Study on Symmetry and Asymmetry Rolling of AA2519-T62 Alloy at Room-Temperature and Cryogenic Conditions

Abstract

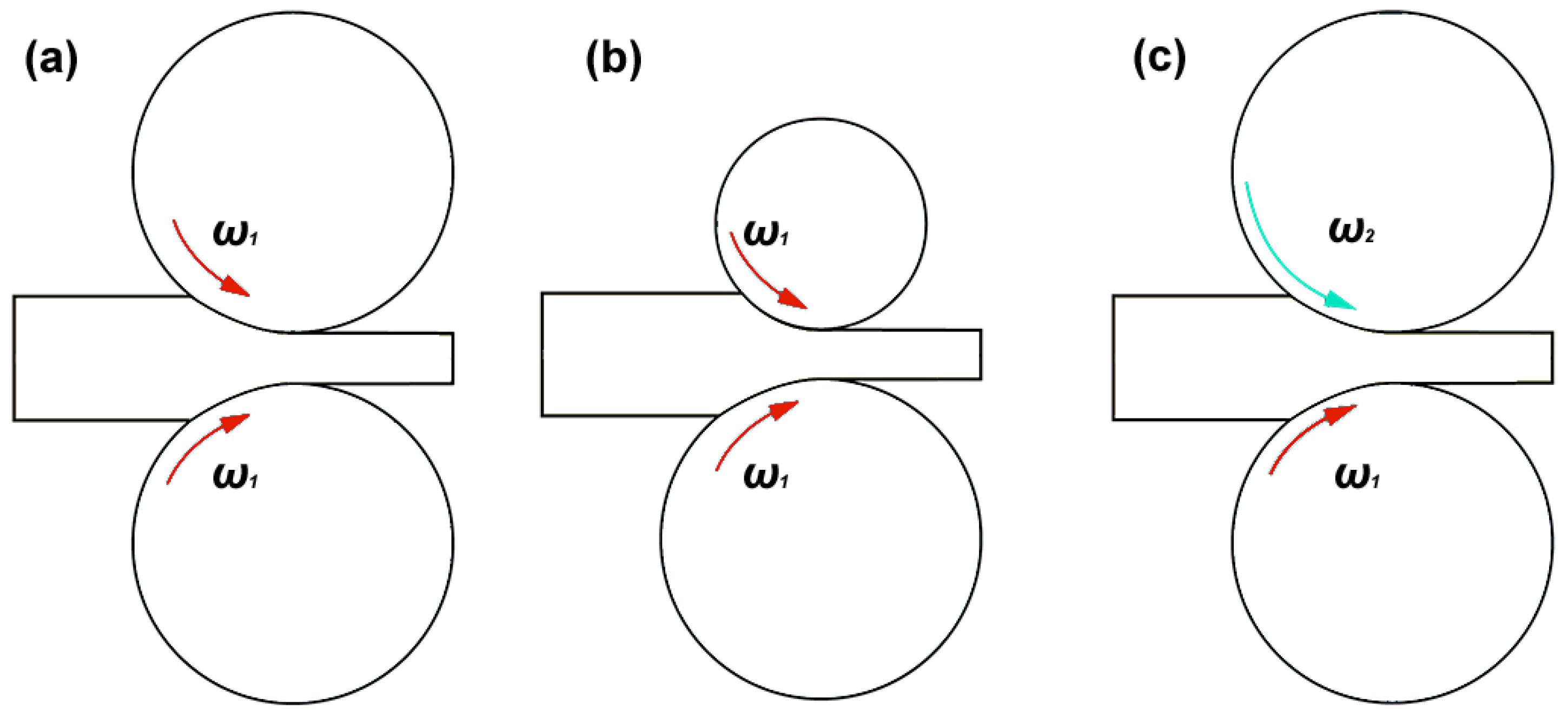

:1. Introduction

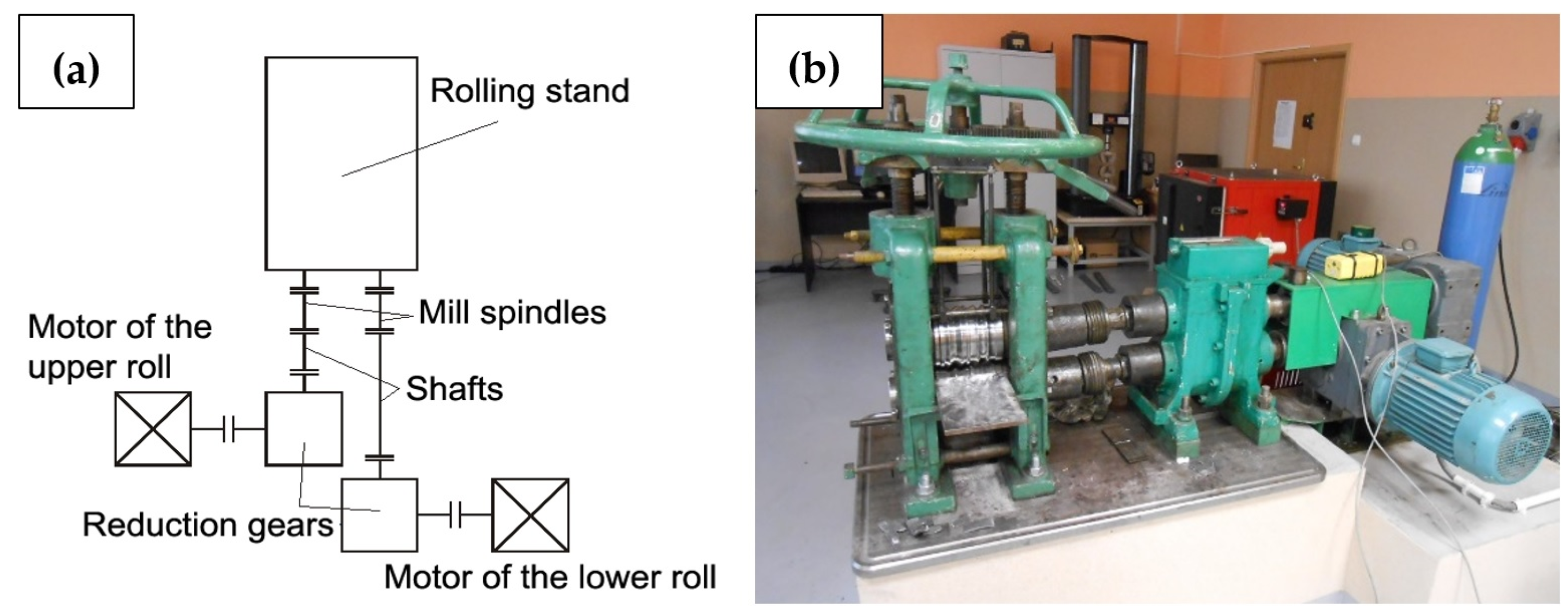

2. Materials and Methods

3. Results and Discussion

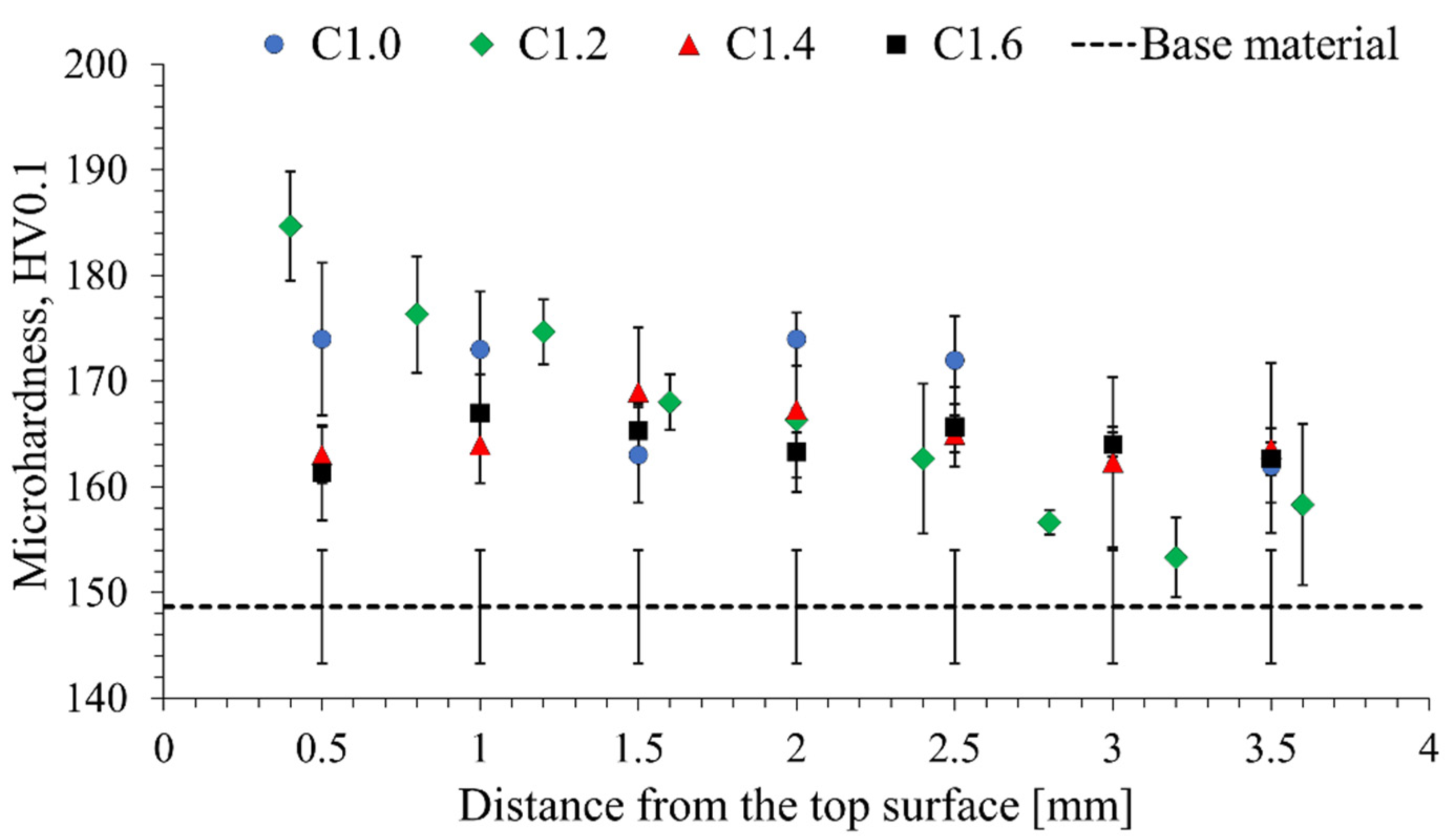

3.1. Microhardness Distribution

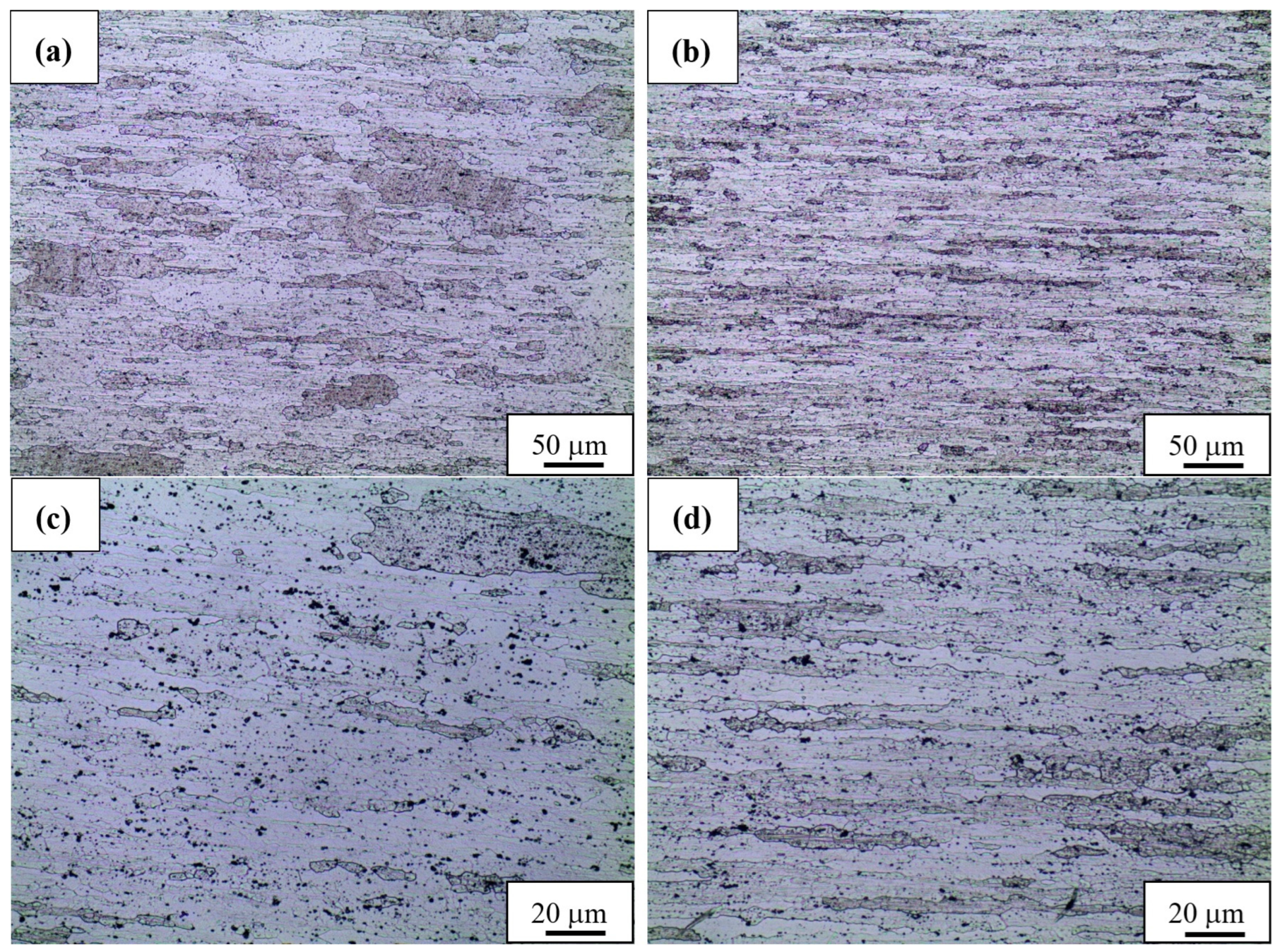

3.2. Light Microscopy Observations

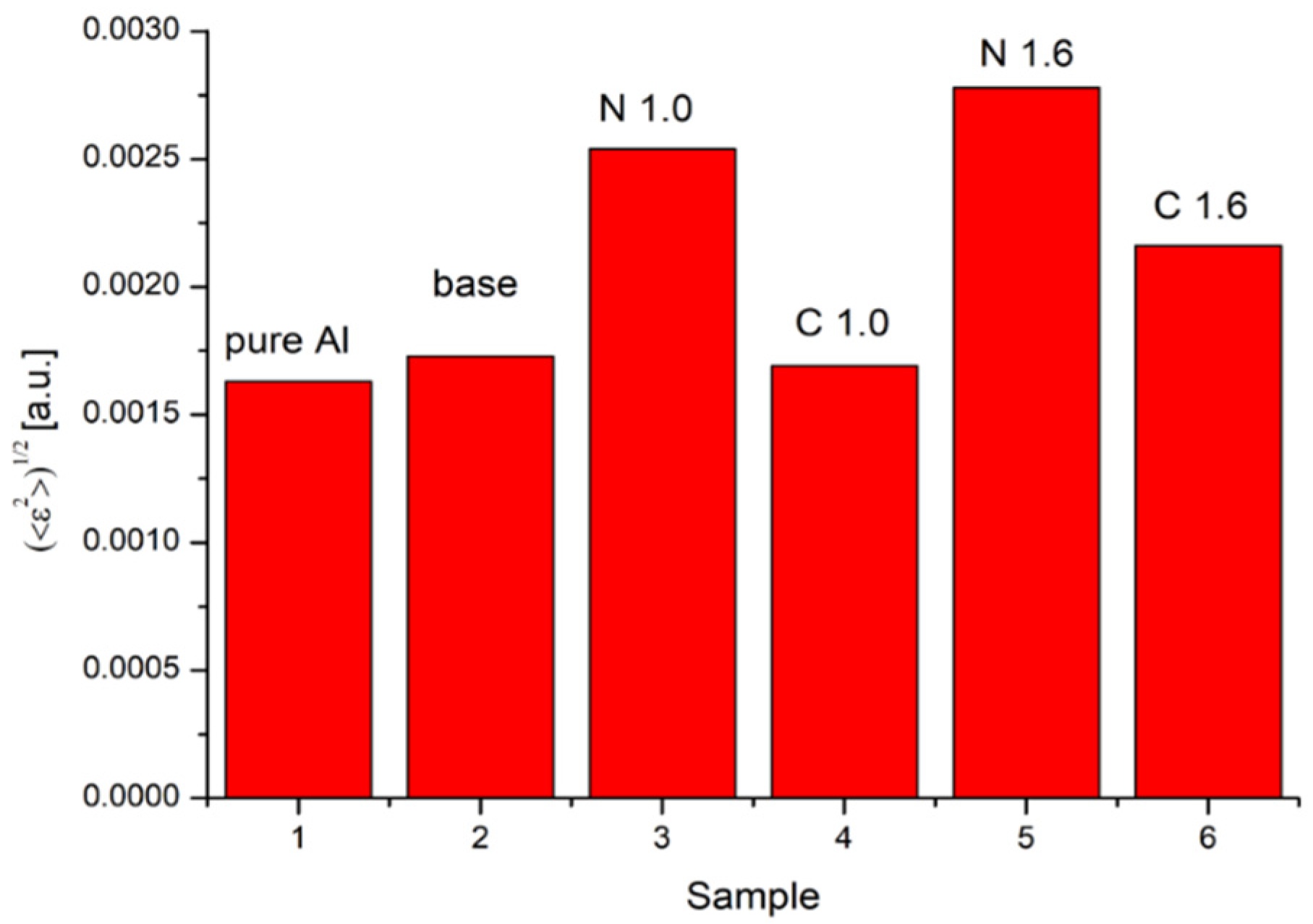

3.3. Microstrains

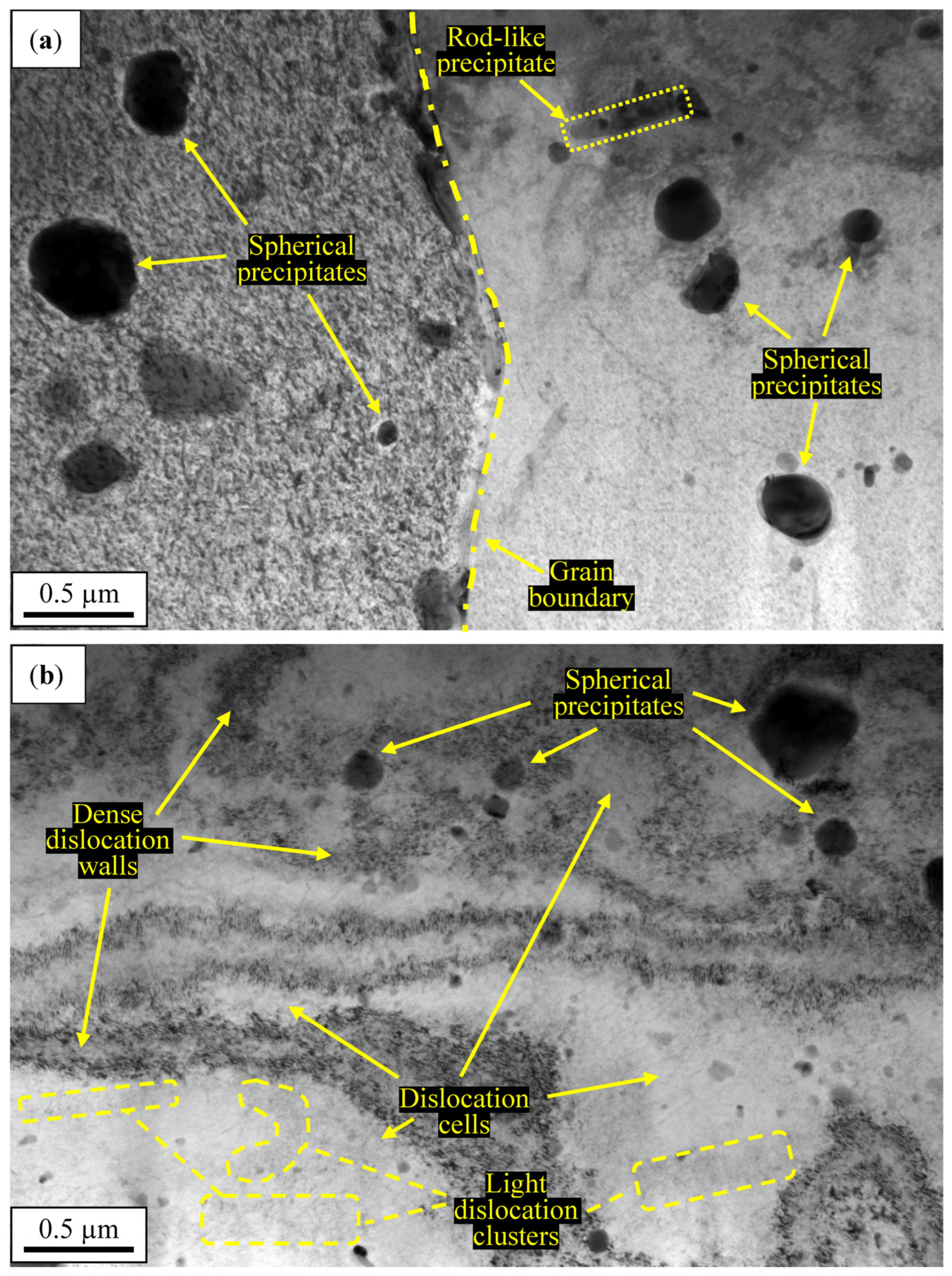

3.4. TEM Observations

4. Conclusions

- Both rolling at room temperature and under cryogenic conditions increase the mi-crohardness of AA2519-T62 by at least 10%. The highest reported increase (25%) was obtained for samples rolled at room temperature in a traditional symmetry rolling process.

- Rolling with the asymmetry ratio of 1.6 caused the decrease in grain size by 44.3% and 65.7% under room-temperature and cryogenic conditions, respectively. Despite the more severe grain refinement, samples rolled under cryogenic conditions are characterized by a lower increase in microhardness than samples rolled at room temperature.

- The application of rolling with the asymmetry ratio contained within the range of 1.2–16 only slightly affected the microhardness values of the samples rolled at room temperature and under cryogenic conditions.

- The strains induced in the base sample were comparable with the one detected for pure Al. The asymmetric rolling caused an induction of the highest strains in the studied samples. Moreover, the cryorolling process is characterized by the induction of significantly lower microstrains than those observed for samples rolled at room temperature.

- The cryorolling process resulted in the formation of the dislocation cell structure with dense dislocation walls of about 0.1–0.2 μm in size. A high accumulation of dislocations is reported in the surrounding of the spherical precipitates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Sabirov, I.; Murashkin, M.; Valiev, R. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development. Mat. Sci. Eng. A Struct. 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Langdon, T.G. Processing of Aluminium Alloys by Severe Plastic Deformation. Mater. Sci. Forum. 2006, 519–521, 45–54. [Google Scholar] [CrossRef]

- Farshidi, M.; Kazeminezhad, M.; Miyamoto, H. Severe plastic deformation of 6061 aluminum alloy tube with pre and post heat treatments. Mat. Sci. Eng. A Struct. 2013, 563, 60–67. [Google Scholar] [CrossRef]

- Shi, J.; Hou, L.; Jinrong, Z.; Zhuang, L.; Zhang, J. Cryogenic rolling-enhanced mechanical properties and microstructural evolution of 5052 Al-Mg alloy. Mat. Sci. Eng. A Struct. 2017, 701, 274–284. [Google Scholar] [CrossRef]

- Rangaraju, N.; Thiagarajan, R.; Balla, V.; Kalvala, P.; Venugopal, P. Effect of cryo-rolling and annealing on microstructure and properties of commercially pure aluminium. Mat. Sci. Eng. A Struct. 2005, 398, 246–251. [Google Scholar] [CrossRef]

- Bruder, E. Mechanical Properties of ARMCO® Iron after Large and Severe Plastic Deformation—Application Potential for Precursors to Ultrafine Grained Microstructures. Metals 2018, 8, 191. [Google Scholar] [CrossRef] [Green Version]

- Azimi, A.; Owolabi, G.; Fallahdoost, H.; Kumar, N.; Whitworth, H. Microstructure and Quasi-Static Mechanical Behavior of Cryoforged AA2519 Alloy. Mater. Sci. Appl. 2019, 10, 137–149. [Google Scholar] [CrossRef] [Green Version]

- Azimi, A.; Owolabi, G.; Fallahdoost, H.; Kumar, N.; Warner, G. High Strain Rate Behavior of Ultrafine Grained AA2519 Processed via Multi Axial Cryogenic Forging. Metals 2019, 9, 115. [Google Scholar] [CrossRef] [Green Version]

- Kashyap, K.T.; Chandrashekar, T. Effects and mechanisms of grain refinement in aluminium alloys. Bull. Mater. Sci. 2001, 24, 345–353. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.C.; Xia, Y.; Jiang, Y.; Zhou, H.; Li, L. Precipitation hardening of 2024-T3 aluminum alloy during creep aging. Mat. Sci. Eng. A Struct. 2013, 565, 420–429. [Google Scholar] [CrossRef]

- Ryen, Ø.; Holmedal, B.; Marthinsen, K.; Furu, T. Precipitation, strength and work hardening of age hardened aluminium alloys. IOP Conf. Ser. Mater. Sci. Eng. 2015, 89, 012013. [Google Scholar] [CrossRef]

- Min, J.; Xie, F.; Liu, Y.; Hou, Z.; Lu, J.; Lin, J. Experimental study on cold forming process of 7075 aluminum alloy in W temper. CIRP J. Manuf. Sci. Technol. 2022, 37, 11–18. [Google Scholar] [CrossRef]

- Pitchandi, M.; Prabhu, A.; Manwatkar, S.; Rao, S.; Svs, N.; Sivakumar, D.; Pant, B.; Mohan, M. Tensile and Fracture Properties of Aluminium Alloy AA2219-T87 Friction Stir Weld Joints for Aerospace Applications. Metall. Mater. Trans. A 2021, 52, 3759–3776. [Google Scholar] [CrossRef]

- Carreno, F.; Ruano, O. Superplasticity of Aerospace 7075 (Al-Zn-Mg-Cu) Aluminium Alloy Obtained by Severe Plastic Deformation. Defect Diffus. Forum 2018, 385, 39–44. [Google Scholar] [CrossRef]

- Venugopal, A.; Mohammad, R.; Koslan, M.F.S.; Shafie, A.; Ali, A.; Eugene, O. Structure Life Extension towards the Structural Integrity of Sukhoi Su-30MKM. Materials 2021, 14, 5562. [Google Scholar] [CrossRef]

- Montier, P.; Moreau, P.A.; Sauvestre, J.-C.; Simon, W.; Bisping, B.; Wallow, P.; Gersbach, K. Process for Manufacturing a Sabot Arrangement for a Sub-Caliber Fin-Stabilized Projectile for a Large Caliber Weapon. U.S. Patent US4747191A, 31 May 1988. [Google Scholar]

- US ARMY CCDC GVSC (FORMERLY TARDEC) WARREN United States. Trilateral Design and Test Code for Military Bridging and Gap-Crossing Equipment. Technical Report. Patent AD1070838, 19 March 2019. [Google Scholar]

- Suri, A. Aluminium Alloy Technologies For Advanced Defence Systems. DRDO Technol. 2018, 26, 1–20. [Google Scholar]

- Özer, G.; Karaaslan, A. Properties of AA7075 aluminum alloy in aging and retrogression and reaging process. Trans. Nonferrous Met. Soc. China 2017, 27, 2357–2362. [Google Scholar] [CrossRef]

- Jia, X.D.; Wang, Y.N.; Zhou, Y.; Cao, M.Y. The Study on Forming Property at High Temperature and Processing Map of 2219 Aluminum Alloy. Metals 2021, 11, 77. [Google Scholar] [CrossRef]

- Zuiko, I.; Gazizov, M.; Kaibyshev, R. Effect of Cold Plastic Deformation on Mechanical Properties of Aluminum Alloy 2519 After Ageing. Mater. Sci. Forum. 2014, 794–796, 888–893. [Google Scholar] [CrossRef]

- Katakam, S.; Bb, B.; Muthupandi, V.; Muthusamy, A. Achieving Superior Strength and Ductility Combination Through Cryorolling in 2219 Aluminum Alloy. J. Mater. Eng. Perform. 2020, 29, 6809–6817. [Google Scholar] [CrossRef]

- Das, P.; Rengaswamy, J.; Singh, I.V. Tensile and Impact-Toughness Behaviour of Cryorolled Al 7075 Alloy. Mater. Des. 2011, 32, 1298–1305. [Google Scholar] [CrossRef]

- Rengaswamy, J.; Brokmeier, H.; Schwebke, B.; Panigrahi, S. Microstructure and texture evolution in cryorolled Al 7075 alloy. J. Alloys Compd. 2010, 496, 183–188. [Google Scholar] [CrossRef]

- Fisher, J.J., Jr.; Kramer, L.S.; Pickens, J.R. Aluminum alloy 2519 in military vehicles. Adv. Mater. Res. Switz. 2002, 160, 43–46. [Google Scholar]

- Kosturek, R.; Śnieżek, L.; Torzewski, J.; Wachowski, M. Low Cycle Fatigue Properties of Sc-Modified AA2519-T62 Extrusion. Materials 2020, 13, 220. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Siva Prasad, G.; Sharmila, T.; SrinivasaRao, K.; Madhusudhan Reddy, G. Effect of welding process on microstructure, mechanical properties and corrosion behavior of AA2519 Al-alloy. AIP Conf. Proc. 2021, 2395, 030003. [Google Scholar] [CrossRef]

- Płonka, B.; Rajda, M.; Zamkotowicz, Z.; Zelechowski, J.; Remsak, K.; Korczak, P.; Szymanski, W.; Sniezek, L. Studies of the AA2519 alloy hot rolling process and cladding with EN AW-1050A alloy. Arch. Met. Mater. 2016, 61, 381–388. [Google Scholar] [CrossRef]

- Zuiko, I.; Mironov, S.; Kaibyshev, R. Microstructural evolution and strengthening mechanisms operating during cryogenic rolling of solutionized Al-Cu-Mg alloy. Mat. Sci. Eng. A Struct. 2018, 745, 82–89. [Google Scholar] [CrossRef]

- Kawalek, A.; Dyja, H.; Mroz, S.; Knapinski, M. Effect of plate asymmetric rolling parameters on the change of the total unit pressure of roll. Metalurgija 2011, 50, 163–166. [Google Scholar]

- Gronostajski, Z.; Pater, Z.; Madej, L.; Gontarz, A.; Lisiecki, L.; Łukaszek-Sołek, A.; Łuksza, J.; Mróz, S.; Muskalski, Z.; Muzykiewicz, W.; et al. Recent development trends in metal forming. Arch. Civ. Mech. Eng. 2019, 19, 898–941. [Google Scholar] [CrossRef]

- Liu, J.; Kawalla, R. Influence of asymmetric hot rolling on microstructure and rolling force with austenitic steel. Trans. Nonferrous Met. Soc. China 2012, 22, s504–s511. [Google Scholar] [CrossRef]

- Wierzba, A.; Mróz, S.; Szota, P.; Stefanik, A.; Mola, R. The influence of the asymmetric ARB process on the properties of Al-Mg-Al multi-layer sheets. Arch. Metall. Mater. 2015, 60, 2821–2825. [Google Scholar] [CrossRef]

- Mróz, S.; Wierzba, A.; Stefanik, A.; Szota, P. Effect of Asymmetric Accumulative Roll-Bonding process on the Microstructure and Strength Evolution of the AA1050/AZ31/AA1050 Multilayered Composite Materials. Materials 2020, 13, 5401. [Google Scholar] [CrossRef] [PubMed]

- Amiri, M.; Fereshteh-Saniee, F. Influence of roll speed difference on microstructure, texture and mechanical properties of 7075 aluminum plates produced via combined continuous casting and rolling process. Trans. Nonferrous Met. Soc. China 2021, 31, 901–912. [Google Scholar] [CrossRef]

- Amegadzie, M.; Bishop, P. Effect of asymmetric rolling on the microstructure and mechanical properties of wrought 6061 aluminum. Mater. Today Commun. 2020, 25, 101283. [Google Scholar] [CrossRef]

- Wronski, M.; Wierzbanowski, K.; Bacroix, B.; Lipinski, P. Asymmetric rolling textures of aluminium studied with crystalline model implemented into FEM. IOP Conf. Ser. Mater. Sci. Eng. 2020, 82, 012012. [Google Scholar] [CrossRef] [Green Version]

- Pustovoytov, D.; Pesin, A.; Tandon, P. Asymmetric (Hot, Warm, Cold, Cryo) Rolling of Light Alloys: A Review. Metals 2021, 11, 956. [Google Scholar] [CrossRef]

- Ko, Y.G.; Masood Chaudry, U.; Hamad, K. Microstructure and mechanical properties of AA6061 alloy deformed by differential speed rolling. Mater. Lett. 2020, 259, 126870. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Grant Norton, M. X-ray Diffraction: A Practical Approach; Springer: New York, NY, USA, 1998. [Google Scholar]

- Vincze, G.; Simões, F.J.P.; Butuc, M.C. Asymmetrical Rolling of Aluminum Alloys and Steels: A Review. Metals 2020, 10, 1126. [Google Scholar] [CrossRef]

- Stradomski, G.; Rydz, D.; Garstka, T.; Pałęga, M.; Dyl, T.; Szarek, A.; Szarek, J.Ł.; Dembiczak, T. Influence of Asymmetric Rolling Process on the Microstructure Properties of Bimetallic Sheet Metals. Materials 2022, 15, 2013. [Google Scholar] [CrossRef]

- Yi, G.; Liang, Y.; Wang, C.; Xu, J. Evolution of Residual Stress Based on Curvature Coupling in Multi-Roll Levelling. Appl. Sci. 2019, 9, 4975. [Google Scholar] [CrossRef] [Green Version]

- Kaibyshev, R.; Sitdikov, O.; Mazurina, I.; Lesuer, D.R. Deformation behavior of a 2219 Al alloy. Mat. Sci. Eng. A Struct. 2002, 334, 104–113. [Google Scholar] [CrossRef]

- Osten, J.; Lux, C.; Milkereit, B.; Reich, M.; Kessler, O. Stress Induced Precipitation during Quenching of Aluminium Alloys. Mater. Sci. Forum 2016, 877, 159–165. [Google Scholar] [CrossRef]

- Wang, F.; Hou, B.; Wang, Y.; Liu, H. Diffusion thermodynamic behavior of milling Ti-6A1-4V alloy in liquid nitrogen cryogenic cooling. Int. J. Adv. Manuf. Technol. 2018, 95, 2783–2793. [Google Scholar] [CrossRef]

- Delgado-López, M.; Esmeralda, A.; Haro Rodriguez, S.; González, J.; Talamantes-Silva, J.; Perez-Gonzalez, F.; Garza-Montes-de-Oca, N.; Colás, R. Changes in Lattice parameter in Aluminium cast Alloys due to aging. Ing. Mecánica Tecnol. Desarro. 2019, 6, 133–139. [Google Scholar]

- Zhang, C.; Huang, G.; Cao, Y.; Li, Q.; Zhu, Y.; Huang, X.; Liu, Q. Investigation on microstructure and localized corrosion behavior in the stir zone of dissimilar friction-stir-welded AA2024/7075 joint. J. Mater. Sci. 2020, 55, 15005–15032. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, Y.; Ma, E. Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation. Acta Mater. 2007, 55, 5822–5832. [Google Scholar] [CrossRef]

- Dymek, S.; Dollar, M. TEM investigation of age-hardenable Al 2519 alloy subjected to stress corrosion cracking tests. Mater. Chem. Phys. 2003, 81, 286–288. [Google Scholar] [CrossRef]

- Sandström, R. Formation of Cells and Subgrains and Its Influence on Properties. Metals 2022, 12, 497. [Google Scholar] [CrossRef]

- Liang, X.; Li, H.; Huang, L.; Hong, T.; Ma, B.; Liu, Y. Microstructural evolution of 2519-T87 aluminum alloy obliquely impacted by projectile with velocity of 816 m/s. Trans. Nonferrous Met. Soc. China 2012, 22, 1270–1279. [Google Scholar] [CrossRef]

- El-Madhoun, Y.; Mohamed, A.; Bassim, M.N. Cyclic stress–strain response and dislocation structures in polycrystalline aluminum. Mat. Sci. Eng. A Struct. 2003, 359, 220–227. [Google Scholar] [CrossRef]

- Oriwol, D.; Trempa, M.; Sylla, L.; Leipner, H.S. Investigation of dislocation cluster evolution during directional solidification of multicrystalline silicon. J. Cryst. Growth 2017, 463, 1–9. [Google Scholar] [CrossRef]

| Fe | Si | Cu | Zn | Ti | Mn | Mg | Ni | Zr | Sc | V | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.11 | 0.08 | 6.32 | 0.05 | 0.08 | 0.17 | 0.33 | 0.02 | 0.19 | 0.16 | 0.10 | Base |

| Variant of Rolling/Asymmetry Ratio av | 20 °C | −196 °C |

|---|---|---|

| I/1.0 (symmetry rolling) | N1.0 | C1.0 |

| II/1.2 | N1.2 | C1.2 |

| III/1.4 | N1.4 | C1.4 |

| IV/1.6 | N1.6 | C1.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosturek, R.; Mróz, S.; Stefanik, A.; Szota, P.; Gębara, P.; Merda, A.; Wachowski, M.; Gloc, M. Study on Symmetry and Asymmetry Rolling of AA2519-T62 Alloy at Room-Temperature and Cryogenic Conditions. Materials 2022, 15, 7712. https://doi.org/10.3390/ma15217712

Kosturek R, Mróz S, Stefanik A, Szota P, Gębara P, Merda A, Wachowski M, Gloc M. Study on Symmetry and Asymmetry Rolling of AA2519-T62 Alloy at Room-Temperature and Cryogenic Conditions. Materials. 2022; 15(21):7712. https://doi.org/10.3390/ma15217712

Chicago/Turabian StyleKosturek, Robert, Sebastian Mróz, Andrzej Stefanik, Piotr Szota, Piotr Gębara, Agata Merda, Marcin Wachowski, and Michał Gloc. 2022. "Study on Symmetry and Asymmetry Rolling of AA2519-T62 Alloy at Room-Temperature and Cryogenic Conditions" Materials 15, no. 21: 7712. https://doi.org/10.3390/ma15217712