Study on the Quality of Mixed Silage of Rapeseed with Alfalfa or Myriophyllum

Abstract

1. Introduction

2. Materials and Methods

2.1. Silage Material Treatment

2.2. Experimental Design

2.3. Measurement Index and Method

2.4. Statistical Analysis

3. Results

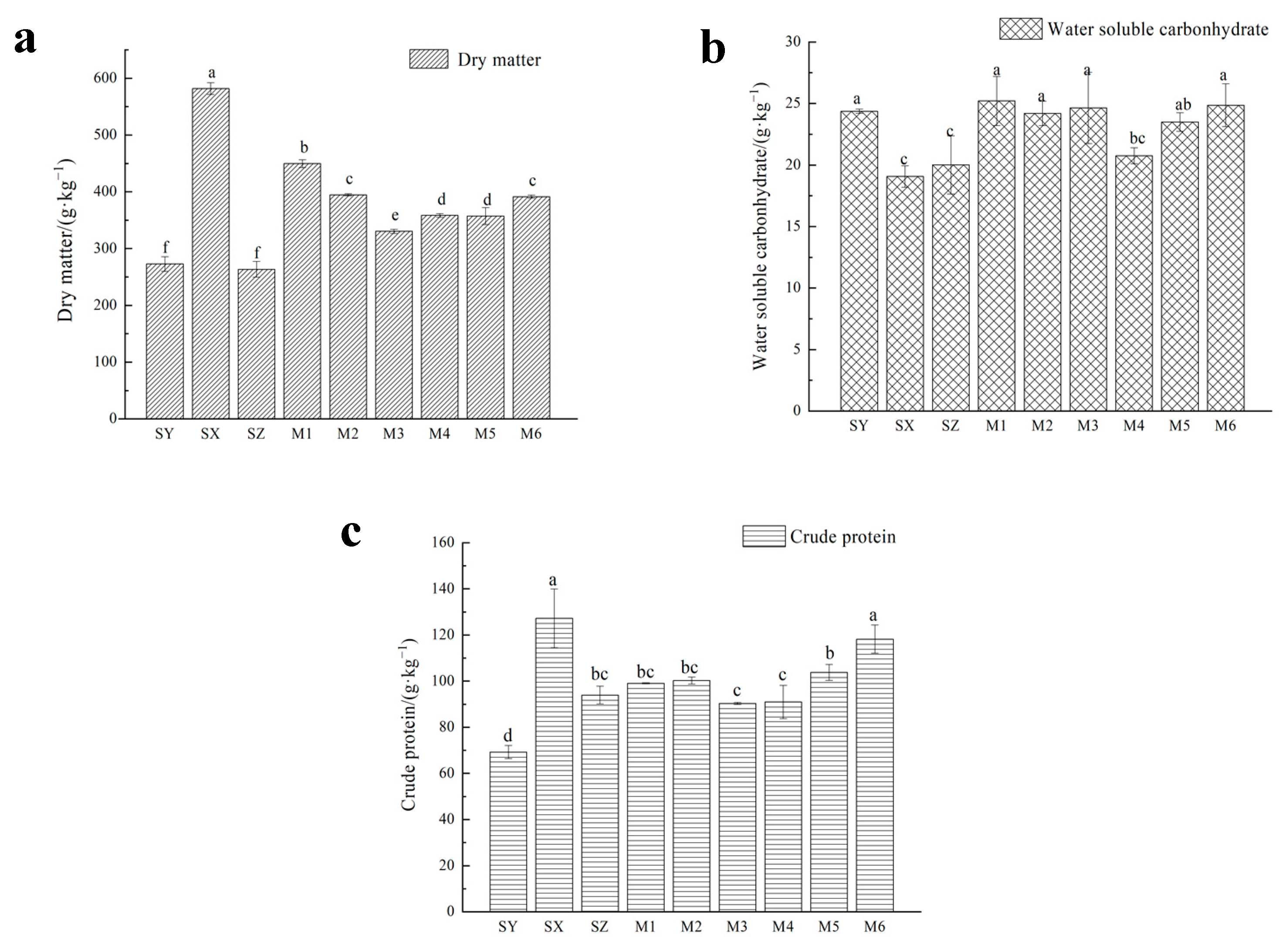

3.1. Chemical Composition of the Raw Materials for Sileage

3.2. Sensory Evaluation of Silage

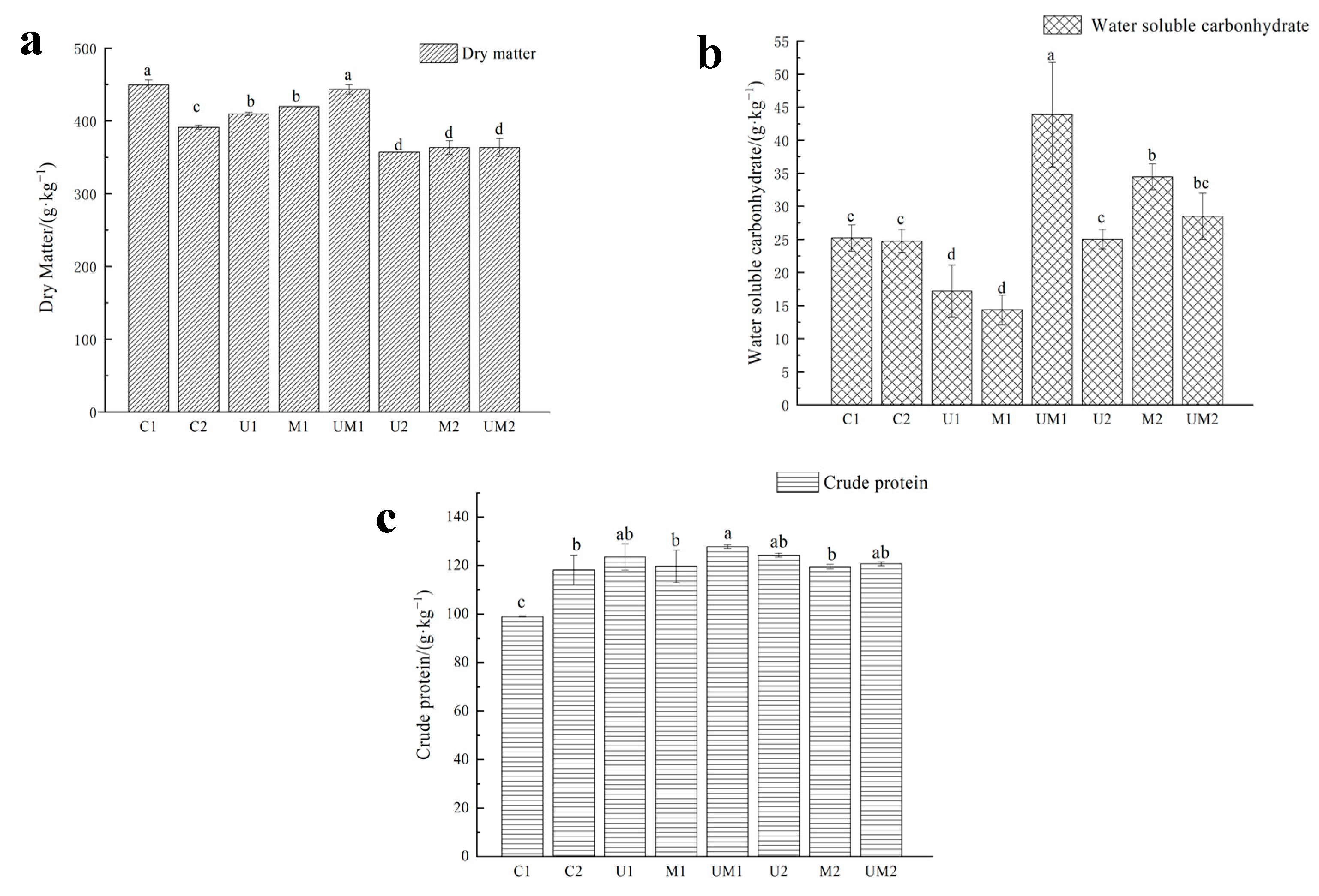

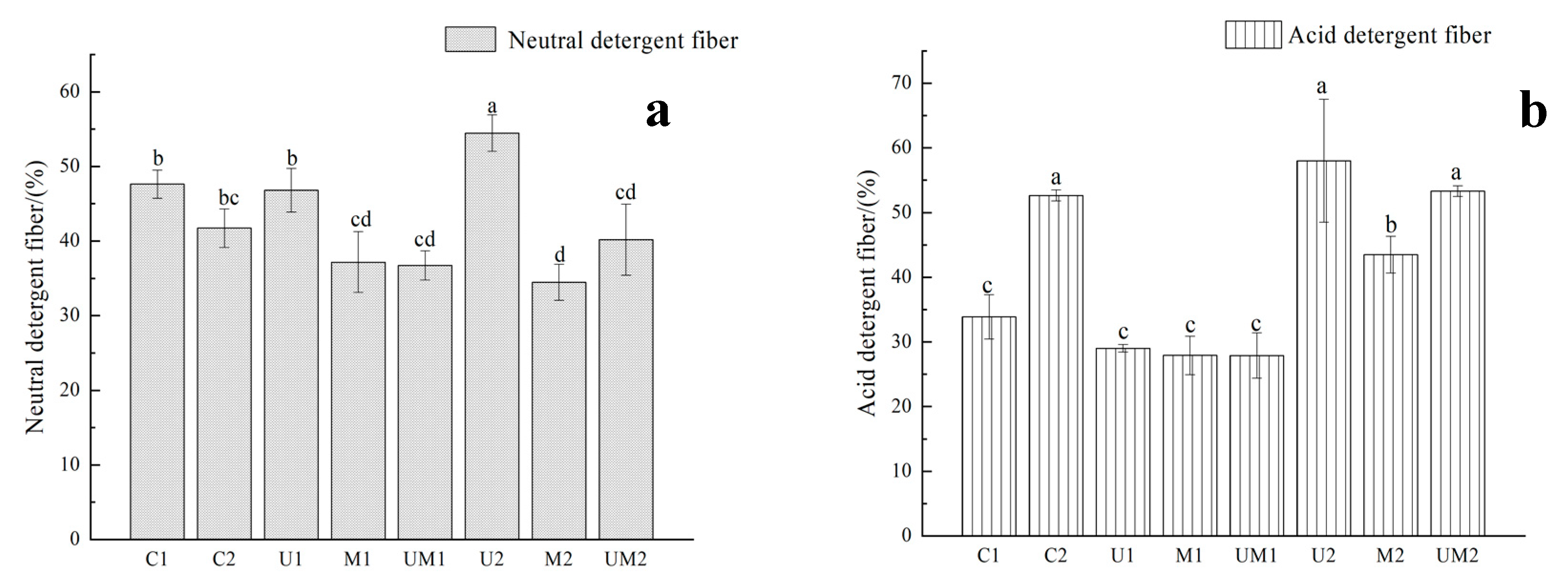

3.3. Analysis of the Nutritional Quality of the Mixed Silage

3.4. Analysis of the Fermentation Quality of Mixed Silage

3.5. Quality Evaluation of the V-Score in Different Treatment Groups

3.6. Comprehensive Evaluation of the Membership Function of Different Treatment Groups

3.7. Effect of Additives on the Nutritional Quality of Mixed Silage

3.8. Effect of Additives on the Fermentation Quality of Mixed Silage

4. Discussion

4.1. Chemical Composition of Materials

4.2. Effect of Mixed Silage of Rapeseed and Alfalfa or M. spicatum on Silage Quality

4.3. Effect of Additives on the Quality of Mixed Silage of Rapeseed and Alfalfa or M. spicatum

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Bureau of Statistics of China (NBS). China Statistical Yearbook of 2019; China Statistics Press: Beijing, China, 2019.

- Canales-Flores, R.A.; Prieto-García, F. Activation Methods of Carbonaceous Materials Obtained from Agricultural Waste. Chem. Biodivers. 2016, 13, 261–268. [Google Scholar] [CrossRef]

- Chang, C.C.; Li, R. Agricultural Waste. Water Environ. Res. 2019, 91, 1150–1167. [Google Scholar] [CrossRef]

- Larsen, S.U.; Hjort-Gregersen, K.; Vazifehkhoran, A.H.; Triolo, J.M. Co-Ensiling of Straw with Sugar Beet Leaves Increases the Methane Yield from Straw. Bioresour. Technol. 2017, 245, 106–115. [Google Scholar] [CrossRef]

- Yokota, H.; Kim, J.H.; Okajima, T.; Ohshima, M. Nutritional Quality of Wilted Napier Grass (Pennisetum Purpureum Schum.) Ensiled with or without Molasses. Asian-Australas. J. Anim. Sci. 1992, 5, 673–679. [Google Scholar] [CrossRef]

- Yunus, M.; Ohba, N.; Tobisa, M.; Shimojo, M.; Masuda, Y. Effect of Glucose and Formic Acid on the Quality of Napiergrass Silage after Treatment with Urea. Asian-Australas. J. Anim. Sci. 2001, 14, 211–215. [Google Scholar] [CrossRef]

- Maxin, G.; Ouellet, D.R.; Lapierre, H. Effect of Substitution of Soybean Meal by Canola Meal or Distillers Grains in Dairy Rations on Amino Acid and Glucose Availability. J. Dairy Sci. 2013, 96, 7806–7817. [Google Scholar] [CrossRef]

- Abdelrahman, M.; Wang, W.; Lv, H.M.; Di, Z.; An, Z.; Lijun, W.; Shaukat, A.; Bo, W.; Guangsheng, Z.; Liguo, Y.; et al. Evaluating the Effect of Forage Rape (Brassica Napus) Ensiling Kinetics on Degradability and Milk Performance as Non-Conventional Forage for Dairy Buffalo. Front. Vet. Sci. 2022, 9, 926906. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Z.; Liu, X.; Huang, G.; Xiao, W.; Han, L. The Composition Characteristics of Different Crop Straw Types and Their Multivariate Analysis and Comparison. Waste Manag. 2020, 110, 87–97. [Google Scholar] [CrossRef]

- Zhou, D.; Abdelrahman, M.; Zhang, X.; Yang, S.; Yuan, J.; An, Z.; Niu, K.; Gao, Y.; Li, J.; Wang, B.; et al. Milk Production Responses and Digestibility of Dairy Buffaloes (Bubalus Bubalis) Partially Supplemented with Forage Rape (Brassica Napus) Silage Replacing Corn Silage. Animals 2021, 11, 2931. [Google Scholar] [CrossRef]

- Barry, T.N. The Feeding Value of Forage Brassica Plants for Grazing Ruminant Livestock. Anim. Feed Sci. Technol. 2013, 181, 15–25. [Google Scholar] [CrossRef]

- Koyama, M.; Yamamoto, S.; Ishikawa, K.; Ban, S.; Toda, T. Anaerobic Digestion of Submerged Macrophytes: Chemical Composition and Anaerobic Digestibility. Ecol. Eng. 2014, 69, 304–309. [Google Scholar] [CrossRef]

- Gallegos, D.; Wedwitschka, H.; Moeller, L.; Weinrich, S.; Zehnsdorf, A.; Nelles, M.; Stinner, W. Mixed Silage of Elodea and Wheat Straw as a Substrate for Energy Production in Anaerobic Digestion Plants. Energy Sustain. Soc. 2018, 8, 7. [Google Scholar] [CrossRef]

- Wen, A.Y.; Yuan, X.J.; Wang, J.; Desta, S.T.; Shao, T. Effects of Four Short-Chain Fatty Acids or Salts on Dynamics of Fermentation and Microbial Characteristics of Alfalfa Silage. Anim. Feed Sci. Technol. 2017, 223, 141–148. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, M.; Wang, X.; Yu, Z.; Na, R. Ensiling Alfalfa with Whole Crop Corn Improves the Silage Quality and in Vitro Digestibility of the Silage Mixtures. Grassl. Sci. 2017, 63, 211–217. [Google Scholar] [CrossRef]

- Muck, R.E. Factors Influencing Silage Quality and Their Implications for Management1. J. Dairy Sci. 1988, 71, 2992–3002. [Google Scholar] [CrossRef]

- Wang, M.; Wang, L.; Yu, Z. Fermentation Dynamics and Bacterial Diversity of Mixed Lucerne and Sweet Corn Stalk Silage Ensiled at Six Ratios. Grass Forage Sci. 2019, 74, 264–273. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.Y.; Zhang, S.J.; Amar, A.; Chaudhry, A.S.; Cheng, L.; Abbasi, I.H.R.; Al-Mamun, M.; Guo, X.F.; Shan, A.S. Using Mixed Silages of Sweet Sorghum and Alfalfa in Total Mixed Rations to Improve Growth Performance, Nutrient Digestibility, Carcass Traits and Meat Quality of Sheep. Animal 2021, 15, 100246. [Google Scholar] [CrossRef]

- Zhu, Y.; Nishino, N.; Kishida, Y.; Uchida, S. Ensiling Characteristics and Ruminal Degradation of Italian Ryegrass and Lucerne Silages Treated with Cell Wall-Degrading Enzymes. J. Sci. Food Agric. 1999, 79, 1987–1992. [Google Scholar] [CrossRef]

- Thomas, T.A. An Automated Procedure for the Determination of Soluble Carbohydrates in Herbage. J. Sci. Food Agric. 1977, 28, 639–642. [Google Scholar] [CrossRef]

- van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Baur, F.J.; Ensminger, L.G. The Association of Official Analytical Chemists (AOAC). J. Am. Oil Chem. Soc. 1977, 54, 171–172. [Google Scholar] [CrossRef]

- Zeng, T.; Li, X.; Guan, H.; Yang, W.; Liu, W.; Liu, J.; Du, Z.; Li, X.; Xiao, Q.; Wang, X.; et al. Dynamic Microbial Diversity and Fermentation Quality of the Mixed Silage of Corn and Soybean Grown in Strip Intercropping System. Bioresour. Technol. 2020, 313, 123655. [Google Scholar] [CrossRef]

- Broderick, G.A.; Kang, J.H. Automated Simultaneous Determination of Ammonia and Total Amino Acids in Ruminal Fluid and In Vitro Media. J. Dairy Sci. 1980, 63, 64–75. [Google Scholar] [CrossRef]

- Japan Grassland Farming Forage Seed Association (JGFFSA). Guide Book for Quality Evaluation of Forage; Japan Sociaty of Grassland Science: Tokyo, Japan, 1994; pp. 82–87. [Google Scholar]

- Yan, C.; Song, S.; Wang, W.; Wang, C.; Li, H.; Wang, F.; Li, S.; Sun, X. Screening Diverse Soybean Genotypes for Drought Tolerance by Membership Function Value Based on Multiple Traits and Drought-Tolerant Coefficient of Yield. BMC Plant Biol. 2020, 20, 321. [Google Scholar] [CrossRef]

- Ennahar, S.; Cai, Y.; Fujita, Y. Phylogenetic Diversity of Lactic Acid Bacteria Associated with Paddy Rice Silage as Determined by 16S Ribosomal DNA Analysis. Appl. Environ. Microbiol. 2003, 69, 444–451. [Google Scholar] [CrossRef]

- Santos, M.C.; Kung, L. Short Communication: The Effects of Dry Matter and Length of Storage on the Composition and Nutritive Value of Alfalfa Silage. J. Dairy Sci. 2016, 99, 5466–5469. [Google Scholar] [CrossRef]

- Dunière, L.; Sindou, J.; Chaucheyras-Durand, F.; Chevallier, I.; Thévenot-Sergentet, D. Silage Processing and Strategies to Prevent Persistence of Undesirable Microorganisms. Anim. Feed Sci. Technol. 2013, 182, 1–15. [Google Scholar] [CrossRef]

- Zhang, J.G.; Kawamoto, H.; Cai, Y.M. Relationships between the Addition Rates of Cellulase or Glucose and Silage Fermentation at Different Temperatures. Anim. Sci. J. 2010, 81, 325–330. [Google Scholar] [CrossRef]

- de Rezende, A.V.; Rabelo, C.H.S.; da Silva, M.R.M.; Härter, C.J.; Veiga, R.M. Wasted Cabbage (Brassica Oleracea) Silages Treated with Different Levels of Ground Corn and Silage Inoculant. R. Bras. Zootec. 2015, 44, 296–302. [Google Scholar] [CrossRef]

- Ni, K.; Wang, F.; Zhu, B.; Yang, J.; Zhou, G.; Pan, Y.; Tao, Y.; Zhong, J. Effects of Lactic Acid Bacteria and Molasses Additives on the Microbial Community and Fermentation Quality of Soybean Silage. Bioresour. Technol. 2017, 238, 706–715. [Google Scholar] [CrossRef]

- Wang, C.; He, L.; Xing, Y.; Zhou, W.; Yang, F.; Chen, X.; Zhang, Q. Fermentation Quality and Microbial Community of Alfalfa and Stylo Silage Mixed with Moringa Oleifera Leaves. Bioresour. Technol. 2019, 284, 240–247. [Google Scholar] [CrossRef]

- Park, S.; Jeong, H.Y.; Kim, H.S.; Yang, M.S.; Chae, K.S. Enhanced Production of Aspergillus Ficuum Endoinulinase in Saccharomyces Cerevisiae by Using the SUC2-Deletion Mutation. Enzyme Microb. Technol. 2001, 29, 107–110. [Google Scholar] [CrossRef]

- Li, H.; Zeng, T.; Du, Z.; Dong, X.; Xin, Y.; Wu, Y.; Huang, L.; Liu, L.; Kang, B.; Jiang, D.; et al. Assessment on the Fermentation Quality and Bacterial Community of Mixed Silage of Faba Bean With Forage Wheat or Oat. Front. Microbiol. 2022, 13, 875819. [Google Scholar] [CrossRef]

- Contreras-Govea, F.; Marsalis, M.; Angadi, S.; Smith, G.; Lauriault, L.M.; Vanleeuwen, D. Fermentabilîty and Nutritive Value of Corn and Forage Sorghum Silage When in Mixture with Lablab Bean. Crop Sci. 2011, 51, 1307–1313. [Google Scholar] [CrossRef]

- Kung, L.; Myers, C.L.; Neylon, J.M.; Taylor, C.C.; Lazartic, J.; Mills, J.A.; Whiter, A.G. The Effects of Buffered Propionic Acid-Based Additives Alone or Combined with Microbial Inoculation on the Fermentation of High Moisture Corn and Whole-Crop Barley. J. Dairy Sci. 2004, 87, 1310–1316. [Google Scholar] [CrossRef]

- McDonald, P.; Henderson, N.; Heron, S. The Biochemistry of Silage; Chalcombe: Marlow, UK, 1991. [Google Scholar]

- Valente, M.E.; Borreani, G.; Caredda, S.; Cavallarin, L.; Sulas, L. Ensiling Forage Garland (Chrysanthemum Coronarium L.) at Two Stages of Maturity and at Different Wilting Levels. Anim. Feed Sci. Technol. 2003, 108, 181–190. [Google Scholar] [CrossRef]

- Wang, Y.; He, L.; Xing, Y.; Zhou, W.; Pian, R.; Yang, F.; Chen, X.; Zhang, Q. Bacterial Diversity and Fermentation Quality of Moringa Oleifera Leaves Silage Prepared with Lactic Acid Bacteria Inoculants and Stored at Different Temperatures. Bioresour. Technol. 2019, 284, 349–358. [Google Scholar] [CrossRef]

- Jiménez-Calderón, J.D.; Martínez-Fernández, A.; Soldado, A.; González, A.; Vicente, F. Faba Bean-Rapeseed Silage as Substitute for Italian Ryegrass Silage: Effects on Performance and Milk Quality of Grazing Dairy Cows. Anim. Prod. Sci. 2020, 60, 913–922. [Google Scholar] [CrossRef]

- Falkner, L.K.; Casler, M.D. Preference for Smooth Bromegrass Clones Is Affected by Divergent Selection for Nutritive Value. Crop Sci. 1998, 38, 690–695. [Google Scholar] [CrossRef]

- Kaplan, M. Effect of Ensiling of Alfalfa with Sorghum on the Chemical Composition and Nutritive Value of Silage Mixtures. J. Anim. Vet. Adv. 2011, 10, 2368–2371. [Google Scholar]

- Van Soest, P.J. Nutritional Ecology of the Ruminant, 2nd ed.; Cornell University Press: New York, NY, USA, 1994. [Google Scholar]

- Muck, R.E.; Moser, L.E.; Pitt, R.E. Postharvest Factors Affecting Ensiling. In Silage Science and Technology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2003; pp. 251–304. [Google Scholar]

- Bureenok, S.; Sisaath, K.; Yuangklang, C.; Vasupen, K.; Schonewille, J.T. Ensiling Characteristics of Silages of Stylo Legume (Stylosanthes Guianensis), Guinea Grass (Panicum Maximum) and Their Mixture, Treated with Fermented Juice of Lactic Bacteria, and Feed Intake and Digestibility in Goats of Rations Based on These Silages. Small Rumin. Res. 2016, 134, 84–89. [Google Scholar] [CrossRef]

- Chen, L.; Guo, G.; Yuan, X.; Shimojo, M.; Yu, C.; Shao, T. Effect of Applying Molasses and Propionic Acid on Fermentation Quality and Aerobic Stability of Total Mixed Ration Silage Prepared with Whole-Plant Corn in Tibet. Asian-Australas. J. Anim. Sci. 2014, 27, 349–356. [Google Scholar] [CrossRef]

- Arbabi, S.; Ghoorchi, T. The Effect of Different Levels of Molasses as Silage Additives on Fermentation Quality of Foxtail Millet (Setaria Italica) Silage. Asian J. Anim. Sci. 2008, 2, 43–50. [Google Scholar] [CrossRef]

- Kung, L.; Taylor, C.C.; Lynch, M.P.; Neylon, J.M. The Effect of Treating Alfalfa with Lactobacillus Buchneri 40788 on Silage Fermentation, Aerobic Stability, and Nutritive Value for Lactating Dairy Cows. J. Dairy Sci. 2003, 86, 336–343. [Google Scholar] [CrossRef]

- Woolford, M.K. The Silage Fermentation; Marcel Dekker Inc.: New York, NY, USA, 1984. [Google Scholar]

- Santos, A.P.M.D.; Santos, E.M.; Oliveira, J.S.D.; Ribeiro, O.L.; Perazzo, A.F.; Martins Araújo Pinho, R.; Macêdo, A.J.D.S.; Pereira, G.A. Effects of Urea Addition on the Fermentation of Sorghum (Sorghum Bicolor) Silage. Afr. J. Range Forage Sci. 2018, 35, 55–62. [Google Scholar] [CrossRef]

- Kung, L.; Robinson, J.R.; Ranjit, N.K.; Chen, J.H.; Golt, C.M.; Pesek, J.D. Microbial Populations, Fermentation End-Products, and Aerobic Stability of Corn Silage Treated with Ammonia or a Propionic Acid-Based Preservative. J. Dairy Sci. 2000, 83, 1479–1486. [Google Scholar] [CrossRef]

- Cesareo, S.D.; Langton, S.R. Kinetic Properties of Helicobacter Pylori Urease Compared with Jack Bean Urease. FEMS Microbiol. Lett. 1992, 99, 15–22. [Google Scholar] [CrossRef]

- Wanapat, M.; Kang, S.; Khejornsart, P.; Pilajun, R. Improvement of Whole Crop Rice Silage Nutritive Value and Rumen Degradability by Molasses and Urea Supplementation. Trop. Anim. Health Prod. 2013, 45, 1777–1781. [Google Scholar] [CrossRef]

- Phesatcha, K.; Wanapat, M. Improvement of Nutritive Value and in Vitro Ruminal Fermentation of Leucaena Silage by Molasses and Urea Supplementation. Asian-Australas. J. Anim. Sci. 2016, 29, 1136–1144. [Google Scholar] [CrossRef]

| Ensilage Materials | Dry Matter (g·kg−1 FM) | Crude Protein (g·kg−1 DM) | Water Soluble Carbohydrate (g·kg−1 DM) | Acid Detergent Fiber (% DM) | Neutral Detergent Fiber (% DM) |

|---|---|---|---|---|---|

| Rapeseed | 274.03 ± 1.21 B | 51.15 ± 0.82 C | 114.48 ± 1.70 A | 33.07 ± 1.04 B | 47.34 ± 1.21 B |

| Alfalfa | 551.63 ± 4.12 A | 186.76 ± 3.43 A | 63.14 ± 3.04 B | 35.11 ± 0.81 B | 46.10 ± 0.72 B |

| M. spicatum. | 281.27 ± 4.57 B | 149.70 ± 0.59 B | 54.15 ± 1.59 B | 48.32 ± 0.95 A | 53.22 ± 0.54 A |

| Material | Treatment | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SY | SX | SZ | M1 | M2 | M3 | M4 | M5 | M6 | |

| Rapeseed | 1 | - | - | 3 | 5 | 7 | 3 | 5 | 7 |

| Alfalfa | - | 1 | - | 7 | 5 | 3 | - | - | - |

| M. spicatum. | - | - | 1 | - | - | - | 7 | 5 | 3 |

| Treatment | Mixture | Additive |

|---|---|---|

| C1 | YX37 | None |

| U1 | 0.3% urea | |

| M1 | 3% molasses | |

| UM1 | 0.3 urea + 3% molasses | |

| C2 | YZ73 | None |

| U2 | 0.3% urea | |

| M2 | 3% molasses | |

| UM2 | 0.3 urea + 3% molasses |

| Symbol | Description |

|---|---|

| DM | Dry matter |

| FM | Fresh matter |

| WSC | Water soluble carbohydrate |

| CP | Crude protein |

| NDF | Neutral detergent fiber |

| ADF | Acid detergent fiber |

| SY | Rapeseed silage |

| SX | Alfalfa silage |

| SZ | Myriophyllum spicatum silage |

| YX | Mixed silage group of rapeseed and alfalfa |

| YZ | Mixed silage group of rapeseed and Myriophyllum spicatum |

| LA | Lactic acid |

| AA | Acetic acid |

| PA | Propionic acid |

| BA | Butyric acid |

| NH3-N | Ammonia nitrogen |

| TN | Total nitrogen |

| SEM | Standard error of mean |

| Group | Mildew | Smell | Color | Quality of Material | Composite Scores | ||||

|---|---|---|---|---|---|---|---|---|---|

| Describe | Average Score | Describe | Average Score | Describe | Average Score | Total Score | Grade | ||

| SY | A little mildew | Strong sour smell, weak aromatic smell | 6.00 | Bright yellow, Slightly white | 1.00 | The stem and leaf structure are well protected, hard and slightly sticky | 2.33 | 9.33 | Level III |

| SX | A little mildew at the bottle mouth | Strong ammonia taste, almost no acid taste | 6.00 | green and slightly white | 1.00 | The stem and leaf structure are well protected, hard and loose | 1.33 | 8.33 | Level III |

| SZ | A little mildew | A faint sour smell | 7.00 | Dark brown, slightly white | 0.67 | The stem and leaf structure are well protected and loose | 2.00 | 9.67 | Level III |

| M1 | No mildew | No sour odor, aromatic fruit flavor | 11.33 | Yellow and slightly green | 1.67 | The stem and leaf structure is well protected, soft and loose. | 3.33 | 15.00 | Level II |

| M2 | No mildew | No sour odor, aromatic fruit flavor | 11.33 | Yellow, slightly green | 1.33 | The stem and leaf structure is well protected, soft and loose. | 2.67 | 14.00 | Level II |

| M3 | No mildew | A faint smell of bread | 9.33 | Slightly white and medium yellow | 1.33 | The stem and leaf structure is well protected, soft and loose. | 2.67 | 14.00 | Level II |

| M4 | A little mildew | Weak aromatic taste | 8.33 | Brown and slightly yellow | 1.00 | The stems and leaves are not rotten, and the texture is soft and loose | 2.67 | 12.00 | Level II |

| M5 | No mildew | No sour smell, weak aromatic fruit flavor | 9.33 | Yellow brown, slightly green | 1.33 | The stem and leaf structure is well protected, soft and loose. | 3.00 | 13.67 | Level II |

| M6 | No mildew | No sour odor, aromatic fruit flavor | 10.33 | Light yellowish brown, slightly green | 1.3 | The stem and leaf structure is well protected, soft and loose. | 3.33 | 15.00 | Level II |

| Item | SY | SX | SZ | Ratio | YX | YZ | Mean | SEM | p | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Species | Ratio | S × R | |||||||||

| pH | 4.71 | 4.47 | 5.66 | 3:7 | 3.95 Bc | 5.32 Aa | 4.63 | 0.031 | <0.001 | 0.154 | <0.001 |

| 5:5 | 4.13 Bb | 5.08 Ab | 4.60 | ||||||||

| 7:3 | 4.77 Ba | 4.56 Ac | 4.66 | ||||||||

| Mean | 4.40 B | 5.06 A | |||||||||

| NH3-N/TN(%) | 7.89 | 7.33 | 5.07 | 3:7 | 4.61 Ac | 5.19 Aa | 4.90 b | 0.220 | <0.001 | <0.001 | <0.001 |

| 5:5 | 5.69 Ab | 3.32 Bb | 4.51 b | ||||||||

| 7:3 | 8.35 Aa | 3.17 Bb | 5.76 a | ||||||||

| Mean | 6.77 A | 4.32 B | |||||||||

| LA/ (g·kg−1 DM) | 34.09 | 63.74 | 12.93 | 3:7 | 96.46 Aa | 18.88 Bc | 57.67 a | 2.245 | <0.001 | 0.029 | <0.001 |

| 5:5 | 81.98 Ab | 25.24 Bb | 53.61 b | ||||||||

| 7:3 | 61.95 Ac | 40.29 Ba | 51.12 b | ||||||||

| Mean | 67.64 A | 26.29 B | |||||||||

| AA/ (g·kg−1 DM) | 16.03 | 40.55 | 75.75 | 3:7 | 38.72 A | 16.90 B | 27.81 | 3.791 | <0.001 | 0.622 | 0.817 |

| 5:5 | 41.37 A | 18.16 B | 29.76 | ||||||||

| 7:3 | 35.27 A | 16.78 B | 26.02 | ||||||||

| Mean | 34.39 A | 28.72 A | |||||||||

| PA/ (g·kg−1 DM) | 6.31 | 3.95 | 5.27 | 3:7 | 7.24 B | 17.23 Aa | 12.24 a | 0.771 | <0.001 | <0.001 | <0.001 |

| 5:5 | 7.21 B | 12.17 Ab | 9.69 b | ||||||||

| 7:3 | 7.18 A | 5.48 Bc | 6.33 c | ||||||||

| Mean | 6.38 B | 9.29 A | |||||||||

| BA/ (g·kg−1 DM) | 1.28 | 1.79 | 1.34 | 3:7 | 1.41 Ab | 1.29 Aa | 1.35 a | 0.084 | <0.001 | <0.001 | <0.001 |

| 5:5 | 1.65 Aa | 0.53 Bb | 1.09 b | ||||||||

| 7:3 | 1.21 Ab | 0.53 Bb | 0.87 c | ||||||||

| Mean | 1.47 A | 0.99 B | |||||||||

| LA/AA | 2.13 | 1.57 | 0.17 | 3:7 | 2.54 Aa | 1.12 Bc | 0.95 b | <0.01 | <0.001 | 0.057 | <0.001 |

| 5:5 | 1.98 Aab | 1.39 Bb | 1.13 a | ||||||||

| 7:3 | 1.76 Bb | 2.40 Aa | 1.02 ab | ||||||||

| Mean | 2.00 A | 1.44 B | |||||||||

| Item | Treatment | (NH3-N/TN) | AA + PA | BA | Scores | Grade | |||

|---|---|---|---|---|---|---|---|---|---|

| Ratio | Scores | Content/%DM | Scores | Content/%DM | Scores | ||||

| V-Score | SY | 7.89 | 44.22 | 2.23 | 0.00 | 0.13 | 29.73 | 73.96 | common |

| SX | 7.33 | 45.35 | 4.45 | 0.00 | 0.18 | 25.67 | 71.02 | common | |

| SZ | 5.03 | 49.93 | 8.10 | 0.00 | 0.13 | 29.26 | 79.19 | common | |

| MI | 4.61 | 50.78 | 4.60 | 0.00 | 0.14 | 28.76 | 79.54 | common | |

| M2 | 5.69 | 48.61 | 4.86 | 0.00 | 0.16 | 26.82 | 75.43 | common | |

| M3 | 8.35 | 43.41 | 4.25 | 0.00 | 0.12 | 30.36 | 73.66 | common | |

| M4 | 5.19 | 49.63 | 3.41 | 0.00 | 0.13 | 29.71 | 79.34 | common | |

| M5 | 3.32 | 53.35 | 3.03 | 0.00 | 0.05 | 35.80 | 89.15 | good | |

| M6 | 3.17 | 53.67 | 2.23 | 0.00 | 0.05 | 35.73 | 89.40 | good | |

| Item | Membership Function Value | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SY | SX | SZ | M1 | M2 | M3 | M4 | M5 | M6 | |

| DM/(g/kg) | 0.0297 | 1.0000 | 0.0000 | 0.5849 | 0.4119 | 0.2417 | 0.2981 | 0.2945 | 0.5338 |

| CP/(g·kg−1 DM) | 0.0000 | 1.0000 | 0.4256 | 0.5136 | 0.5345 | 0.3637 | 0.3745 | 0.5958 | 0.8441 |

| WSC/(g·kg−1 DM) | 0.8627 | 0.0000 | 0.1535 | 1.0000 | 0.8352 | 0.9080 | 0.2746 | 0.7222 | 0.9435 |

| NDF/(% DM) | 0.0000 | 0.0394 | 0.0579 | 0.4635 | 0.0939 | 0.2700 | 0.7184 | 1.0000 | 0.7370 |

| ADF/(% DM) | 0.5053 | 0.4683 | 0.0000 | 0.8168 | 1.0000 | 0.9977 | 0.2375 | 0.2087 | 0.2888 |

| pH | 0.5543 | 0.6979 | 0.0000 | 1.0000 | 0.8974 | 0.5220 | 0.1994 | 0.3402 | 0.6422 |

| NH3-N/TN/(%) | 0.0884 | 0.1377 | 0.6304 | 0.7194 | 0.5106 | 0.0000 | 0.6109 | 0.9679 | 1.0000 |

| LA/(g·kg−1 DM) | 0.2533 | 0.6083 | 0.0000 | 1.0000 | 0.8266 | 0.5868 | 0.0713 | 0.1474 | 0.3275 |

| AA/(g·kg−1 DM) | 1.0000 | 0.5894 | 0.0000 | 0.6201 | 0.5757 | 0.6778 | 0.9854 | 0.9644 | 0.9875 |

| PA/(g·kg−1 DM) | 0.8221 | 1.0000 | 0.9011 | 0.7522 | 0.7547 | 0.7572 | 0.0000 | 0.3809 | 0.8853 |

| BA/(g·kg−1 DM) | 0.4007 | 0.0000 | 0.3543 | 0.3047 | 0.1134 | 0.4735 | 0.3985 | 1.0000 | 0.9929 |

| Mean | 0.4106 | 0.5037 | 0.2294 | 0.7068 | 0.5958 | 0.5282 | 0.3790 | 0.6020 | 0.7439 |

| Ranking | 8 | 6 | 9 | 2 | 4 | 5 | 7 | 3 | 1 |

| Item | Treatments | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | U1 | M1 | UM1 | U2 | M2 | UM2 | SEM | p-Value | |

| pH | 3.95 e | 4.56 d | 4.72 bc | 3.55 f | 4.60 cd | 5.56 a | 4.73 b | 4.70 bc | 0.032 | <0.001 |

| NH3-N/TN (%) | 4.61 d | 3.17 e | 9.25 b | 5.05 d | 8.00 c | 10.82 a | 4.66 d | 9.68 b | 0.194 | <0.001 |

| LA//(g·kg−1 DM) | 96.46 c | 40.29 f | 56.90 de | 133.71 b | 145.95 a | 55.752 e | 63.21 d | 53.06 e | 2.050 | <0.001 |

| AA//(g·kg−1 DM) | 38.72 bc | 16.78 f | 46.11 a | 41.28 ab | 33.77 cd | 30.97 d | 14.72 f | 24.18 e | 1.800 | <0.001 |

| PA//(g·kg−1 DM) | 7.24 a | 5.48 b | 2.13 d | 1.63 e | 1.93 de | 2.74 c | 2.34 cd | 2.65 c | 0.139 | <0.001 |

| BA//(g·kg−1 DM) | 1.41 a | 0.53 cd | 0.82 b | 0.58 cd | 0.64 c | 0.66 bc | 0.46 d | 0.55 cd | 0.047 | <0.001 |

| LA/AA | 2.54 c | 2.40 cd | 1.24 e | 3.26 b | 4.32 a | 1.81 de | 4.62 a | 2.23 cd | 0.177 | <0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Wan, C.; Ma, Y.; Zhang, K.; Wang, F.; Shen, S. Study on the Quality of Mixed Silage of Rapeseed with Alfalfa or Myriophyllum. Int. J. Environ. Res. Public Health 2023, 20, 3884. https://doi.org/10.3390/ijerph20053884

Chen S, Wan C, Ma Y, Zhang K, Wang F, Shen S. Study on the Quality of Mixed Silage of Rapeseed with Alfalfa or Myriophyllum. International Journal of Environmental Research and Public Health. 2023; 20(5):3884. https://doi.org/10.3390/ijerph20053884

Chicago/Turabian StyleChen, Siwei, Chen Wan, Yingjun Ma, Keqiang Zhang, Feng Wang, and Shizhou Shen. 2023. "Study on the Quality of Mixed Silage of Rapeseed with Alfalfa or Myriophyllum" International Journal of Environmental Research and Public Health 20, no. 5: 3884. https://doi.org/10.3390/ijerph20053884

APA StyleChen, S., Wan, C., Ma, Y., Zhang, K., Wang, F., & Shen, S. (2023). Study on the Quality of Mixed Silage of Rapeseed with Alfalfa or Myriophyllum. International Journal of Environmental Research and Public Health, 20(5), 3884. https://doi.org/10.3390/ijerph20053884