Wastewater Treatment Plants as a Source of Malodorous Substances Hazardous to Health, Including a Case Study from Poland

Abstract

:1. Introduction

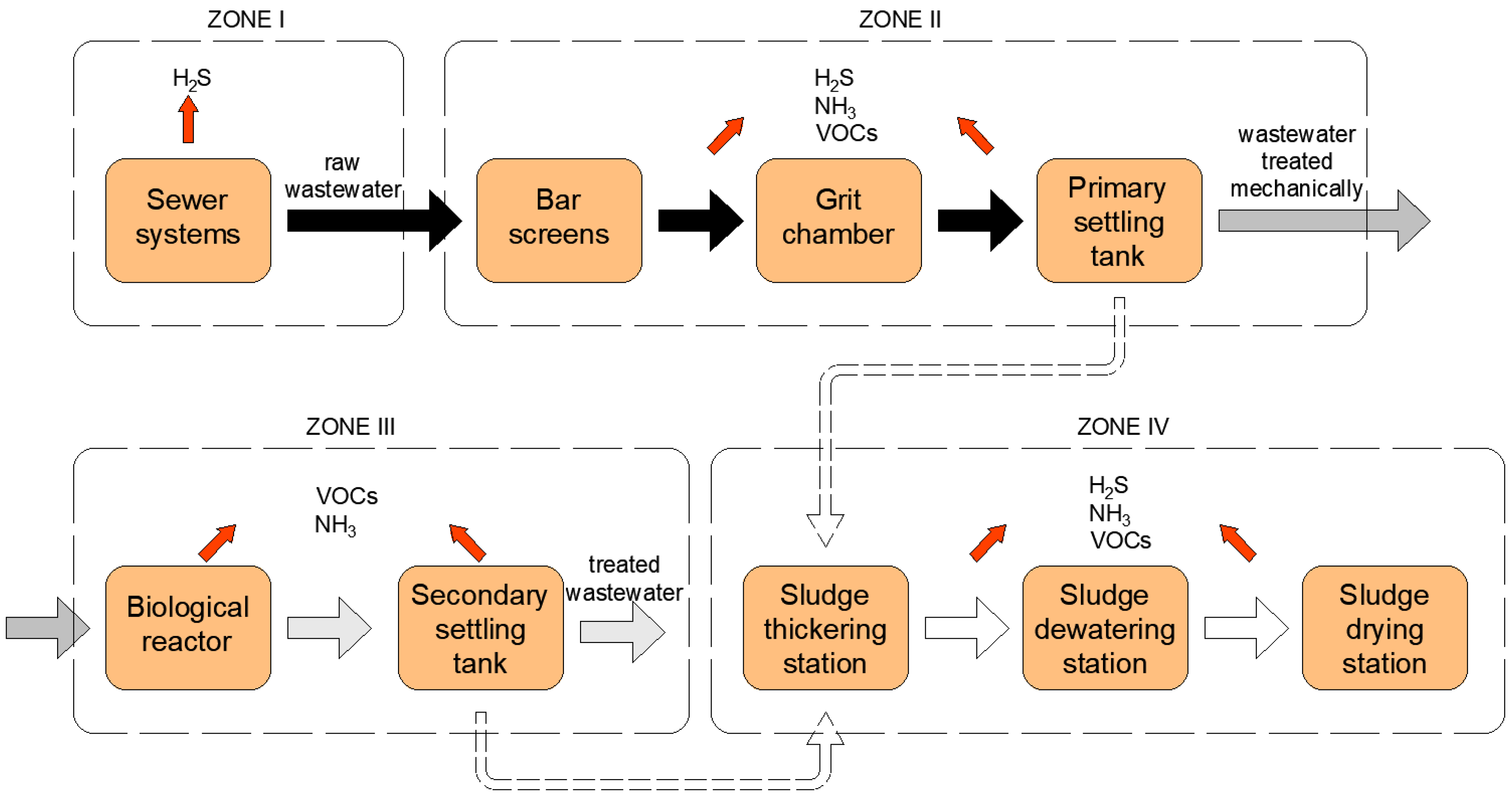

2. Wastewater Treatment Plant as a Source of Malodorous Substances Hazardous to Health

3. Effects of Malodorous Substances on Human Health and the Environment

4. Odour Measuring Techniques

5. Evaluation of the Problem of Odour Nuisance of Wastewater Treatment Plants on the Example of Poland

5.1. Analysis of Statistical Data on Odour Nuisance Complaints with Consideration of Wastewater Treatment Plants as Municipal Facilities

5.2. Recognition of Odour Nuisance and Air Quality Due to Malodorous Substances

5.2.1. Odour Nuisance of Polish Wastewater Treatment Plants

5.2.2. Assessment of Air Quality Due to the Presence of Hydrogen Sulphide, Ammonia and Volatile Organic Compounds

6. Opportunities to Counteract the Odour Nuisance of Wastewater Treatment Plants

6.1. Legal Regulations in Poland to Combat Odour Nuisance

6.2. Solutions to Reduce and Eliminate the Impact of Malodorous Substances Generated in Wastewater Treatment Plants on People and the Environment

6.2.1. Hermetisation

6.2.2. Sorption Processes

6.2.3. Biological Methods

6.2.4. Thermal Neutralization and Ozonation

6.2.5. Neutralization and Masking

7. Conclusions

- Emission of odorous substances from wastewater treatment plants should be taken into account at the design stage of such a facility, by including appropriate solutions in the technological line (e.g., hermetisation of devices, purification of air taken from devices), which will reduce the impact of these substances on people and the environment. In many wastewater treatment plants that are struggling with the problem of odour nuisance, such solutions are introduced at the stage of operation, which is obviously a beneficial action. Nevertheless, they should be an indispensable element of the wastewater treatment process at the design stage.

- The operator of each wastewater treatment plant should take steps to determine the community reaction (CR) on this facility, which can be accomplished by collecting and analysing complaints from local residents, as well as conducting a surveys among these residents. It should be highlighted that the results of such surveys will also allow the operator to determine the range of impact of the facility, and this information can be the basis for the application of solutions which reduce and eliminate the impact of odorous substances.

- Despite the lack of direct legal regulations in Poland (and in many European Union countries) and the lack of the need to meet the requirements for the emission of odorous substances from the wastewater treatment plant, operators should show initiative to systematically perform such measurements, because the presence of certain substances in the air creates a risk to human health (HI > 1). It is worth pointing out that many substances included in the volatile organic compounds exhibit carcinogenic properties, which also confirms the validity of monitoring the presence of these substances in the air in the range of treatment plant.

- A paradigm shift should be pursued that odour emission is a local problem. Of course, the perception of odours is an individual matter; however, the unfavourable impact of malodorous substances on the human body is confirmed and indisputable. The issue of reducing the emission of odorous substances should be considered with the use of unambiguous legal regulations (in many countries, internal regulations regarding the prevention of odour nuisance have no legal force) and control methods with a confirmed degree of reliability of the obtained results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NH3 | Ammonia |

| BNR | Biological Nutrient Removal |

| CaO | Calcium oxide (Quick Lime) |

| Ca(OH)2 | Calcium Hydroxide (Hydrated Lime) |

| CIEP | Chief Inspectorate of Environmental Protection |

| H2S | Hydrogen Sulphide |

| HI | Risk Assessment |

| LTEL (NDS in Poland) | Long-Term Exposure Limit |

| MBR | Membrane Bioreactor |

| MBBR | Moving Bed Biofilm Reactor |

| PAH | Polycyclic Aromatic Hydrocarbons |

| PCB | Polychlorinated Biphenyls |

| PIEP | Provincial Inspectorate of Environmental Protection |

| STEL (NDSCh in Poland) | Short-Term Exposure Limit |

| WWTP | Wastewater Treatment Plant |

| VOCs | Volatile Organic Compounds |

References

- Ren, B.M.; Zhao, Y.Q.; Lyczko, N.; Nzihou, A. Current Status and Outlook of Odor Removal Technologies in Wastewater Treatment Plant. Waste Biomass Valoriz. 2019, 10, 1443–1458. [Google Scholar] [CrossRef]

- Fan, F.Q.; Xu, R.H.; Wang, D.P.; Meng, F.G. Application of activated sludge for odor control in wastewater treatment plants: Approaches, advances and outlooks. Water Res. 2020, 181, 16. [Google Scholar] [CrossRef]

- Blanco-Rodriguez, A.; Camara, V.F.; Campo, F.; Becheran, L.; Duran, A.; Vieira, V.D.; de Melo, H.; Garcia-Ramirez, A.R. Development of an electronic nose to characterize odours emitted from different stages in a wastewater treatment plant. Water Res. 2018, 134, 92–100. [Google Scholar] [CrossRef] [PubMed]

- Lewkowska, P.; Cieslik, B.; Dymerski, T.; Konieczka, P.; Namiesnik, J. Characteristics of odors emitted from municipal wastewater treatment plant and methods for their identification and deodorization techniques. Environ. Res. 2016, 151, 573–586. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.W.; Kang, X.Y.; Liu, X.L.; Yue, P.; Sun, J.B.; Lu, C. Simultaneous removal of bioaerosols, odors and volatile organic compounds from a wastewater treatment plant by a full-scale integrated reactor. Process Saf. Environ. Protect. 2020, 144, 2–14. [Google Scholar] [CrossRef]

- Wang, B.; Sivret, E.C.; Parcsi, G.; Wang, X.G.; Stuetz, R.M. Characterising Volatile Organic Compounds from Sewer Emissions by Thermal Desorption coupled with Gas-Chromatography-Mass Spectrometry. In Proceedings of the 3rd Biannual International Conference on Environmental Odour Monitoring and Control (NOSE), Palermo, Italy, 23–26 September 2012; pp. 73–78. [Google Scholar]

- Bylinski, H.; Gebicki, J.; Namiesnik, J. Evaluation of Health Hazard Due to Emission of Volatile Organic Compounds from Various Processing Units of Wastewater Treatment Plant. Int. J. Environ. Res. Public Health 2019, 16, 16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jian, L.; Lin, L.; Junxin, L.; Meiyan, L. Odors and volatile organic compounds emission from main processing units of wastewater treatment plant. Chin. J. Environ. Eng. 2016, 10, 2329–2334. [Google Scholar] [CrossRef]

- Asadi, M.; McPhedran, K. Estimation of greenhouse gas and odour emissions from a cold region municipal biological nutrient removal wastewater treatment plant. J. Environ. Manag. 2021, 281, 11. [Google Scholar] [CrossRef]

- Zarra, T.; Galang, M.G.K.; Oliva, G.; Belgiorno, V. Smart instrumental Odour Monitoring Station for the efficient odour emission management and control in wastewater treatment plants. Chemosphere 2022, 309, 12. [Google Scholar] [CrossRef]

- Szakiel, J. Evaluation of odor nuisance on the example of selected municipal facilities. In General Quality Problems; Institute of Exploitation Technology—National Research Institute: Radom, Poland, 2018; pp. 130–140. (In Polish) [Google Scholar]

- Wojciechowski, R.; Piaskowski, K. Reducing wastewater rot in a discharge sewer using a novel pipeline flushing and aeration method. Exploiter Forum. 2020, 2, 34–38. (In Polish) [Google Scholar]

- Brandt, E.M.F.; Souza, C.L.; Chernicharo, C.A.L. Alternativas para o controle de odores e corrosão em sistemas de coleta e tratamento de esgoto. Eng. Sanitária Ambient. 2017, 22, 611–623. [Google Scholar] [CrossRef] [Green Version]

- Kulig, A.; Szylak-Szydlowski, M.; Wisniewska, M. Application of Field Olfactometry to Monitor the Odour Impact of a Municipal Sewage System. Energies 2022, 15, 15. [Google Scholar] [CrossRef]

- Jiang, G.M.; Melder, D.; Keller, J.; Yuan, Z.G. Odor emissions from domestic wastewater: A review. Crit. Rev. Environ. Sci. Technol. 2017, 47, 1581–1611. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.; Choi, E.; Choi, I.; Shin, T.; Im, H.; Ahn, S. Characterization of odor emission from alternating aerobic and anoxic activated sludge systems using real-time total reduced sulfur analyzer. Chemosphere 2014, 117, 394–401. [Google Scholar] [CrossRef] [PubMed]

- Senatore, V.; Zarra, T.; Galang, M.G.; Oliva, G.; Buonerba, A.; Li, C.W.; Belgiorno, V.; Naddeo, V. Full-Scale Odor Abatement Technologies in Wastewater Treatment Plants (WWTPs): A Review. Water 2021, 13, 21. [Google Scholar] [CrossRef]

- Burgues, J.; Donate, S.; Esclapez, M.D.; Sauco, L.; Marco, S. Characterization of odour emissions in a wastewater treatment plant using a drone-based chemical sensor system. Sci. Total Environ. 2022, 846, 13. [Google Scholar] [CrossRef] [PubMed]

- Hort, C.; Gracy, S.; Platel, V.; Moynault, L. Evaluation of sewage sludge and yard waste compost as a biofilter media for the removal of ammonia and volatile organic sulfur compounds (VOSCs). Chem. Eng. J. 2009, 152, 44–53. [Google Scholar] [CrossRef]

- Gebicki, J.; Bylinski, H.; Namiesnik, J. Measurement techniques for assessing the olfactory impact of municipal sewage treatment plants. Environ. Monit. Assess. 2016, 188, 15. [Google Scholar] [CrossRef]

- Zwoździak, J.; Piechocka, A. Sewage sludge processing, odor emission and the possibilities of their future development. Q. Environ. Eng. Des. 2018, 170, 35–42. [Google Scholar] [CrossRef]

- Bylinski, H.; Barczak, R.J.; Gebicki, J.; Namiesnik, J. Monitoring of odors emitted from stabilized dewatered sludge subjected to aging using proton transfer reaction-mass spectrometry. Environ. Sci. Pollut. Res. 2019, 26, 5500–5513. [Google Scholar] [CrossRef] [Green Version]

- Grzelka, A.; Romanik, E.; Miller, U. Odour nuisance assessment of the food industry wastewater treatment plant. In Proceedings of the 11th Conference on Interdisciplinary Problems in Environmental Protection and Engineering (EKO-DOK), Polanica Zdroj, Poland, 8–10 April 2019. [Google Scholar]

- Howe, B. Odors at Wastewater Treatment Plants. When Covering a Problem Makes Sense. Water World 2016, 16191305. Available online: https://www.waterworld.com/home/article/16191305/odors-at-wastewater-treatment-plants (accessed on 5 December 2022).

- Andraskar, J.; Yadav, S.; Kapley, A. Challenges and Control Strategies of Odor Emission from Composting Operation. Appl. Biochem. Biotechnol. 2021, 193, 2331–2356. [Google Scholar] [CrossRef] [PubMed]

- Faris, A.M.; Nile, B.K.; Mussa, Z.H.; Alesary, H.F.; Al Juboury, M.F.; Hassan, W.H.; Al-Bahrani, H.A.; Barton, S. Fate and emission of methyl mercaptan in a full-scale MBBR process by TOXCHEM simulation. J. Water Clim. Change 2022, 13, 2386–2398. [Google Scholar] [CrossRef]

- Balami, S.; Shrestha, E.; Dhungana, A.; Chhatkuli, A.; Shrestha, M.; Chaulagain, R. Self-Perception, Knowledge and Awareness of Halitosis among Students of Higher Learning Institutions of Chitwan. MedS Alliance J. Med. Med. Sci. 2022, 2, 33–38. [Google Scholar] [CrossRef]

- Kim, H.; Murthy, S.; McConnell, L.L.; Peot, C.; Ramirez, M.; Strawn, M. Characterization of wastewater and solids odors using solid phase microextraction at a large wastewater treatment plant. Water Sci. Technol. 2002, 46, 9–16. [Google Scholar] [CrossRef] [PubMed]

- List of Substances and Chemical Compounds That Cause Nuisance Odor. National Fund for Environmental Protection and Water Management. Available online: https://www.gov.pl/web/klimat/uciazliwosc-zapachowa (accessed on 2 December 2022). (In Polish)

- Database of Hazardous Chemicals. Available online: https://www.ciop.pl/ (accessed on 2 December 2022).

- Klemba, K. Biogas plant as a potential source of odor emission risks and preventive measures. Proc. Natl. Acad. Sci. USA 2015, 99, 1527–1531. (In Polish) [Google Scholar]

- Shusterman, D. Critical-Review—The health significance of environmental odor pollution. Arch. Environ. Health 1992, 47, 76–87. [Google Scholar] [CrossRef]

- Maldonado, C.S.; Weir, A.; Rumbeiha, W.K. A comprehensive review of treatments for hydrogen sulfide poisoning: Past, present, and future. Toxicol. Mech. Methods 2022, 33, 183–196. [Google Scholar] [CrossRef]

- Uliasz-Misiak, B. Environmental Risk Associated with Exploitation of Hydrocarbon Deposits Containing Hydrogen Sulfide. Annu. Set Environ. Prot. 2015, 17, 1498–1511. (In Polish) [Google Scholar]

- International Chemical Safety Cards. International Labour Organization. Available online: https://www.ilo.org/global/lang--en/index.htm (accessed on 3 December 2022).

- Our Air. Available online: https://powietrze.uni.wroc.pl/ (accessed on 3 December 2022).

- Schauberger, G.; Piringer, M.; Mikovits, C.; Zollitsch, W.; Hortenhuber, S.J.; Baumgartner, J.; Niebuhr, K.; Anders, I.; Andre, K.; Hennig-Pauka, I.; et al. Impact of global warming on the odour and ammonia emissions of livestock buildings used for fattening pigs. Biosyst. Eng. 2018, 175, 106–114. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, T.; Cai, C.; Zhang, Y.X.; Liu, H.L. Oxidation of ethanethiol in aqueous alkaline solution by ferrate(VI): Kinetics, stoichiometry and mechanism. Chem. Eng. J. 2019, 361, 1557–1564. [Google Scholar] [CrossRef]

- Aventaggiato, L.; Colucci, A.P.; Strisciullo, G.; Favalli, F.; Gagliano-Candela, R. Lethal Hydrogen Sulfide poisoning in open space: An atypical case of asphyxiation of two workers. Forensic Sci. Int. 2020, 308, 6. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.J.; Xu, X.H.; Jiang, L.; Qiao, J.B.; Zhou, H.Y.; Li, K.X. Preliminary results of toxicity studies in rats following low-dose and short-term exposure to methyl mercaptan. Toxicol. Rep. 2019, 6, 431–438. [Google Scholar] [CrossRef] [PubMed]

- Antczak, J. Chemical Accidents vs. Ecological Security. In Research Papers of Wrocław University of Economics; Publisher of the University of Economics in Wrocław: Wrocław, Poland, 2016; Volume 436, pp. 21–29. (In Polish) [Google Scholar] [CrossRef]

- Dobrzyniewski, D.; Szulczynski, B.; Gebicki, J. Determination of Odor Air Quality Index (OAQI(I)) Using Gas Sensor Matrix. Molecules 2022, 27, 25. [Google Scholar] [CrossRef] [PubMed]

- Byliński, H. Application of Instrumental and Sensory Techniques for the Assessment of Ambient Air Quality, Taking into Account the Negative Environmental Impact of Odor Nuisance Compounds Formed from Sewage Sludge; Gdansk University of Technology: Gdańsk, Poland, 2019; pp. 1–183. (In Polish) [Google Scholar]

- Spinazze, A.; Polvara, E.; Cattaneo, A.; Invernizzi, M.; Cavallo, D.M.; Sironi, S. Dynamic Olfactometry and Oil Refinery Odour Samples: Application of a New Method for Occupational Risk Assessment. Toxics 2022, 10, 13. [Google Scholar] [CrossRef]

- Sironi, S.; Capelli, L.; Centola, P.; Del Rosso, R.; Pierucci, S. Odour impact assessment by means of dynamic olfactometry, dispersion modelling and social participation. Atmos. Environ. 2010, 44, 354–360. [Google Scholar] [CrossRef]

- Giungato, P.; de Gennaro, G.; Barbieri, P.; Briguglio, S.; Amodio, M.; de Gennaro, L.; Lasigna, F. Improving recognition of odors in a waste management plant by using electronic noses with different technologies, gas chromatography-mass spectrometry/olfactometry and dynamic olfactometry. J. Clean. Prod. 2016, 133, 1395–1402. [Google Scholar] [CrossRef]

- Lehtinen, J.; Veijanen, A. Odour Monitoring by Combined TD-GC-MS-Sniff Technique and Dynamic Olfactometry at the Wastewater Treatment Plant of Low H2S Concentration. Water Air Soil Pollut. 2011, 218, 185–196. [Google Scholar] [CrossRef]

- Szyłak-Szydłowski, M. Determination of the odour concentration using field olfactometry method. Gas Water Sanit. Technol. 2019, 4, 131–134. (In Polish) [Google Scholar] [CrossRef]

- Kulig, A.; Szylak-Szydlowski, M. Assessment of the Effects of Wastewater Treatment Plant Modernization by Means of the Field Olfactometry Method. Water 2019, 11, 15. [Google Scholar] [CrossRef] [Green Version]

- Wisniewska, M.; Kulig, A.; Lelicinska-Serafin, K. The Use of Chemical Sensors to Monitor Odour Emissions at Municipal Waste Biogas Plants. Appl. Sci. 2021, 11, 16. [Google Scholar] [CrossRef]

- Barczak, R.; Kulig, A. Classification of Research Methods Used in the Odour Impact Assessment of the Municipal Sewage Treatment Plant. Traczewska, T.M., Ed.; Publishing House of Wrocław University of Technology: Wrocław, Poland, 2012; pp. 65–72. [Google Scholar]

- Szulczyński, B. New Ways to Instrumentally Determine Selected Odor Characteristics Using Sensing Techniques; Gdansk University of Technology: Gdańsk, Poland, 2021; pp. 1–148. (In Polish) [Google Scholar]

- Lamagna, A.; Reich, S.; Rodriguez, D.; Boselli, A.; Cicerone, D. The use of an electronic nose to characterize emissions from a highly polluted river. Sens. Actuator B-Chem. 2008, 131, 121–124. [Google Scholar] [CrossRef]

- Lieberzeit, P.A.; Rehman, A.; Najafi, B.; Dickert, F.L. Real-life application of a QCM-based e-nose: Quantitative characterization different plant-degradation processes. Anal. Bioanal. Chem. 2008, 391, 2897–2903. [Google Scholar] [CrossRef] [PubMed]

- Data Made Available by the Chief Inspector of Environmental Protection in Warsaw.

- Sówka, I. Methods of Identification of Odour Gases Emitted from Industrial Plants; Publishing House of Wrocław University of Technology: Wrocław, Poland, 2011. (In Polish) [Google Scholar]

- Szynkowska, M.I.; Zwoździak, J. Contemporary Issues of Odor; Scientific and Technical Publishers: Warszawa, Poland, 2010. (In Polish) [Google Scholar]

- Borowski, J. Odors nuisance and wastewater evaporation. Install. Mark. 2017, 6. Available online: https://www.rynekinstalacyjny.pl/artykul/oczyszczanie-sciekow/30858,uciazliwosc-zapachowa-a-parowanie-sciekow (accessed on 7 December 2022). (In Polish).

- Czarnota, J.; Maslon, A. Evaluation of the Effectiveness of a Wastewater Treatment Plant with MBBR Technology. Annu. Set Environ. Prot. 2019, 21, 906–925. [Google Scholar]

- Data Made Available by Department of Water and Wastewater Management in Trzebownisko, Podkarpackie Voivodeship, Poland.

- Hamoda, M.F.; Alshalahi, S.F. Assessment of hydrogen sulfide emission in a wastewater pumping station. Environ. Monit. Assess. 2021, 193, 16. [Google Scholar] [CrossRef] [PubMed]

- Michałkiewicz, M.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Mizerna-Nowotna, P. Odor and microbiological nuisance of wastewater treatment plants-case study. Environ. Prot. 2016, 38, 41–48. (In Polish) [Google Scholar]

- Lasaridi, K.; Katsabanis, G.; Kyriacou, A.; Maggos, T.; Manios, T.; Fountoulakis, M.; Kalogerakis, N.; Karageorgos, P.; Stentiford, E.I. Assessing odour nuisance from wastewater treatment and composting facilities in Greece. Waste Manag. Res. 2010, 28, 977–984. [Google Scholar] [CrossRef]

- Lafita, C.; Penya-Roja, J.M.; Sempere, F.; Waalkens, A.; Gabaldon, C. Hydrogen sulfide and odor removal by field-scale biotrickling filters: Influence of seasonal variations of load and temperature. J. Environ. Sci. Health Part A-Toxic/Hazard. Subst. Environ. Eng. 2012, 47, 970–978. [Google Scholar] [CrossRef]

- Zarra, T.; Reiser, M.; Naddeo, V.; Belgiorno, V.; Kranert, M. Odour Emissions Characterization from Wastewater Treatment Plants by Different Measurement Methods. Chem. Eng. Trans. 2014, 40, 37–42. [Google Scholar] [CrossRef]

- Li, R.Y.; Han, Z.L.; Shen, H.Z.; Qi, F.; Ding, M.M.; Song, C.; Sun, D.Z. Emission characteristics of odorous volatile sulfur compound from a full-scale sequencing batch reactor wastewater treatment plant. Sci. Total Environ. 2021, 776, 10. [Google Scholar] [CrossRef]

- Dincer, F.; Muezzinoglu, A. Odor-causing volatile organic compounds in wastewater treatment plant units and sludge management areas. J. Environ. Sci. Health Part A-Toxic/Hazard. Subst. Environ. Eng. 2008, 43, 1569–1574. [Google Scholar] [CrossRef] [PubMed]

- Jeon, E.C.; Son, H.K.; Sa, J.H. Emission Characteristics and Factors of Selected Odorous Compounds at a Wastewater Treatment Plant. Sensors 2009, 9, 311–326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Czerwińska, J.; Wielgosiński, G.; Zawadzka, A. Air quality on the wastewater treatment plant in Lask. Gas Water Sanit. Technol. 2018, 1, 12–14. (In Polish) [Google Scholar] [CrossRef]

- Gonzalez, D.; Colon, J.; Sanchez, A.; Gabriel, D. Multipoint characterization of the emission of odour, volatile organic compounds and greenhouse gases from a full-scale membrane-based municipal WWTP. J. Environ. Manag. 2022, 313, 10. [Google Scholar] [CrossRef] [PubMed]

- US EPA. Risk Assessment Guidance for Superfund. Volume I: Human Health Evaluation Manual (Part F, Supplemental Guidance for Inhalation Risk Assessment). Off. Superfund Remediat. Technol. Innov. Environ. Prot. Agency 2009, I, 1–68. [Google Scholar]

- Sattler, M.; Devanathan, S. Which meteorological conditions produce worst-case odors from area sources? J. Air Waste Manag. Assoc. 2007, 57, 1296–1306. [Google Scholar] [CrossRef]

- Korzeniowska-Rejmer, E.; Generowicz, A. Influence of meteorological and field conditions on the dispersion of pollutants from municipal landfills in the atmospheric air. Tech. J. Environ. 2012, 109, 113–127. (In Polish) [Google Scholar]

- Maśliński, M. Regulations against odor nuisance. In Proceedings of the Prevention of Odor Emissions in Municipal and Industrial Facilities; SMM Legal: Otwock, Poland, 2019. (In Polish) [Google Scholar]

- Sówka, I. Monitoring of air quality in Poland for malodorous substances. In Proceedings of the Information Technologies in Environmental Protection and Shaping; Wroclaw University of Technology: Warsaw, Poland, 2017. (In Polish) [Google Scholar]

- Council Directive 91/271/EEC of 21 May 1991 Concerning Urban Waste-Water Treatment. Available online: http://data.europa.eu/eli/dir/1991/271/oj (accessed on 9 March 2023).

- Department of Air and Climate Protection. Code against Odor Nuisance—Draft; Department of Air and Climate Protection: Washington, DC, USA, 2016. (In Polish)

- Infomil NeR, Digitale NeR. Available online: https://www.infomil.nl/ (accessed on 28 December 2022).

- Wierzbińska, M.; Świeńczyk, B. Legal regulations in Poland and EU countries in the field of air protection with particular emphasis on the aspect of odor nuisance. Ecol. Eng. 2020, 21, 1–14. (In Polish) [Google Scholar] [CrossRef]

- Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control) (Recast) (Text with EEA Relevance). Available online: http://data.europa.eu/eli/dir/2010/75/oj (accessed on 9 March 2023).

- Bokowa, A.; Diaz, C.; Koziel, J.A.; McGinley, M.; Barclay, J.; Schauberger, G.; Guillot, J.M.; Sneath, R.; Capelli, L.; Zorich, V.; et al. Summary and Overview of the Odour Regulations Worldwide. Atmosphere 2021, 12, 53. [Google Scholar] [CrossRef]

- Japan Ministry of the Environment. The Offensive Odor Control Law. Available online: http://www.env.go.jp/en/laws/air/offensive_odor/ (accessed on 9 March 2023).

- Arrêté du 12 février 2003 relatif aux prescriptions applicables aux installations classées soumises à autorisation sous la rubrique 2730 traitement de sous-produits d’origine animale, y compris débris, issues et cadavres, à l’exclusion des activités visées par d’autres rubriques de la nomenclature, des établissements de diagnostic, de recherche et d’enseignement. JORF 2003, 89, 6654. Available online: https://www.legifrance.gouv.fr/loda/id/JORFTEXT000000419523 (accessed on 9 March 2023).

- Arrêté du 22 avril 2008 fixant les règles techniques auxquelles doivent satisfaire les installations de compostage soumises à autorisation en application du titre Ier du livre V du code de l’environnement. JORF 2008, 114, 8058. Available online: https://www.legifrance.gouv.fr/loda/id/JORFTEXT000018800981/ (accessed on 9 March 2023).

- Cseh, M.; Nárai, K.F.; Barcs, E.; Szepesi, D.B.; Szepesi, D.J.; Dicke, J.L. Odor setback distance calculations around animal farms and solid waste landfills. Idojárás 2010, 114, 303–318. [Google Scholar]

- Linee Guida Relative alla Costruzione e All’esercizio Degli Impianti di Produzione di Compost. Revoca della d.g.r 2003, n. 7/12764). Regione Lombardia, Bollettino Ufficiale. Available online: https://www.territorioambiente.com/wp-content/uploads/2014/07/dgr_7_12764_esercizio_impianti_produzione_compost.pdf (accessed on 9 March 2023).

- Nařízení Vlády č. 353/2002 Sb., Kterým se Stanoví Emisní Limity a Další Podmínky Provozování Ostatních Stacionárních Zdrojů Znečišťování Ovzduší v Platném Znění. Available online: https://www.zakonyprolidi.cz/cs/2002-353 (accessed on 28 February 2023).

- Murawska, J.; Rauba, M. Organization of the Operation of the Municipal Sewage Treatment Plant in Bialystok in the Context of Reducing Microbiological Pollution Entering the Atmosphere. Available online: https://depot.ceon.pl/handle/123456789/21719 (accessed on 9 March 2023). (In Polish).

- Sówka, I.; Zwoździak, P.; Zwoździak, A.; Zwoździak, J. Problems of odor nuisance of selected municipal management facilities. Inst. Environ. Eng. 2008, 409–414. Available online: http://www.pzits.not.pl/docs/ksiazki/Ekotoks_2008/Sowka%20409-414.pdf (accessed on 9 March 2023). (In Polish).

- Biedrzycka, A. Deodorization of Płaszów wastewater treatment plant. Mod. Eng. Constr. 2019, 22–25. (In Polish) [Google Scholar]

- Wos, P.; Dyka, M.; Korniluk, M.; Lagod, G. Influence of “Hajdow” wastewater treatment plant modernization on wastewater purification process and amount of emerging waste. Proc. ECOpole 2007, 1, 277–281. (In Polish) [Google Scholar]

- Brudniak, A.; Niedźwiedzka, K. Identification and Analysis of the Causes of Odour Nuisance of Wastewater Management Facilities (WTP) of the City of Olsztyn; Department of Environmental Engineering in Olsztyn: Olsztyn, Poland, 2014; pp. 109–120. (In Polish) [Google Scholar]

- Marquez, P.; Benitez, A.; Caballero, A.; Siles, J.A.; Martin, M.A. Integral evaluation of granular activated carbon at four stages of a full-scale WWTP deodorization system. Sci. Total Environ. 2021, 754, 10. [Google Scholar] [CrossRef]

- Wysocka, I. Utilizing Iron Corrosion in Reducing Odour Emissions; Publishing House of the Polish Academy of Sciences Committee on Environmental Engineering: Zabrze, Poland, 2020; pp. 1–177. (In Polish) [Google Scholar]

- Cyganecka-Wilkoszewska, A.; Sudoł, J. Solutions for combating odor nuisance in MPWiK facilities in the city of Warsaw. In Proceedings of the Prevention of Odor Emissions in Municipal and Industrial Facilities, Otwock, Poland, 12–13 February 2019. (In Polish). [Google Scholar]

- Cyganecka-Wilkoszewska, A.; Bisak, A. (Un)nuisance neighbor. Design solutions and methods of action eliminating the problem of odor nuisance of sewage and sludge management facilities on the example of the Warsaw sewage treatment plant “Czajka”. In Proceedings of the II Technical Conference on “Prevention of Odor Emission in Municipal Management Facilities, Zegrze, Poland, 28–29 November 2017. (In Polish). [Google Scholar]

- Alinezhad, E.; Haghighi, M.; Rahmani, F.; Keshizadeh, H.; Abdi, M.; Naddafi, K. Technical and economic investigation of chemical scrubber and biofiltration in removal of H2S and NH3 from wastewater treatment plant. J. Environ. Manag. 2019, 241, 32–43. [Google Scholar] [CrossRef]

- Zheng, T.L.; Li, L.; Chai, F.G.; Wang, Y.J. Factors impacting the performance and microbial populations of three biofilters for co-treatment of H2S and NH3 in a domestic waste landfill site. Process Saf. Environ. Protect. 2021, 149, 410–421. [Google Scholar] [CrossRef]

- Wysocka, I. Absorption processes in reducing the odor nuisance of wastewater. MethodsX 2023, 10, 101996. [Google Scholar] [CrossRef]

- Barbusinski, K.; Parzentna-Gabor, A.; Kasperczyk, D. Removal of Odors (Mainly H2S and NH3) Using Biological Treatment Methods. Clean Technol. 2021, 3, 138–155. [Google Scholar] [CrossRef]

- Wysocka, I.; Gebicki, J.; Namiesnik, J. Technologies for deodorization of malodorous gases. Environ. Sci. Pollut. Res. 2019, 26, 9409–9434. [Google Scholar] [CrossRef] [Green Version]

- Gracian, C.; Nastasi, V. Odorous VOC removal by an advanced water scrubber in waste water treatment plant. In Proceedings of the Conference IWA2021, Bilbao, Spain, 16 August 2022. [Google Scholar]

- Kerc, A.; Olmez, S.S. Ozonation of Odorous Air in Wastewater Treatment Plants. Ozone-Sci. Eng. 2010, 32, 199–203. [Google Scholar] [CrossRef]

- Kullavanijaya, E.; Trimm, D.; Cant, N. Adsocat: Adsorption/catalytic combustion for VOC and odour control. In Proceedings of the 12th International Congress on Catalysis, Granada, Spain, 9–14 July 2000; pp. 569–574. [Google Scholar]

- Estrada, J.M.; Lebrero, R.; Quijano, G.; Kraakman, N.B.; Muñoz, R. Odour abatement technologies in WWTPs: Energy and economic efficiency. In Sewage Treatment Plants; Stamatelatou, K., Tsagarakis, K.P., Eds.; IWA Publishing: London, UK, 2020; pp. 163–187. [Google Scholar]

- Sówka, I. Best practices in reducing nuisance odor nuisance. In Proceedings of the Meeting of the Air Protection and Energy Working Group: Implementation of the Air Protection Program in the Podkarpackie Voivodeship, Rzeszów, Poland, 5–7 April 2017. [Google Scholar]

| Chemical Compounds | Mixtures of Chemical Compounds | Odour Characteristics | Characteristics Depending on Concentration with Indication of Possible Influence on Humans TD */LTEL **/STEL *** [mg/m3] | Degree of Nuisance |

|---|---|---|---|---|

| Sulphur containing compounds | Hydrogen sulphide | rotten eggs | 0.14/7/14 | High |

| Methyl mercaptan (Methanethiol) | stinky, rotten cabbage, radish | 0.0042/1/2 | High | |

| Benzyl mercaptan | stinky, strong, disgusting | n.d. | High | |

| Butyl mercaptan (Butano-1-thiol) | rotten cabbage, skunk secretion, mustard | 0.001–0.002/1/2 | High | |

| Ethyl mercaptan (Ethanethiol) | stinky, skunk secretion, garlic | 0.0001/1/2 | High | |

| Allyl mercaptan (2-Propentiol) | stink, garlic, coffee | n.d. | High | |

| Diethyl sulphide | rotten vegetables, garlic, stinky | n.d. | High | |

| Dimethyl sulphide | rotten vegetables, cabbage, turnips, stinky | n.d. | High | |

| Dimethyl disulphide | stinky, disgusting | 0.003–0.014/2.5/5 | High | |

| Nitrogen containing compounds | Ammonia | suffocating, pungent, irritating, ammoniacal | >0.4/14/28 | Medium |

| Methylamine | ammoniacal, fishy | 0.03/5/15 | Low | |

| Dimethylamine | ammoniacal, fishy | n.d./3/9 | High | |

| Trimethylamine | ammoniacal, fishy | 2/4.9/12.5 | High | |

| Pyridine | faint, sweetish, unpleasant | 0.04–14/5/n.d. | Medium | |

| Other organic compounds | Indol | rotten proteins, faeces, faeces | n.d. | High |

| Skatol | faeces, faeces | n.d. | High | |

| Volatile fatty acids | Butyric acid | rancid butter, sweat | n.d. | High |

| Propionic acid | pungent, rancid, irritating | 0.084–60/30/45 | Medium | |

| Acetic acid | pungent, acetic | 0.5–2.5/25/50 | Medium | |

| Ketones | Acetone | sweet, musty, fruity, ethereal | 484–968/600/1800 | Medium |

| Butanone | pungent, minty, similar to acetone | n.d. | Low |

| Chemical Compound | Impact on Humans | Impact on the Environment | Ref. |

|---|---|---|---|

| Hydrogen sulphide | respiratory failure, convulsions, hypotension, cardiac arrhythmia, nervous system impairment, lacrimation, death | in animals: respiratory problems, nervous system paralysis, death; causes acid rain in effect, lowering the pH of soil and water; water soluble—can travel long distances | [33,34] |

| Methyl mercaptan | watery eyes, cough, headache, scratchy throat, nausea, shortness of breath, convulsions, cyanosis, pulmonary oedema, liver and kidney damage, cardiac arrhythmia, loss of consciousness, narcotic effects | air pollution, flammable, aquatic pollution, toxic to aquatic organisms, damage to embryos or foetuses | [30,35] |

| Ammonia | corrosive effect, pain, tearing, swelling and redness of the eyes, cough, sore throat, salivation, nausea, vomiting, pain behind the sternum, shortness of breath, respiratory arrest, fibrosis of the lung tissue with severe respiratory failure | increased nitrogen deposition—degradation of sensitive ecosystems, formation of atmospheric aerosols, reduced visibility, impact on radiation balance, contribution to greenhouse gases, contribution to global warming, eutrophication | [30,36,37] |

| Ethyl mercaptan | nervous system impairment, convulsions, respiratory impairment, tearing and eye pain, headache, cough, diarrhoea | data not available | [38] |

| Volatile fatty acids | caustic effect, pain tearing and redness of the eyes, sore throat, cough, shortness of breath, bronchospasm, ulcers, visual disturbances, risk of corneal damage, vomiting, abdominal pain, possible bleeding from the gastrointestinal tract | acute and chronic toxicity to aquatic organisms, the ability to bioaccumulate in organisms, cause pH changes in water resulting in hypoxia of reservoirs | [29,30] |

| Dimethyl disulphide | cough, eye pain, photophobia, vomiting, abdominal pain, iron disorders, haemolytic anaemia, allergic dermatitis, headache | in animals: convulsions, coma, liver damage, haemolytic anaemia | [30] |

| Legal Regulation | Content to Reduce/Eliminate Odour Nuisance |

|---|---|

| Act of 27 April 2001. Environmental Protection Law (Journal of Laws of 2001, item 519) | indication of reference values for individual substances in the air and activities whose conduct causes deterioration of the environment, which authorizes the issuance of a decision to suspend such activities |

| Act of 23 April 1964 Civil Code (Journal of Laws of 2017, item 459, as amended) | indicating that the owner of a building should refrain from activities that would interfere with the use of neighbouring properties beyond the average |

| Regulation of the Minister of Infrastructure of 12 April 2002 on the technical conditions to be met by buildings and their location (Journal of Laws of 2015, item 1422), Article 12, paragraph 6 | indications regarding the location of a livestock building or an outbuilding on a plot in relation to a residential building, a collective residence building or a public utility building existing on an adjacent building plot |

| Act of 14 December 2012 on waste (Journal of Laws of 2013, item 21, as amended) | tightening regulations on landfills, waste incineration or co-incineration plants, waste transportation, and the use of municipal sewage sludge |

| Regulation of the Minister of Environment of 26 January 2010 on reference values for certain substances in the air (Journal of Laws of 2010 No. 16, item 87) | the determination of reference values, due to the need for health protection, for 167 substances or groups of substances, including odoriferous substances (ammonia, mercaptans, hydrogen sulphide or dimotylein) |

| Regulation of the Minister of Environment of 27 August 2014 on the types of installations that may cause significant pollution of individual natural elements or the environment as a whole (Journal of Laws of 2014, item 1169) | specification of the types of installations that may cause significant pollution of individual natural elements or the environment as a whole |

| Country | Law | Scope of Influence |

|---|---|---|

| Netherlands |

|

|

| France |

|

|

| Germany |

|

|

| Czech Republic |

|

|

| Hungary |

|

|

| Italy |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czarnota, J.; Masłoń, A.; Pajura, R. Wastewater Treatment Plants as a Source of Malodorous Substances Hazardous to Health, Including a Case Study from Poland. Int. J. Environ. Res. Public Health 2023, 20, 5379. https://doi.org/10.3390/ijerph20075379

Czarnota J, Masłoń A, Pajura R. Wastewater Treatment Plants as a Source of Malodorous Substances Hazardous to Health, Including a Case Study from Poland. International Journal of Environmental Research and Public Health. 2023; 20(7):5379. https://doi.org/10.3390/ijerph20075379

Chicago/Turabian StyleCzarnota, Joanna, Adam Masłoń, and Rebeka Pajura. 2023. "Wastewater Treatment Plants as a Source of Malodorous Substances Hazardous to Health, Including a Case Study from Poland" International Journal of Environmental Research and Public Health 20, no. 7: 5379. https://doi.org/10.3390/ijerph20075379