Abstract

Sterol composition is used as a “fingerprint” to demonstrate the authenticity of olive oils. Our study’s objective was to exhaustively characterize the sterol composition of Empeltre olive oils from clonal selection during the ripening period in 2017, 2018, and 2019. We likewise assessed the influence of crop year, fruit ripening, and clonal selection on the oils’ regulatory compliance in terms of sterol composition. Empeltre olive oils were shown to have medium-range β-sitosterol and Δ5-avenasterol content, along with elevated amounts of campesterol and Δ7-stigmastenol. A total of 26% and 12% of the samples were non-compliant in terms of apparent β-sitosterol and Δ7-stigmastenol, respectively. Crop year was the most influential factor in the case of most sterols. Clone type was the least influential factor, except in the case of campesterol. Olive maturity was only significant for Δ7-sterols. We likewise applied a discriminant analysis, with “crop year” as the grouping variable: 94.9% of the oils were thereby classified correctly.

1. Introduction

Extra virgin olive oil (EVOO) is one of the edible vegetable oils most widely consumed in Mediterranean countries due to its health benefits [1,2] and its renowned organoleptic characteristics. These properties are due to the chemical composition of olive oil, of which the glyceric fraction is the majority (98–98.5%). The rest, or minority fraction, is constituted, among other components, of sterols, polyphenols, tocopherols, and pigments. These compounds provide the unique nature of olive oil.

Pre-and post-harvest factors [3,4] affect olive oil quality and chemical composition. Studies have been described concerning the variation in the composition of sterols [5], fatty acids [6], polyphenols [7], alcohols [8], or waxes [9].

Countries that are not traditional olive oil consumers, such as the US or Brazil, have considerably increased their level of consumption over the last ten years [10]. Consequently, EVOO is the oil that achieves the highest price on the markets and is thus highly susceptible to certain fraudulent activities that endanger its authenticity. Deliberate mislabeling or adulteration through illegal blending with other oils or fats of lower economic value are the most common practices [11]. To safeguard olive oils, a series of regulations have been developed that regulate the physicochemical and organoleptic characteristics of olive oils according to their commercial category, and these regulations must be respected according to the country in which the oils are marketed. Among the most important regulations, Regulation (ECC) No 2568/91 is mandatory in the European Union [12] under sanction, but the international standards of the International Olive Oil Council (IOC) [13] and Codex [14] are not. The cultivation of olive trees in countries with climates quite different from the Mediterranean area has led to the appearance of commercial regulations in such nations as well [15,16]. Those standards generally take natural variations in the ranges of certain chemical compounds, such as sterols, into account.

The total concentration and composition of sterols in vegetable oils depend on the type of fruit or oilseed; they also differ from animal fats [17]. Sterols (4-desmethylsterols) are the main chemical compounds naturally present in the unsaponifiable fraction of olive oil. The sterol profile is used as a “fingerprint” to verify the authenticity of olive oil and is considered a purity parameter, according to commercial standards [12,13,14,15]. Non-compliance with a single limit value specified in the standards presumably indicates illegal blending with oils other than olive oil. Testing for non-compliance is a mode of protecting olive oil authenticity. However, numerous cases have been reported where genuine single-varietal olive oils naturally exceeded these limits; as a consequence, their economic value has decreased. In Spain, for example, certain olive oils from cultivars such as Cornicabra and Empeltre exceed the limits [12] for campesterol [18,19,20] and Δ7-stigmastenol [21,22,23,24] (4.0% and 0.5%, respectively). Similar non-compliances have likewise been described in single-varietal oils from non-Mediterranean countries, such as Argentina [16], Australia [25,26], the United States [27], and Iran [28].

Natural variations in sterol composition influenced by genetics [29,30,31,32,33], environment (soil, location, climate, water) [19,25,27,28,30,34,35,36], fruit ripening stage [18,25,31,32,37,38], or technological factors [19,26] have been described. Such variations could at least partially explain the deviations of certain genuine olive oils from established regulatory limits.

Empeltre [21,39] is a traditional olive cultivar located in NE Spain, with an area of 70,000 ha [39]. This cultivar is widely grown in the region of Aragon and protected under a total of six Protected Designations of Origin (PDO), two of which are in Aragon. In 1998–2002, a clonal pre-selection [23,24] was carried out with the purpose of genetically improving this cultivar, taking into account, among other parameters, the sterol composition of the oils obtained from it, especially its Δ7-stigmastenol content. The selected clones were subsequently planted in two comparative trials, one of which was conducted in Aragon [40].

The aim of the present study is to exhaustively characterize the sterol composition of Empeltre olive oil from Aragon clonal selection to evaluate the influence of environmental, fruit ripening, and clonal selection factors, and to ascertain the regulatory compliance of total and individual sterol amounts.

2. Materials and Methods

2.1. Plant Material and Fruit Samples

Empeltre [23,41] is a variety with low rooting capacity. For this reason, it is normally propagated by grafting. This cultivar has a high and constant production every year. The fruit is black when ripe, medium-sized, elongated, and slightly asymmetrical. The fruits are early ripening.

Eight Empeltre clones of olive trees, grown in an experimental orchard of Centro Transferencia Agroalimentaria in Alcañiz in the province of Teruel (NE Spain; altitude 295 m; longitude 41°03′ N; latitude 0°08′ W), were selected based on region of origin (Aragon). Our study was carried out over three consecutive seasons: 2017, 2018, and 2019. All olive trees were cultivated under identical agronomic and pedoclimatic conditions. The clonal selection was planted in 2004 at a 6 × 5 m spacing in clay loam soil with a drip irrigation system according to evapotranspiration. Standard cultivation practices were followed, so olive trees were well supervised and showed no nutrient deficiency or pest damage.

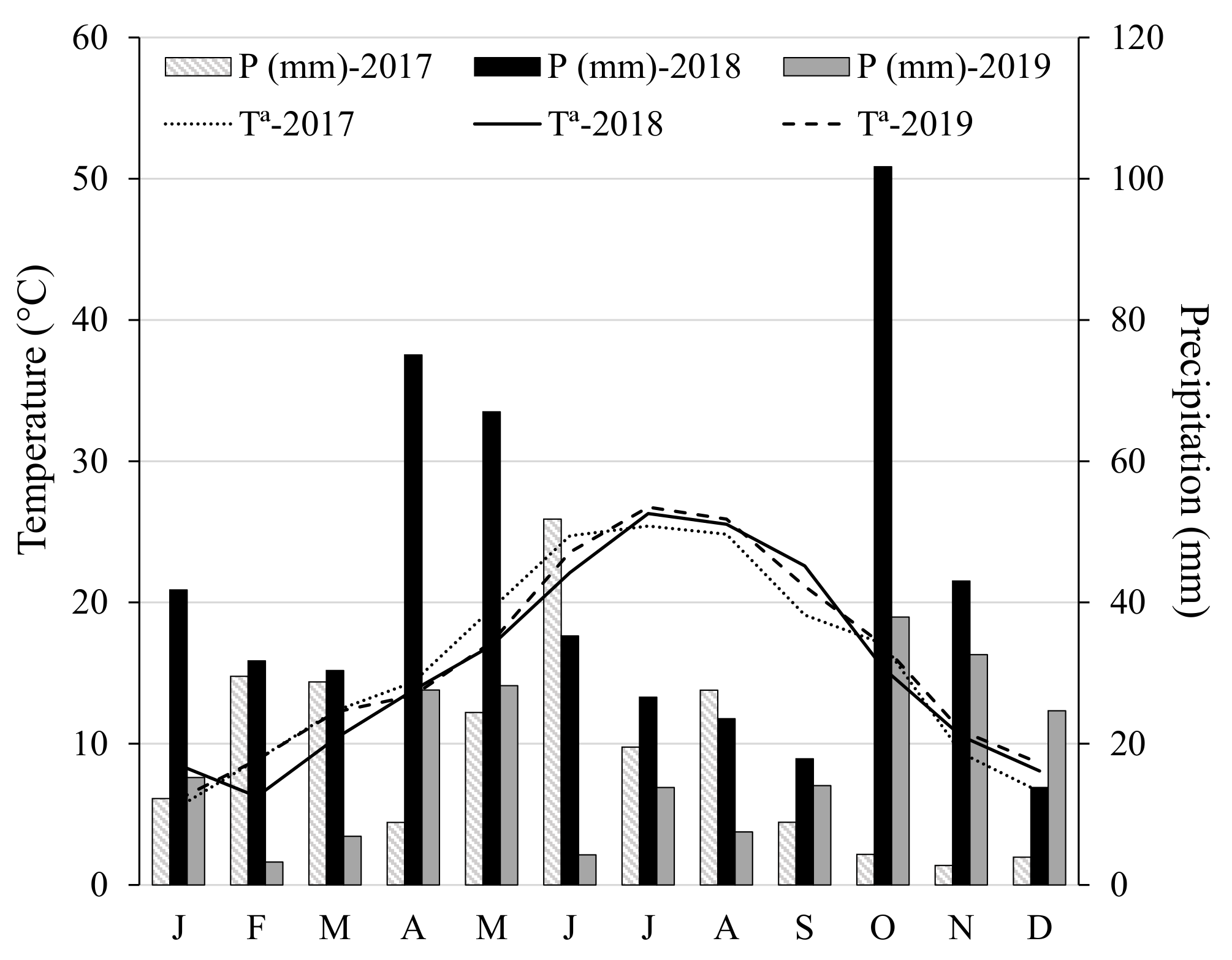

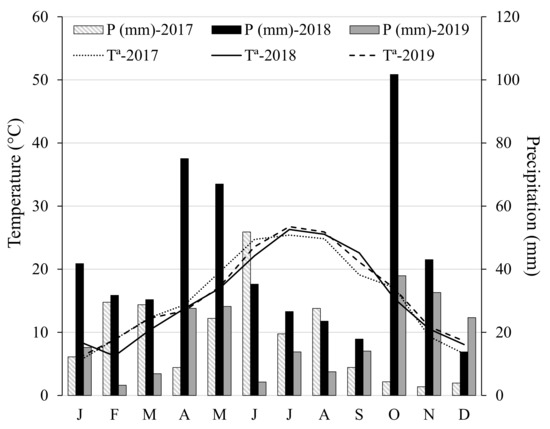

The Alcañiz region has a cold, semi-arid climate (“BSk” type) according to the Köppen–Geiger climate classification [42], featuring irregular, scarce precipitation combined with wide absolute thermal amplitude owing to extreme temperatures in winter and summer. Figure 1 shows the weather data registered for the three years of study.

Figure 1.

Mean values of temperature and rainfall registered in Alcañiz (Teruel) during three consecutive crop seasons (2017, 2018, and 2019). J: January; F: February; M: March; A: April; M: May; J: June; J: July; A: August; S: September; O: October; N: November; D: December.

The clones we studied (3 trees per clone), numbered 1 to 8, came from a clonal pre-selection [23]. The clone identified in this study as “Std” corresponds to a group of clones comprising Nos. 1, 5, and 8, as a previous study observed no differences among them [40].

The olive fruits were hand-harvested at fortnightly intervals from October to December and were processed in the laboratory on the same day. The ripening index (RI) was determined according to the method described by Hermoso et al. [43] based on the color changes observed in the olives’ skin and pulp.

2.2. Olive Oil Extraction

Olive samples (4 kg) were processed, and their oil extracted using the two-phase Abencor® laboratory oil mill (MC2, Ingeniería y Sistemas, S.L., Sevilla, Spain) [44]. The fruits were milled by a 3-mm-sieve stainless hammer mill, and the olive paste was malaxed for 30 min at 30 °C. The olive oils were then separated by centrifugation at 3500 rpm for one minute and further decanting. Finally, oils were filtered and the samples were stored in 125 mL amber glass bottles under a nitrogen atmosphere at −20 °C until analysis.

2.3. Determination of Physicochemical Quality Parameters

Free acidity, peroxide value, and ultraviolet (UV) absorption characteristics (K232, K270, ΔK) were determined according to methods described in Annexes II, III, and IX, respectively, of the consolidated European Regulation EEC No 2568/91 [11].

2.4. Determination of Sterol Composition

Sterol composition was determined according to the method described in Annex V of the consolidated European Regulation EEC No 2568/91 [11]. Sterol derivatives (trimethylsilyl ethers) were analyzed by an Agilent gas chromatograph (6890, Agilent, Santa Clara, CA, USA) equipped with a split/splitless injector (injection volume: 1 µL; split ratio: 1:50; 285 °C) and a flame-ionization detector (FID) (300 °C). Individual sterols were separated by a CP-Sil 8 CB capillary column (25 m length × 0.25 mm inner diameter × 0.25 µm film thickness) (Supelco, Bellefonte, PA, USA), and helium was used as a carrier gas (flow: 1 mL/min). The oven temperature was isothermal at 265 °C.

Individual peaks were identified by comparing the retention times of sterols with those of the standard samples. α-cholestanol was used as the internal standard for the quantification of individual sterols expressed as a relative percentage. The total sum of sterols was expressed as mg/kg. Apparent β-sitosterol was calculated as the sum of β-sitosterol, Δ5-avenasterol, clerosterol, sitostanol, and Δ5,24-stigmastadienol.

2.5. Statistical Analysis

We characterized the Empeltre clonal selection oils by descriptive analysis of all results obtained during the three years of study (78 samples). The effects of crop year, clone, and fruit maturity on individual and total sterol content were evaluated using univariate factorial analysis of variance (three-way ANOVA; p < 0.05). Clones 4 and 7 were excluded from three-way ANOVA analysis due to insufficient data. Results were grouped into three different ripening stages (green, spotted, and ripe) to evaluate the ripening effect. One-way ANOVA and a post hoc Duncan’s test (p < 0.05) were used to determine the influence of different harvest dates on sterol composition for each crop year. A study of relationships among individual sterols was carried out using Pearson’s correlation.

Finally, we conducted a multivariate analysis to study the discriminatory capacity regarding the sterol composition of Empeltre olive oils in the clonal selection of the study. For this purpose, we performed a canonical discriminant analysis (DA), which uses canonical correlation and principal component analysis techniques. To choose the most discriminating independent variables, we applied the step-wise method using Wilks’ lambda and its chi-square approximation as the exclusion method, along with the Snedecor’s F statistic as the selection criterion.

Statistical analyses were performed using IBM SPSS Statistics 24.0 software (IBM Corp., Armonk, NY, USA). Graphs were constructed with Excel 2016 (Microsoft Corp., Redmond, Washington, USA).

3. Results and Discussion

3.1. Sterol Composition and Regulatory Compliance of Empeltre Olive Oils

Table 1 shows the average results of the physicochemical quality parameters and the relative sterol composition, as well the total sterol content of the featured Empeltre olive oils. The 78 olive oil samples analyzed in the course of the 2017, 2018, and 2019 crop years were classified as extra virgin olive oils (EVOO) based on their physicochemical quality (acidity ≤ 0.8% oleic acid; peroxide value ≤ 20 meq O2/kg; K270 ≤ 0.22; K232 ≤ 2.50) according to the different regulations [12,13,14]. The low acidity levels we observed indicate that these olive oils came from healthy fruit.

Table 1.

Descriptive statistic of physicochemical quality parameters and sterol composition during three crop years (2017, 2018, and 2019) (n = 78).

In all cases, the total sterol content lay above the minimum limit (1000 mg/kg) established for virgin olive oils (VOO) [12,13,14], resulting in a mean value of 1490 mg/kg within a range of 1158 to 1943 mg/kg. As expected, the average individual sterol profile obtained in the olive oil from selected Empeltre clones was: β-sitosterol as the main sterol (85.58 ± 1.54%), followed by minor contents of Δ5-avenasterol (5.62 ± 1.32%), campesterol (3.16 ± 0.21%), and stigmasterol (1.34 ± 0.81%). The latter sterol displayed a high standard deviation, due to wide variation among the crop years in this study. These results were similar to those which have previously been reported on the Empeltre cultivar [16,22,23,25] and on other Spanish [20,32], Italian [31], Tunisian [35,45], and Algerian [46] cultivars. The percentages of these four sterols enable us to differentiate Empeltre olive oil as a monovarietal oil featuring medium-range contents of β-sitosterol and Δ5-avenasterol, but high levels of campesterol and stigmasterol, according to the classification elaborated by Kyçyk et al. [33] on the basis of 43 monovarietal oils from the Córdoba Germplasm Bank.

Lower quantities of cholesterol, 24-methylene-cholesterol, campestanol, clerosterol, sitostanol, Δ5,24-stigmastadienol, Δ7-stigmastenol, and Δ7-avenasterol were found in all samples. On the other hand, brassicasterol, a sterol marker for olive oil adulteration with Brassicaceae oils (e.g., rapeseed, canola), was not detected in any of the samples. Other sterols, such as Δ7-campestanol (present in sunflower oil) and Δ5,23-stigmastadienol (present in refined olive oils due to the refining process) were found in trace amounts in some of the samples (data not shown).

Regarding compliance with the limits established by European [12] and international regulations [13,14] regarding relative sterol composition, not all samples satisfied the requirements to be considered as genuine virgin olive oils (values in bold type in Table 1). The mean percentage of apparent β-sitosterol (93.52 ± 0.72%) was above the legal limit [12,13,14] (≥93%): the range of values obtained for this parameter (92.04–94.54%) showed that 26% of all samples analyzed during the three study crop years were non-compliant virgin olive oils. This non-compliance could suggest the presence of seed oils. Kyçyk et al. [33] reported that 23% of the monovarietal oils they analyzed had apparent β-sitosterol below 93%. Similarly, Rivera del Álamo et al. [20] described a non-compliance of 15–20% of the commercial Cornicabra virgin olive oils (334 samples) they analyzed during five consecutive crop years. Other authors [28,46,47] have also described monovarietal virgin olive oils from different countries that do not fulfill legislative limits for this parameter.

The mean percentage of Δ7-stigmastenol obtained from the 78 samples of virgin olive oils analyzed in our study was remarkably high (0.46 ± 0.10%), featuring a wide range of values (0.23–0.76%). A total of 12% of the samples had Δ7-stigmastenol values showing above the established 0.5% limit [12,13,14]. Elevated Δ7-stigmastenol values in Empeltre oils had also been observed in studies conducted over the period of 1998 to 2022 [23,24]. Garcia [21,22] has suggested that high Δ7-stigmastenol contents in Empeltre olive oils are a varietal peculiarity. Similar arguments have been propounded by Salvador et al. [18] and Rivera et al. [20] regarding the high campesterol content observed in the Spanish Cornicabra cultivar. High Δ7-stigmastenol content in other monovarietal oils has been described in Argentinian [16], Tunisian [45,46], and Palestinian [48] olive oils. Elevated Δ7-stigmastenol values (%) have likewise been observed in Compositae oils (e.g., sunflower, safflower).

The other sterols all complied with the limits specified in standard regulations for virgin olive oils [12,13,14].

3.2. Factors Exerting an Influence on Sterol Composition

The effects of clone type, crop year, and fruit maturity on sterol content and composition are shown in Table 2. Results of three-way ANOVA demonstrated that crop year was the variable under study which most significantly affected [19,49] the majority of the sterols we analyzed, along with total sterol content. Moreover, its effect was statistically significant for all evaluated parameters. Ripening also significantly modulated sterol composition [18,26,28,31,47,49]. Its impact, however, was much less pronounced than that of crop year, except in the case of sitostanol. In contrast, the degree of fruit ripeness was neither significant for Δ7-sterols such as Δ7-stigmastenol and Δ7-avenasterol, nor for clerosterol. Few sterols showed significant differences according to clone. Among them, campesterol and Δ7-stigmastenol were the ones most affected by clone type, and the latter was the factor which exerted the main effect on those sterols. Interactions among two effects (crop year × clone, crop year × fruit maturity, or clone × fruit maturity) showed significant differences for some parameters, but were less notable than independent effects, except for the influence of ripening factor on Δ7-stigmastenol and Δ7-avenasterol. The ripening effect was exclusively significant on Δ7-stigmastenol when interacting with crop year (p < 0.001) or clone type (p < 0.01).

Table 2.

Analysis of variance (F-values) by 3-way ANOVA of sterol composition in three crop years (Y) (2017, 2018, and 2019) on four Empeltre clones (C) (2, 3, 6, and Std) and in three fruit maturity stages (M) (green, spotted, and ripe).

3.3. Changes in Sterol Composition According to Degree of Olive Ripeness

As shown in Table 2, total sterol concentration displayed significant differences according to the olives’ degree of ripeness. In the three crop years studied, no consistent pattern was observed in the evolution of sterol content (Table 3, Table 4, Table 5, Table 6 and Table 7), as similarly observed by Salvador et al. [18] in studies on Cornicabra oils over four consecutive seasons. An evident increase in the concentration of olive oil sterols as the fruit matured (higher than 20%) occurred in 2019. In contrast, most clones showed similar contents in December 2018 compared to the beginning of the sampling, although with some oscillations during the sampling period, except for Clone 2, in which sterols increased by 12%. In 2017, a significant increase in sterols (37%) was observed in December compared to October in olive oils from the “Std” clone, but such variation was minimal or non-existent in the other clones. Other authors have observed a decrease in sterol content [6,32,38] and have explained it as a dilution effect of increasing oil content during fruit ripening [38]. The evolution of sterols directly in the olive pulp [50] has been less studied, but increases in sterol concentration have indeed been observed in the pulp as ripening progresses. Inês et al. [51] suggested that the increase they observed in sterol biosynthesis in early fruits was because the rates of mitosis and membrane formation were at maximum levels. The complexity of the enzymatic pathways involved in sterol biosynthesis [52,53] and the participation of sterols in the biosynthesis of other compounds [37,54], as well as abiotic stress effects on olives (a less studied factor) [53,55], generate a wide range of variability in sterol concentration throughout ripening. Navas-López et al. [30] observed that cultivar type was the main contributor to total variability in sterols. Their study involved seven cultivars grown in five different environments. However, hardly any references have been published [56] regarding the trends of total and individual sterol content during the olive ripening process specifically in the Empeltre cultivar. The dynamics of biosynthesis in the fruit and the accumulation of sterols in Empeltre olive oil could differ from those hitherto described in other cultivars [56].

Table 3.

Evolution of sterol composition (%) and total sterols (mg/kg) according to picking date a for clone 2 in the crop years 2017, 2018, and 2019.

Table 4.

Evolution of sterol composition (%) and total sterols (mg/kg) according to picking date a for clone 3 in the crop years 2017, 2018, and 2019.

Table 5.

Evolution of sterol composition (%) and total sterols (mg/kg) according to picking date a for clone 6 in the crop years 2017, 2018, and 2019.

Table 6.

Evolution of sterol composition (%) and total sterols (mg/kg) according to picking date a for clone “Std” in the crop years 2017, 2018, and 2019.

Table 7.

Evolution of sterol composition (%) and total sterols (mg/kg) according to picking date a for clones 4 and 7 in the crop years 2017, 2018, and 2019.

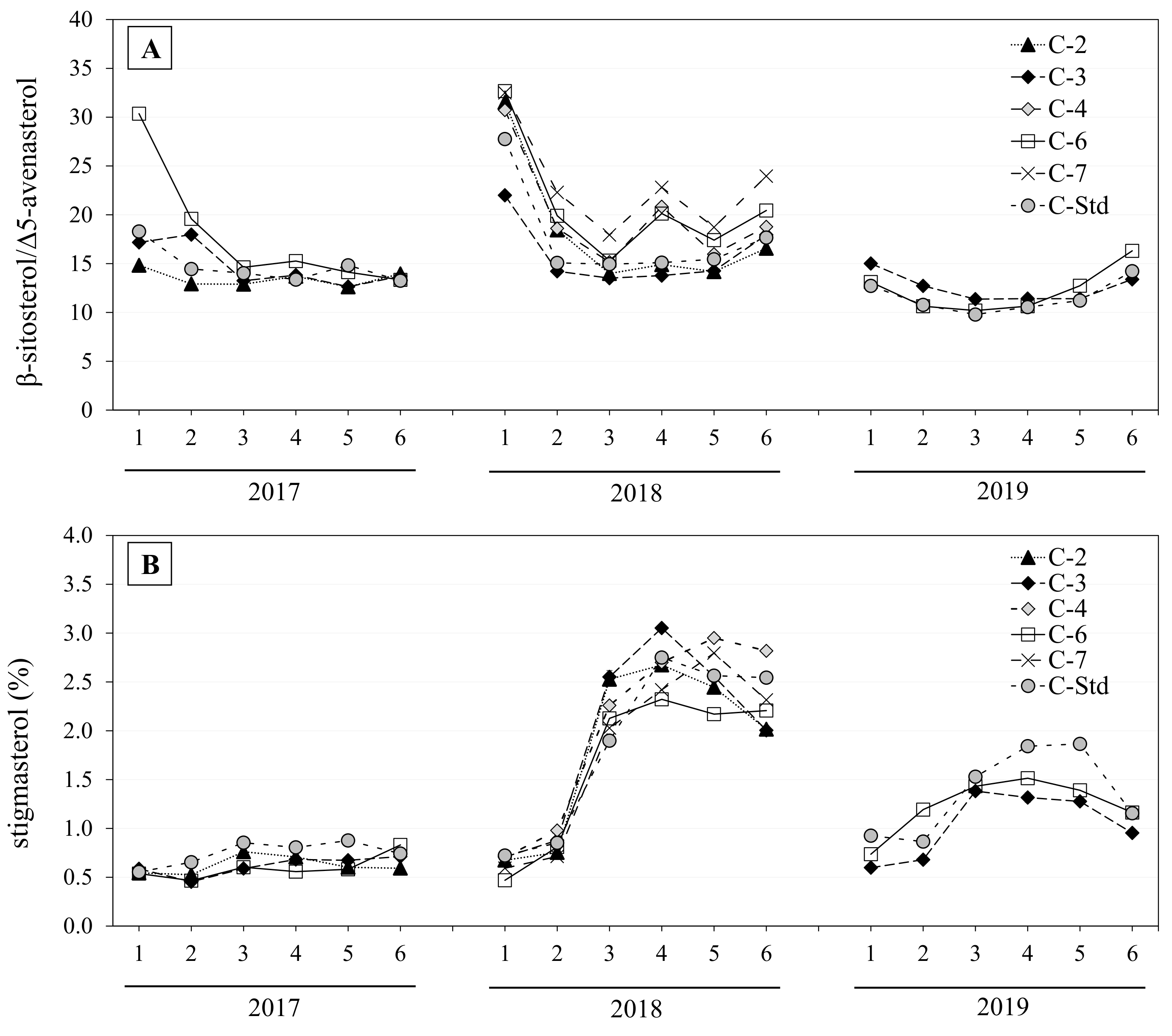

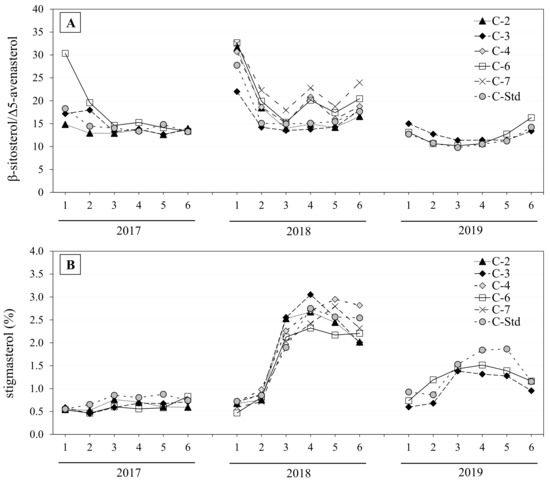

In terms of sterol composition, most of the sterols we analyzed presented significant differences according to olive maturity. The evolution of each individual sterol was highly variable (Table 3, Table 4, Table 5, Table 6 and Table 7), but coincided with the most widely observed patterns collected and discussed by Lukić et al. [56] in several monovarietal oils. In general, in our study, the net change in relative β-sitosterol content was slightly negative at the end of the sampling period (December). During the initial sampling period (October and early November), initial β-sitosterol content decreased and stabilized until mid-December, the last sampling date. In the 2019 harvest, this behavior differed in “Std” and Clone 6, as β-sitosterol relative levels increased in those two clone types in December. The changes we observed in the β-sitosterol pattern during ripening suggest a modification of the biosynthesis of this sterol or of oil accumulation in the fruit, as its stabilization coincides with the end of the lipogenesis period [56]. Meanwhile, Δ5-avenasterol showed a trend that was inverse to β-sitosterol, as indicated by the strong negative correlation obtained among those two sterols (r = −0.902, p < 0.01), likewise observed in other monovarietal oils from several countries [6,32,57,58]. In our study, Δ5-avenasterol increased by 30% on average during the sampling period, but its evolution was different in 2019, as occurred with β-sitosterol. During that year, a decrease in initial Δ5-avenasterol content was predominant, especially in the oils coming from Clone 6. In line with this, Gutiérrez et al. [38] have already hypothesized that the enzymatic activity that regulates the β-sitosterol/Δ5-avenasterol ratio was the cause of the high correlation they observed in their study. Indeed, Δ5-avenasterol is the precursor in the biosynthesis of β-sitosterol [52,59]. Several other authors [26,60] indicate that the β-sitosterol/Δ5-avenasterol ratio can decrease as fruit ripening progresses due to the decrease in the proportion of oil to stone, which is rich in β-sitosterol, but poor in Δ5-avenasterol. Fernández-Cuesta et al. [50] have ruled out the latter hypothesis by observing significant changes in both sterols directly in the pulp as the fruit ripened, thereby confirming that the activity of the enzymes involved in the biosynthesis of both sterols was responsible for the differences in their contents. This hypothesis would explain the high negative correlation we found between the two compounds. Other studies have found no significant differences between oils obtained from whole fruit versus oils obtained exclusively from olive pulp [26,60]. Figure 2A shows the evolution of the β-sitosterol/Δ5-avenasterol ratio in the olive oils obtained in our investigation over the three years of study.

Figure 2.

Evolution of the ratio of β-sitosterol/Δ5-avenasterol (A) and stigmasterol (B) by clone (C-2, C-3, C-4, C-6, C-7 and C-Std) throughout sampling in the 2017, 2018, and 2019 crop years. Harvest dates: 1 (1–4 October), 2 (16–18 October), 3 (28 October–7 November), 4 (11–22 November), 5 (25–29 November) and 6 (11–13 December).

Relative campesterol content decreased slightly during sampling [47,61] (Table 3, Table 4, Table 5, Table 6 and Table 7). Although this was the prevalent trend, a relative uniformity was likewise observed [29,38,61], especially in the 2018 crop year. As for stigmasterol, most of the studies reported in the review by Lukić et al. [56] describe an increase in its content, especially in the later stages of ripening, although that increase is not significant (as opposed to our results). However, the study of the effect of ripening on stigmasterol content presented difficulties in our trial. This sterol’s increase varied considerably, depending on the crop year (Figure 2B), which caused a high dispersion in our set of results. The highest average increases observed during the overall sampling period were in 2018 (72%) and 2019 (31%). Intense increases in late October-early November were observed during 2018 and 2019, after which they stabilized or slightly decreased in December. The increase in stigmasterol was so pronounced in mid-autumn 2018 that it implied regulatory non-compliance for the parameter for apparent β-sitosterol [12,13,14] throughout that sampling period (values in bold in Table 3, Table 4, Table 5, Table 6 and Table 7). The corresponding increment was lower in the crop year 2017 (22%). The possible relation we observed between stigmasterol and apparent β-sitosterol was confirmed by their high negative correlation (r = −0.975; p < 0.01). This association has previously been reported in Empeltre [21] and other cultivars [29,33,35]. In contrast, there was no significant correlation with β-sitosterol, although it is the precursor in the biosynthesis of stigmasterol [52,59]. Certain authors have related the stigmasterol content in olive oil with fruit quality and therefore, with olive oil quality, confirming a positive correlation between high acidity and the amount of stigmasterol [21,62]. No such relationship was found in our investigation, as the olive oils we studied had very low acidity (Table 1), which indicated satisfactory olive health.

No correlation was observed between fruit ripening and the parameter for apparent β-sitosterol.

The effect of ripeness on the relative amounts of minority sterols was varied. Cholesterol remained relatively constant, but 24-methylene-cholesterol, an intermediate metabolite in the synthesis of campesterol, increased significantly. Other minority sterols, such as Δ7-stigmastenol and Δ7-avenasterol, were not affected by fruit ripening (Table 2), but showed significant differences in terms of crop year × maturity interaction. Those two Δ7-sterols, which correlated positively with each other [37] (r = 0.793, p < 0.01), displayed parallel trends throughout ripening, according to the year under study (upward in 2017, downward in 2018, and relatively constant in 2019). Sitostanol, one of the main stanols in olive oil (a hydrogenated form of β-sitosterol, its precursor), decreased drastically throughout the sampling. This sterol was the only one which correlated significantly with the ripening index (r = −0.866; p < 0.01). Sakouhi et al. [37] ascribed the decrease in the stanols sitostanol and campestanol to their conversion into brassinosteroids, i.e., steroid hormones that regulate plant growth and development.

3.4. Changes in Sterol Composition by Crop Year Effect

Although our study did not directly address environmental factors, such as temperature, solar radiation (UV), precipitation, or humidity, these, among other aspects, could have been responsible for the significant interannual differences observed in sterol composition. Recent studies reported by Du et al. [53] indicate that enzymes involved in the sterol biosynthesis pathway are key in plant responses to abiotic stress. Drought is the most persistent and therefore, the most studied abiotic stress in olives, although high temperatures and UV-B radiation activate adaptive mechanisms that are not well known [55]. Such environmental factors have been scarcely addressed directly in relation to the modulation of sterol composition in olive fruit, and thus also in olive oil, although their influence has been demonstrated [26,55]. Many further studies have evidenced the effect of the environment in trials conducted at geographical locations with different climatic characteristics [24,27,28,34,35,48].

The oils from crop year 2017 had the highest sterol concentration and the highest relative contents of Δ7-stigmastenol and Δ7-avenasterol, but the lowest contents of stigmasterol. The 2017 autumn harvest was characterized by extreme drought (16 mm of autumn rainfall only), combined with the widest thermal oscillation and the lowest minimum temperatures (Figure 1): all these factors caused a substantial loss of moisture in the fruit [63]. In contrast, the autumn of 2018 was extremely rainy (10 times more rainfall than in autumn 2017) and had the narrowest thermal oscillation. Immediately after the high precipitation period in October 2018, olive oils had the highest stigmasterol amounts, but lower percentages of Δ5-avenasterol and apparent β-sitosterol (resulting in non-compliant samples; values in bold in Table 3, Table 4, Table 5, Table 6 and Table 7). Among the three crop years we studied, this circumstance only occurred in 2018. The lowest relative amounts of β-sitosterol, but the highest of Δ5-avenasterol, were observed in the 2019 season. Summer and autumn of 2019 had higher average and maximum temperatures, although these differences were not pronounced compared to the conditions in 2018.

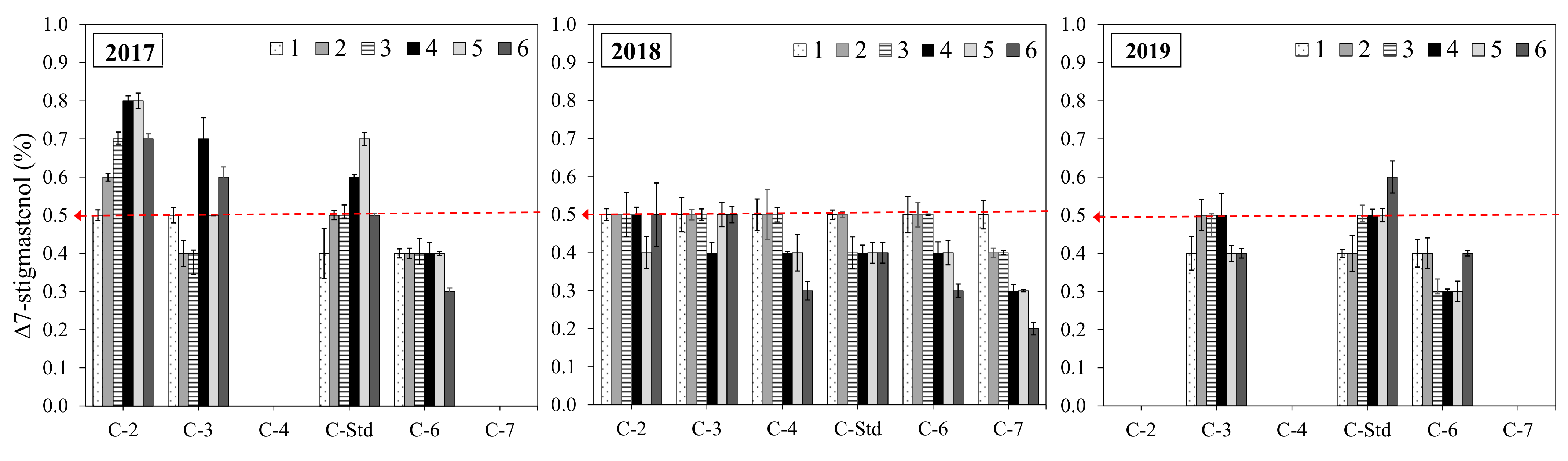

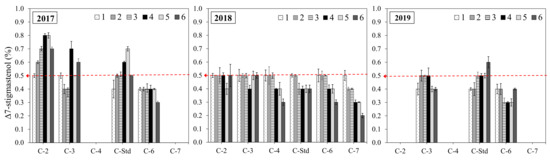

In line with these results, several authors have likewise described an increase in stigmasterol associated with greater water availability in Empeltre [24] and other cultivars [64,65]; however, Guillaume et al. [26] described lower stigmasterol and apparent β-sitosterol in association with higher levels of irrigation in Australian oils. On the other hand, higher contents of Δ7-stigmastenol and total sterols have been described in regions or seasons with low rainfall, or even in studies featuring irrigation deficit in Empeltre [21] and other cultivars [26,27,64], in line with our results. Figure 3 clearly shows the influence of crop year on compliance with the regulatory limit for Δ7-stigmastenol (0.5%). A variation in sterol content associated with water treatments is not evident; a significant decrease in sterol concentration has been described [64,65], but inconsistency can also be noted in results [66] stemming from irrigated cultivars.

Figure 3.

Evolution of Δ7-stigmastenol (%) according to harvest date and clone (C-2, C-3, C-4, C-6, C-7, and C-Std) in the three crop years studied (2017, 2018, and 2019). Harvest dates: 1 (1–4 October), 2 (16–18 October), 3 (28 October–7 November), 4 (11–22 November), 5 (25–29 November), and 6 (11–13 December). Non-compliance norm: Δ7-stigmastenol > 0.05 (%). Red arrow: limit established by the current EU/IOC/CODEX regulatory for OOV for Δ7-stigmastenol ≤ 0.5%.

The direct influence of temperature on sterol composition in olive fruit and olive oils has been less studied. Hamze et al. [36] conducted temperature-controlled experiments using open chambers. Their experiments reported an increase in sterol concentration caused by a moderate increment in air temperature (3–4 °C), in contrast with our study. That increment also induced an increase in stigmasterol, whereas apparent β-sitosterol and Δ5-avenasterol decreased. Those results are in line with Piravi-Vanak et al. [34], who reported that cold climate regions generate oils with higher β-sitosterol and lower stigmasterol content.

3.5. Changes in Sterol Composition According to Clonal Type

No significant differences were observed for most sterols in regard to clone type (Table 2). Δ7-stigmastenol, and especially campesterol, were the most affected sterols among those which showed significant differences. Along with total sterol concentration, Δ7-avenasterol and Δ5,24-stigmastadienol displayed significant differences, but with low effect. Results from Arbequina [24,67] and Empeltre [46,67] clonal selections yielded significant differences in very few parameters caused by clone type in olive fruit and/or olive oil.

Several studies have reported a considerable genetic influence on campesterol content [20,26,29,32], thereby corroborating the pronounced influence of clone type on this sterol in olive oils. In our study, Clone 6 presented higher values in this respect than the other clones.

Figure 3 shows the effects of clone type on Δ7-stigmastenol. Most Δ7-stigmastenol values were generally high; the “Std” Clone and Clone 2 had the highest rate of non-compliances, and most of these could be observed in 2017. In contrast, Clone 6 displayed the lowest values for this sterol. This clonal characteristic should be taken into account by producers who want to select clones for olive oils whose authenticity is not called into question.

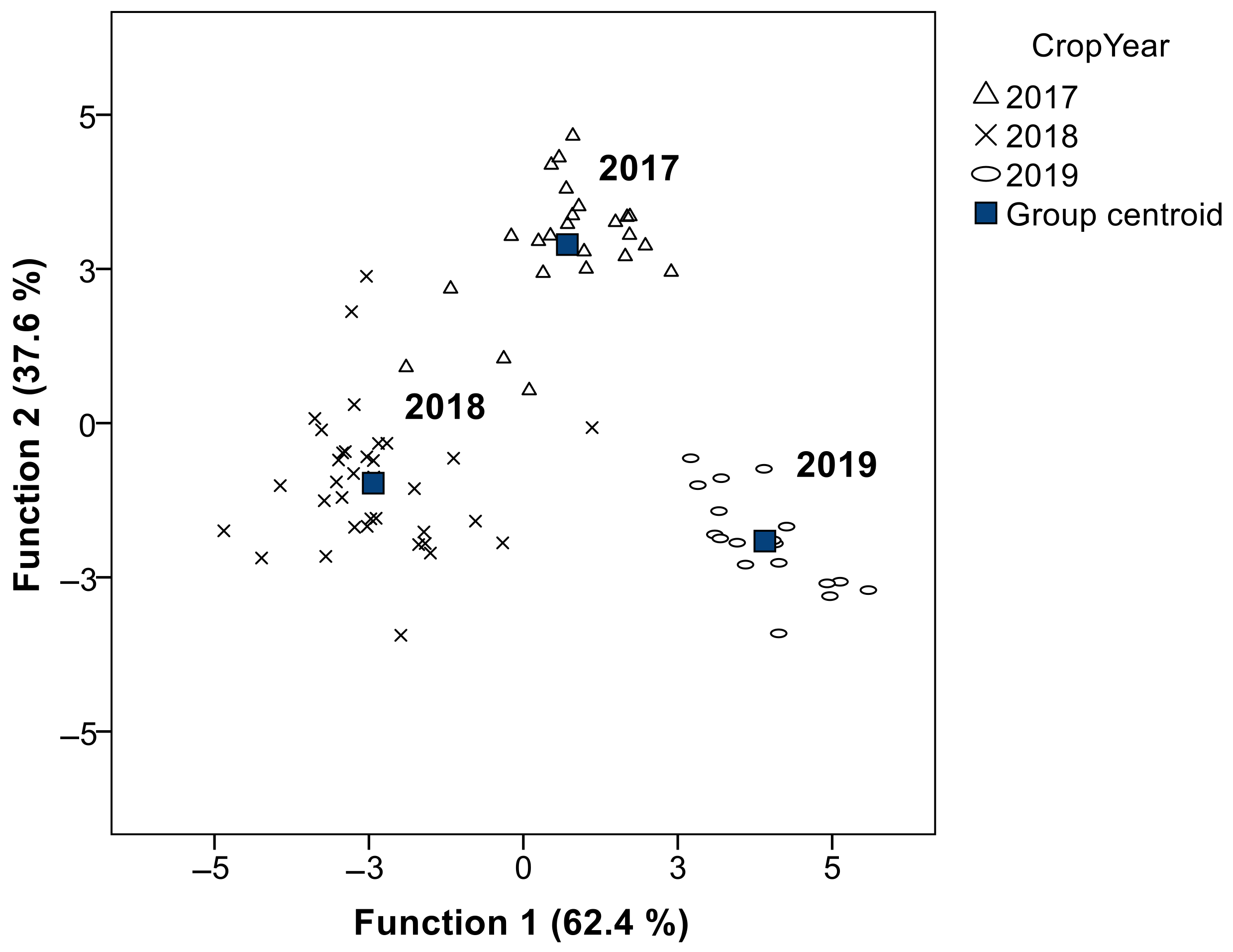

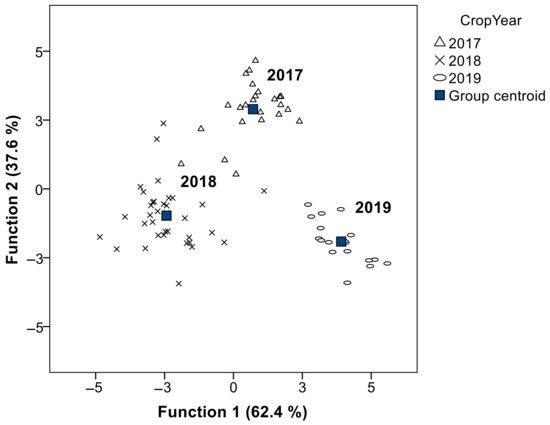

3.6. Discriminant Analysis

We applied a canonical discriminant analysis to visualize the discrimination capacity of the sterol composition of the Empeltre olive oils under study. The grouping variable “crop year” was the one displaying the best classifying ability (94.9% of the oils were classified correctly). The six most discriminating variables were total sterols, Δ5,24-stigmastadienol, Δ7-avenasterol, Δ5-avenasterol, stigmasterol, and campesterol. Figure 4 shows the 78 samples projected onto a biplot defined by the two canonical discriminant functions that explained 100% of the total variation (p < 0.001). The classification results (Table 8) show an effective separation between the three years under study based on sterol composition. The year 2017 showed greater differentiation compared to the other two years. According to Canonical Discriminant Function 1 (63.9% of the total variance), the 2018 samples were differentiated by higher b-sitosterol and campesterol contents, but lower Δ5-avenasterol compared to 2019. Canonical Discriminant Function 2 (36.1% of the total variance) differentiated the years 2018 and 2019 versus 2017 by higher stigmasterol but lower total sterols, apparent β-sitosterol, and Δ7-stigmasternol.

Figure 4.

Canonical discriminant functions biplot and centroids of crop years obtained from sterols composition.

Table 8.

Combined within-group correlations between discriminant variables and standardized canonical discriminant functions and eigenvalues.

4. Conclusions

The results presented in this study regarding the characterization of sterol composition in Empeltre olive oils have revealed high percentages of non−compliances vis−à−vis official regulations that determine an olive oil’s presumed authenticity. In general, sterols were mainly affected by harvest year and less by degree of ripening. The least significant effect was clone type, although this latter factor exerted the most pronounced effect on campesterol and Δ7−stigmasterol. The high Δ7−stigmastenol content observed in the Empeltre olive oils in our study reinforces the hypothesis regarding varietal peculiarity raised previously. However, the non−compliances we detected in this sterol could be caused by particular environmental factors associated with crop year, as revealed by the results of canonical discriminant analysis (DA). Environmental factors could also be responsible for the non−compliance rate of apparent β−sitosterol, which is affected by an increase in stigmasterol content.

Our results suggest that commercial standards should generally take natural variations in sterol composition into account with the purpose of avoiding economic damage to certain producers whose single−varietal olive oils have abnormal sterol content, while still ensuring that consumers are protected from fraud.

Author Contributions

Conceptualization, A.C.S.-G. and R.R.-G.; methodology, R.R.-G.; data curation, R.R.-G.; formal analysis, A.C.S.-G. and R.R.-G.; investigation, R.R.-G.; writing—original draft preparation, R.R.-G.; writing—review and editing, A.C.S.-G. and R.R.-G.; supervision, A.C.S.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

Rey−Giménez is grateful for the collaboration of the Centro de Transferencia Agroalimentaria (Aragon Government) for the development of this study, especially to Diego Laya. A special mention to the technical team of Aceites, Grasas, y Lácteos Area of the Laboratorio Agroambiental (Aragon Government) for their excellent technical and human support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- López−Miranda, J.; Pérez−Jiménez, F.; Ros, E.; De Caterina, R.; Badimón, L.; Covas, M.I.; Escrich, E.; Ordovás, J.M.; Soriguer, F.; Abia, R.; et al. Olive oil and health: Summary of the II international conference on olive oil and health consensus report, Jaén and Córdoba, Spain, 2008. Nutr. Metab. Cardiovasc. Dis. 2010, 20, 284–294. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on the substantiation of health claims related to olive oil and maintenance of normal blood LDL−cholesterol concentrations (ID1316, 1332), maintenance of normal (fasting) blood concentrations of triglycerides (ID 1316, 1332), maintenance of normal blood HDL−cholesterol concentrations (ID 1316, 1332) and maintenance of normal blood glucose concentrations (ID 4244) pursuant to Article 13(1) of Regulation (EC) No 1924/2006. EFSA J. 2011, 9, 2044–2062. [Google Scholar]

- Mele, M.A.; Islam, M.Z.; Kang, H.M.; Giuffrè, A.M. Pre−and post−harvest factors and their impact on oil composition and quality of olive fruit. Emir. J. Food Agric. 2018, 30, 592–603. [Google Scholar]

- Gharbi, I.; Issaoui, M.; Mehri, S.; Cheraief, I.; Sifi, S.; Hammami, M. Agronomic and Technological Factors Affecting Tunisian Olive Oil Quality. Agric. Sci. 2015, 6, 513–526. [Google Scholar] [CrossRef]

- Giuffrè, A.M.; Louadj, L.; Poiana, M.; Macario, A. Composition en stérols des huiles extraites d’olives de cultivars de la province de Reggio Calabria (Sud d’Italie). Riv. Ital. Sostanze Grasse 2012, 89, 177–183. [Google Scholar]

- Beltrán, G.; Del Rio, C.; Sánchez, S.; Martínez, L. Influence of harvest date and crop yield on the fatty acid composition of virgin olive oils from cv. Picual. J. Agric. Food Chem. 2004, 52, 3434–3440. [Google Scholar] [CrossRef]

- Beltrán, G.; Aguilera, M.P.; Del Rio, C.; Sanchez, S.; Martinez, L. Influence of fruit ripening process on the natural antioxidant content of Hojiblanca virgin olive oils. Food Chem. 2005, 89, 207–215. [Google Scholar] [CrossRef]

- Giuffrè, A.M. The effects of cultivar and harvest year on the fatty alcohol composition of olive oils from Southwest Calabria (Italy). Grasas Aceites 2014, 65, e011. [Google Scholar] [CrossRef]

- Giuffrè, A.M. Influence of harvest year and cultivar on wax composition of olive oils. Eur. J. Lipid Sci. Technol. 2013, 115, 549–555. [Google Scholar] [CrossRef]

- International Olive Council (IOC). Available online: https://www.internationaloliveoil.org/what−we−do/economic−affairs−promotion−unit/ (accessed on 22 May 2022).

- European Union Commission. 2020 Annual Report: The EU Agri−Food Fraud Network and the Administrative Assistance and Cooperation System; European Union Commission: Brussels, Belgium, 2021; pp. 1–21.

- Consolidated Text. Commission Regulation 2568/91 of 11 July 1991 on the Characteristics of Olive Oil and Olive−Residue Oil and on the Relevant Methods of Analysis. Available online: https://eur−lex.europa.eu/legal−content/EN/ALL/?uri=CELEX%3A01991R2568−20161204 (accessed on 5 August 2022).

- International Olive Council (IOC). Trade standard Applying to Olive Oils and Olive Pomace Oils, COI/T.15/NC No 3/Rev.18/2022. Available online: https://www.internationaloliveoil.org/what−we−do/chemistry−standardisation−unit/standards−and−methods/ (accessed on 4 August 2022).

- Codex Standard 33−1981; Codex Standard for Olive Oils and Olive Pomace Oils. Codex Alimentarius Commission: Rome, Italy, Revised in 1989, 2003, 2015, 2017. Amended in 2009, 2013, 2021.

- García−González, D.L.; Tena, N.; Romero, I.; Aparicio−Ruiz, R.; Morales, M.T.; Aparicio, R. A study of the differences between trade standards inside and outside Europe. Grasas Aceites 2017, 68, e210. [Google Scholar] [CrossRef]

- Ceci, L.N.; Carelli, A.A. Characterization of monovarietal Argentinian olive oils from new productive zones. J. Am. Oil Chem. Soc. 2007, 84, 1125–1136. [Google Scholar] [CrossRef]

- Cert, A.; Moreda, W.; García Moreno, J. Determinación de esteroles y dialcoholes triterpénicos en aceite de oliva mediante separación de la fracción por cromatografía líquida de alta eficacia y análisis por cromatografía de gases. Estandarización del método analítico. Grasas Aceites 1997, 48, 207–218. [Google Scholar] [CrossRef][Green Version]

- Salvador, M.D.; Aranda, F.; Fregapane, G. Influence of fruit ripening on Cornicabra virgin olive oil quality. A study of four successive crop seasons. Food Chem. 2001, 73, 45–53. [Google Scholar] [CrossRef]

- Salvador, M.D.; Aranda, F.; Gómez−Alonso, S.; Fregapane, G. Influence of extraction system, production year and area on Cornicabra virgin olive oil: A study of five crop seasons. Food Chem. 2003, 80, 359–366. [Google Scholar] [CrossRef]

- Rivera Del Álamo, R.M.; Fregapane, G.; Aranda, F.; Gómez−Alonso, S.; Salvador, M.D. Sterol and alcohol composition of Cornicabra virgin olive oil: The campesterol content exceeds the upper limit of 4% established by EU regulations. Food Chem. 2004, 84, 533–537. [Google Scholar] [CrossRef]

- Gracia, M.S. Composición química de distintas calidades de aceites de oliva virgen de la variedad “Empeltre” en el Bajo Aragón. Grasas Aceites 2001, 52, 52–58. [Google Scholar]

- Gracia, M.S.; Royo, A.; Gillen, M. Composición química de aceites de las variedades Arbequina y Empeltre cultivadas en regadío. Grasas Aceites 2009, 60, 321–329. [Google Scholar] [CrossRef]

- Tous, J.; Romero, A.; Plana, J.; Espada, J.L.; Gracia, M.S.; Lizar, B.; Rallo, J.; Martorell, A.; Iñiguez, A.; Gracia, J.; et al. Selección clonal de la variedad de olivo “Empeltre” en el Valle del Ebro y Baleares. Frutic. Prof. 2006, 160, 13–18. [Google Scholar]

- Romero, A.; Tous, J.; Gracia, M.S. Fatty acids and sterol composition of “Empeltre” virgin oil in Ebro Valley and Balearic Islands. Acta Hortic. 2011, 924, 385–392. [Google Scholar] [CrossRef]

- Mailer, R.J.; Ayton, J.; Graham, K. The influence of growing region, cultivar and harvest timing on the diversity of Australian olive oil. J. Am. Oil Chem. Soc. 2010, 87, 877–884. [Google Scholar] [CrossRef]

- Guillaume, C.; Ravetti, L.; Ray, D.L.; Johnson, J. Technological factors affecting sterols in Australian olive oils. J. Am. Oil Chem. Soc. 2012, 89, 29–39. [Google Scholar] [CrossRef]

- Li, X.; Flynn, J.D.; Wang, S.C. The effects of variety, growing region, and drought stress on fatty acid and sterol compositions of California olive oil. J. Am. Oil Chem. Soc. 2019, 96, 215–230. [Google Scholar] [CrossRef]

- Noorali, M.; Barzegar, M.; Sahari, M.A. Sterol and fatty acid compositions of olive oil as an indicator of cultivar and growing area. J. Am. Oil Chem. Soc. 2014, 91, 1571–1581. [Google Scholar] [CrossRef]

- Lukić, M.; Lukić, I.; Krapac, M.; Sladonja, B.; Pilizota, V. Sterols and triterpene diols in olive oil as indicators of variety and degree of ripening. Food Chem. 2013, 136, 251–258. [Google Scholar] [CrossRef]

- Navas−Lopez, J.F.; León, L.; Trentacoste, E.R.; de la Rosa, R. Multi−environment evaluation of oil accumulation pattern parameters in olive. Plant Physiol. Biochem. 2019, 139, 485–494. [Google Scholar] [CrossRef]

- Giuffrè, A.M.; Louadj, L. Influence of crop season and cultivar on sterol composition of monovarietal olive oils in reggio Calabria (Italy). Czech J. Food Sci. 2013, 31, 256–263. [Google Scholar] [CrossRef]

- Sánchez, J.; Osorio, E.; Montaño, A.M.; Martínez, M. Sterol and erythrodiol + uvaol content of virgin olive oils from cultivars of Extremadura (Spain). Food Chem. 2004, 87, 225–230. [Google Scholar] [CrossRef]

- Kyçyk, O.; Aguilera, M.P.; Gaforio, J.J.; Jiménez, A.; Beltrán, G. Sterol composition of virgin olive oil of forty−three olive cultivars from the World Collection Olive Germplasm Bank of Cordoba. J. Sci. Food Agric. 2016, 96, 4143–4150. [Google Scholar] [CrossRef]

- Piravi−Vanak, Z.; Ghasemi, J.B.; Ghavami, M.; Ezzatpanah, H.; Zolfonoun, E. The influence of growing region on fatty acids and sterol composition of Iranian olive oils by unsupervised clustering methods. J. Am. Oil Chem. Soc. 2012, 89, 371–378. [Google Scholar] [CrossRef]

- Temime, S.B.; Manai, H.; Methenni, K.; Baccouri, B.; Abaza, L.; Daoud, D.; Sánchez Casas, J.; Osorio Bueno, E.; Zarrouk, M. Sterolic composition of Chétoui virgin olive oil: Influence of geographical origin. Food Chem. 2007, 110, 368–374. [Google Scholar] [CrossRef]

- Hamze, L.; Miserere, A.; Molina, M.S.; Maestri, D.; Searles, P.S.; Rousseaux, M.C. Influence of environmental growth temperature on tocopherol and sterol oil concentrations in olive fruit. J. Sci. Food Agric. 2022, 102, 2741–2749. [Google Scholar] [CrossRef] [PubMed]

- Sakouhi, F.; Absalon, C.; Harrabi, S.; Vitry, C.; Sebei, K.; Boukhchina, S.; Fouquet, E.; Kallel, H. Dynamic accumulation of 4−desmethylsterols and phytostanols during ripening of Tunisian Meski olives (Olea europea L.). Food Chem. 2009, 112, 897–902. [Google Scholar] [CrossRef]

- Gutiérrez, F.; Jiménez, B.; Ruiz, A.; Albi, M.A. Effect of olive ripeness on the oxidative stability of virgin olive oil extracted from the varieties picual and hojiblanca and on the different components involved. J. Agric. Food Chem. 1999, 47, 121–127. [Google Scholar] [CrossRef] [PubMed]

- Barranco, D.; Trujillo, I.; Rallo, L. Elaiografía Hispánica. In Variedades de olivo en España; Barranco, D., Caballero, J.M., Del Río, C., Martín, A., Tous, J., Trujillo, I., Eds.; Junta de Andalucía, MAPA and Mundi Prensa: Madrid, Spain, 2005; pp. 46–231. [Google Scholar]

- Romero, A.; Ninot, A.; Hermoso, J.F.; Tous, J. Clonal selection of Empeltre olive cultivar in Spain. In VII International Symposiun on Olive Growing; International Society for Horticultural Science: San Juan, Argentina, 2012. [Google Scholar]

- Tous, J.; Romero, A.; Plana, J.; Espada, J.L.; Gracia, M.S.; Lizar, B.; Rallo, J.; Martorell, A.; Iñiguez, A.; García, J.; et al. Ficha varietal del cultivar “Empeltre”. Olivae 2004, 102, 31–32. [Google Scholar]

- López, F.; Cabrera, M.; Cuadrat, J.M. La división climática en Aragón. In Atlas Climático de Aragón; Gobierno de Aragón: Zaragoza, Spain, 2007; pp. 155–166. [Google Scholar]

- Hermoso, M.; Uceda, M.; García, A.; Morales, B.; Frías, M.L.; Fernández, A. Elaboración de Aceite de Oliva de Calidad. Colección: Apuntes, 5/91; Consejería de Agricultura y Pesca, Junta de Andalucía: Sevilla, Spain, 1991. [Google Scholar]

- Martínez, J.M.; Muñoz, E.; Alba, J.; Lanzón, A. Informe sobre la utilización del analizador de rendimientos ‘‘Abencor’’. Grasas Aceites 1975, 26, 379–385. [Google Scholar]

- Manai−Djebali, H.; Krichène, D.; Ouni, Y.; Gallardo, L.; Sánchez, J.; Osorio, E.; Douja, D.; Flamini, G.; Arrouk, M. Chemical profiles of five minor olive oil varieties grown in central Tunisia. J. Food Compost. Anal. 2012, 27, 109–119. [Google Scholar] [CrossRef]

- Chennit, B.; del Carmen Pérez−Camino, M.; Gómez−Coca, R.B.; Moreda, W.; Boudriche, L.; Madani, K. Characterization of kabylian virgin olive oils according to fatty alcohols, waxes, and fatty acid alkyl esters. J. Food Meas. Charact. 2021, 15, 4960–4971. [Google Scholar] [CrossRef]

- Chtourou, F.; Jabeur, H.; Lazzez, A.; Bouaziz, M. Characterization and discrimination of Oueslati virgin olive oils from adult and young trees in different ripening stages using sterols, pigments, and alcohols in tandem with chemometrics. J. Agric. Food Chem. 2017, 65, 3512–3522. [Google Scholar] [CrossRef]

- Abu−Alruz, K.; Afaneh, I.A.; Quasem, J.M.; Hmidat, M.A.; Abbady, J.; Mazahreh, A.S. Factors affecting D-7-stigmastenol in Palestinian olive oil. Res. J. Appl. Sci. 2011, 11, 797–805. [Google Scholar] [CrossRef]

- Anastasopoulos, E.; Kalogeropoulos, N.; Kaliora, A.C.; Kountouri, A.; Andrikopoulos, N.K. The influence of ripening and crop year on quality indices, polyphenols, terpenic acids, squalene, fatty acid profile, and sterols in virgin olive oil (Koroneiki cv.) produced by organic versus non−organic cultivation method. Int. J. Food Sci. Technol. 2011, 46, 170–178. [Google Scholar] [CrossRef]

- Fernández−Cuesta, A.; León, L.; Velasco, L.; De la Rosa, R. Changes in squalene and sterols associated with olive maturation. Food Res. Int. 2013, 54, 1885–1889. [Google Scholar] [CrossRef]

- Inês, C.; Corbacho, J.; Paredes, M.A.; Labrador, J.; Cordeiro, A.M.; Gomez−Jimenez, M.C. Regulation of sterol content and biosynthetic gene expression during flower opening and early fruit development in olive. Physiol. Plant. 2019, 167, 526–539. [Google Scholar] [CrossRef]

- Moreau, R.A.; Nyström, L.; Whitaker, B.D.; Winkler−Moser, J.K.; Baer, D.J.; Gebauer, S.K.; Hicks, K.B. Phytosterols and their derivatives: Structural diversity, distribution, metabolism, analysis, and health−promoting uses. Prog. Lipid Res. 2018, 70, 35–61. [Google Scholar] [CrossRef]

- Du, Y.; Fu, X.; Chu, Y.; Wu, P.; Liu, Y.; Ma, L.; Tian, H.; Zhu, B. Biosynthesis and the Roles of Plant Sterols in Development and Stress Responses. Int. J. Mol. Sci. 2022, 23, 2332. [Google Scholar] [CrossRef]

- Venkatramesh, M.; Karunanandaa, B.; Sun, B.; Gunter, C.A.; Boddupalli, S.; Kishore, G.M. Expression of a Streptomyces 3−hydroxysteroid oxidase gene in oilseeds for converting phytosterols to phytostanols. Phytochemistry 2003, 62, 39–46. [Google Scholar] [CrossRef]

- Dias, M.C.; Pinto, D.C.G.A.; Figueiredo, C.; Santos, C.; Silva, A.M.S. Phenolic and lipophilic metabolite adjustments in Olea europaea (olive) trees during drought stress and recovery. Phytochemistry 2021, 185, 112695. [Google Scholar] [CrossRef]

- Lukić, M.; Lukić, I.; Moslavac, T. Sterols and triterpene diols in virgin olive oil: A comprehensive review on their properties and significance, with a special emphasis on the influence of variety and ripening degree. Horticulturae 2021, 7, 493. [Google Scholar] [CrossRef]

- Vekiari, S.A.; Oreopoulou, V.; Kourkoutas, Y.; Kamoun, N.; Msallem, M.; Psimouli, V.; Arapoglou, D. Characterization and seasonal variation of the quality of virgin olive oil of the Throumbolia and Koroneiki varieties from Southern Greece. Grasas Aceites 2010, 61, 221–231. [Google Scholar] [CrossRef]

- Dag, C.; Demirtas, I.; Ozdemir, I.; Bekiroglu, S.; Ertas, E. Biochemical characterization of Turkish extra virgin olive oils from six different olive varieties of identical growing conditions. J. Am. Oil Chem. Soc. 2015, 92, 1349–1356. [Google Scholar] [CrossRef]

- Morikawa, T.; Mizutani, M.; Aoki, N.; Watanabe, B.; Saga, H.; Saito, S.; Oikawa, A.; Suzuki, H.; Sakurai, N.; Shibata, D.; et al. Cytochrome P450 CYP710A encodes the sterol C−22 desaturase in Arabidopsis and tomato. Plant Cell 2006, 18, 1008–1022. [Google Scholar] [CrossRef]

- Ranalli, A.; Pollastri, L.; Contento, S.; Di Loreto, G.; Lannucci, E.; Lucera, L.; Russi, F. Sterol and alcohol components of seed, pulp and whole olive fruit oils. Their use to characterise olive fruit variety by multivariates. J. Sci. Food Agric. 2002, 82, 854–859. [Google Scholar] [CrossRef]

- Boulkroune, H.; Lazzez, A.; Guissous, M.; Bellik, Y.; Smaoui, S.; Kamoun, N.G.; Madani, T. Characterization of sterolic and alcoholic fractions of some Algerian olive oils according to the variety and ripening stage. Oilseeds Fats Crops Lipids. 2017, 24, A502. [Google Scholar] [CrossRef]

- Gutiérrez, F.; Varona, I.; Albi, M.A. Relation of acidity and sensory quality with sterol content of olive oil from stored fruit. J. Agric. Food Chem. 2000, 48, 1106–1110. [Google Scholar] [CrossRef]

- Rey-Giménez, R.; Sánchez-Gimeno, A.C. Crop year, harvest date and clone effects on fruit characteristics, chemical composition and olive oil stability from an Empeltre clonal selection grown in Aragon. J. Sci. Food Agric. 2022. [Google Scholar] [CrossRef]

- Fernandes−Silva, A.A.; Gouveia, J.B.; Vasconcelos, P.; Ferreira, T.C.; Villalobos, F.J. Effect of different irrigation regimes on the quality attributes of monovarietal virgin olive oil from cv. “cobrançosa”. Grasas Aceites 2013, 64, 41–49. [Google Scholar] [CrossRef]

- Stefanoudaki, E.; Williams, M.; Chartzoulakis, K.; Harwood, J. Effect of irrigation on quality attributes of olive oil. J. Agric. Food Chem. 2009, 57, 7048–7055. [Google Scholar] [CrossRef]

- Berenguer, M.J.; Vossen, P.M.; Grattan, S.R.; Connell, J.H.; Polito, V.S. Tree irrigation levels for optimum chemical and sensory properties of olive oil. HortScience 2006, 41, 427–432. [Google Scholar] [CrossRef]

- Tous, J.; Romero, A.; Plana, J. Selección clonal en variedades (En Arbequina). In Variedades de Olivo en España; Rallo, L., Barranco, D., Caballero, J.M., Del Río, C., Martín, A., Tous, J., Trujillo, I., Eds.; Junta de Andalucía, MAPA and Ediciones Mundi−Prensa: Madrid, Spain, 2005; pp. 395–404. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).