proc. 2021, 46, 634–637. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Wang, K.; Tam, C.M. Assessing relationships among properties of demolished concrete, recycled aggregate and recycled aggregate concrete using regression analysis. J. Hazard. Mater. 2008, 152, 703–704. [Google Scholar] [CrossRef]

- De Rossi, A.; Ribeiro, M.J.; Labrincha, J.A.; Novais, R.M.; Hotza, D.; Moreira, R.F. Effect of the particle size range of construction and demolition waste on the fresh and hardened-state properties of fly ash-based geopolymer mortars with total replacement of sand. Process. Saf. Environ. Prot. 2019, 129, 130–137. [Google Scholar] [CrossRef]

- Spanish Ministry of Public Works. Instrucción de Hormigón Estructural EHE-08 (Spanish Structural Concrete Code). BOE 2008, 203, 258e66. [Google Scholar]

- Gómez, J.M.; Agulló, L.; Vázquez, E. Relationship between porosity and concrete properties with natural aggregate replacement by recycled concrete aggregate. In Proceedings of the Second International Conference on Engineering Materials, 16–19 August 2001; pp. 147–156. [Google Scholar]

- Rodríguez-Robles, D.; García-González, J.; Juan-Valdés, A.; Pozo, J.M.M.D.; Guerra-Romero, M.I. Quality assessment of mixed and ceramic recycled aggregates from construction and demolition wastes in the concrete manufacture according to the Spanish standard. Materials 2014, 7, 5843–5857. [Google Scholar] [CrossRef]

- Agrela, F.; De Juan, M.S.; Ayuso, J.; Geraldes, V.L.; Jiménez, J.R. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Barra, M. Estudio de la Durabilidad del Hormigón de árido Reciclado en su Aplicación como Hormigón Estructural. Ph.D. Thesis, Universidad Técnica de Cataluña, Barcelona, Spain, 1996. [Google Scholar]

- Wang, B.; Yang, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105–565. [Google Scholar] [CrossRef]

- Zhan, B.; Xuan, D.; Zeng, W.; Sun Poon, C. Carbonation treatment of recycled concrete aggregate: Effect on transport properties and steel corrosion of recycled aggregate concrete. Cem. Concr. Res. 2019, 104, 103–360. [Google Scholar] [CrossRef]

- Sánchez, M.; Alaejos, P. Estudio Sobre las Propiedades del Árido Reciclado—Utilización en Hormigón Estructural; CEDEX—Ministerio de Fomento: Madrid, Spain, 2006. [Google Scholar]

- Asociación Española de Gestores de RCD, GEAR. Guía Española de Áridos Reciclados Procedentes de Residuos de Construcción y Demolición (RCD); Asociación Española de Gestores de RCD: Madrid, Spain, 2012. [Google Scholar]

- Guía práctica. Gestión de los residuos de construcción y demolición (RCDs). Consejería de Medio Ambiente, Gobierno de Cantabria. 2010. Available online: https://asociacionversos.org/wp-content/uploads/2021/08/Guia-Practica-de-Gestion-de-los-RCD-en-Cantabria.pdf (accessed on 17 February 2023).

- Saiz, P.; González, M.; Fernández, M. Characterization and influence of fine recycled aggregates on masonry mortars properties. Mater. Constr. 2015, 65, 319. [Google Scholar]

- Li, Z.; Liu, J.; Tian, Q. Method for controlling the absorbed water content of recycled fine aggregates by centrifugation. Constr Build Mater. 2018, 160, 316–325. [Google Scholar] [CrossRef]

- Kaarthik, M.; Maruthachalam, D. A sustainable approach of characteristic strength of concrete using recycled fine aggregate. Mater. Today: Proc. 2021, 45, 6377–6380. [Google Scholar] [CrossRef]

- Sáiz, P. Utilización de Arenas Procedentes de RESIDUOS de Construcción y Demolición, RCD, en la Fabricación de Morteros de Albañilería. Ph.D. Thesis, Escuela Técnica Superior de Edificación, Universidad Politécnica de Madrid, Madrid, Spain, 2016. [Google Scholar]

- Peña, D. Regresión y Diseño de Experimentos; Alianza Editorial: Madrid, Spain, 2010; ISBN 9788420693897. [Google Scholar]

- Rodrigues, F.; Carvalho, M.T.; Evangelista, L.; de Brito, J. Physical–chemical and mineralogical characterization of fine aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2013, 52, 438–445. [Google Scholar] [CrossRef]

- UNE-EN 933-1:2012; Tests for Geometrical Properties Of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. UNE: Madrid, Spain, 2012.

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Manso, J.M. Effect of fine recycled concrete aggregate on the mechanical behavior of self-compacting concrete. Constr. Build. Mater. 2020, 263, 120–671. [Google Scholar] [CrossRef]

- Chinzorigt, G.; Kwan, M.; Yu, M.; Lee, H.; Enkbold, O.; Choi, D. Strength, shrinkage and creep and durability aspects of concrete including CO2 treated recycled fine aggregate. Cem. Concr. Res. 2020, 136, 106062. [Google Scholar] [CrossRef]

- UNE-EN 13139: 2003; Aggregates for Mortar. Aenor International: Madrid, Spain, 1999.

- Sabih, G.; Tarefder, R.A.; Jamil, S.M. Optimization of Gradation and Fineness Modulus of Naturally Fine Sands for Improved Performance as Fine Aggregate in Concrete. Procedia Eng. 2016, 145, 66–73. [Google Scholar] [CrossRef]

- UNE 146404:2018; Aggregates for Concrete: Determination of the Coefficient of Friability of the Sands. UNE: Madrid, Spain, 2018.

- González-Ortega, M.A.; Cavalaro, S.H.P.; Aguado, A. Influence of barite aggregate friability on mixing process and mechanical properties of concrete. Constr. Build. Mater. 2015, 74, 169–175. [Google Scholar] [CrossRef]

- Morón, A.; Ferrández, D.; Saiz, P.; Vega, G.; Morón, C. Influence of Recycled Aggregates on the Mechanical Properties of Synthetic Fibers-Reinforced Masonry Mortars. Infrastructures 2021, 6, 84. [Google Scholar] [CrossRef]

- UNE 83115:1989 EX; Aggregates for Concrete: Determination of the Coefficient of Friability of the Sands. UNE: Madrid, Spain, 1989.

- UNE-EN 1097-3: 1999; Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids. UNE: Madrid, Spain, 1999.

- Ferrández, D.; Saiz, P.; Morón, C.; Díaz, J.P. Estudio del comportamiento de los morteros reciclados frente al ruido de impacto. Inf. Construcción 2019, 71, e292. [Google Scholar] [CrossRef]

- UNE-EN 1097-6:2014; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of particle density and Water Absorption. UNE: Madrid, Spain, 2014.

- Liu, Q.; Singh, A.; Xiao, J.; Li, B.; WY Tam, V. Workability and mechanical properties of mortar containing recycled sandfrom aerated concrete blocks and sintered clay bricks. Resour. Conserv. Recycl. 2020, 157, 104–728. [Google Scholar] [CrossRef]

- Park, W.J.; Noguchi, T.; Shin, S.H.; Oh, D.Y. Modulus of elasticity of recycled aggregate concrete. Mag. Concr. Res. 2015, 67, 585–591. [Google Scholar] [CrossRef]

- Bustos García, A. Morteros con Propiedades Mejoradas de Ductilidad por Adición de Fibras de Vidrio, Carbono y Basalto. Ph.D. Thesis, Escuela Técnica Superior de Edificación UPM, Madrid, Spain, 2019. [Google Scholar]

- Morón, C.; Ferrández, D.; Saiz, P.; Yedra, E. Measuring system of capillary rising damp in cement mortars. Measurement 2019, 135, 252–259. [Google Scholar] [CrossRef]

- Saiz, P.; Fernández, D.; Morón, C.; Martínez, F. Behavior of masonry mortars fabricated with recycled aggregate towards moisture. DYNA 2019, 94, 442–446. [Google Scholar]

- Robalo, K.; Costa, H.; do Carmo, R.; Julio, E. Experimental development of low cement content and recycled construction and demolition waste aggregates concrete. Constr. Build. Mater. 2020, 273, 121680. [Google Scholar] [CrossRef]

- Kim, J. Properties of recycled aggregate concrete designed with equivalent mortar volume mix design. Constr. Build. Mater. 2021, 301, 124091. [Google Scholar] [CrossRef]

- Bontempi, E. A new approach for evaluating the sustainability of raw materials substitution based on embodied energy and the CO2 footprint. J. Clean. Prod. 2017, 162, 162–169. [Google Scholar] [CrossRef]

- Angelin, A.F.; Miranda, E.J.P., Jr.; Dos Santos, J.M.C.; Lintz, R.C.C.; Gachet-Barbosa, L.A. Rubberized mortar: The influence of aggregate granulometry in mechanical resistances and acoustic behavior. Constr. Build. Mater. 2018, 200, 248–254. [Google Scholar] [CrossRef]

- Juan-Valdés, A.; Rodríguez, D.; García-González, J.; Guerra, M.I.; Morán, J.M. Mechanical and microstructural characterization of non-structural precast concrete made with recycled mixed ceramic aggregates from construction and demolition wastes. J. Clean. Prod. 2018, 180, 482–493. [Google Scholar] [CrossRef]

- Fleck, W.E.P.; Jones, M.H.; Kuntze, R.A.; Mc Adie, H.G. The Differential Thermal Analysis of Natural and Synthetic Hydrates of Calcium Sulphate. Can. J. Chem. 1960, 38, 936–943. [Google Scholar] [CrossRef]

- Huan, Q.; Zhu, X.; Xiong, G.; Wang, C.; Liu, D.; Zhao, L. Recycling of crushed waste clay brick as aggregates in cement mortars: An approach from macro- and micro-scale investigation. Constr. Build. Mater. 2021, 274, 122068. [Google Scholar] [CrossRef]

- Yedra, E.; Ferrández, D.; Saiz, P.; Morón, C. Low-cost system for measuring the evolution of mechanical properties in cement mortars as a function of mixing water. Constr. Build. Mater. 2020, 244, 118–127. [Google Scholar]

- Nedeljković, M.; Visser, J.; Nigland, T.G.; Valcke, S.; Schlangen, E. Physical, chemical and mineralogical characterization of Dutch fine recycled concrete aggregates: A comparative study. Constr. Build. Mater. 2020, 270, 121475. [Google Scholar] [CrossRef]

- Ulsen, C.; Kahn, H.; Hawlitscschek, G.; Masini, E.A.; Angulo, S.C.; John, V.M. Production of recycled sand from construction and demolition waste. Constr. Build. Mater. 2013, 40, 1168–1173. [Google Scholar] [CrossRef]

- UNE-EN 1744-1:2010+A1:2013; Tests for Chemical Properties of Aggregates—Part 1: Chemical Analysis. UNE: Madrid, Spain, 2013.

- Ahmed, S.; Alhoubi, Y.; Elmesalami, N.; Yhenia, S.; Abed, F. Effect of recycled aggregates and treated wastewater on concrete subjected to different exposure conditions. Constr. Build. Mater. 2020, 266, 120–930. [Google Scholar] [CrossRef]

- Yuang-Chung, L.; Datov, A.; Chun-Chief, A.; Feng-Chih, C.; Pei-Cheng, C. Sulfur content reduction of waste oil by modified NaY zeolite. Microporous Mesoporous Mater. 2021, 313, 110–816. [Google Scholar]

- UNE-EN 998-2:2018; Specification for Mortar for Masonry—Part 2: Masonry Mortar. UNE: Madrid, Spain, 2018.

- Barrios, A.M.; Ferrandez, D.; Saiz, P.; Atanes-Sánchez, E.; Fernández, C.M. Study of the properties of lime and cement mortars made from recycled ceramic aggregate and reinforced with fibers. J. Build. Eng. 2021, 35, 102097. [Google Scholar] [CrossRef]

- Colangelo, F.; Petrillo, A.; Farina, I. Comparative environmental evaluation of recycled aggregates from construction and demolition wastes in Italy. Sci. Total Environ. 2021, 798, 149–250. [Google Scholar] [CrossRef]

| Type | RA–Con | RA–Cer | RA–Mix | |||

|---|---|---|---|---|---|---|

| Test | W Statistic | p-Value | W Statistic | p-Value | W Statistic | p-Value |

| Fine content | 0.928636 | 0.092688 | 0.968940 | 0.641494 | 0.974845 | 0.779908 |

| Fineness modulus | 0.938668 | 0.156609 | 0.959768 | 0.440422 | 0.974616 | 0.774718 |

| Friability | 0.963739 | 0.522800 | 0.958691 | 0.419649 | 0.942720 | 0.192893 |

| Set density | 0.949215 | 0.267455 | 0.920243 | 0.059527 | 0.963892 | 0.526158 |

| Relative density | 0.979905 | 0.884980 | 0.933410 | 0.119093 | 0.958022 | 0.407095 |

| Absorption | 0.976486 | 0.706861 | 0.936322 | 0.050249 | 0.950606 | 0.144408 |

| ANOVA | Typical Deviation (%) | Variation Coefficient | Confidence Interval (99.7%) | |||

|---|---|---|---|---|---|---|

| RA | Quantity | Average (%) | Homogeneous Groups | |||

| Con | 24 | 5.17 | X | 0.964 | 0.186 | [2.28; 8.10] |

| Mix | 24 | 5.48 | X | 0.799 | 0.146 | [3.08; 7.88] |

| Cer | 24 | 5.63 | X | 0.796 | 0.141 | [3.24; 8.02] |

| ANOVA | Typical Deviation (%) | Variation Coefficient | Confidence Interval (99.7%) | |||

|---|---|---|---|---|---|---|

| RA | Quantity | Average (%) | Homogeneous Groups | |||

| Con | 24 | 4.84 | X | 0.614 | 0.127 | [3.00; 6.68] |

| Mix | 24 | 5.33 | XX | 0.565 | 0.106 | [3.64; 7,03] |

| Cer | 24 | 5.02 | X | 0.469 | 0.093 | [3.61; 6.43] |

| ANOVA | Typical Deviation (%) | Variation Coefficient | Confidence Interval (99.7%) | |||

|---|---|---|---|---|---|---|

| RA | Quantity | Average (%) | Homogeneous Groups | |||

| Con | 24 | 24.60 | X | 0.682 | 0.028 | [22.55; 26.65] |

| Mix | 24 | 27.10 | X | 0.797 | 0.029 | [24.71; 29.49] |

| Cer | 24 | 26.26 | X | 0.660 | 0.025 | [24.28; 28.24] |

| ANOVA | Typical Deviation (%) | Variation Coefficient | Confidence Interval (99.7%) | |||

|---|---|---|---|---|---|---|

| RA | Quantity | Average (%) | Homogeneous Groups | |||

| Con | 24 | 1300.8 | X | 35.3 | 0.027 | [1194.9; 1406.6] |

| Mix | 24 | 1238.2 | X | 43.1 | 0.035 | [1108.9; 1367.5] |

| Cer | 24 | 1258.1 | X | 36.5 | 0.029 | [1148.7; 1367.6] |

| ANOVA | Typical Deviation (%) | Variation Coefficient | Confidence Interval (99.7%) | |||

|---|---|---|---|---|---|---|

| RA | Quantity | Average (%) | Homogeneous Groups | |||

| Con | 24 | 2210.3 | X | 38.3 | 0.017 | [2095.6; 2325.1] |

| Mix | 24 | 2141.8 | X | 26.0 | 0.012 | [2063.8; 2219.7] |

| Cer | 24 | 2136.1 | X | 25.5 | 0.012 | [2059.6; 2212.6] |

| ANOVA | Typical Deviation (%) | Variation Coefficient | Confidence Interval (99.7%) | |||

|---|---|---|---|---|---|---|

| RA | Quantity | Average (%) | Homogeneous Groups | |||

| Con | 36 | 6.35 | X | 0.57 | 0.089 | [4.66; 8.05] |

| Mix | 36 | 6.70 | X | 0.68 | 0.102 | [4.65; 8.75] |

| Cer | 36 | 7.30 | X | 0.58 | 0.079 | [5.56; 9.04] |

| Mineral Phase | Calcite | Quartz | Gypsum | Sanidine | Phlogopite | Basanite |

|---|---|---|---|---|---|---|

| RA–Con | **** | ***** | * | * | * | * |

| RA–Cer | **** | ***** | ** | ** | ** | * |

| RA–Mix | **** | ***** | ** | ** | ** | * |

| Mineral | RA–Con | RA–Mix | RA–Cer |

|---|---|---|---|

| % Calcite | 17.12 | 17.53 | 18.90 |

| % Gypsum | 4.14 | 4.35 | 5.38 |

| Samples | Al2O3 | CaO | Fe2O3 | K2O | MgO | SiO2 | MnO | TiO2 | SO3 | P2O5 | NaO2 | I. Loss (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA–Con | 6.22 | 11.43 | 1.52 | 2.15 | 0.65 | 66.9 | 0.035 | 0.14 | - | 0.10 | 0.38 | 9.35 |

| RA–Mix | 6.88 | 10.38 | 1.27 | 2.20 | 0.57 | 68.4 | 0.025 | 0.13 | - | 0.11 | 0.24 | 9.50 |

| RA–Cer | 10.26 | 16.85 | 2.84 | 2.38 | 1.75 | 43.7 | - | 0.35 | 4.32 | 0.12 | 0.80 | 16.25 |

| Test | Regulation | RA–Con | RA–Mix | RA–Cer |

|---|---|---|---|---|

| Chloride content (%) | UNE–EN 1744-1 | 0.0054 | 0.0026 | 0.0041 |

| Total sulfur (%) | UNE–EN 1744-1 | 0.69 | 0.81 | 0.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saiz Martínez, P.; Ferrández, D.; Melane-Lavado, A.; Zaragoza-Benzal, A. Characterization of Three Types of Recycled Aggregates from Different Construction and Demolition Waste: An Experimental Study for Waste Management. Int. J. Environ. Res. Public Health 2023, 20, 3709. https://doi.org/10.3390/ijerph20043709

Saiz Martínez P, Ferrández D, Melane-Lavado A, Zaragoza-Benzal A. Characterization of Three Types of Recycled Aggregates from Different Construction and Demolition Waste: An Experimental Study for Waste Management. International Journal of Environmental Research and Public Health. 2023; 20(4):3709. https://doi.org/10.3390/ijerph20043709

Chicago/Turabian StyleSaiz Martínez, Pablo, Daniel Ferrández, Alberto Melane-Lavado, and Alicia Zaragoza-Benzal. 2023. "Characterization of Three Types of Recycled Aggregates from Different Construction and Demolition Waste: An Experimental Study for Waste Management" International Journal of Environmental Research and Public Health 20, no. 4: 3709. https://doi.org/10.3390/ijerph20043709

APA StyleSaiz Martínez, P., Ferrández, D., Melane-Lavado, A., & Zaragoza-Benzal, A. (2023). Characterization of Three Types of Recycled Aggregates from Different Construction and Demolition Waste: An Experimental Study for Waste Management. International Journal of Environmental Research and Public Health, 20(4), 3709. https://doi.org/10.3390/ijerph20043709