Performance Enhancement of a Centrifugal Compressor by Designing a Tandem Cascade Diffuser

Abstract

:1. Introduction

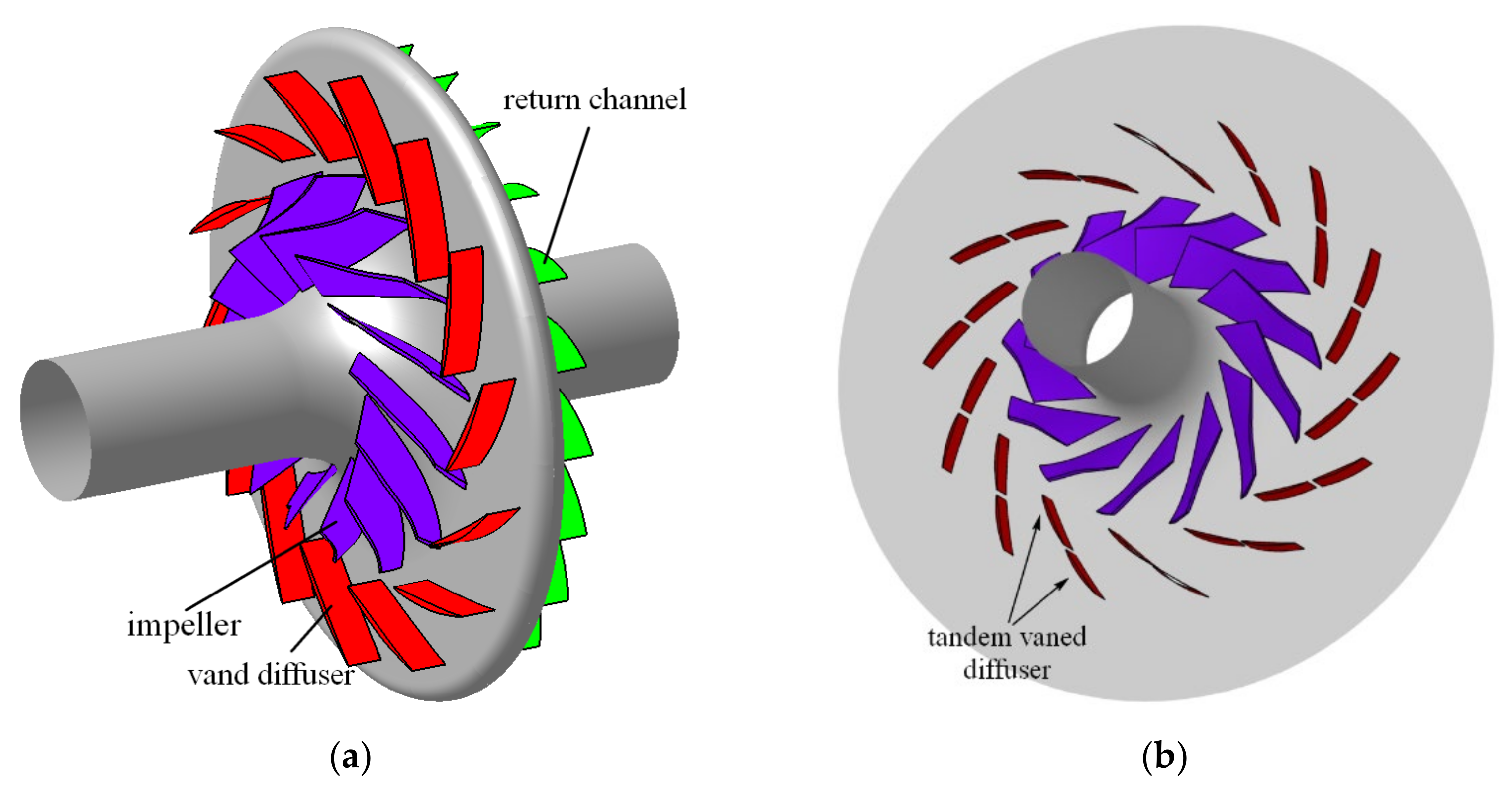

2. Computational Model and Numerical Method

2.1. Definition of Total Bending Angle of Tandem Vane Diffuser

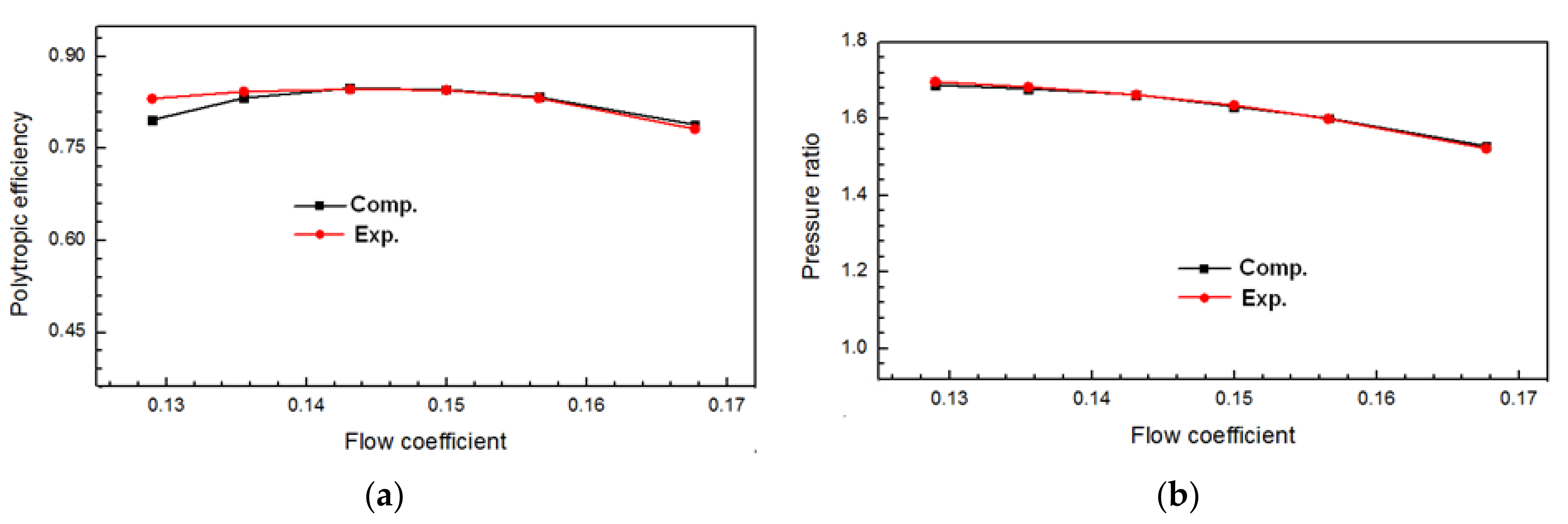

2.2. Numerical Method

- Global residuals and block residuals decrease by at least three orders of magnitude.

- The relative error of flow rate at inlet and outlet is less than 0.02% and the pressure ratio converges to a fixed value or a small range of periodical oscillations occur in the range of ± 0.2%.

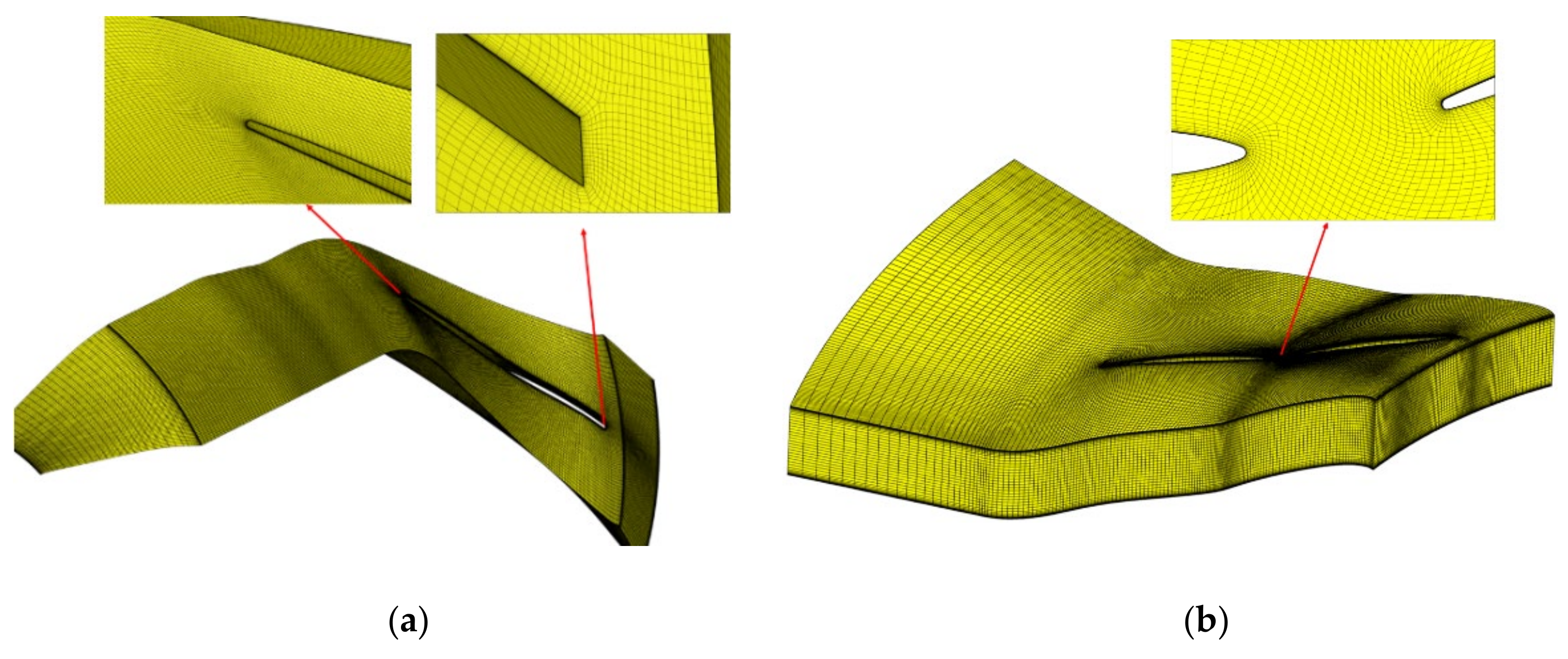

2.3. Computational Meshes and Grid Independence Verification

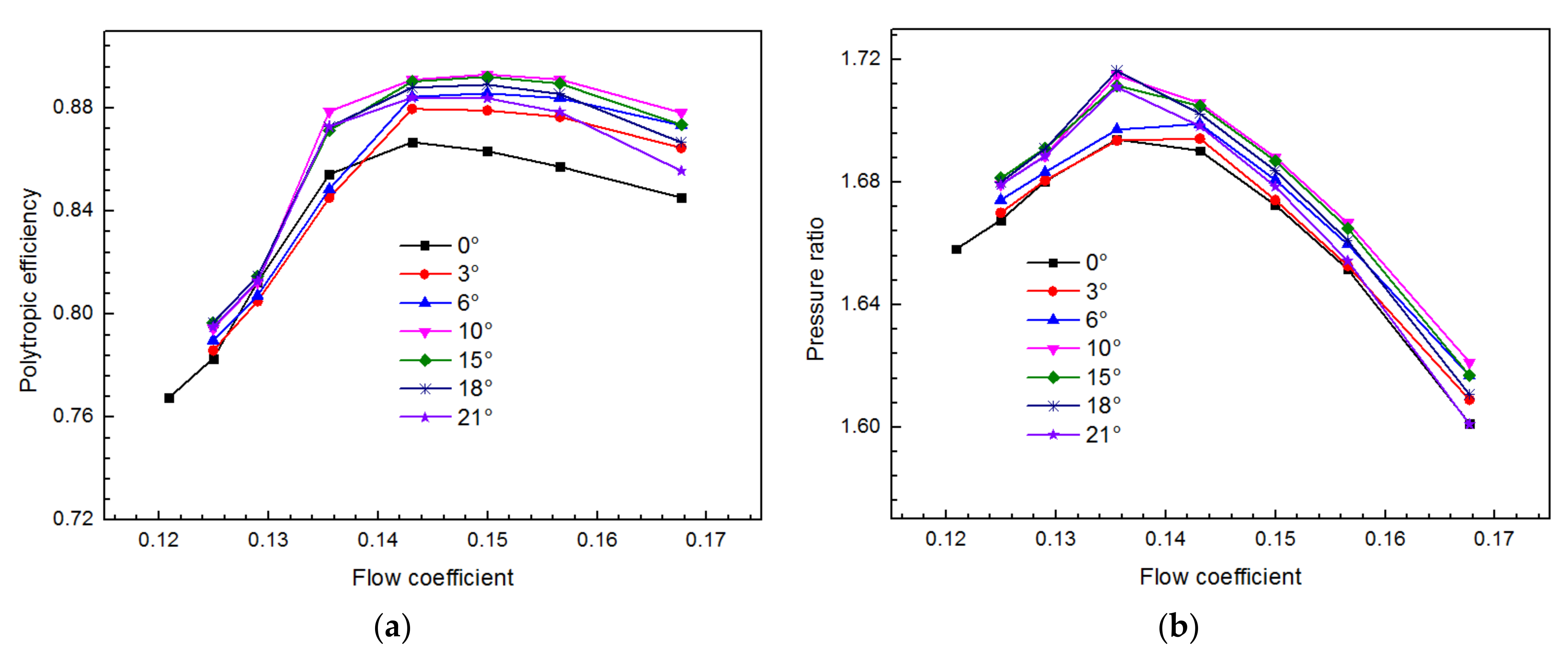

3. Calculation Results and Analysis

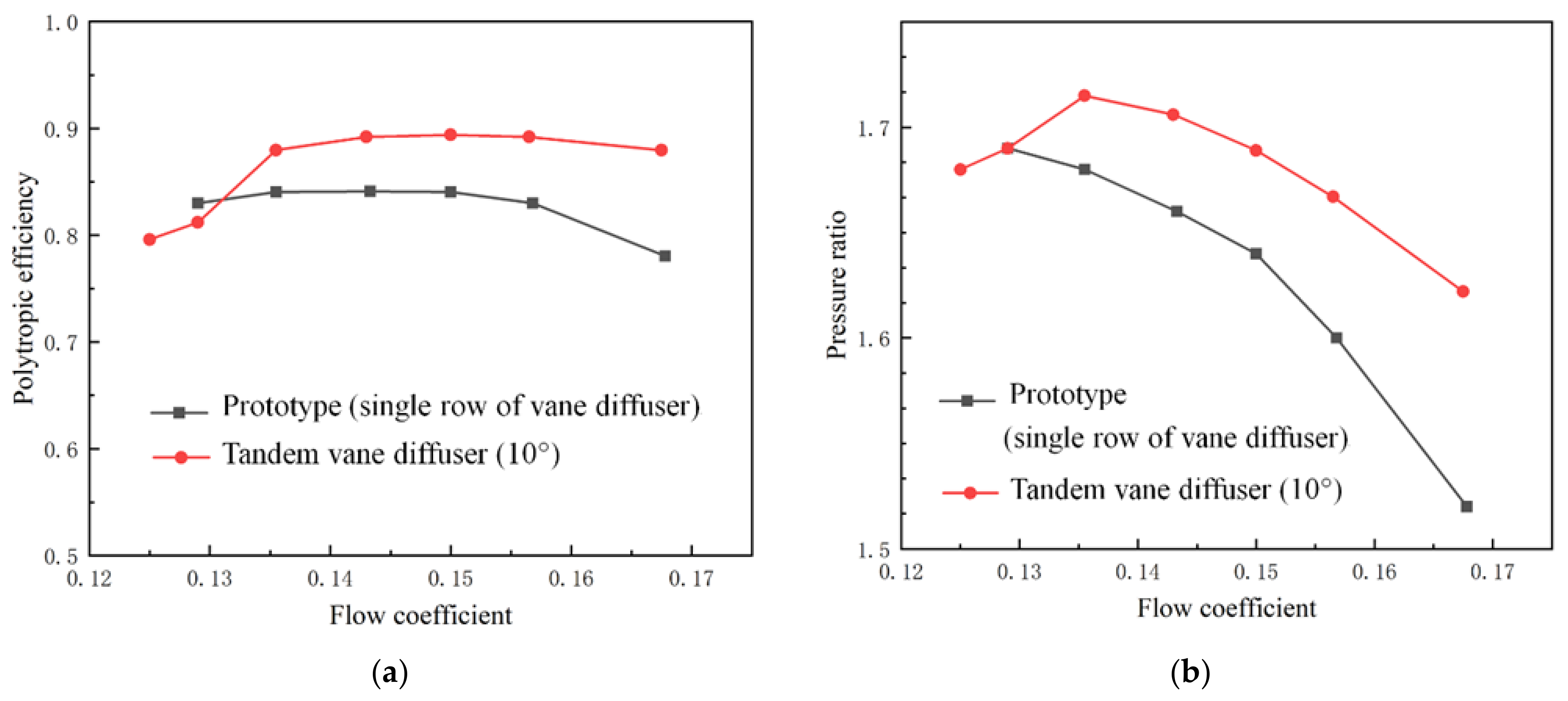

3.1. Analysis on Performance of Stage

3.2. Analysis on Flow Field in the Diffuser at a Small Flow Rate

4. Conclusions

- The efficiency and pressure ratio of the compressor stage increases with the increase of the total bending angle of the tandem blade diffuser in a certain range. The results show that the optimal performance is obtained by the 10° model for the compressor studied.

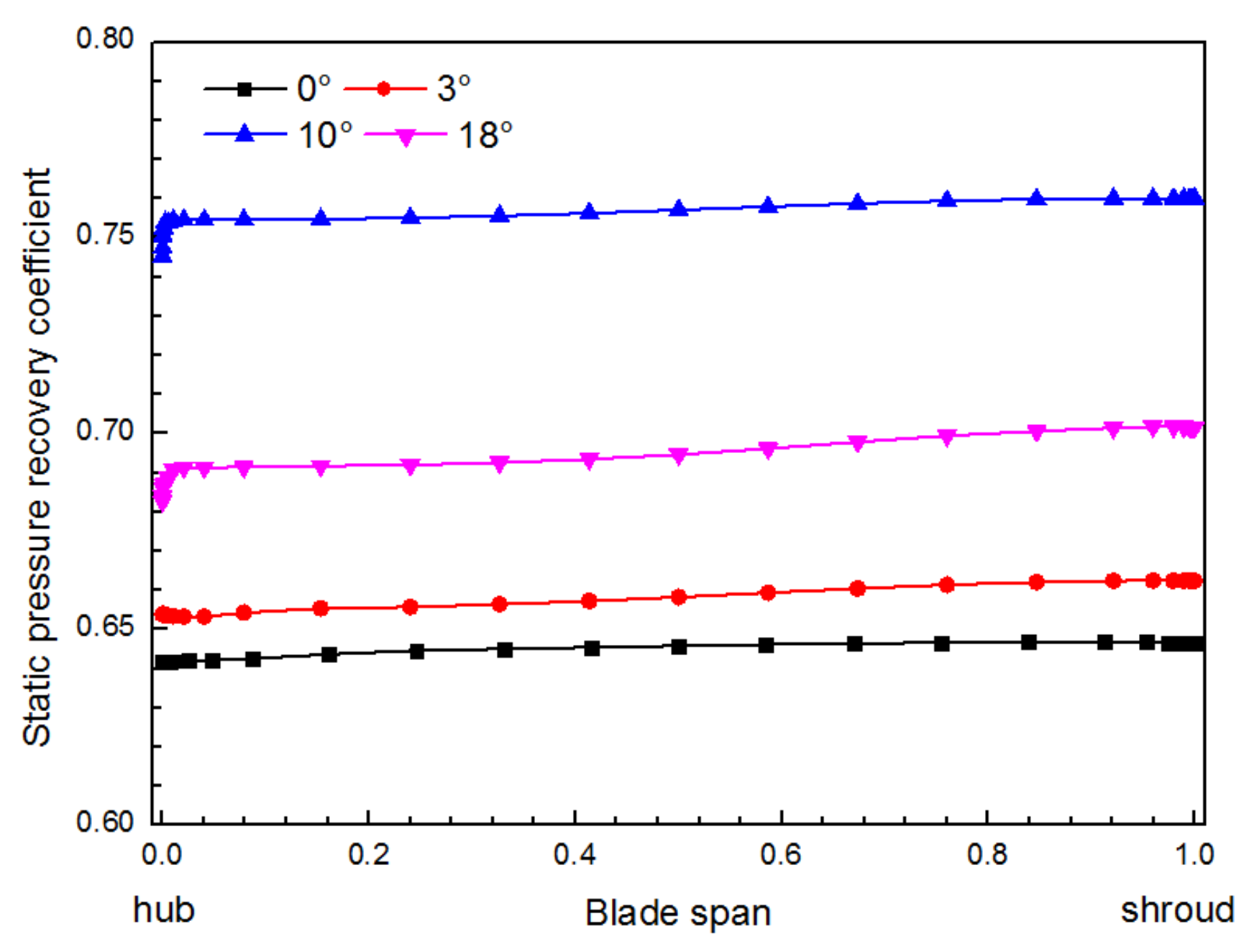

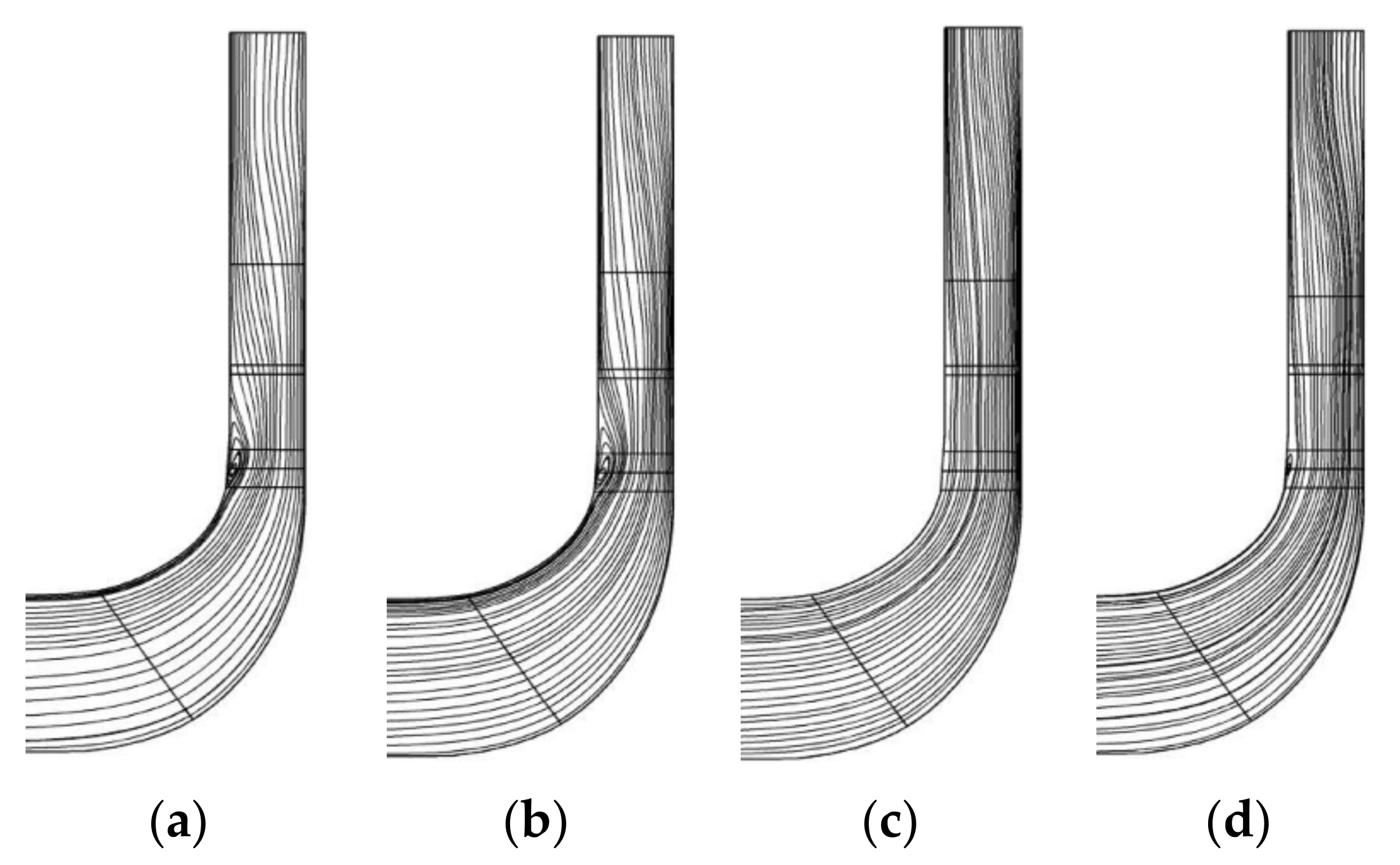

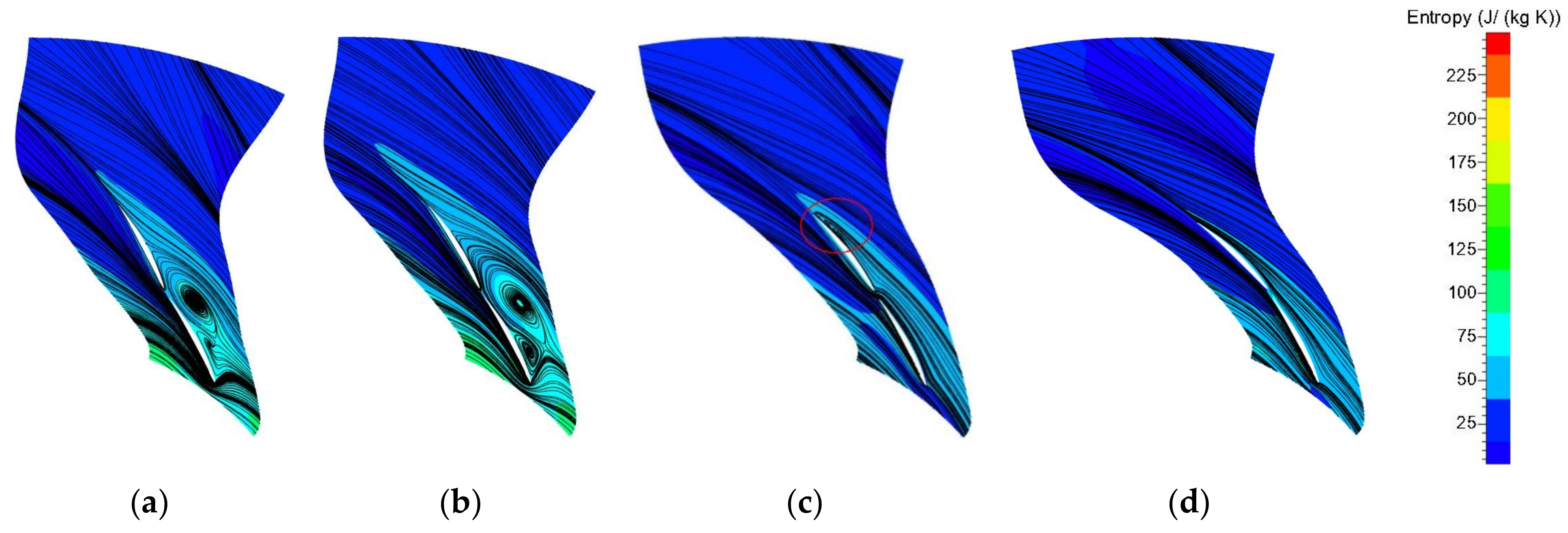

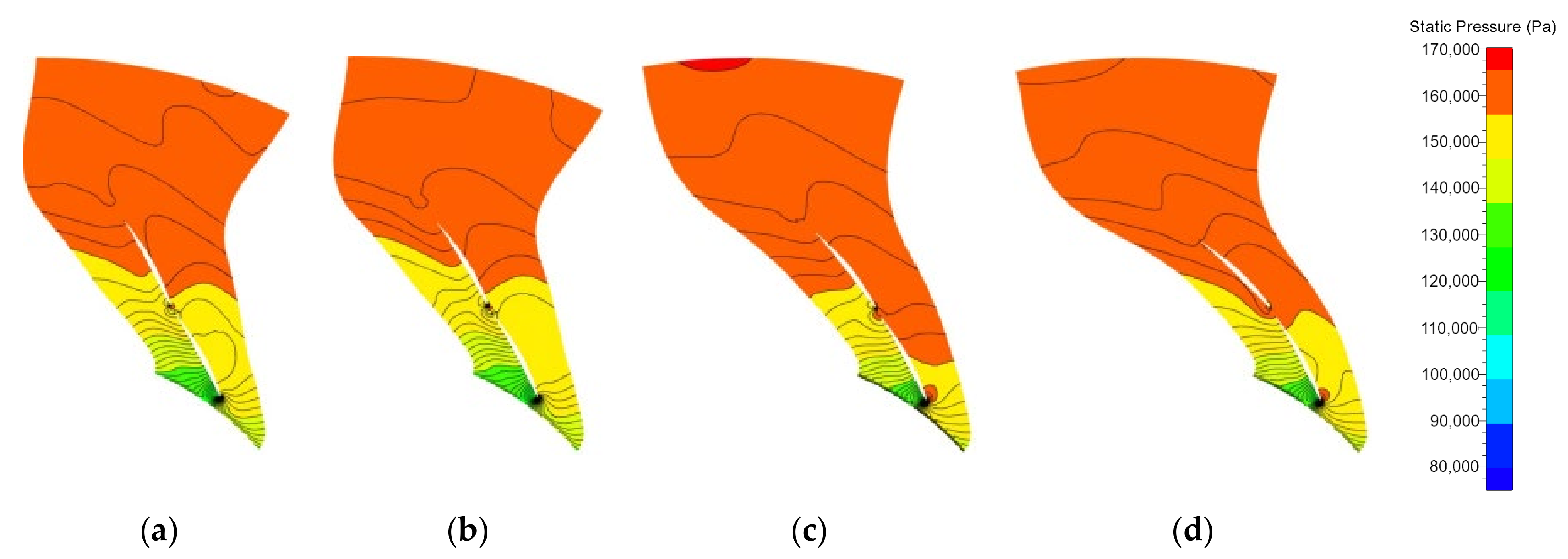

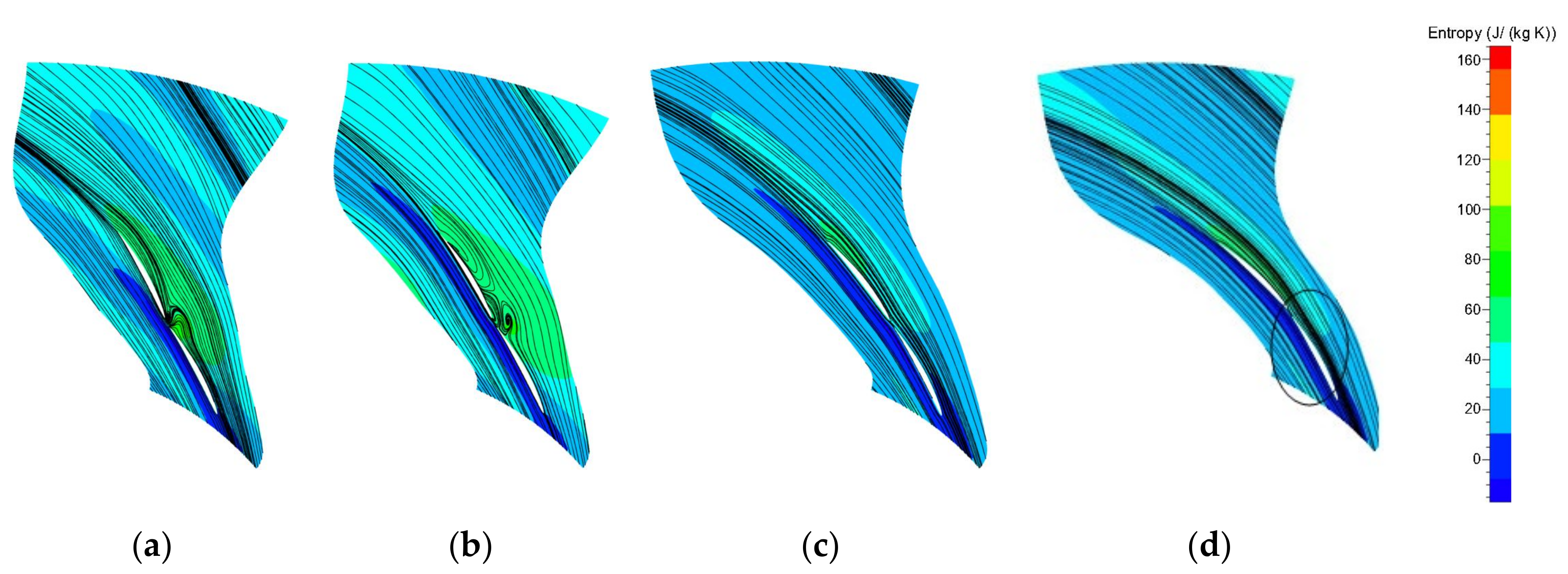

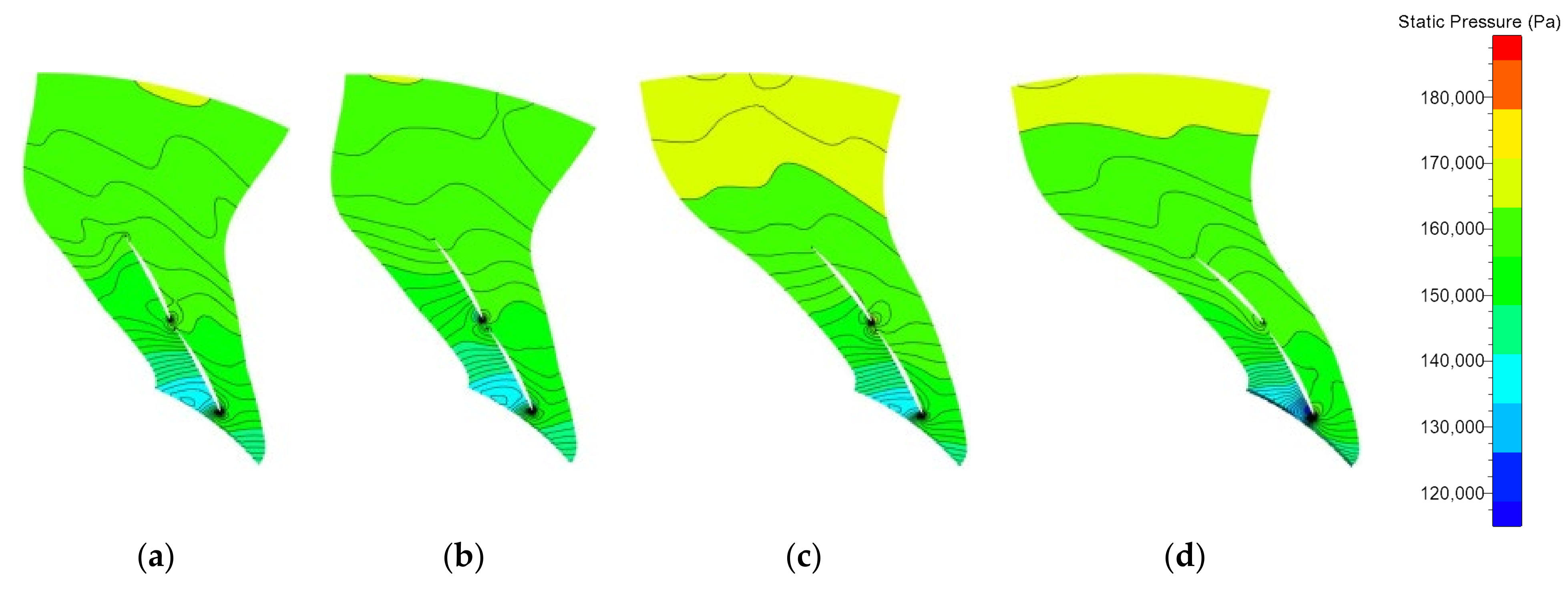

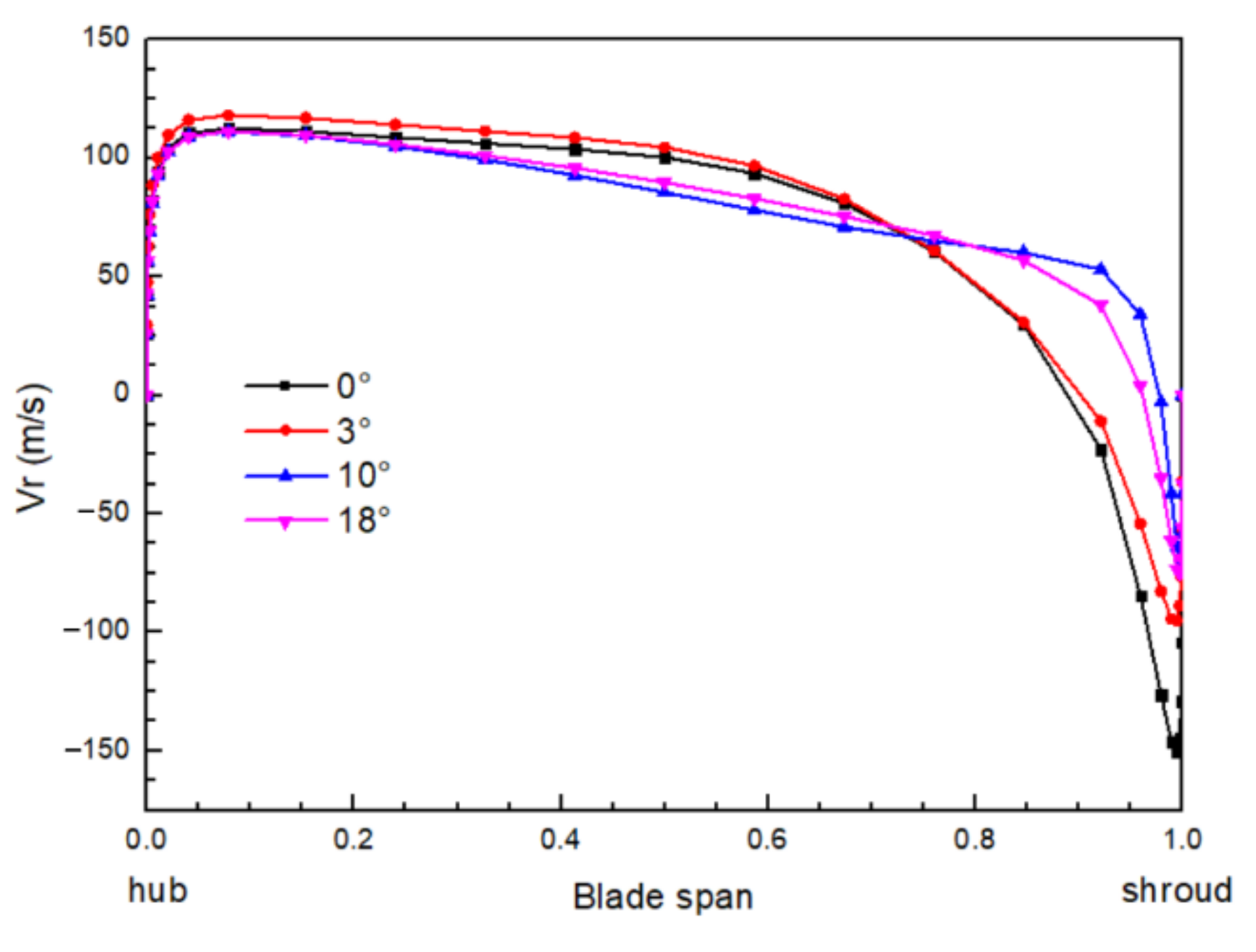

- The analysis of the meridional flow field of the impeller-diffuser at the low flow condition reveals that the increase of the total bending angle in a reasonable range effectively reduces the separation area near the shroud side of the diffuser. The increase of the total bending angle improves the separation in the diffuser flow field, thus greatly increasing the static pressure recovery coefficient and reducing the total pressure loss coefficient in the whole range of blade heights.

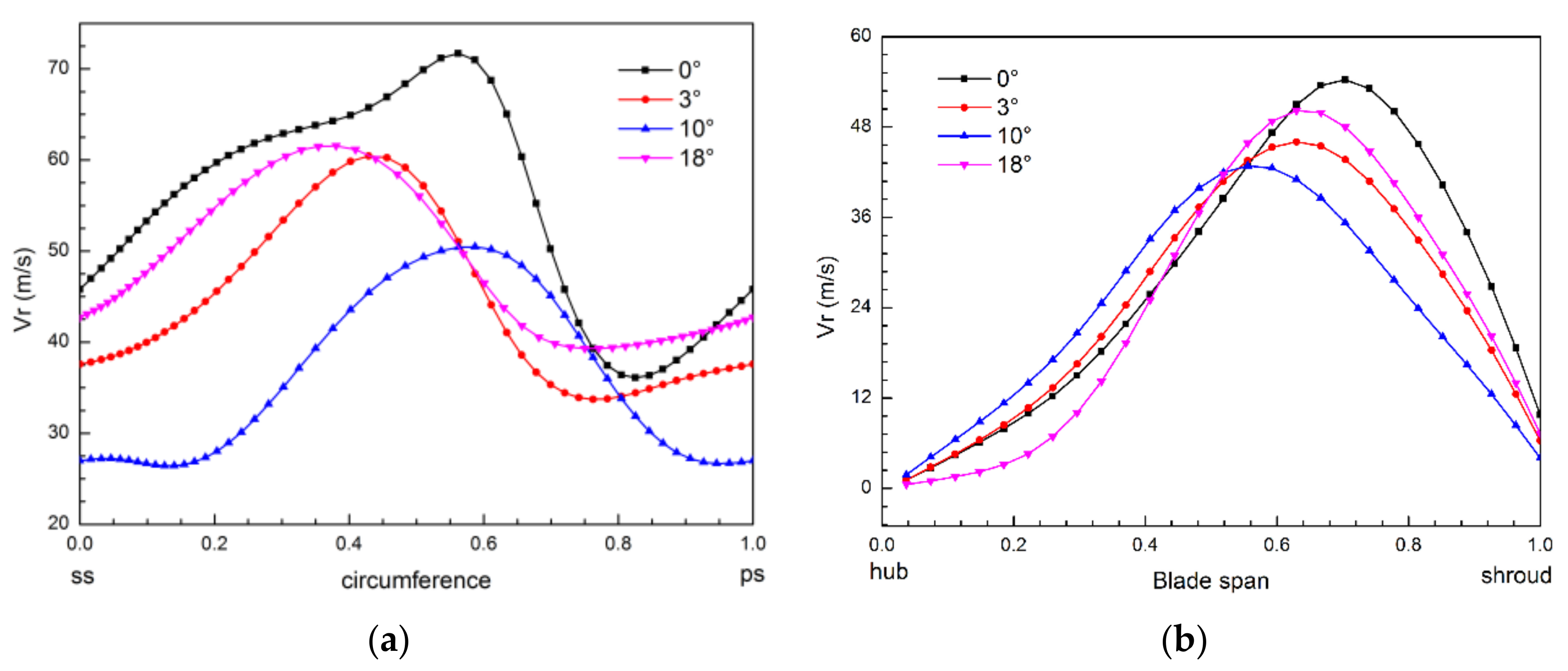

- By analyzing the radial-circumferential sections of the diffuser, it is found that the increase of the total bending angle in a certain range improves the distribution of radial velocity in the diffuser inlet and outlet and the relative velocity distribution at the outlet of the front row blade.

- The minimum total pressure loss coefficient and the maximum static pressure recovery coefficient are achieved with the 10° model, and thus the optimum performance of the compressor is obtained at this value of the total bending angle.

- It is found that a proper increase in the total bending angle improves the performance of the compressor stage by significantly reducing the separation near the shroud and uniformly disturbing flow velocity at the impeller outlet and diffuser outlet. Sufficient increase of the total bending angle is necessary to produce beneficial effects, whereas excessive increasing will instead deteriorate the compressor’s performance.

- Compared with the stage of the prototype with single row of vane diffuser, the stage with newly designed tandem vane diffuser of the 10° model achieves the performance improvement, the efficiency increased about 6%, and the total pressure increased about 3.5% at the design flow coefficient of 0.15.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cumpsty, N.A. Compressor Aerodynamics; Wiley: New York, NY, USA, 1989. [Google Scholar]

- Van den Braembussche, R. Design and optimization of centrifugal compressors. In Thermodynamics and Fluid Mechanics of Turbomachinery; Ucer, A.S., Stow, P., Hirsch, C., Wennerstrom, A., Eds.; Martinus Nijhoff Publishers: Dordrecht, The Netherlands, 1985; Volume II, pp. 829–885. [Google Scholar]

- Krain, H. Review of Centrifugal Compressor’s Application and Development. J. Turbomach. 2005, 127, 25–34. [Google Scholar] [CrossRef]

- Anish, S.; Sitaram, N.; Kim, H.D. A Numerical Study of the Unsteady Interaction Effects on Diffuser Performance in a Centrifugal Compressor. ASME J. Turbomach. 2014, 136, 011012. [Google Scholar] [CrossRef]

- Bousquet, Y.; Binder, N.; Dufour, G.; Carbonneau, X.; Roumeas, M.; Trébinjac, I. Numerical Simulation of Stall Inception Mechanisms in a Centrifugal Compressor with Vaned Diffuser. ASME J. Turbomach. 2016, 138, 121005. [Google Scholar] [CrossRef] [Green Version]

- Dou, H.-S.; Zhang, B.W.; Wei, Y.K.; Sun, Y.Y.; Lu, F.A.; Diao, Q. Flow instability study in centrifugal compressor based on energy gradient theory. In Proceedings of the 13th Asian International Conference on Fluid Machinery (13th AICFM), Tokyo, Japan, 7–10 September 2015. [Google Scholar]

- Du, Y.; Dou, H.-S.; Lu, F. Counter-Propagating Rotating Stall of Vaned Diffuser in a Centrifugal Compressor near Design Condition. ASME J. Turbomach. 2020, 142, 111007. [Google Scholar] [CrossRef]

- Marsan, A.; Trébinjac, I.; Coste, S.; Leroy, G. Temporal behaviour of a corner separation in a radial vaned diffuser of a centrifugal compressor operating near surge. J. Therm. Sci. 2013, 22, 555–564. [Google Scholar] [CrossRef]

- Aalburg, C.; Simpson, A.; Schmitz, M.B.; Michelassi, V.; Evangelisti, S.; Belardini, E.; Ballarini, V. Design and testing of multistage centrifugal compressors with small diffusion ratios. ASME J. Turbomach. 2012, 134, 041019. [Google Scholar] [CrossRef]

- Kim, H.-W.; Park, J.-I.; Ryu, S.-H.; Choi, S.-W.; Ghal, S.-H. The Performance Evaluation with Diffuser Geometry Variations of the Centrifugal Compressor in a Marine Engine (70 mw) Turbocharger. J. Eng. Gas Turbines Power 2009, 131, 012201. [Google Scholar] [CrossRef]

- Zemp, A.; Abhari, R.S. Vaned Diffuser Induced Impeller Blade Vibrations in a High-Speed Centrifugal Compressor. ASME J. Turbomach. 2013, 135, 021015. [Google Scholar] [CrossRef]

- Senoo, Y.; Hayami, H.; Ueki, H. Low-Solidity Tandem-Cascade Diffusers for Wide-Flow-Range Centrifugal Blowers. In Proceedings of the ASME 1983 International Gas Turbine Conference and Exhibit, Phoenix, Arizona, USA, 27–31 March 1983. [Google Scholar] [CrossRef] [Green Version]

- Oh, J.; Buckley, C.W.; Agrawal, G.L. Numerical Investigation of Low Solidity Vaned Diffuser Performance in a High-Pressure Centrifugal Compressor—Part III: Tandem Vanes. ASME J. Turbomach. 2012, 134, 061025. [Google Scholar] [CrossRef] [Green Version]

- Sakaguchi, D.; Fujii, T.; Ueki, H.; Ishida, M.; Hayami, H. Control of secondary flow in a low solidity circular cascade diffuser. J. Therm. Sci. 2012, 21, 384–390. [Google Scholar] [CrossRef] [Green Version]

- Saha, U.; Roy, B. Experimental investigations on tandem compressor cascade performance at low speeds. Exp. Therm. Fluid Sci. 1997, 14, 263–276. [Google Scholar] [CrossRef]

- Roy, B.; Saha, U.K. Effect of Tip Clearance at Midspan Section of Controlled Diffusion Compressor Cascade. Int. J. Turbo Jet-Engines 1995, 12, 223–230. [Google Scholar] [CrossRef]

- Heinrich, A.; Tiedemann, C.; Peitsch, D. Experimental Investigations of the Aerodynamics of Highly Loaded Tandem Vanes in a High-Speed Stator Cascade. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Payyappalli, M.M.; Shine, S.R. Numerical Investigation on Tandem Compressor Cascades. In Proceedings of the ASME 2015 Gas Turbine India Conference, Hyderabad, India, 2–3 December 2015. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, Z.-X.; Liu, Z.-W. Investigation on Influence of Design Parameters for Tandem Cascades Diffuser Using DOE Method. Eng. Appl. Comput. Fluid Mech. 2014, 8, 240–251. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Li, Y.; Wang, Z.X. Numerical investigation of unsteady flow in tandem cascade diffuser. J. Eng. Thermophys. 2017, 38, 1571–1576. [Google Scholar]

- Shan, S.J.; Hou, A.P.; Li, J.X.; Liu, R.Y.; Zhang, M.M. Effect of percent pitch on performance of high load tandem cascade. J. Aerosp. Power 2018, 33, 1193–1203. (In Chinese) [Google Scholar]

- Roy, B.; Puranam, S.V.; Mulmule, A.S. Aerodynamic design of a part-span tandem bladed rotor for low speed axial compressor/fan. In Proceedings of the 27th AIAA Applied Aerodynamics Conference, San Antonio, TX, USA, 22–25 June 2009. [Google Scholar]

- Böhle, M.; Frey, T. Numerical and Experimental Investigations of the Three-Dimensional-Flow Structure of Tandem Cascades in the Sidewall Region. J. Fluids Eng. 2014, 136, 071102. [Google Scholar] [CrossRef]

- Llamas, X.; Eriksson, L. Parameterizing Compact and Extensible Compressor Models Using Orthogonal Distance Minimization. J. Eng. Gas Turbines Power 2017, 139, 012601. [Google Scholar] [CrossRef]

- Teichel, S.; Verstraete, T.; Seume, J. Optimized Multidisciplinary Design of a Small Transonic Compressor for Active High-Lift Systems. Int. J. Gas Turbine, Propuls. Power Syst. 2017, 9, 19–26. [Google Scholar] [CrossRef]

- Li, X.; Liu, Z.; Lin, Y. Multipoint and Multiobjective Optimization of a Centrifugal Compressor Impeller Based on Genetic Algorithm. Math. Probl. Eng. 2017, 2017, 6263274. [Google Scholar] [CrossRef] [Green Version]

- Ding, J.; Wang, S.T.; Liu, X.; Xu, H.; Wang, Z.Q. Optimization design of multi-section airfoils for heavy-duty gas turbine compressor. J. Aerosp. Power 2017, 32, 549–557. (In Chinese) [Google Scholar]

- Ju, Y.; Zhang, C. Multi-Objective Optimization Design Method for Tandem Compressor Cascade at Design and Off Design Conditions. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010. [Google Scholar] [CrossRef]

- Ju, Y.P.; Zhang, C.H. Design Optimization and Experimental Study of Tandem Impeller for Centrifugal Compressor. J. Propuls. Power 2014, 30, 1490–1501. [Google Scholar] [CrossRef]

- Cheng, H.; Liu, B.; Li, J.; Yang, X.D. A study of parameter optimization of axial compressor tandem cascade. J. Propuls. Technol. 2017, 38, 2224–2234. [Google Scholar]

| Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Flow Coefficient | 0.16768 | 0.15658 | 0.14997 | 0.14310 | 0.13554 | 0.12899 | 0.12090 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Xu, W.; Yang, S.; Lu, F.; Dou, H. Performance Enhancement of a Centrifugal Compressor by Designing a Tandem Cascade Diffuser. Energies 2022, 15, 4570. https://doi.org/10.3390/en15134570

Zhang S, Xu W, Yang S, Lu F, Dou H. Performance Enhancement of a Centrifugal Compressor by Designing a Tandem Cascade Diffuser. Energies. 2022; 15(13):4570. https://doi.org/10.3390/en15134570

Chicago/Turabian StyleZhang, Shuo, Wenqian Xu, Shuhua Yang, Fuan Lu, and Huashu Dou. 2022. "Performance Enhancement of a Centrifugal Compressor by Designing a Tandem Cascade Diffuser" Energies 15, no. 13: 4570. https://doi.org/10.3390/en15134570

APA StyleZhang, S., Xu, W., Yang, S., Lu, F., & Dou, H. (2022). Performance Enhancement of a Centrifugal Compressor by Designing a Tandem Cascade Diffuser. Energies, 15(13), 4570. https://doi.org/10.3390/en15134570