Gloss of Varnished MDF Panels Veneered with Sanded and Thermally Compressed Veneer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials, the Pre-Treatment Process of the Wood Veneer, the Surface Varnishing Process and Statistical Analysis

2.2. Gloss Measurement

3. Results

3.1. Statistical Analysis

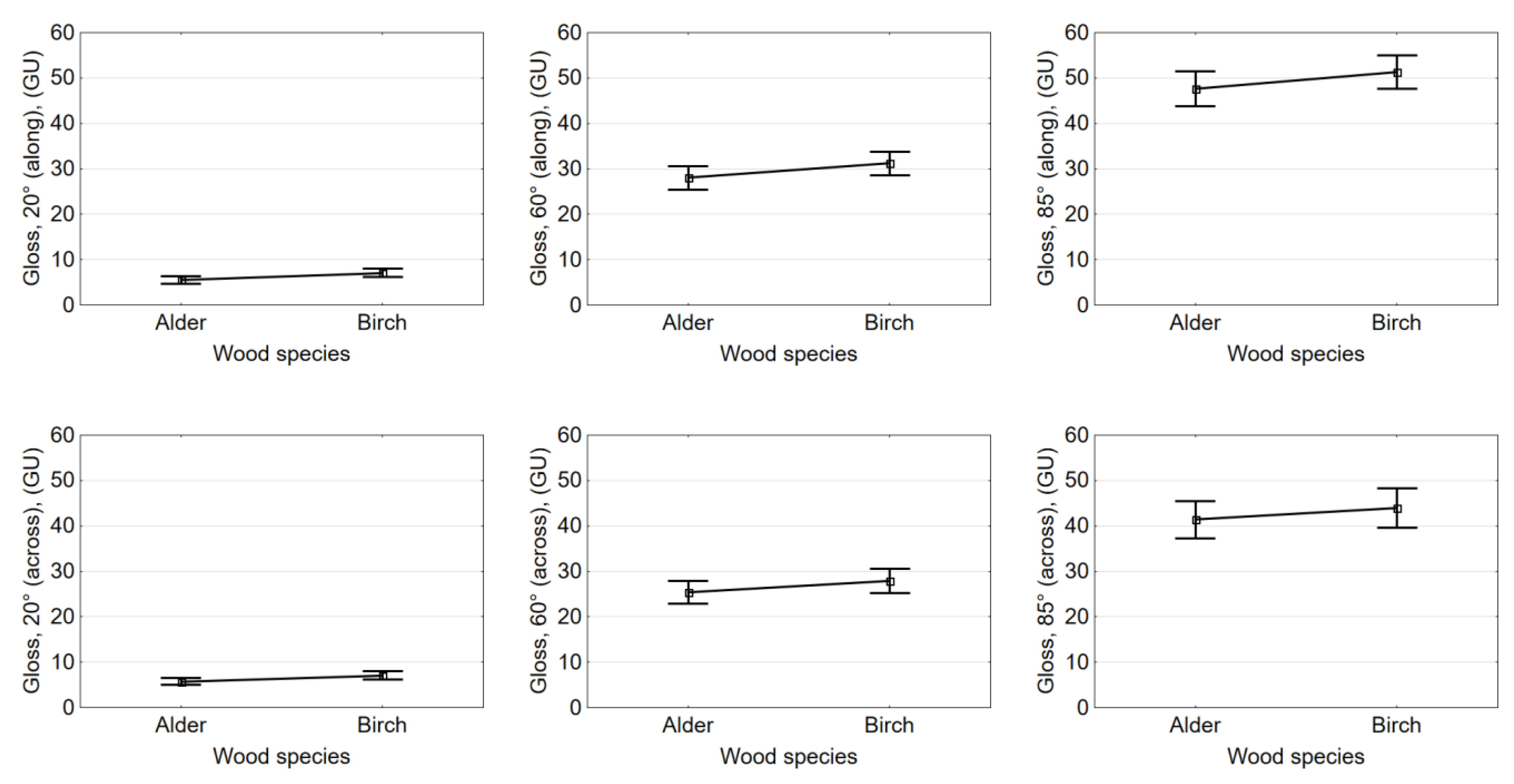

3.2. Effect of Wood Species and Direction of the Wood Fibers on the Surface Gloss of Varnished Samples

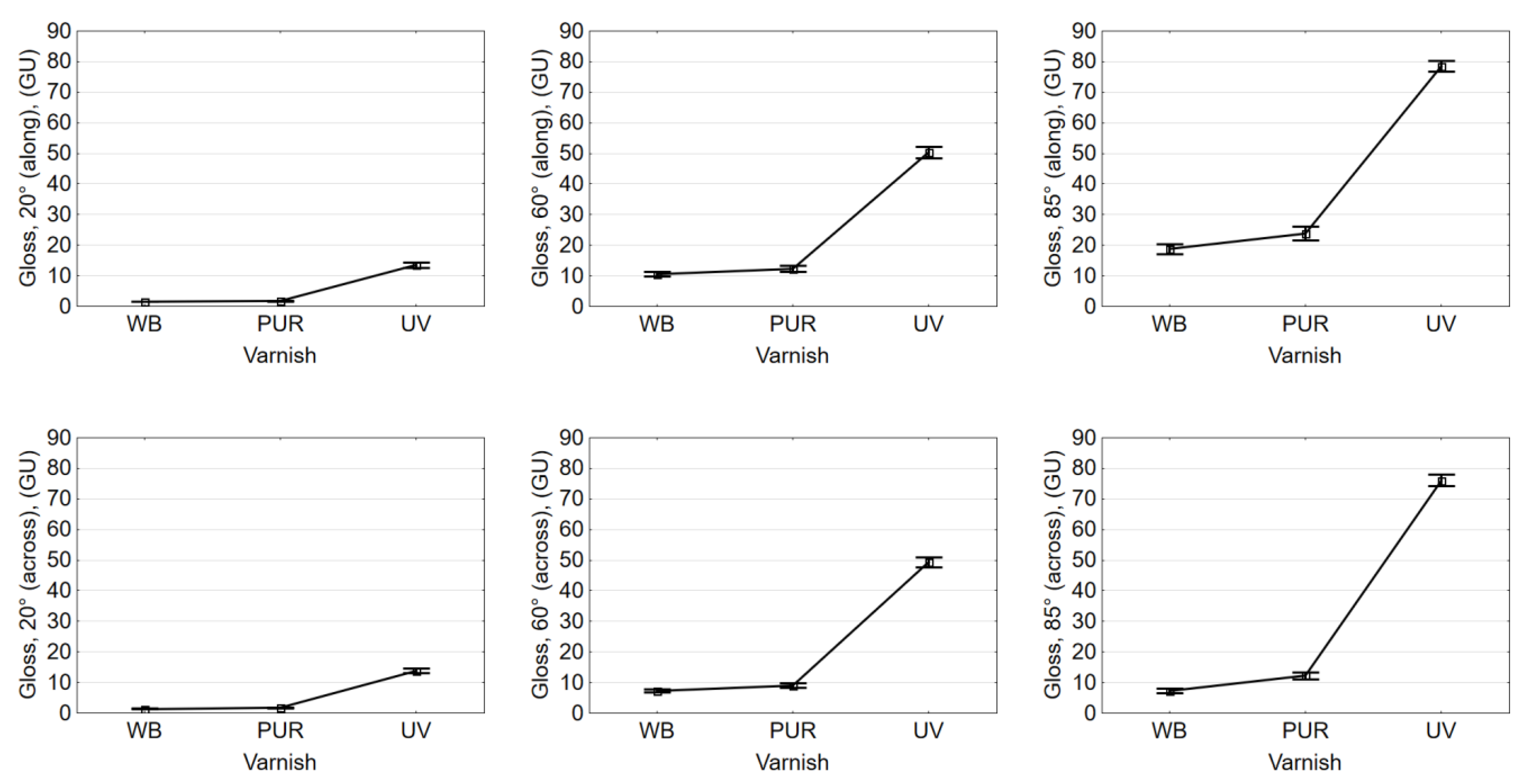

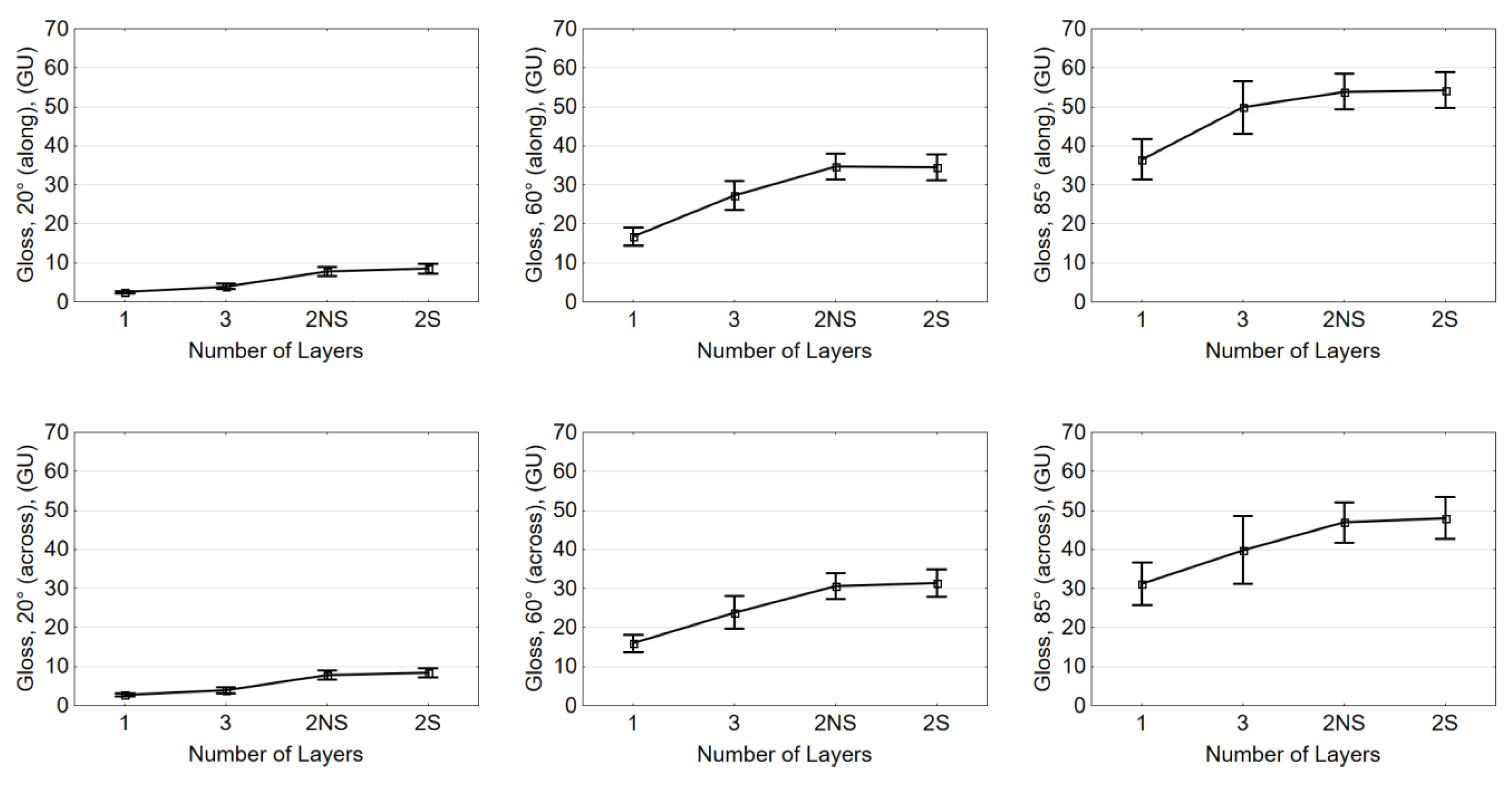

3.3. Effect of Type of Varnish and Number of Varnish Layers on the Surface Gloss of Varnished Samples

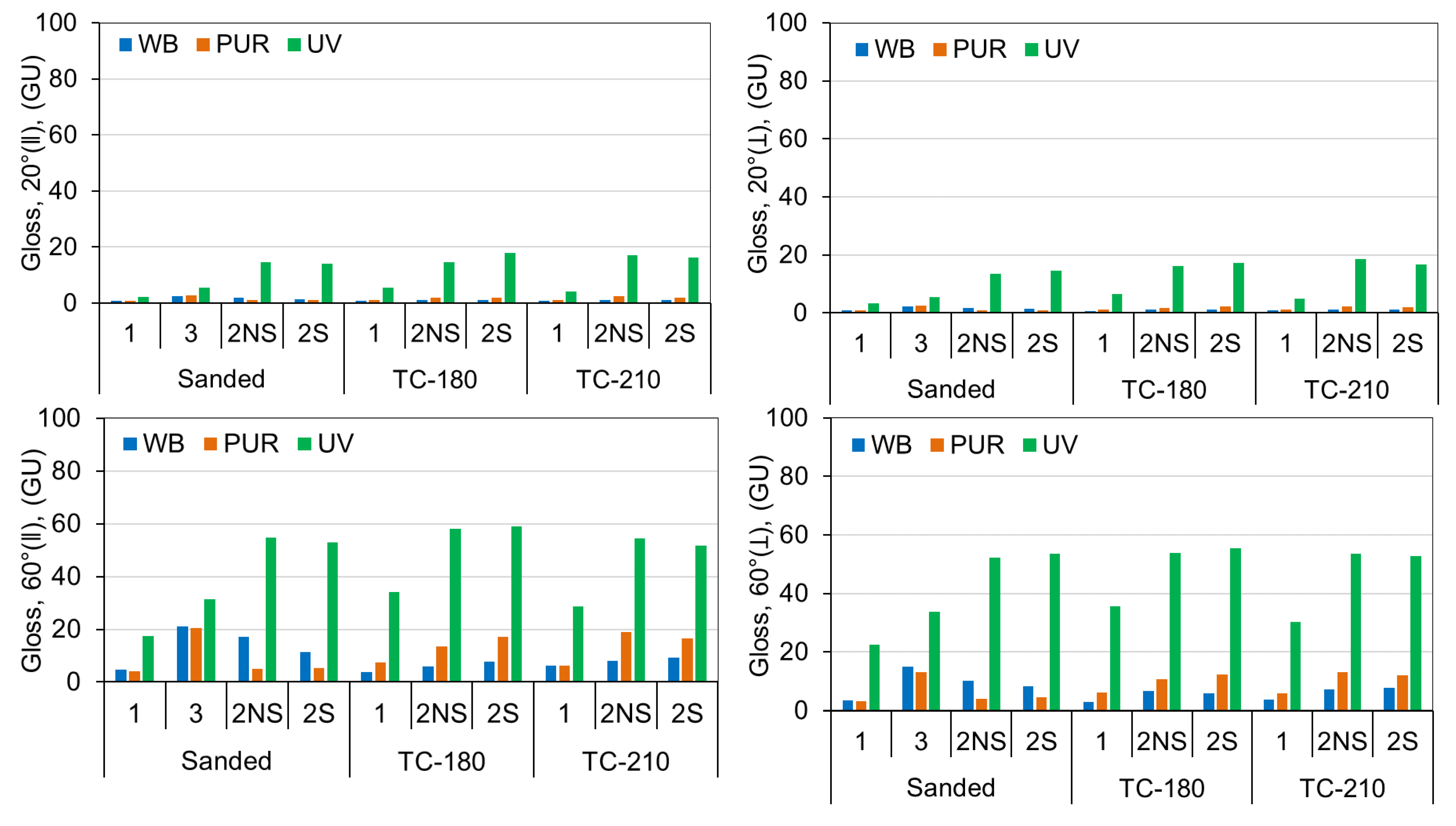

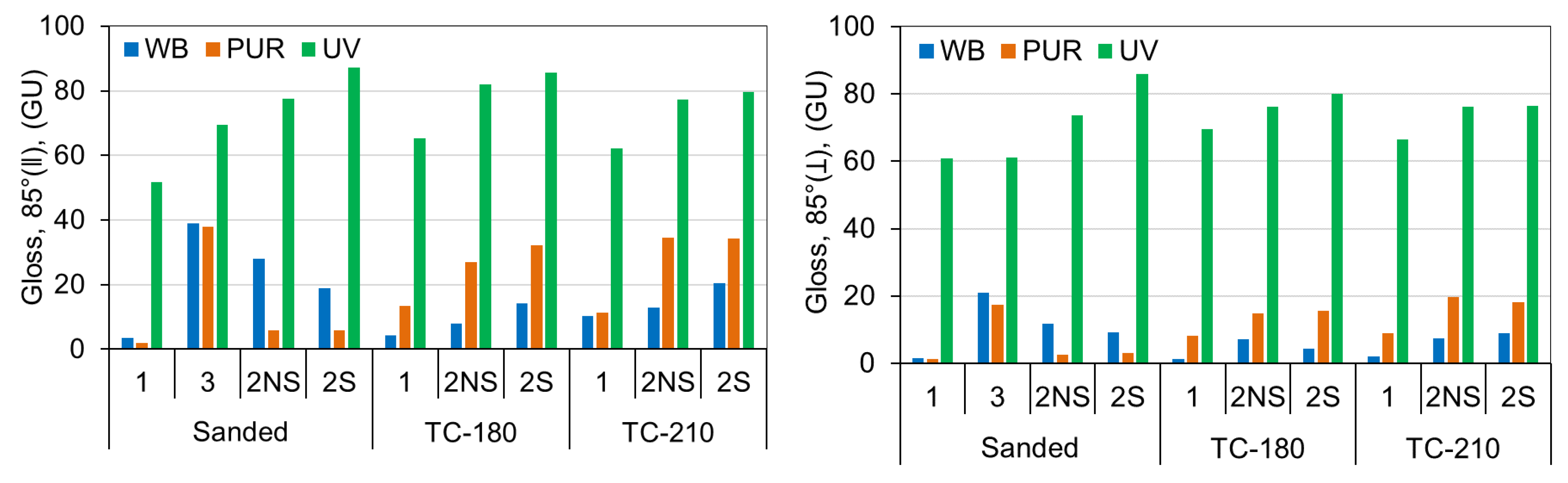

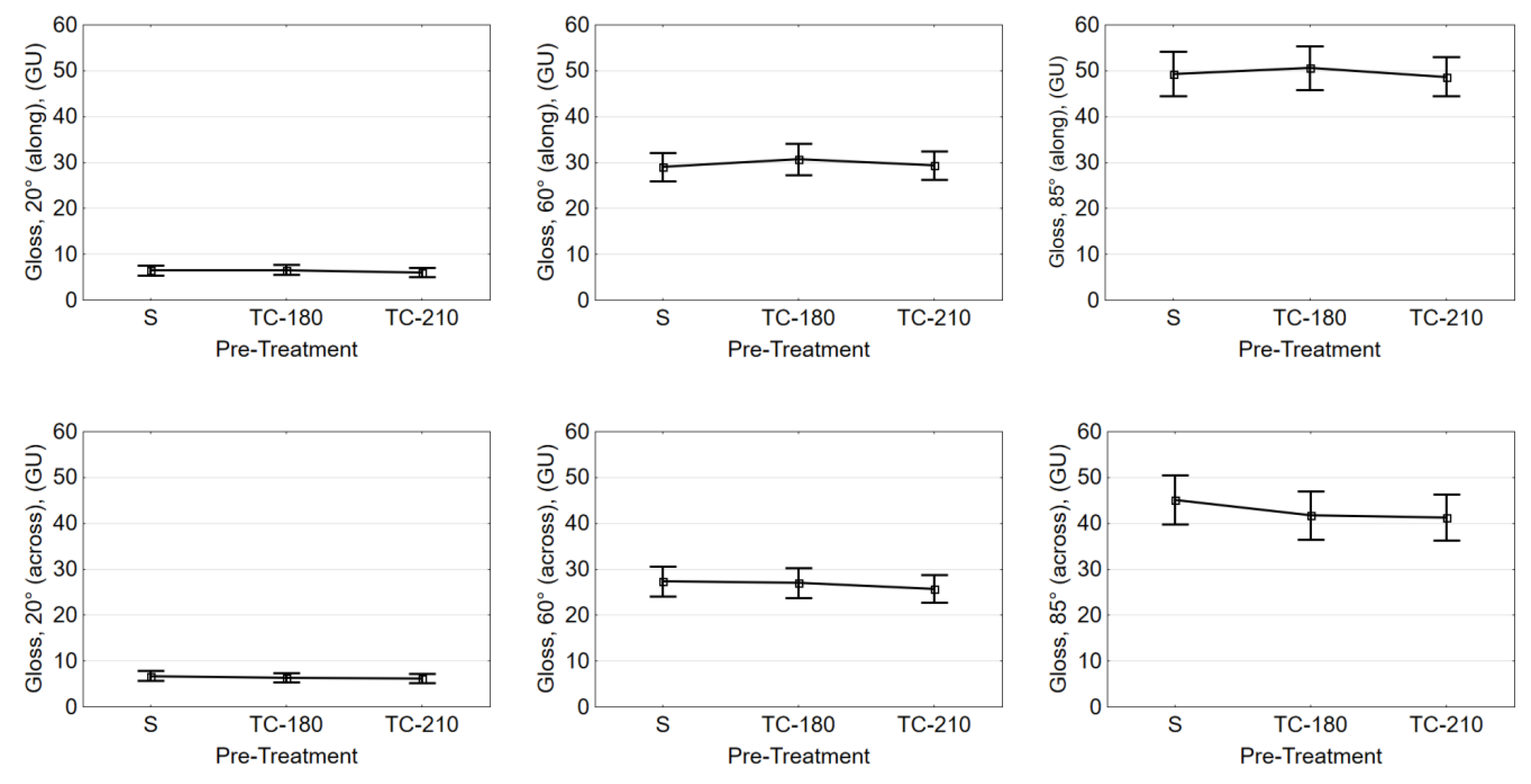

3.4. Effect of the Pre-treatment Process of Wood Veneer on the Surface Gloss of Varnished Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Williams, R.S. Finishing of Wood. In Wood Handbook—Wood as an Engineering Material; General Technical Report FPL-GTR-190; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; Chapter 16; pp. 16-1–16-39. [Google Scholar]

- Henke, M.; Lis, B.; Krystofiak, T. Gloss Level of HDF Finished with Different Numbers of Layers and Hardened with UV Hg-Ga Lamps of Selected Power. Coatings 2022, 12, 533. [Google Scholar] [CrossRef]

- Slabejová, G.; Šmidriaková, M.; Fekiač, J. Gloss of transparent coating on beech wood surface. Acta Fac. Xylologiae Zvolen 2016, 58, 37–44. [Google Scholar] [CrossRef]

- Çakicier, N.; Korkut, S.; Korkut, D.S.; Kurtoğlu, A.; Erdinler, E.S.; Ulay, G. The effects of protective dye layer applied on lacquer product layer hardness, scratch resistance and glossiness of various blockboard types. Afr. J. Agric. Res. 2011, 6, 2303–2308. [Google Scholar] [CrossRef]

- Çakicier, N.; Korkut, S.; Korkut, D.S. Varnish layer hardness, scratch resistance, and glossiness of various wood species as affected by heat treatment. BioResources 2011, 6, 1648–1658. [Google Scholar]

- Gupta, S.; Singh, C.P.; Kumar, V.S.K. Gloss of four common wood coatings measured before and after their exposure to high humidity. Cienc. da Madeira (Braz. J. Wood Sci.) 2016, 7, 94–99. [Google Scholar] [CrossRef]

- Arnold, M. Planing and sanding of wood surfaces—Effects on surface properties and coating performance. In Proceedings of the PRA’s 7th International Woodcoatings Congress “Reducing the Environmental Footprint”, Amsterdam, The Netherlands, 12–13 October 2010; Middlesex: Hampton, VA, USA. [Google Scholar]

- Bekhta, P.; Proszyk, S.; Krystofiak, T.; Mamonova, M.; Pinkowski, G.; Lis, B. Effect of thermomechanical densification on surface roughness of wood veneers. Wood Mater. Sci. Eng. 2014, 9, 233–245. [Google Scholar] [CrossRef]

- Salca, E.A.; Krystofiak, T.; Lis, B.; Mazela, B.; Proszyk, S. Some coating properties of black alder wood as function of varnish type and applications method. BioResources 2016, 11, 7580–7594. [Google Scholar] [CrossRef] [Green Version]

- Sönmez, A.; Budakçı, M.; Yakin, M. Effect of application methods on the hardness gloss and adhesion strength of waterborne lacquer product coating on the wooden surface. J. Polytech. 2004, 7, 229–235. [Google Scholar]

- Demirci, Z.; Sönmez, A.; Budakçı, M. Effect of thermal ageing on the gloss and the adhesion strength of the wood varnish layers. BioResources 2013, 8, 1852–1867. [Google Scholar] [CrossRef] [Green Version]

- Sönmez, A.; Budakçı, M.; Pelit, H. The effect of the moisture content of wood on the layer performance of water borne lacquer productes. BioResources 2011, 6, 3166–3177. [Google Scholar]

- Bekhta, P.; Proszyk, S.; Lis, B.; Krystofiak, T. Gloss of thermally densified alder (Alnus glutinosa Goertn.), beech (Fagus sylvatica L.), birch (Betula verrucosa Ehrh.), and pine (Pinus sylvestris L.) wood veneers. Eur. J. Wood Prod. 2014, 72, 799–808. [Google Scholar] [CrossRef] [Green Version]

- Bekhta, P.; Krystofiak, T.; Proszyk, S.; Lis, B. Surface gloss of lacquered medium density fibre-board panels veneered with thermally compressed birch wood. Prog. Org. Coat. 2018, 117, 10–19. [Google Scholar] [CrossRef]

- Aksoy, A.; Deveci, M.; Baysal, E.; Toker, H. Colour and gloss changes of Scots pine after heat modification. Wood Res. 2011, 56, 329–336. [Google Scholar]

- Simsek, H.; Baysal, E. An investigation on colour and gloss changes of wood impregnated with borates. Wood Res. 2012, 57, 271–277. [Google Scholar]

- Pelit, H.; Budakçı, M.; Sönmez, A.; Burudurlu, E. Surface roughness and brightness of scots pine (Pinus sylvestris) applied with water-based varnish after densification and heat treatment. J. Wood Sci. 2015, 61, 586–594. [Google Scholar] [CrossRef]

- de Paula, M.H.; de Mesquita, R.R.S.; de Almeida Costa, M.; Gonçalez, J.C.; Ananías, R.A.; Janin, G. Effect of applying finishing products and sanding on the surface of marupa wood. Maderas. Cienc. Y Tecnol. 2020, 22, 45–54. [Google Scholar] [CrossRef] [Green Version]

- Qi, L.; Chantler, M.J.; Siebert, P.; Dong, J. The joint effect of mesoscale and microscale roughness on perceived gloss. Vis. Res. 2015, 115, 209–217. [Google Scholar] [CrossRef]

- Honson, V.; Huynh-Thu, Q.; Arnison, M.; Monaghan, D.; Isherwood, Z.J.; Kim, J. Effects of Shape, Roughness and Gloss on the Perceived Reflectance of Colored Surfaces. Front. Psychol. 2020, 11, 485. [Google Scholar] [CrossRef] [Green Version]

- Salca, E.A.; Krystofiak, T.; Lis, B.; Hiziroglu, S. Glossiness Evaluation of Coated Wood Surfaces as Function of Varnish Type and Exposure to Different Conditions. Coatings 2021, 11, 558. [Google Scholar] [CrossRef]

- Gürleyen, L. Effects of artificial weathering on the color, gloss, adhesion, and pendulum hardness of UV system parquet varnish applied to doussie (Afzelia africana) wood. BioResources 2021, 16, 1616–1627. [Google Scholar] [CrossRef]

- Ayata, Ü.; Sahin, S.; Gürleyen, L.; Esteves, B. Effect of thermal aging on adhesion resistance strength of UV system varnish-applied laminated parquet layers. BioResources 2018, 13, 861–868. [Google Scholar] [CrossRef]

- Ghosh, M.; Gupta, S.; Kumar, V.S.K. Studies on the loss of gloss of shellac and polyurethane finishes exposed to UV. Maderas. Cienc. Tecnol. 2015, 17, 39–44. [Google Scholar] [CrossRef] [Green Version]

- Zivkovic, V. Gloss and gloss measurement. Drv. Ind. 2004, 55, 145–150. [Google Scholar]

- Senol, S.; Budakçı, M. Effect of Thermo-Vibro-Mechanic® Densification Process on the Gloss and Hardness Values of Some Wood Materials. BioResources 2019, 14, 9611–9627. [Google Scholar] [CrossRef]

- Gürleyen, T.; Ayata, Ü.; Gürleyen, L.; Esteves, B.; Sivrikaya, H.; Can, A. The determination of colour and glossiness values on the parquets that underwent single and double layered UV varnishing system treatment. In Proceedings of the 2nd International Conference on Material Science and Technology in Cappadocia (IMSTEC’17), Nevsehir, Turkey, 11–13 October 2017; pp. 408–412. [Google Scholar]

- Bekhta, P.; Hiziroglu, S.; Shepelyuk, O. Properties of plywood manufactured from compressed veneer as building material. Mater. Des. 2009, 30, 947–953. [Google Scholar] [CrossRef]

- Diouf, P.N.; Stevanovic, T.; Cloutier, A.; Fang, C.-H.; Blanchet, P.; Koubaa, A.; Mariotti, N. Effects of thermo-hygro-mechanical densification on the surface characteristics of trembling aspen and hybrid poplar wood veneers. Appl. Surf. Sci. 2011, 257, 3558–3564. [Google Scholar] [CrossRef]

- Navi, P.; Sandberg, D. Thermo-Hydro-Mechanical Processing of Wood; EPEL Press: Lausanne, Switzerland, 2012. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Krystofiak, T. Colour in short-term thermo-mechanically densified veneer of various wood species. Eur. J. Wood Prod. 2014, 72, 785–797. [Google Scholar] [CrossRef]

- Bekhta, P.; Krystofiak, T.; Lis, B.; Bekhta, N. The Impact of Sanding and Thermal Compression of Wood, Varnish Type and Artificial Aging in Indoor Conditions on the Varnished Surface Color. Forests 2022, 13, 300. [Google Scholar] [CrossRef]

- DIN 67530; Reflectometer as a Means for Gloss Assessment of Plane Surfaces of Paint Coatings and Plastics. European Standards: Brussels, Belgium, 1982.

- ISO 2813; Paints and Varnishes—Determination of Specular Gloss of Non-Metallic Paint Films at 20 Degrees, 60 Degrees and 85 Degrees. ISO: Geneva, Switzerland, 1994.

- Bekhta, P.; Krystofiak, T.; Lis, B.; Bekhta, N. Surface Roughness of Varnished Wood Pre-treated by Sanding and Thermal Compression. Forests 2022, 13, 777. [Google Scholar] [CrossRef]

- Lee, S.-C.H.; Kwok, N.-H.; Guo, H.; Hung, W.-T. The effect of wet film thickness on VOC emissions from a finishing varnish. Sci. Total Environ. 2003, 302, 75–84. [Google Scholar] [CrossRef]

- Laine, K.; Rautkari, L.; Hughes, M.; Kutnar, A. Reducing the setrecovery of surface densified solid scots pine wood by hydrothermal post-treatment. Eur. J. Wood Prod. 2013, 71, 17–23. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Krystofiak, T.; Sedliačik, J.; Novák, I.; Mamonova, M. Effect of short-term thermomechanical densification on the structure and properties of wood veneers. Wood Mater. Sci. Eng. 2017, 12, 40–54. [Google Scholar] [CrossRef]

- Lee, S.S.; Koo, S.S.; Lee, S.S.; Chai, S.G.; Lim, J.C.H. Gloss reduction in low temperature curable hybrid powder coatings. Prog. Org. Coat. 2003, 46, 266–272. [Google Scholar] [CrossRef]

- Korkut, D.S.; Hiziroglu, S.; Aytin, A. Effect of heat treatment on surface characteristics of wild cherry wood. BioResources 2013, 8, 1582–1590. [Google Scholar] [CrossRef]

| Source of Variation | F Value | |||||

|---|---|---|---|---|---|---|

| Gloss | ||||||

| 20°(ǁ) | 60°(ǁ) | 85°(ǁ) | 20°(ꓕ) | 60°(ꓕ) | 85°(ꓕ) | |

| Wood species (WS) | 22.800 * | 21.537 * | 14.541 * | 20.912 * | 12.892 * | 0.867 ** |

| Varnish (V) | 1618.910 * | 1821.280 * | 2010.086 * | 2396.335 * | 2938.813 * | 2204.702 * |

| Layers (L) | 256.569 * | 166.933 * | 95.832 * | 293.030 * | 160.771 * | 25.093 * |

| Pre-treatment (PT) | 2.170 ** | 8.888 * | 24.494 * | 6.821 * | 5.237 * | 3.346 * |

| WS × V | 12.279 * | 7.377 * | 0.457 ** | 9.756 * | 6.616 * | 0.751 ** |

| WS × L | 3.886 * | 0.917 ** | 1.448 ** | 4.777 * | 1.079 ** | 0.923 ** |

| WS × PT | 5.746 * | 2.311 * | 0.196 ** | 11.588 * | 2.674 ** | 0.376 ** |

| V × L | 232.626 * | 83.505 * | 17.739 * | 266.427 * | 89.287 * | 10.973 * |

| V × PT | 2.298 ** | 18.074 * | 30.552 * | 4.597 * | 11.734 * | 10.146 * |

| L × PT | 2.973 * | 2.415 * | 1.602 ** | 0.600 ** | 1.764 ** | 3.134 * |

| WS × V × L | 3.015 * | 0.728 ** | 0.640 ** | 3.932 * | 0.426 ** | 0.600 ** |

| WS × V × PT | 8.815 * | 5.419 * | 2.109 ** | 14.459 * | 3.797 * | 0.658 ** |

| WS × L × PT | 0.359 ** | 1.569 ** | 2.374 ** | 2.762 | 0.315 ** | 1.433 ** |

| V × L × PT | 3.112 * | 2.869 * | 4.378 * | 1.302 ** | 3.671 * | 2.129 * |

| WS × V × L × PT | 0.355 ** | 1.295 ** | 2.002 * | 3.395 * | 0.545 ** | 0.489 ** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bekhta, P.; Lis, B.; Krystofiak, T.; Tokarczyk, M.; Bekhta, N. Gloss of Varnished MDF Panels Veneered with Sanded and Thermally Compressed Veneer. Coatings 2022, 12, 913. https://doi.org/10.3390/coatings12070913

Bekhta P, Lis B, Krystofiak T, Tokarczyk M, Bekhta N. Gloss of Varnished MDF Panels Veneered with Sanded and Thermally Compressed Veneer. Coatings. 2022; 12(7):913. https://doi.org/10.3390/coatings12070913

Chicago/Turabian StyleBekhta, Pavlo, Barbara Lis, Tomasz Krystofiak, Maciej Tokarczyk, and Nataliya Bekhta. 2022. "Gloss of Varnished MDF Panels Veneered with Sanded and Thermally Compressed Veneer" Coatings 12, no. 7: 913. https://doi.org/10.3390/coatings12070913

APA StyleBekhta, P., Lis, B., Krystofiak, T., Tokarczyk, M., & Bekhta, N. (2022). Gloss of Varnished MDF Panels Veneered with Sanded and Thermally Compressed Veneer. Coatings, 12(7), 913. https://doi.org/10.3390/coatings12070913