Elevated Temperature Baseplate Effect on Microstructure, Mechanical Properties, and Thermal Stress Evaluation by Numerical Simulation for Austenite Stainless Steel 316L Fabricated by Directed Energy Deposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

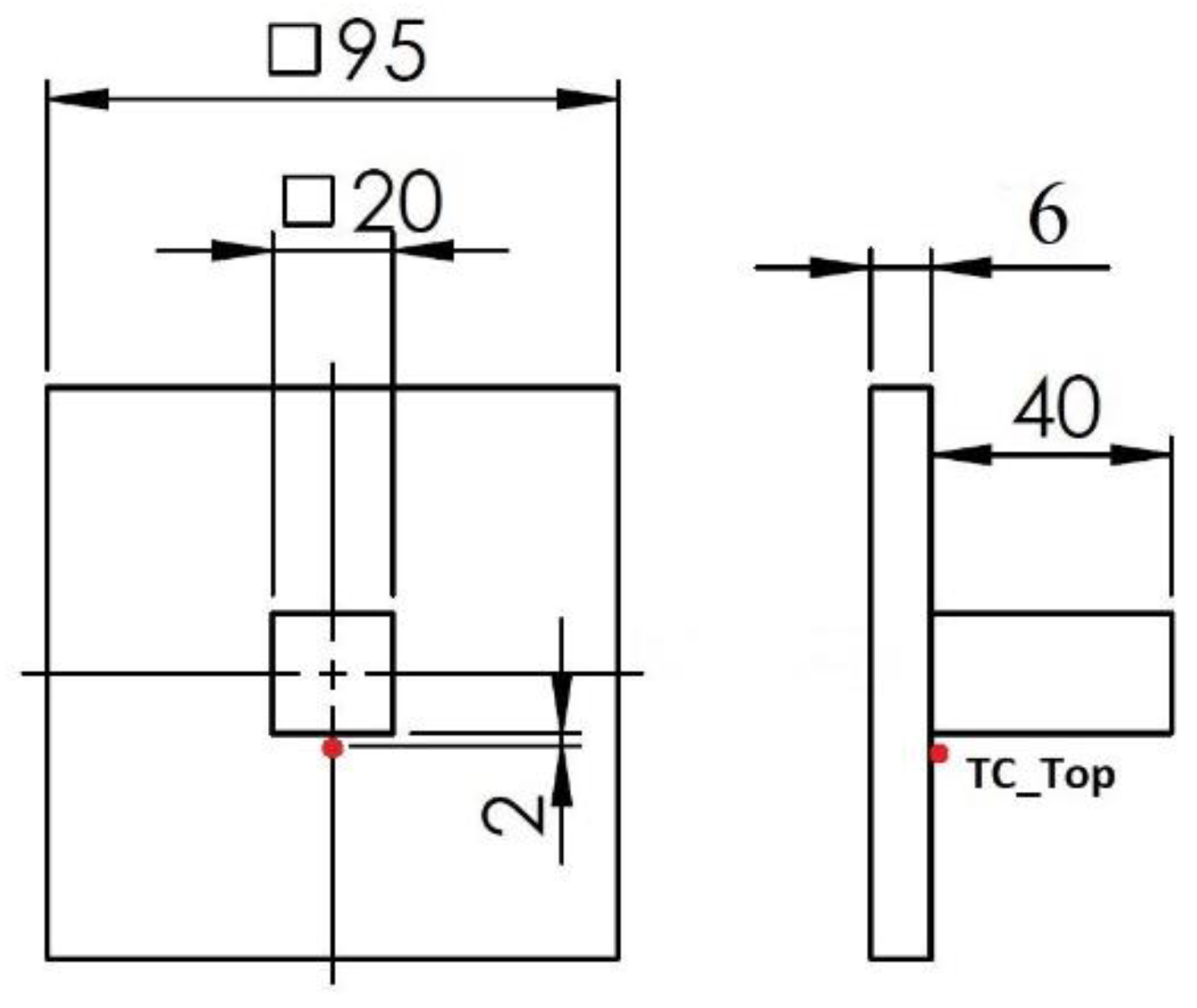

2.2. Experimental Setup

2.3. In Situ Temperature Measurement

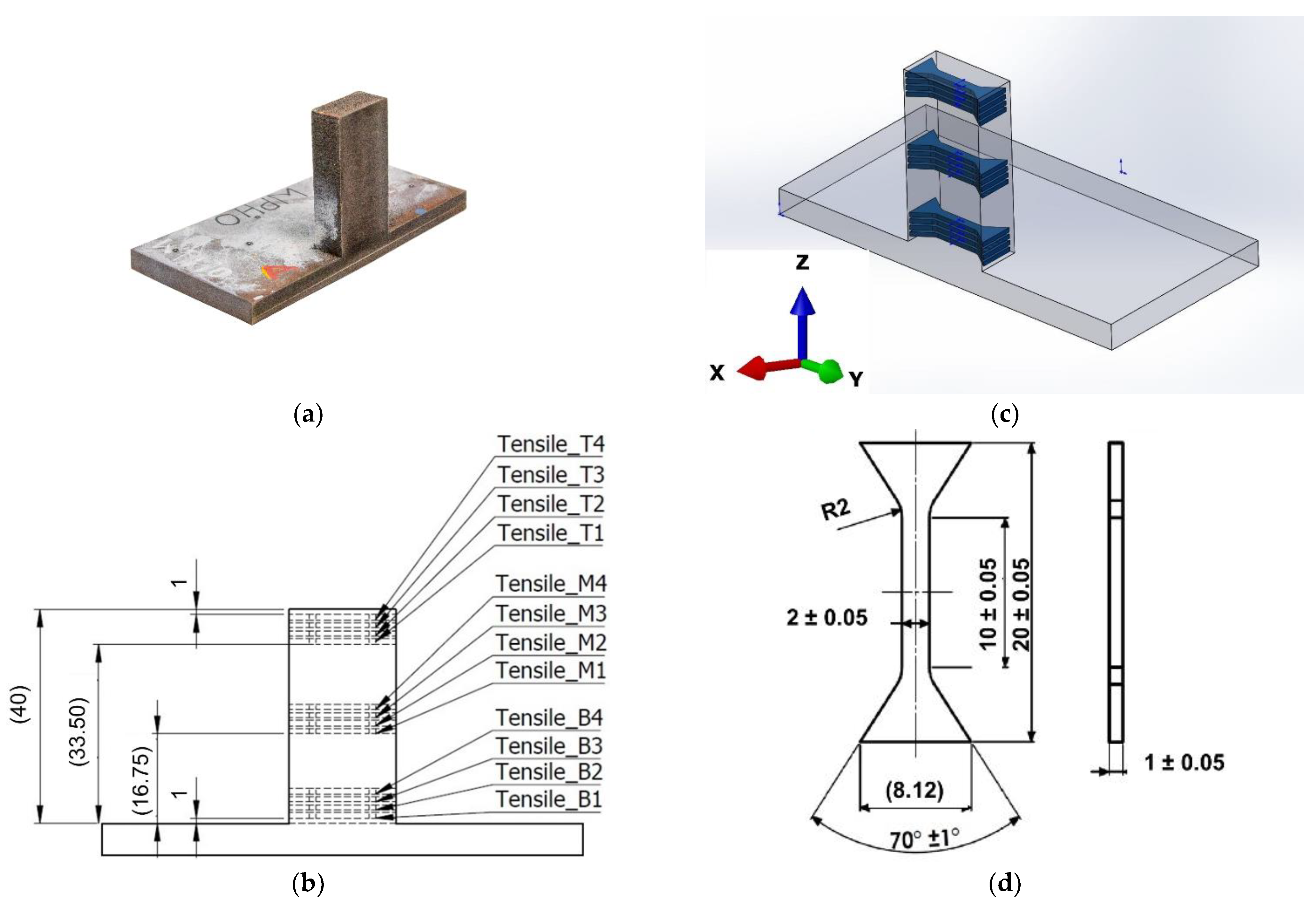

2.4. Tensile Test

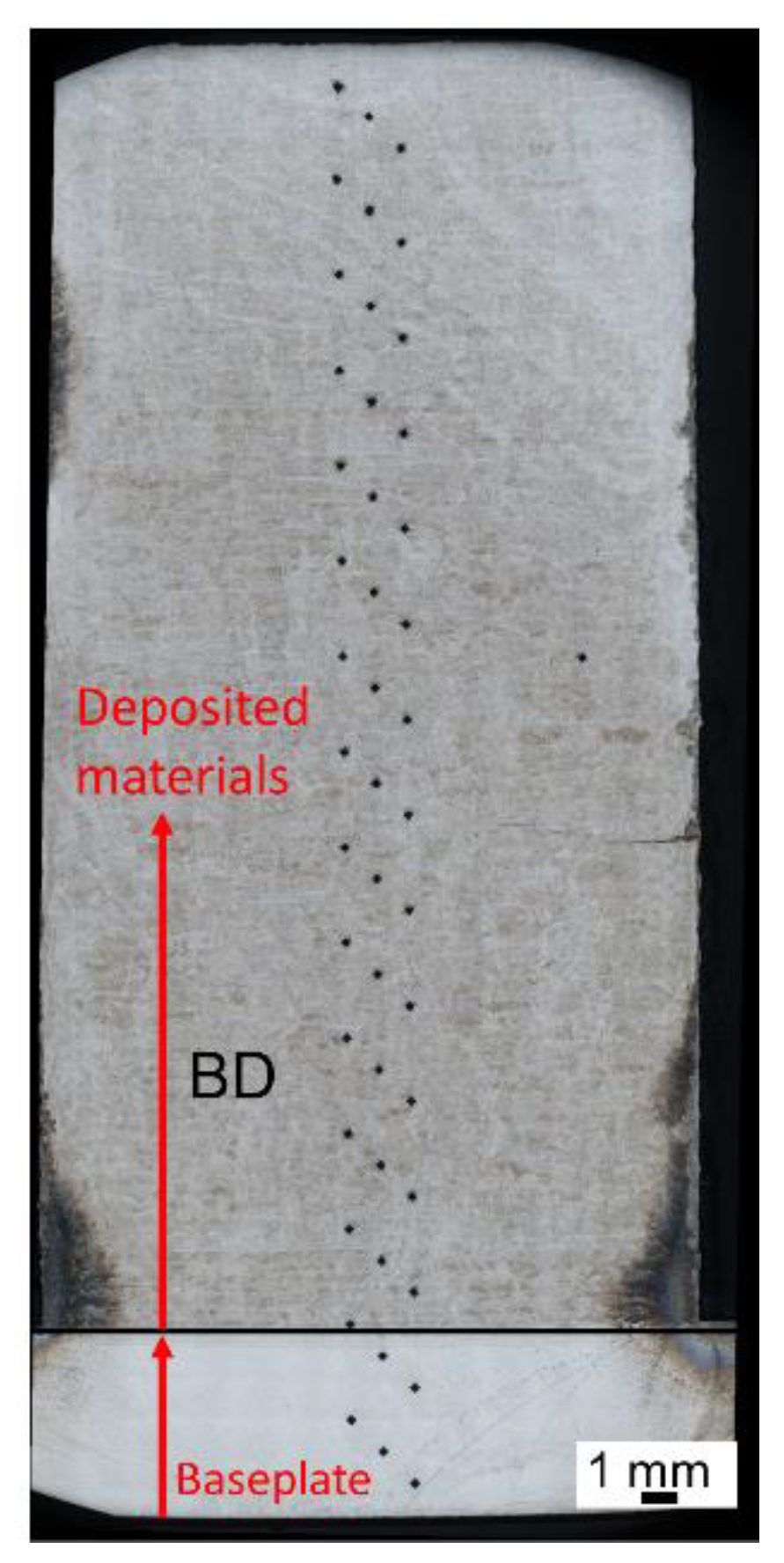

2.5. Hardness and Microstructural Evaluation Methods

2.6. Numerical Simulation

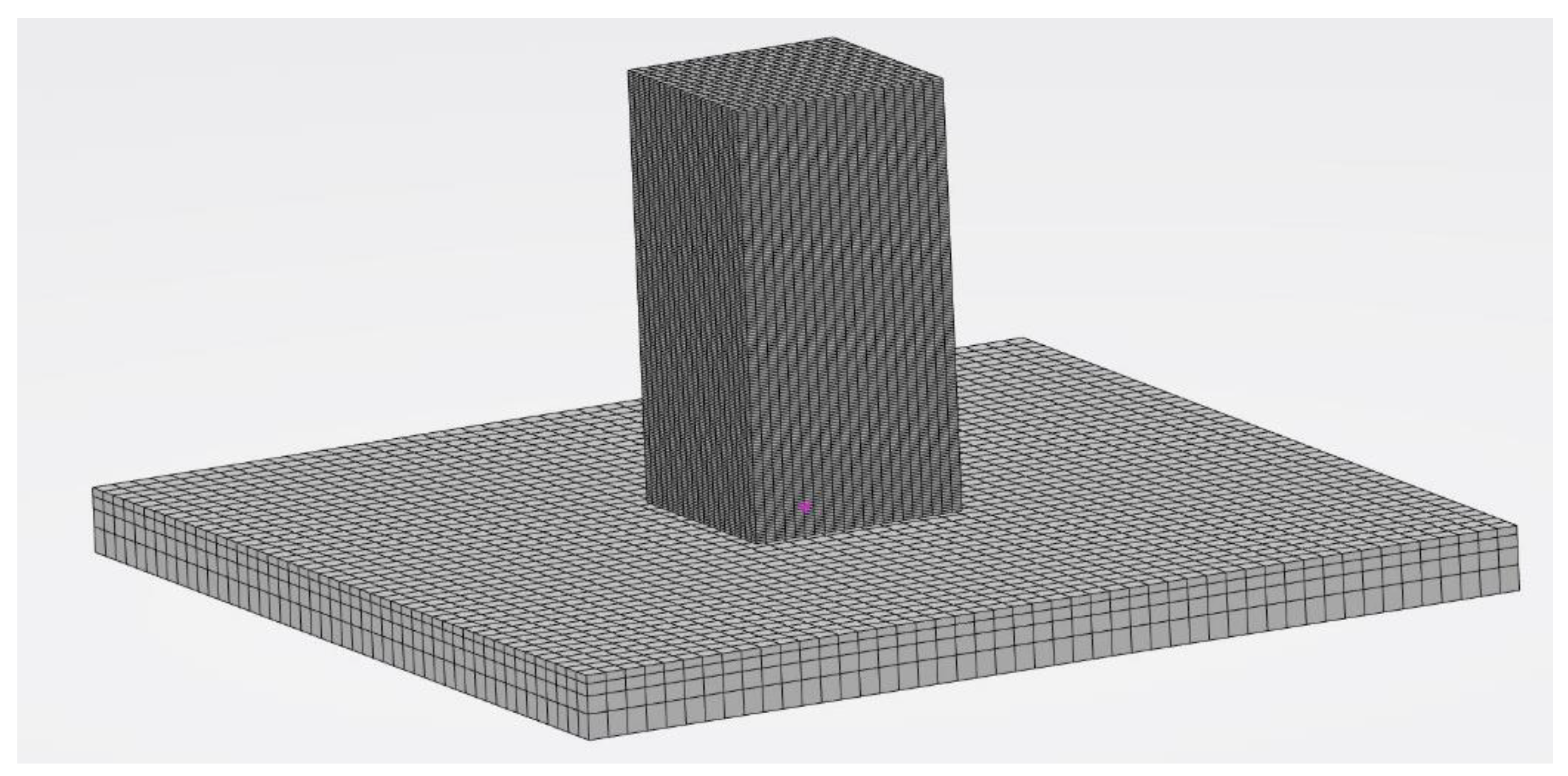

2.6.1. Thermal Analysis

2.6.2. Mechanical Analysis

2.7. FEM Model

3. Results

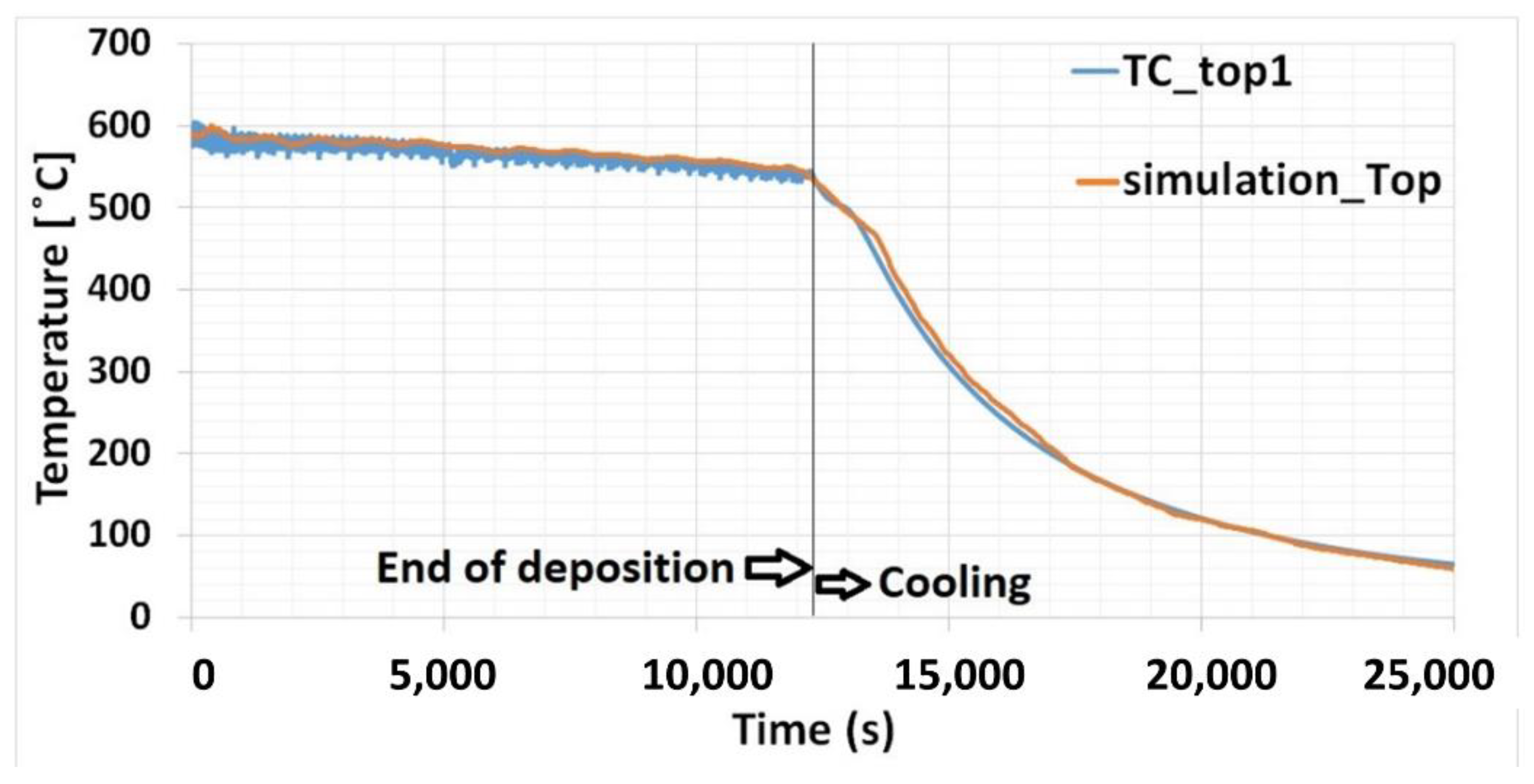

3.1. Thermal Analysis

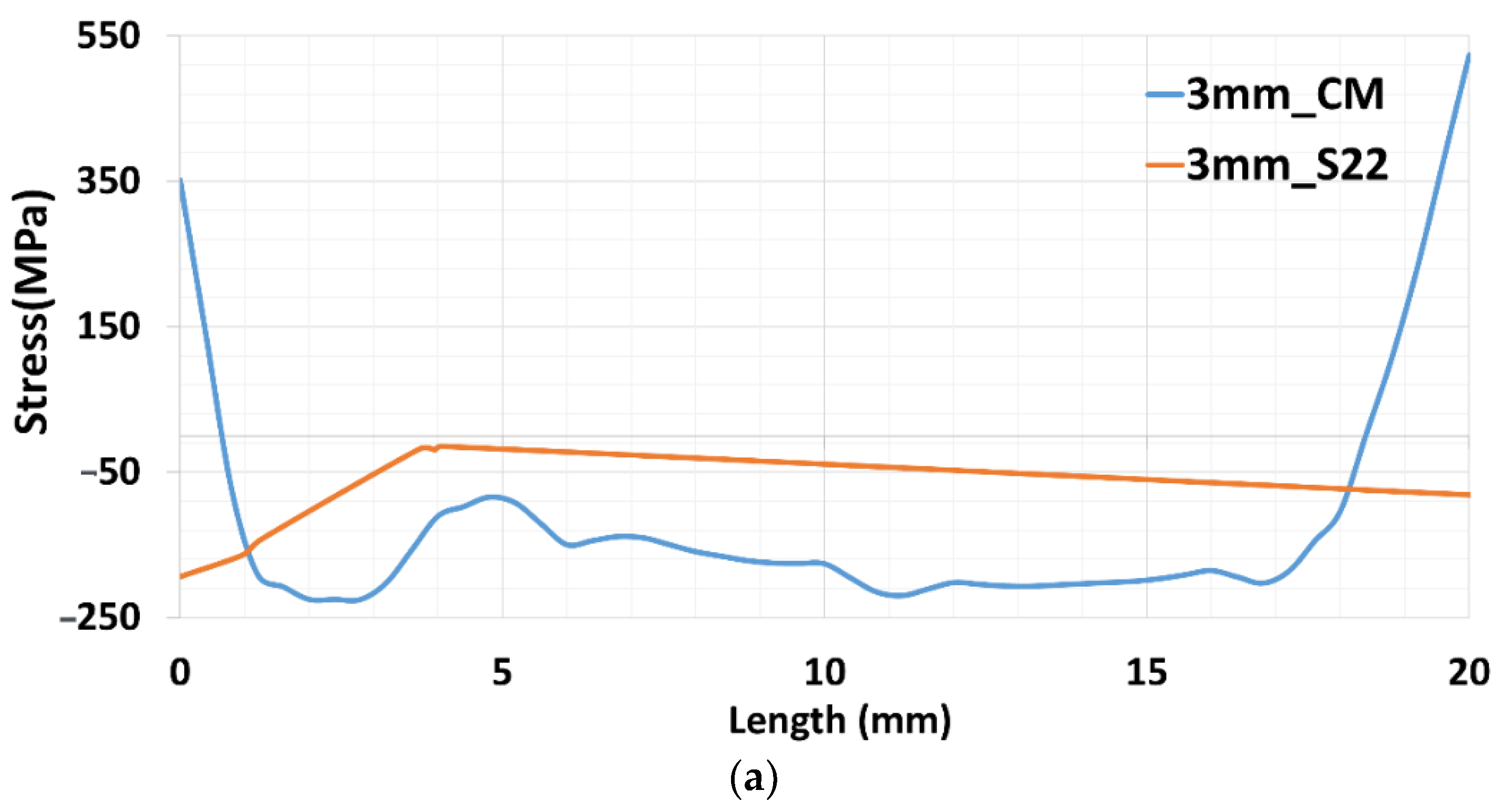

3.2. Mechanical Analysis

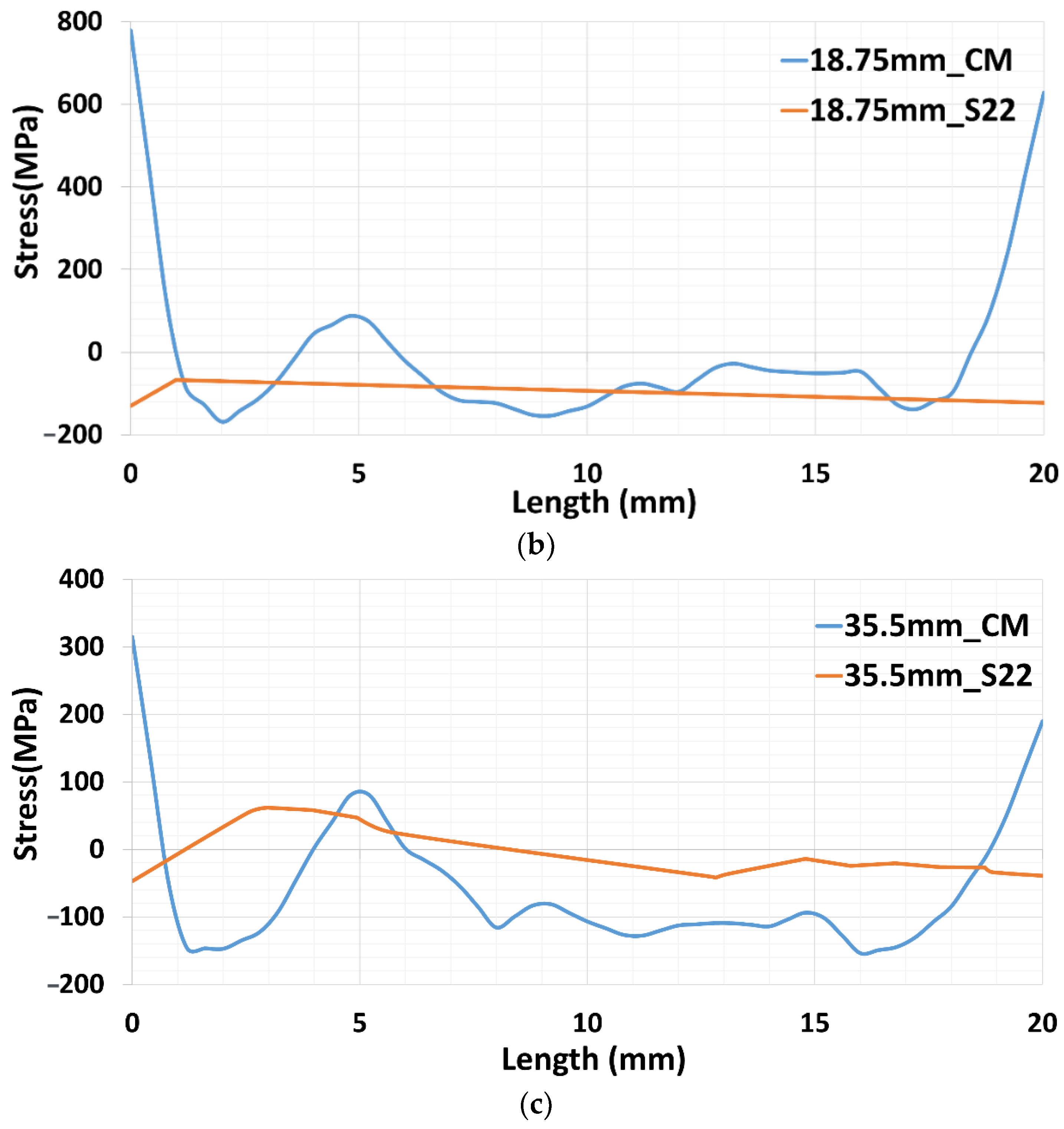

3.3. Temperature Profile and Thermal Stress Evolution

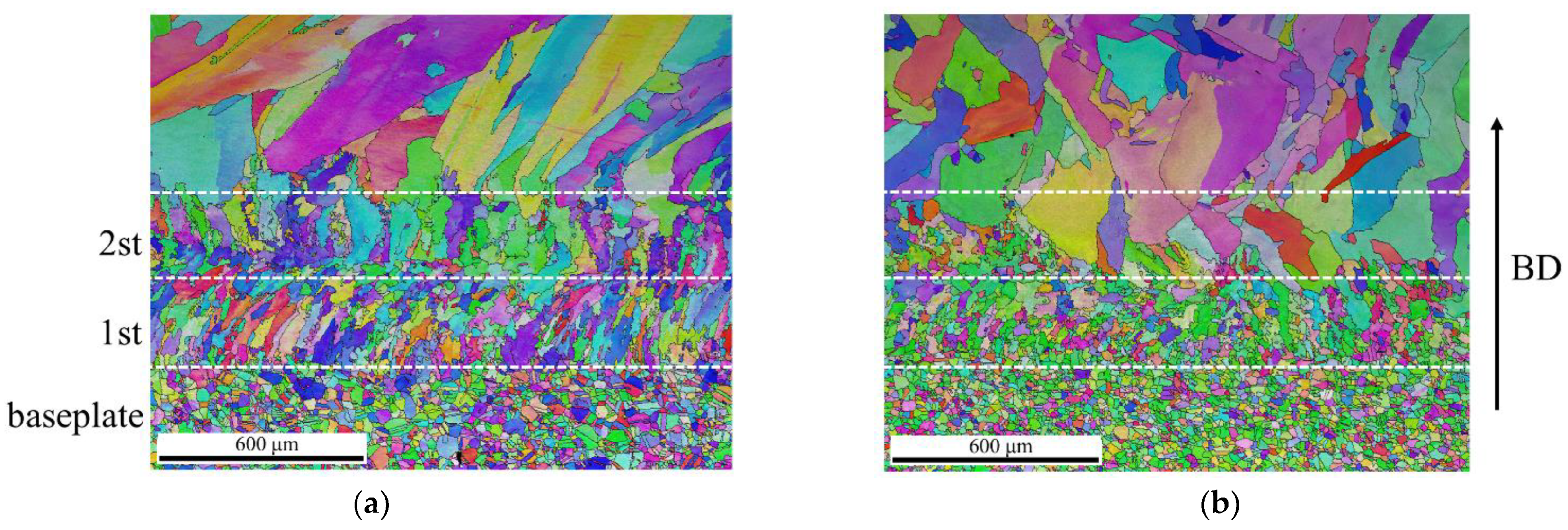

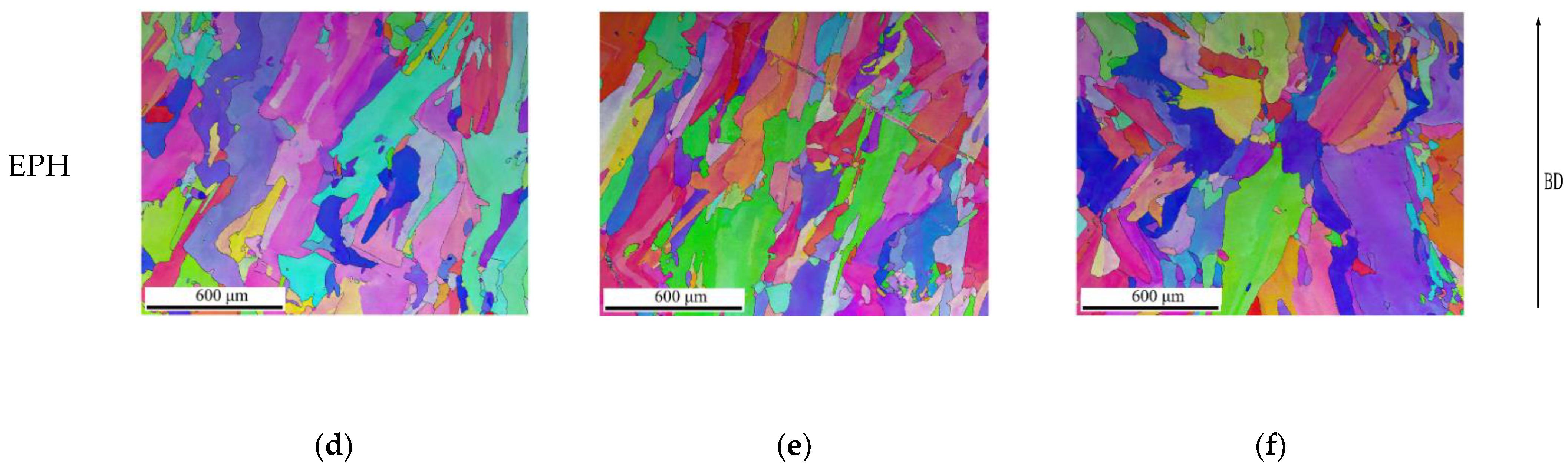

3.4. Microstructure Evaluation

3.5. Mechanical Properties

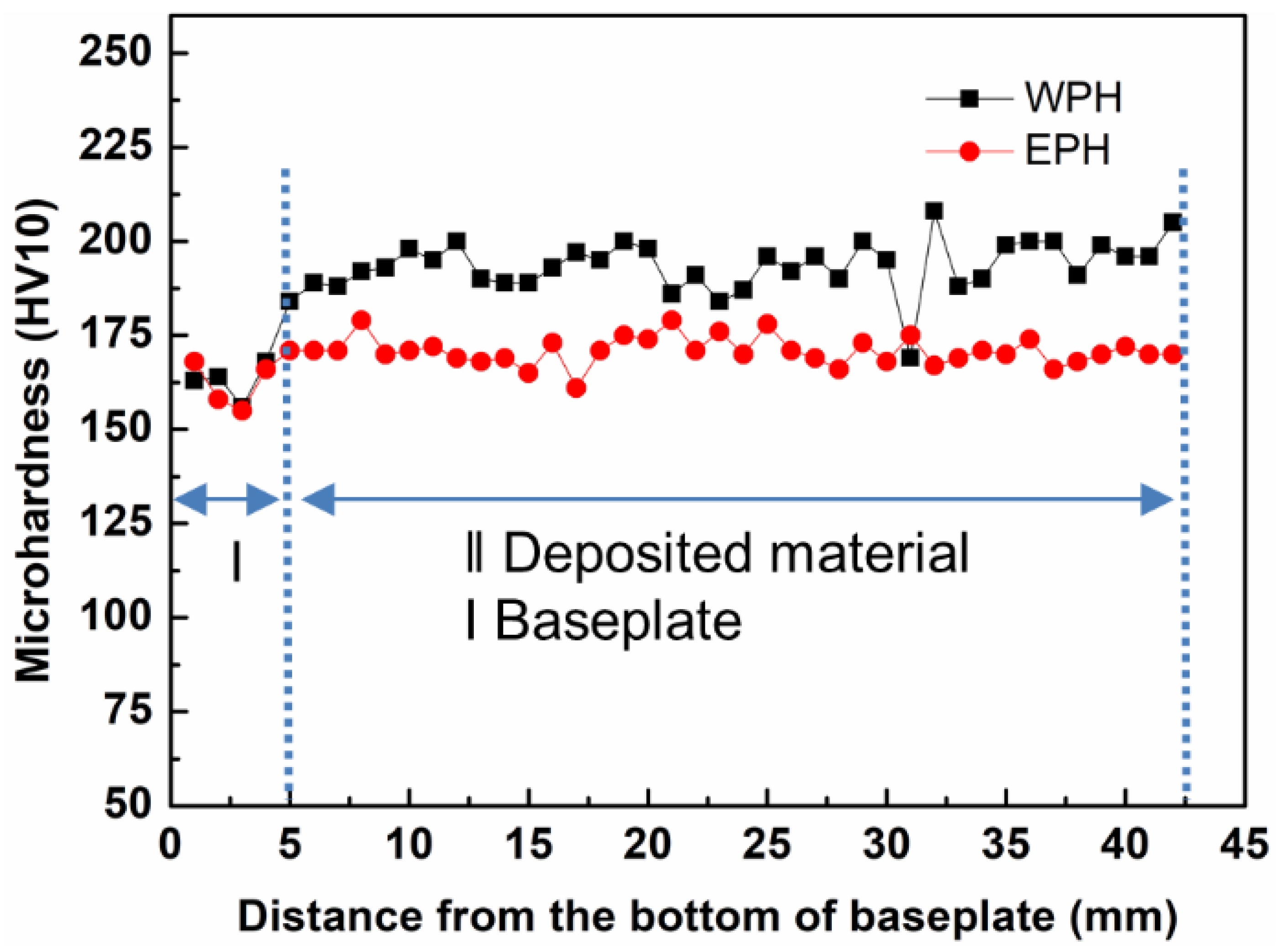

3.5.1. Hardness

3.5.2. Tensile Properties

4. Conclusions

- A thermal model was simulated using two heat sources. Introducing a stationary secondary heat source helps to simulate material deposition with external heating. Both the thermal and mechanical results agree well with the experimental data. Further thermal boundary definition needs to be improved to increase the accuracy and stability of the numerical results. The thermal evaluation at different layers reveals an increase in the peak temperature near the baseplate due to elevated temperature baseplate heating. Consequently, a nodal peak stress drop was noticed in different layers inside the deposited structure. The promising results demonstrate the lower risk of failures such as crack development due to internal stress. These results promote the deposition of multiple materials.

- Elevated temperature baseplate preheating contributes to a coarse grain feature throughout the bulk, especially for the first deposited layer. Remarkably, coarse grains are stimulated to grow from the second deposited layer, in contrast with finer grains with a slower grain growth rate in the case of deposition on the room temperature baseplate. A more homogenous microstructure can be achieved due to the continuously elevated temperature baseplate heating.

- Elevated temperature baseplate preheating yields a significant decrease in hardness and yield strength throughout the deposit, especially for the bottom region near the baseplate. Meanwhile, no significant effect on strain can be found. In addition, less heterogeneity in hardness and yield strength measurement can be achieved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kiran, A.; Hodek, J.; Vavřík, J.; Urbánek, M.; Džugan, J. Numerical Simulation Development and Computational Optimization for Directed Energy Deposition Additive Manufacturing Process. Materials 2020, 13, 2666. [Google Scholar] [CrossRef] [PubMed]

- Caiazzo, F.; Alfieri, V. Directed energy deposition of stainless steel wire with laser beam: Evaluation of geometry and affection depth. Procedia CIRP 2021, 99, 348–351. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of directed energy deposition-based additive manufacturing in repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Ahn, D.-G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf. Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Kiran, A.; Hodek, J.; Vavrík, J.; Lukáš, O.; Urbánek, M. Distortion Modelling of Steel 316l Symmetric Base Plate for Additive Manufacturing Process and Experimental Calibration. In Proceedings of the 29th International Conference on Metallurgy and Materials, Brno, Czech, 20–22 May 2020; pp. 862–867. [Google Scholar] [CrossRef]

- Lu, X.; Lin, X.; Chiumenti, M.; Cervera, M.; Hu, Y.; Ji, X.; Ma, L.; Yang, H.; Huang, W. Residual Stress and Distortion of Rectangular and S-Shaped Ti-6Al-4V Parts by Directed Energy Deposition: Modelling and Experimental Calibration. Addit. Manuf. 2019, 26, 166–179. [Google Scholar] [CrossRef]

- Shim, D.-S.; Baek, G.-Y.; Lee, E.-M. Effect of substrate preheating by induction heater on direct energy deposition of AISI M4 powder. Mater. Sci. Eng. A 2017, 682, 550–562. [Google Scholar] [CrossRef]

- Kempen, K.; Vrancken, B.; Buls, S.; Thijs, L.; Humbeeck, J.; Kruth, J.-P. Selective laser melting of crack-free high density M2 High Speed Steel Parts by Baseplate Preheating. J. Manuf. Sci. Eng. 2014, 136, 061026–061031. [Google Scholar] [CrossRef]

- Meng, W.; Xiaohui, Y.; Zhang, W.; Junfei, F.; Lijie, G.; Ma, Q.; Bing, C. Additive manufacturing of a functionally graded material from inconel625 to Ti6Al4V by laser synchronous preheating. J. Mater. Process. Technol. 2019, 275, 116368. [Google Scholar] [CrossRef]

- Kiran, A.; Koukolíková, M.; Vavřík, J.; Urbánek, M.; Džugan, J. Base plate preheating effect on microstructure of 316L stainless steel single track deposition by directed energy deposition. Materials 2021, 14, 5129. [Google Scholar] [CrossRef]

- Jendrzejewski, R.; Śliwiński, G.; Krawczuk, M.; Ostachowicz, W. Temperature and stress during laser cladding of double-layer coatings. Surf. Coat. Technol. 2006, 201, 3328–3334. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.J.; et al. The microstructure, mechanical properties and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Yu, J.; Rombouts, M.; Maes, G. Cracking behavior and mechanical properties of austenitic stainless steel parts produced by laser metal deposition. Mater. Des. 2013, 45, 228–235. [Google Scholar] [CrossRef]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304l made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Bassini, E. Directed energy deposition of aisi 316l stainless steel powder: Effect of process parameters. Metals 2021, 11, 932. [Google Scholar] [CrossRef]

- Thompson, S.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of direct laser deposition for additive manufacturing; part i: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Mertens, R.; Vrancken, B.; Holmstock, N.; Kinds, Y.; Kruth, J.-P.; Van Humbeeck, J. Influence of powder bed preheating on microstructure and mechanical properties of H13 tool steel SLM parts. Phys. Procedia 2016, 83, 882–890. [Google Scholar] [CrossRef]

- Liu, W.; Dupont, J.N. In-Situ Reactive Processing of Nickel Aluminides by Laser-Engineered Net Shaping. Metall. Mater. Trans. A 2003, 34, 2633–2641. [Google Scholar] [CrossRef]

- Park, J.; Kim, J.; Ji, I.; Lee, S.H. Numerical and Experimental Investigations of Laser Metal Deposition (LMD) Using STS 316L. Appl. Sci. 2020, 10, 4874. [Google Scholar] [CrossRef]

- Kiran, A.; Li, Y.; Hodek, J.; Brázda, M.; Urbánek, M.; Džugan, J. Heat Source Modeling and Residual Stress Analysis for Metal Directed Energy Deposition Additive Manufacturing. Materials 2022, 15, 2545. [Google Scholar] [CrossRef]

- Dzugan, J.; Seifi, M.; Prochazka, R.; Rund, M.; Podany, P.; Konopik, P.; Lewandowski, J.J. Effects of Thickness and Orientation on the Small Scale Fracture Behaviour of Additively Manufactured Ti-6Al-4V. Mater. Charact. 2018, 143, 94–109. [Google Scholar] [CrossRef]

- Chvostová, E.; Horváth, J.; Konopik, P.; Rzepa, S.; Melzer, D. Optimization of Test Specimen Dimensions for Thermal Power Station Exposure Device. IOP Conf. Ser. Mater. Sci. Eng. 2020, 723, 12009. [Google Scholar] [CrossRef]

- Dal, M.; Fabbro, R. An Overview of the State of Art in Laser Welding Simulation. Opt. Laser Technol. 2016, 78, 2–14. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H. Numerical Simulation of Temperature Field and Residual Stress in Multi-Pass Welds in Stainless Steel Pipe and Comparison with Experimental Measurements. Comput. Mater. Sci. 2006, 37, 269–277. [Google Scholar] [CrossRef]

- Radaj, D. Welding Residual Stresses and Distortion: Calculation and Measurement; DVS-Verlag: Düsseldorf, Germany, 2003; Volume 2, ISBN 978-3-87155-791-0. [Google Scholar]

- Kiran, A.; Hodek, J.; Vavřík, J.; Brázda, M.; Urbánek, M.; Cejpek, J. Design & Modelling of Double Cantilever Structure by Stainless Steel 316L Deposited Using Additive Manufacturing Directed Energy Deposition Process. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1178, 012027. [Google Scholar] [CrossRef]

- Prime, M.B. Cross-Sectional Mapping of Residual Stresses by Measuring the Surface Contour after a Cut. J. Eng. Mater. Technol. Asme 2001, 123, 162–168. [Google Scholar] [CrossRef]

- Hodek, J.; Prantl, A.; Džugan, J.; Strunz, P. Determination of Directional Residual Stresses by the Contour Method. Metals 2019, 9, 1104. [Google Scholar] [CrossRef]

- Hosseinzadeh, F.; Bouchard, P.; Kowal, J. Towards Good Practice Guidelines for the Contour Method of Residual Stress Measurement. J. Eng. 2014, 2014, 453–468. [Google Scholar] [CrossRef]

- Moheimani, S.K.; Iuliano, L.; Saboori, A. The Role of Substrate Preheating on the Microstructure, Roughness, and Mechanical Performance of AISI 316L Produced by Directed Energy Deposition Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2022. [Google Scholar] [CrossRef]

- Kuo, Y.-L.; Nagahari, T.; Kakehi, K. The Effect of Post-Processes on the Microstructure and Creep Properties of Alloy718 Built Up by Selective Laser Melting. Materials 2018, 11, 996. [Google Scholar] [CrossRef]

- Huang, H.W.; Wang, Z.B.; Lu, J.; Lu, K. Fatigue Behaviors of AISI 316L Stainless Steel with a Gradient Nanostructured Surface Layer. Acta Mater. 2015, 87, 150–160. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Goh, P.C.; Wei, J.; Hardacre, D.; Li, H. Fatigue and Fracture Behaviour of Laser Powder Bed Fusion Stainless Steel 316L: Influence of Processing Parameters. Mater. Sci. Eng. A 2017, 703, 251–261. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components–Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and Heterogeneity of Microstructure and Mechanical Properties in Metal Additive Manufacturing: A Critical Review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Liu, F.; Lin, X.; Leng, H.; Cao, J.; Liu, Q.; Huang, C.; Huang, W. Microstructural Changes in a Laser Solid Forming Inconel 718 Superalloy Thin Wall in the Deposition Direction. Opt. Laser Technol. 2013, 45, 330–335. [Google Scholar] [CrossRef]

- Tian, Y.; McAllister, D.; Colijn, H.; Mills, M.; Farson, D.; Nordin, M.; Babu, S. Rationalization of Microstructure Heterogeneity in INCONEL 718 Builds Made by the Direct Laser Additive Manufacturing Process. Metall. Mater. Trans. A 2014, 45, 4470–4483. [Google Scholar] [CrossRef]

| 0.2% Yield Strength (MPa) | Ultimate Strength (MPa) | Elongation (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Location | WPH | EPH | Decrease by | WPH | EPH | Decrease by | WPH | EPH | Decrease by |

| Bottom | 449 | 324 | 28% | 627 | 579 | 8% | 29 | 29 | −1% |

| Middle | 420 | 324 | 23% | 605 | 575 | 5% | 34 | 32 | 5% |

| Top | 413 | 338 | 18% | 601 | 602 | −1% | 28 | 29 | −1.75% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiran, A.; Li, Y.; Koukolíková, M.; Brázda, M.; Hodek, J.; Urbánek, M.; Džugan, J.; Raghavan, S.; Odehnal, J. Elevated Temperature Baseplate Effect on Microstructure, Mechanical Properties, and Thermal Stress Evaluation by Numerical Simulation for Austenite Stainless Steel 316L Fabricated by Directed Energy Deposition. Materials 2022, 15, 4165. https://doi.org/10.3390/ma15124165

Kiran A, Li Y, Koukolíková M, Brázda M, Hodek J, Urbánek M, Džugan J, Raghavan S, Odehnal J. Elevated Temperature Baseplate Effect on Microstructure, Mechanical Properties, and Thermal Stress Evaluation by Numerical Simulation for Austenite Stainless Steel 316L Fabricated by Directed Energy Deposition. Materials. 2022; 15(12):4165. https://doi.org/10.3390/ma15124165

Chicago/Turabian StyleKiran, Abhilash, Ying Li, Martina Koukolíková, Michal Brázda, Josef Hodek, Miroslav Urbánek, Ján Džugan, Srinivasan Raghavan, and Josef Odehnal. 2022. "Elevated Temperature Baseplate Effect on Microstructure, Mechanical Properties, and Thermal Stress Evaluation by Numerical Simulation for Austenite Stainless Steel 316L Fabricated by Directed Energy Deposition" Materials 15, no. 12: 4165. https://doi.org/10.3390/ma15124165

APA StyleKiran, A., Li, Y., Koukolíková, M., Brázda, M., Hodek, J., Urbánek, M., Džugan, J., Raghavan, S., & Odehnal, J. (2022). Elevated Temperature Baseplate Effect on Microstructure, Mechanical Properties, and Thermal Stress Evaluation by Numerical Simulation for Austenite Stainless Steel 316L Fabricated by Directed Energy Deposition. Materials, 15(12), 4165. https://doi.org/10.3390/ma15124165