Effect of Cooling Mode on the Microstructure of High-Strength Steel during Hot Rolling

Abstract

:1. Introduction

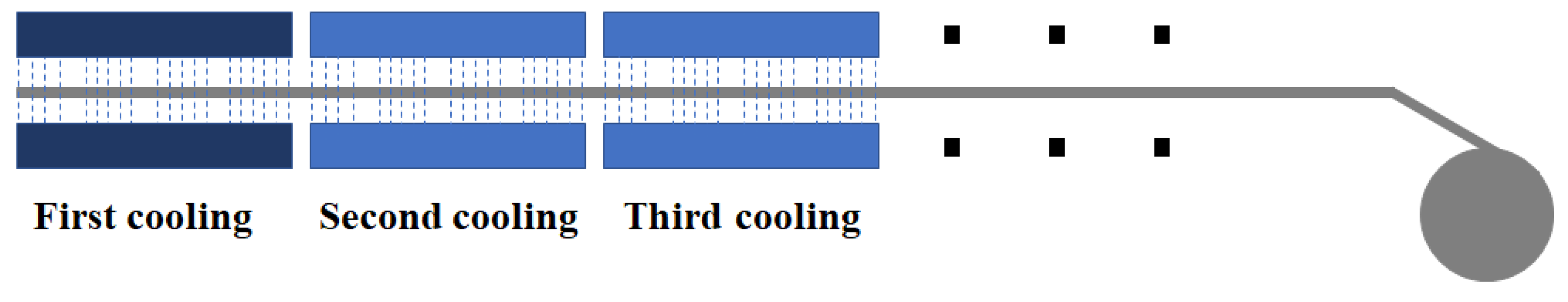

2. Materials and Methods

2.1. Specimen Preparation

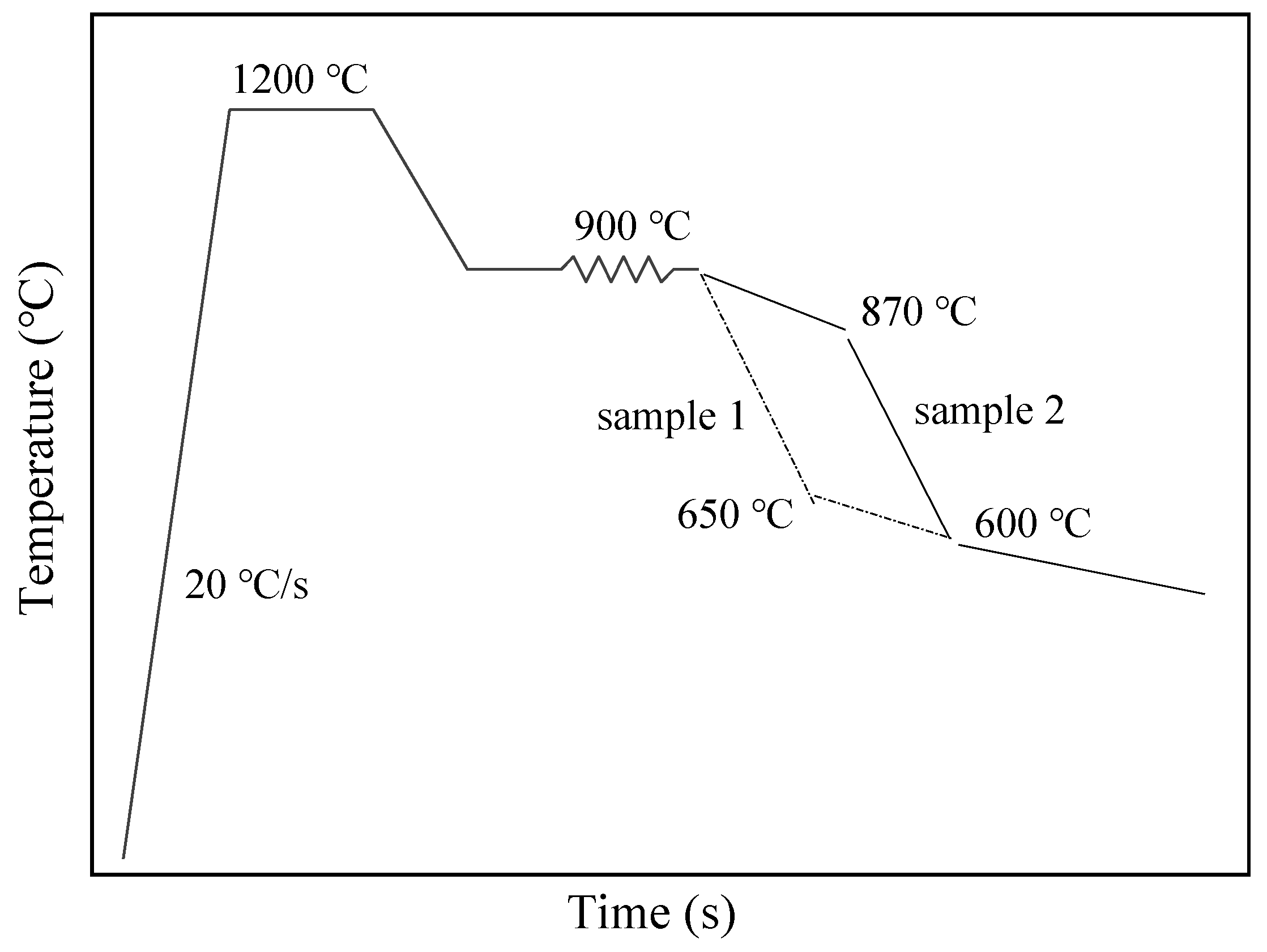

2.2. Experimental Methods and Characterization Techniques

3. Results

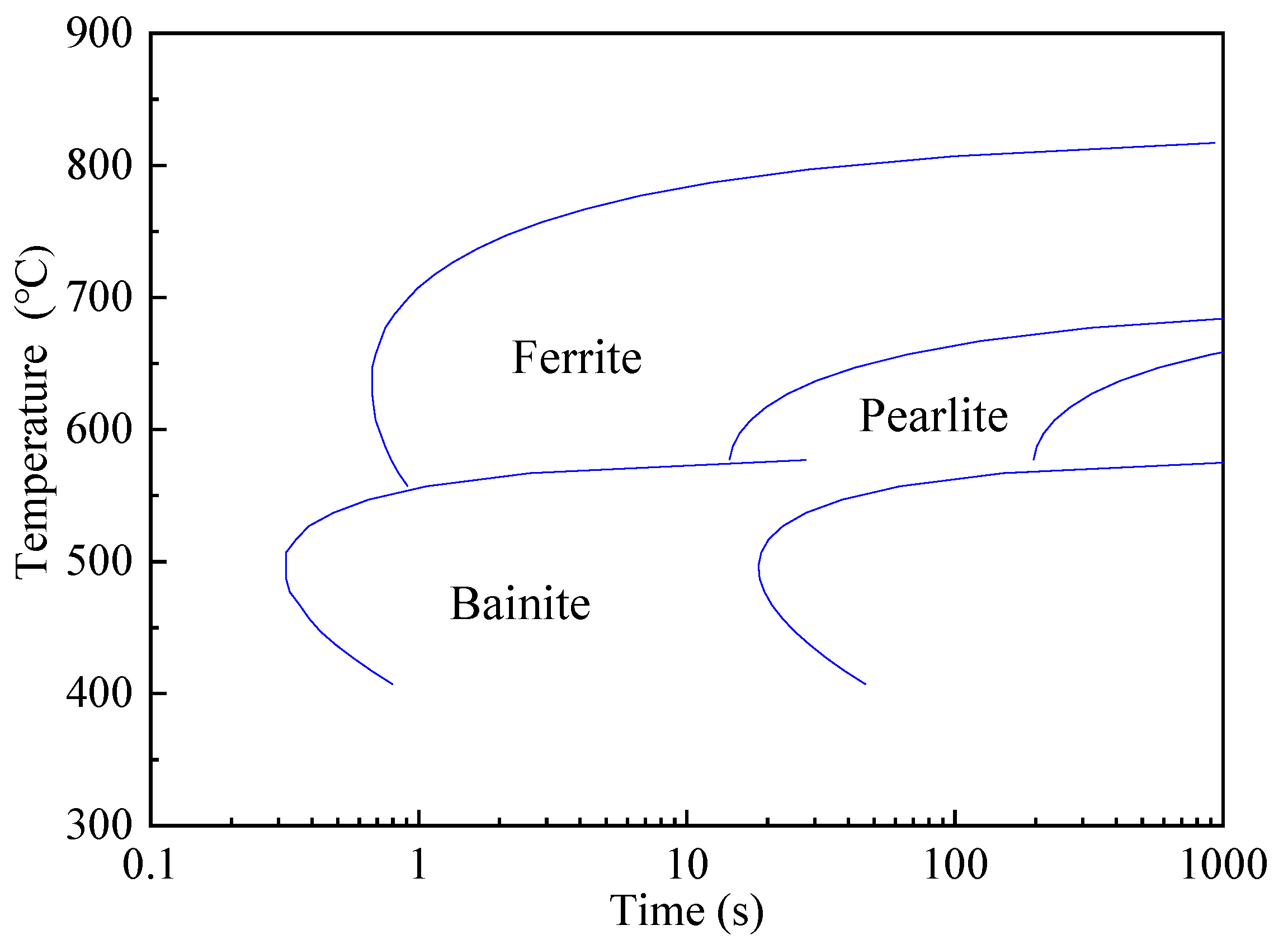

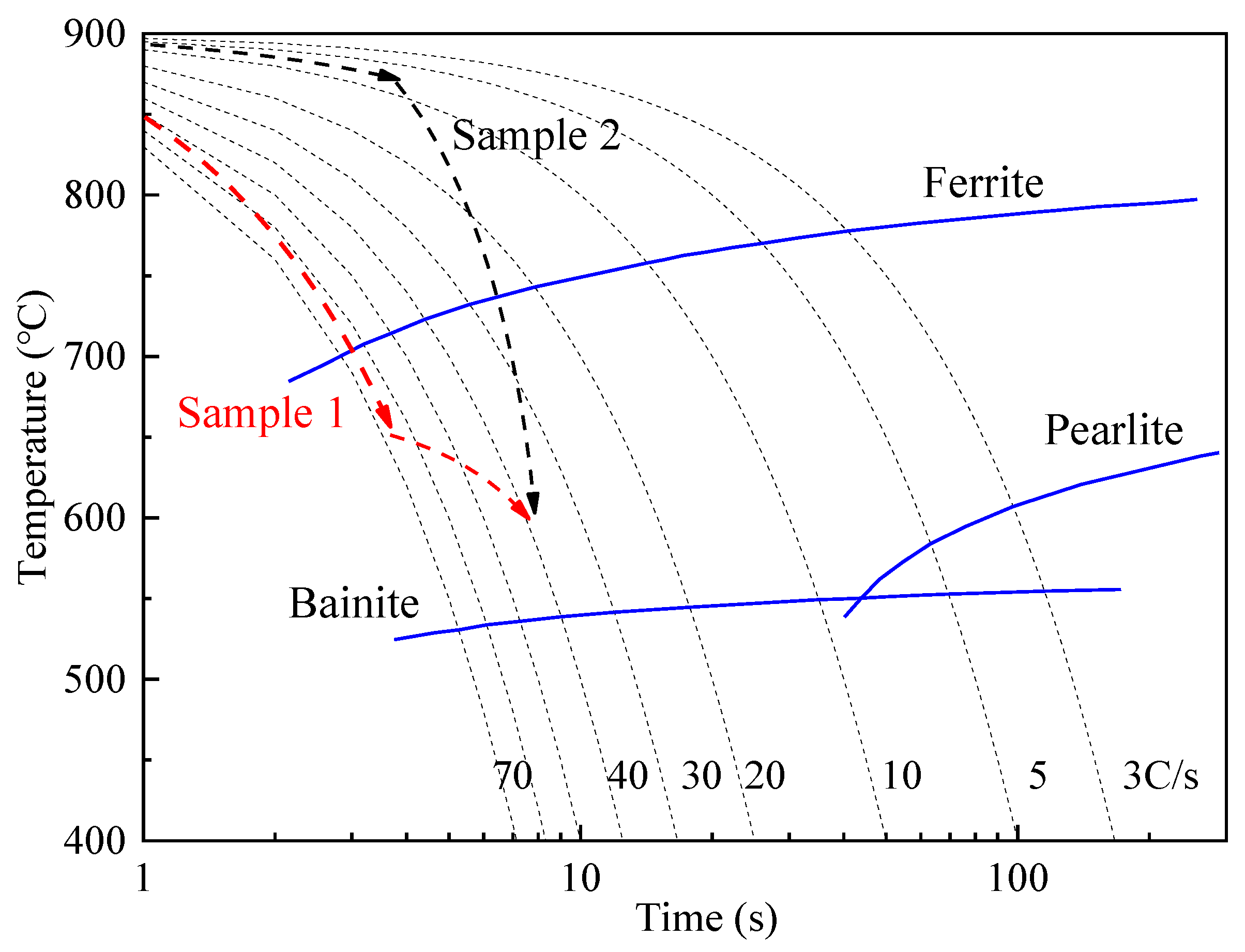

3.1. Phase Change Calculation for Different Cooling Processes

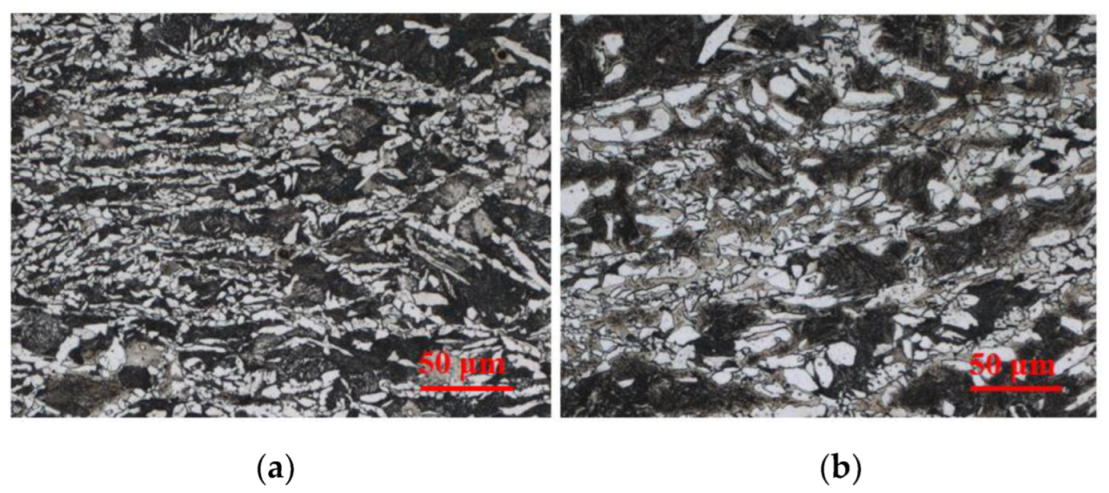

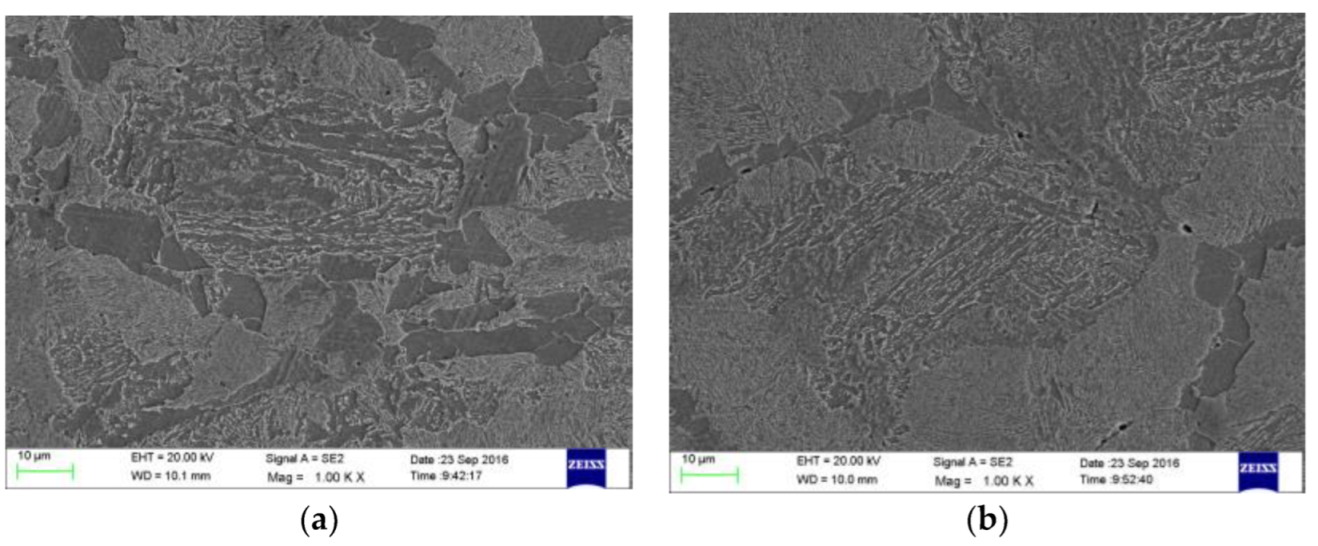

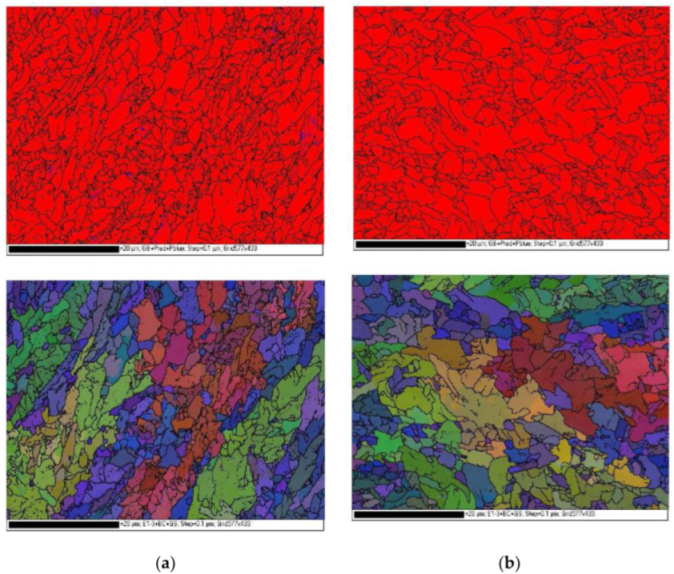

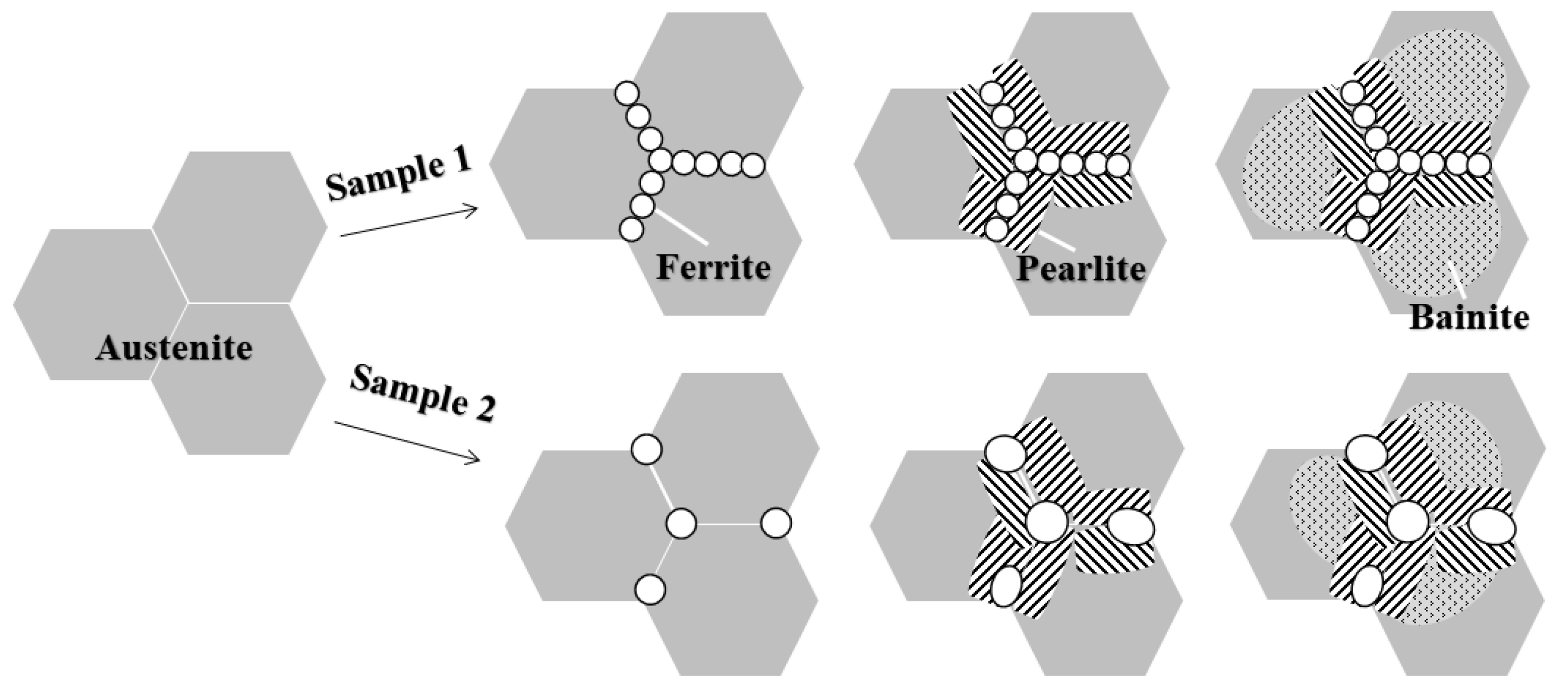

3.2. Simulation Structure of Different Cooling Processes

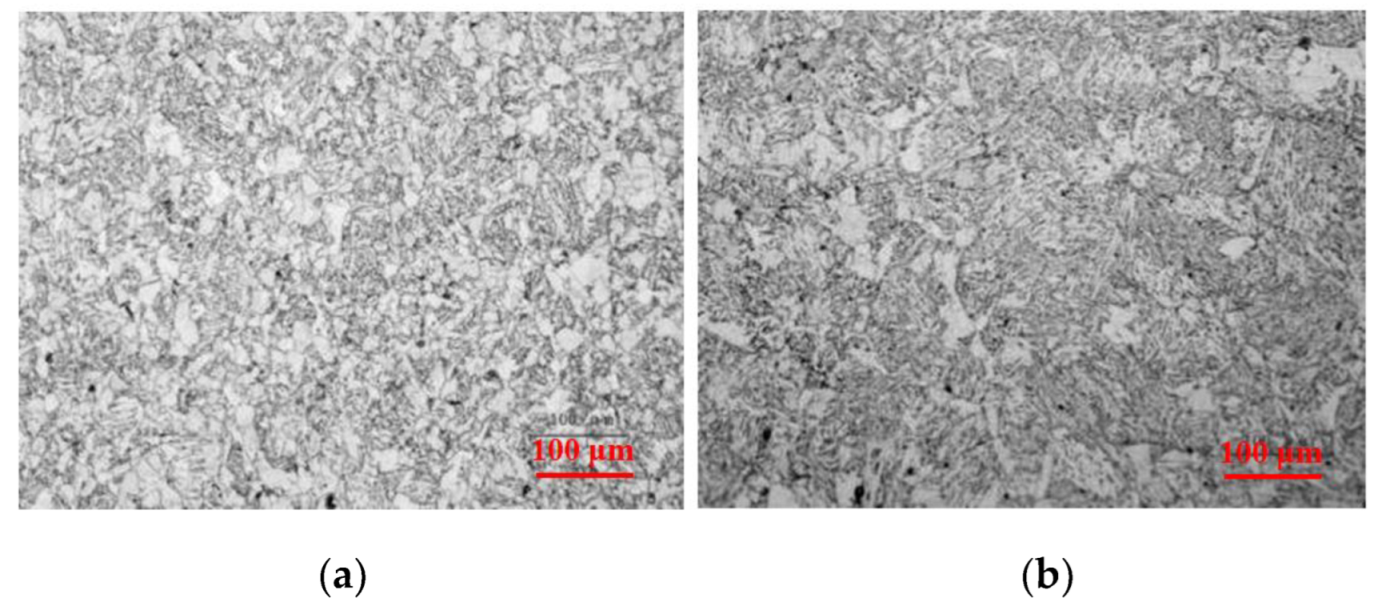

3.3. Comparison Results of the Industrial Production Test

4. Discussion

5. Conclusions

- According to the theoretical calculation and compared with the traditional cooling method, the front-section fast cooling mode increased the phase transformation ratio of the test steel from 22.7% to 33.4% before coiling, and the microstructure stress of the hot-rolled coil after coiling was significantly reduced, which improved the coil collapse problem.

- Through the thermal simulation experiments, the samples used the front-section fast cooling mode and could be cooled to the “nose tip” temperature of ferrite as soon as possible, which significantly increases the proportion of ferrite in the structure before coiling, and the grain size of the organization is finer. This is beneficial to the reduction of the microstructure stress during the cooling process of the hot-rolled coil after coiling.

- There is good similarity between the industrial production and the thermal simulation experiment. According to the statistics of industrial products, it is found that the proportion of coil collapse of high-strength steel above 780 MPa produced by the front-section fast cooling mode reduced from 9.363% to 0.533%, and the defects of hot-rolled coil collapse in the production process were resolved well.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gui, Z.X.; Liang, W.K.; Zhang, Y.S. Formability of aluminum-silicon coated boron steel in hot stamping process. Trans. Nonferrous Met. Soc. China 2014, 6, 1750–1757. [Google Scholar] [CrossRef]

- Liu, H.S.; Xing, Z.W.; Lei, C.X. Hot formation quality of high strength steel BR1500HS for hot stamping without cooling system. Trans. Nonferrous Met. Soc. China 2012, 22 (Suppl. 2), 542–547. [Google Scholar] [CrossRef]

- Liu, H.L.; Chen, Y.; Li, C.C.; Guan, L.; Wang, X.N. Design and analysis of hot forming parts with extra thick specification. Mater. Sci. Forum 2021, 1026, 59–64. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Z.F.; Cao, Z.F.; Qi, T.; Wang, X.; Zhao, Q. Study on the hot stamping of rectangular box with ultra-high strength steel. Adv. Mater. Res. 2013, 763, 156–159. [Google Scholar] [CrossRef]

- Gu, X.; Xu, Y.; Wang, X.; Liu, R.; Peng, F.; Liu, H.; Misra, R.D.K.; Li, J.; Hou, X. Austenite formation and mechanical behavior of a novel TRIP- assisted steel with ferrite/martensite initial structure. Mater. Sci. Eng. A 2020, 803, 140468. [Google Scholar] [CrossRef]

- Liu, X.D.; Xu, Y.B.; Misra, R.D.K.; Peng, F.; Wang, Y.; Du, Y.B. Mechanical properties in double pulse resistance spot welding of Q&P 980 steel. J. Mater. Processing Technol. 2019, 263, 186–197. [Google Scholar]

- Srivastava, A.K.; Jha, G.; Gope, N.; Singh, S.B. Effect of heat treatment on microstructure and mechanical properties of cold rolled C-Mn-Si TRIP-aided steel. Mater. Charact. 2006, 57, 127–135. [Google Scholar] [CrossRef]

- Li, H.P.; Jiang, R.; He, L.F.; Yang, H.; Wang, C.; Zhang, C.Z. Influence of deformation degree and cooling rate on microstructure and phase transition temperature of B1500HS steel. Acta Metall. Sin. 2018, 31, 33–47. [Google Scholar] [CrossRef]

- Li, H.; Shi, C.L.; Yin, H.X.; Lu, Z.F.; Sheng, G.Y. Effect of finish cooling temperature of annealing on mechanical properties and microstructure of automotive TRIP steel. Heat Treat. Met. 2018, 43, 141–144. [Google Scholar]

- Shanmugam, S.; Ramisetti, N.K.; Misra, R. Effect of cooling rate on the microstructure and mechanical properties of Nb-microalloyed steels. Mater. Sci. Eng. A 2007, 460, 335–343. [Google Scholar] [CrossRef]

- Siahpour, P.; Miresmaeili, R.; Rouhaghdam, A.S. Temperature effect of hot rolling process on microstructure, strength and fracture toughness of X65 pipeline steel. Trans. Indian Inst. Met. 2018, 71, 1531–1541. [Google Scholar] [CrossRef]

- Chen, D.M.; An, Z.Z.; Wang, G.D.; Liu, H.T. Effects of hot rolling and coiling temperatures on microstructure, texture and magnetic properties of 1.6 wt% Si non-oriented silicon steel. Mater. Today Commun. 2022, 31, 103807. [Google Scholar] [CrossRef]

- Natarajan, V.V.; Challa, V.S.A.; Misra, R.D.K.; Sidorenko, D.M.; Mulholland, M.D.; Manohar, M.; Hartmann, J.E. The determining impact of coiling temperature on the microstructure and mechanical properties of a titanium-niobium ultrahigh strength microalloyed steel: Competing effects of precipitation and bainite. Mater. Sci. Eng. A 2016, 665, 1–9. [Google Scholar] [CrossRef]

- Banks, K.; Tuling, A.; Mintz, B. Influence of chemistry and runout table parameters on hot coil collapse in C-Mn steels. Ironmak. Steelmak. 2011, 38, 204–210. [Google Scholar] [CrossRef] [Green Version]

- Hu, J.; Du, L.X.; Wang, J.J.; Xie, H.; Gao, C.R.; Misra, R.D.K. Structure–mechanical property relationship in low carbon microalloyed steel plate processed using controlled rolling and two-stage continuous cooling. Mater. Sci. Eng. A 2013, 585, 197–204. [Google Scholar] [CrossRef]

- Qaban, A.; Mohmed, T.; Quazi, M.M.; Naher, S. The effect of Al and Nb contents, cooling rate and rolling condition on the microstructure and corrosion behaviour of HSLA steel. Mater. Today Commun. 2020, 25, 101362. [Google Scholar] [CrossRef]

- Roccisano, A.; Nafisi, S.; Stalheim, D.; Ghomashchi, R. Effect of TMCP rolling schedules on the microstructure and performance of X70 steel. Mater. Charact. 2021, 178, 111207. [Google Scholar] [CrossRef]

- Liu, H.L.; Liu, C.J.; Jiang, M.F. Effect of rare earths on impact toughness of a low-carbon steel. Mater. Des. 2012, 33, 306–312. [Google Scholar] [CrossRef]

- Onink, M.; Brakman, C.M.; Root, J.H.; Tichelaar, F.D.; Mittemeijer, E.J.; Sybrand, V.D.Z. Redistribution of carbon during the austenite to ferrit transformation in pure Fe-C alloys. Mater. Sci. Forum 1994, 63, 163–165. [Google Scholar] [CrossRef]

- Qiu, Z.; Shao, J.; He, A.; Yang, Q.; Xia, X. Research on relaxing the residual stress of 700 MPa high strength strip steel based on intensive cooling technology. Chin. J. Eng. 2016, 38, 555–560. [Google Scholar]

- Yu, W.; Wang, Y. Relationship between cooling parameters and warping of hot rolled strips. Chin. J. Eng. 2016, 38, 1734–1740. [Google Scholar]

- Yi, H.-L.; Wang, X.; Du, L.-X.; Wang, G.-D. Microstructure and mechanical properties of 710 MPa hot-rolled high-strength steel. Northeast Univ. Nat. Sci. 2009, 30, 1421. [Google Scholar]

- Zhang, D.H.; Wang, B.X.; Zhou, N.; Yu, M.; Wang, J. Cooling efficiency of laminar cooling system for plate mill-science direct. J. Iron Steel Res. Int. 2008, 15, 24–28. [Google Scholar] [CrossRef]

- Li, H.J.; Li, Z.L.; Guo, Y.U.A.N.; Wang, Z.D.; Wang, G.D. Development of new generation cooling control system after rolling in hot rolled strip based on UFC. J. Iron Steel Res. Int. 2013, 20, 29–34. [Google Scholar] [CrossRef]

- Hosseinifar, F.; Ekrami, A. The effect of cold-rolling prior to the inter-critical heat treatment on microstructure and mechanical properties of 4340 steel with ferrite-Martensite microstructure. Mater. Sci. Eng. A 2022, 830, 142314. [Google Scholar] [CrossRef]

- Dorin, T.; Wood, K.; Taylor, A.; Hodgson, P.; Stanford, N. Effect of coiling treatment on microstructural development and precipitate strengthening of a strip cast steel. Acta Mater. 2016, 115, 167–177. [Google Scholar] [CrossRef]

| C | Si | Mn | Nb | Cr | Ti | Al | N |

|---|---|---|---|---|---|---|---|

| 0.14 | 0.20 | 1.50 | 0.03 | 0.20 | 0.02 | 0.025 | 0.004 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Du, W.; Lu, H.; Fu, Y.; Yu, S.; Liu, C. Effect of Cooling Mode on the Microstructure of High-Strength Steel during Hot Rolling. Metals 2022, 12, 1219. https://doi.org/10.3390/met12071219

Liu H, Du W, Lu H, Fu Y, Yu S, Liu C. Effect of Cooling Mode on the Microstructure of High-Strength Steel during Hot Rolling. Metals. 2022; 12(7):1219. https://doi.org/10.3390/met12071219

Chicago/Turabian StyleLiu, Hongliang, Wenbin Du, Hongzhou Lu, Yujing Fu, Shuai Yu, and Chengjun Liu. 2022. "Effect of Cooling Mode on the Microstructure of High-Strength Steel during Hot Rolling" Metals 12, no. 7: 1219. https://doi.org/10.3390/met12071219

APA StyleLiu, H., Du, W., Lu, H., Fu, Y., Yu, S., & Liu, C. (2022). Effect of Cooling Mode on the Microstructure of High-Strength Steel during Hot Rolling. Metals, 12(7), 1219. https://doi.org/10.3390/met12071219