Effect of Green Food Processing Technology on the Enzyme Activity in Spelt Flour

Abstract

:1. Introduction

| Inactivated Enzyme | Process Conditions | Residual Activity [%] | Processing Media | Reference |

|---|---|---|---|---|

| Alkaline phosphatase (ALP) | 70 °C, 8 MPa, 30 min | 6 | Milk | [15] |

| α-amylase | 35 °C, 30 MPa, 24 h | 40 | α-amylase from A. oryzae | [16] |

| Cellulase | 41 °C, 12 MPa, 150 min | 48 | Cellulase enzyme from Trichoderma longibrachiatum | [17] |

| Lipase Lipozyme 435 | 60 °C, 20 MPa, exposure time (6 h) and depressurization steps (1–3) | 30 | Lipase from Candida antarctica (Lipozyme 435, food grade) immobilized on a macroporous anionic resin | [18] |

| Lipoxygenase (LOX) Peroxidase (POD) | 50 °C, 10.3 MPa, 15 min | 1 | Lipoxygenase from soybean | [19] |

| 55 °C, 62.1 MPa, 15 min | 10 | Peroxidase from horseradish | ||

| Polyphenol oxidase (PPO) | 55 °C, 25 MPa, 20 min | 0 | Apple juice | [20] |

| Polyphenol oxidase (PPO) Peroxidase (POD) Pectin esterase (PE) Polygalacturonase (PG) | 39 °C, 10 MPa, 30 min | 90 | Beetroot juice | [21] |

| 31 °C, 60 MPa, 30 min | 94 | |||

| 39 °C, 10 MPa, 30 min | 92 | |||

| 39 °C, 10 MPa, 30 min | 93 | |||

| Polyphenol oxidase (PPO) | 55 °C, 12 MPa, 15 min | 0 | Apples in syrup | [22] |

| Polyphenol oxidase (PPO) | 55 °C, 30 MPa, 60 min | 40 | Cloudy apple juice | [23] |

| Polyphenol oxidase (PPO) | 37 °C, 25MPa, 10 min | 10 | Pacific white shrimp | [24] |

| Polyphenol oxidase (PPO) | 40 °C, 10 MPa, 20 min | 3 | Apple juice | [20] |

| Polyphenol oxidase (PPO) Horseradish peroxidase (POD) | 50 °C, 65 MPa, 30 min | 12 1 | Mushroom polyphenol oxidase from Agaricus bisporus; Horseradish peroxidase from Amoracia rusticana roots | [25] |

| Polyphenol oxidase (PPO) Peroxidase (POD) | 35 °C, 60 MPa, 30 min | 0 65 | Strawberry juice | [26] |

| Polyphenol oxidase (PPO) Peroxidase (POD) | 45 °C, 60 MPa, 30 min | 20 47 | Cloudy apple juice | [27] |

| Polyphenol oxidase (PPO) Peroxidase (POD) | 50 °C, 25 MPa, 6 h | 34 0 | Mate tea leaves | [28] |

2. Materials and Methods

2.1. Materials

2.2. Methods

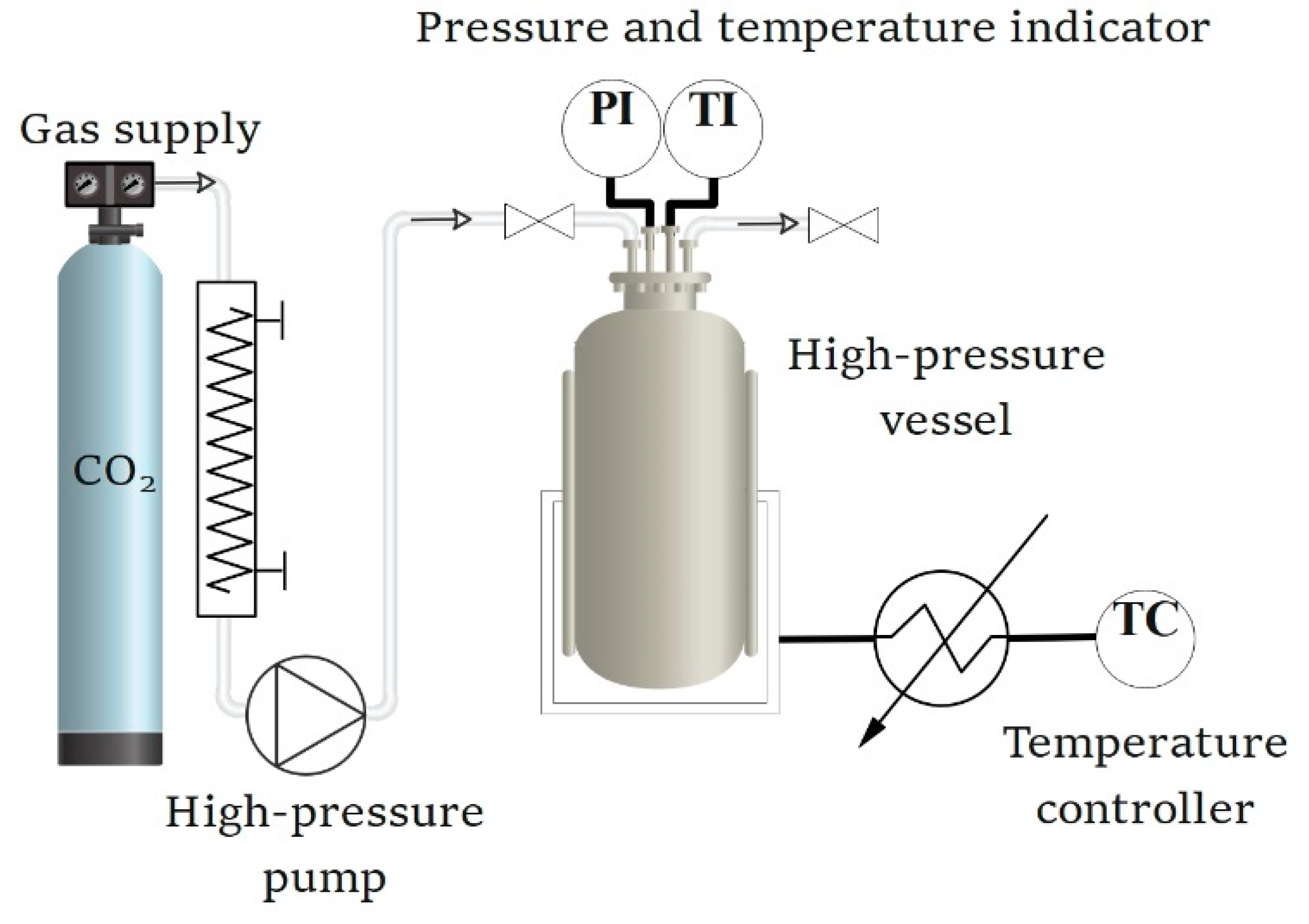

2.2.1. Equipment and Processing Protocols

2.2.2. Protein Extract Preparation

2.2.3. Determination of Protein Concentration

2.2.4. Measurement of Specific Enzyme’s Activity

α-Amylase Activity Assay

Lipase Activity Assay

Peroxidase Activity Assay

Polyphenol Oxidase Activity Assay

Protease Activity Assay

Statistical Analysis

2.2.5. Flour Characterization Methods

2.2.6. Characterization of Baked Bread

3. Results and Discussion

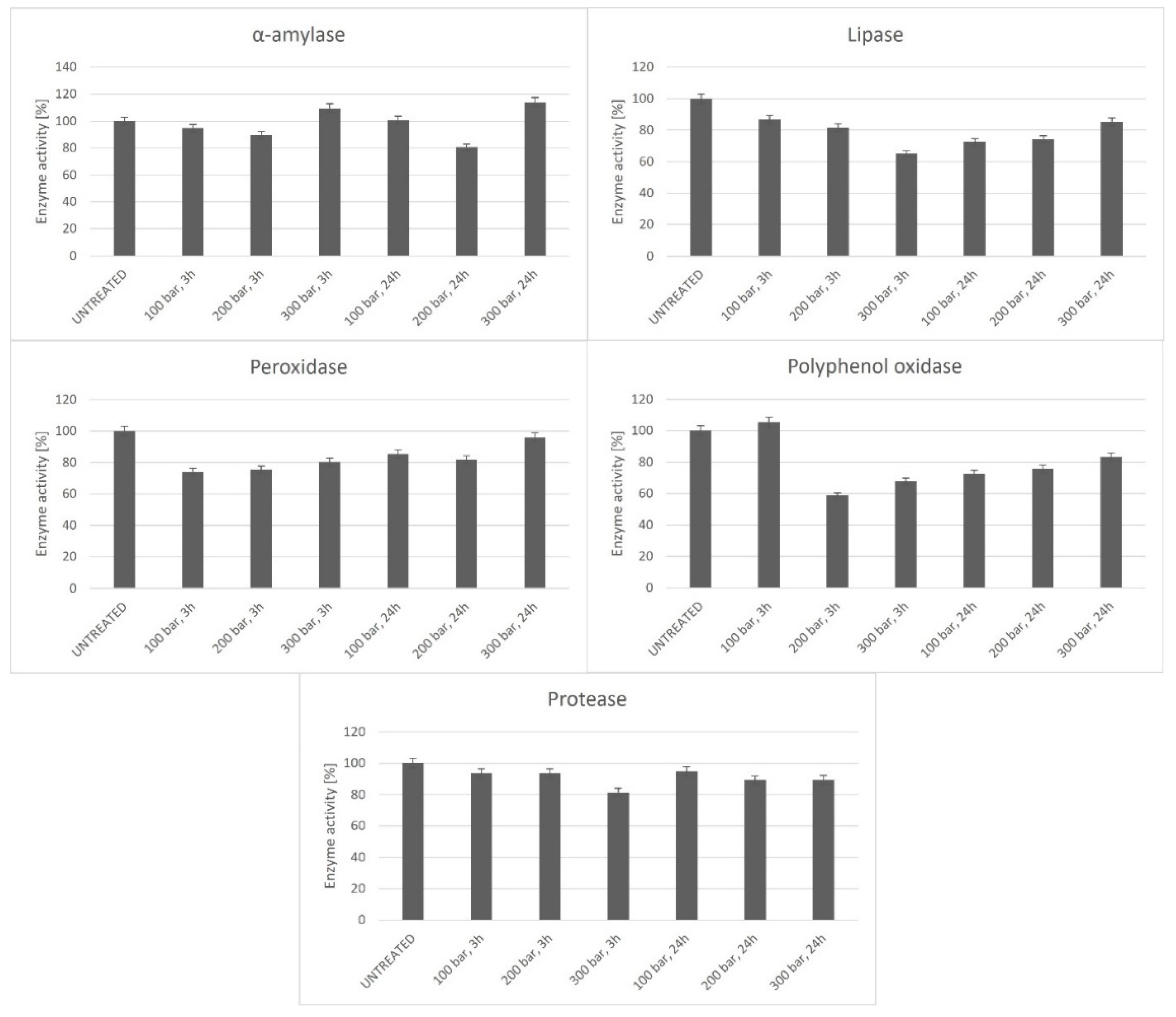

3.1. Influence of scCO2 Process upon Enzyme Activity Loss

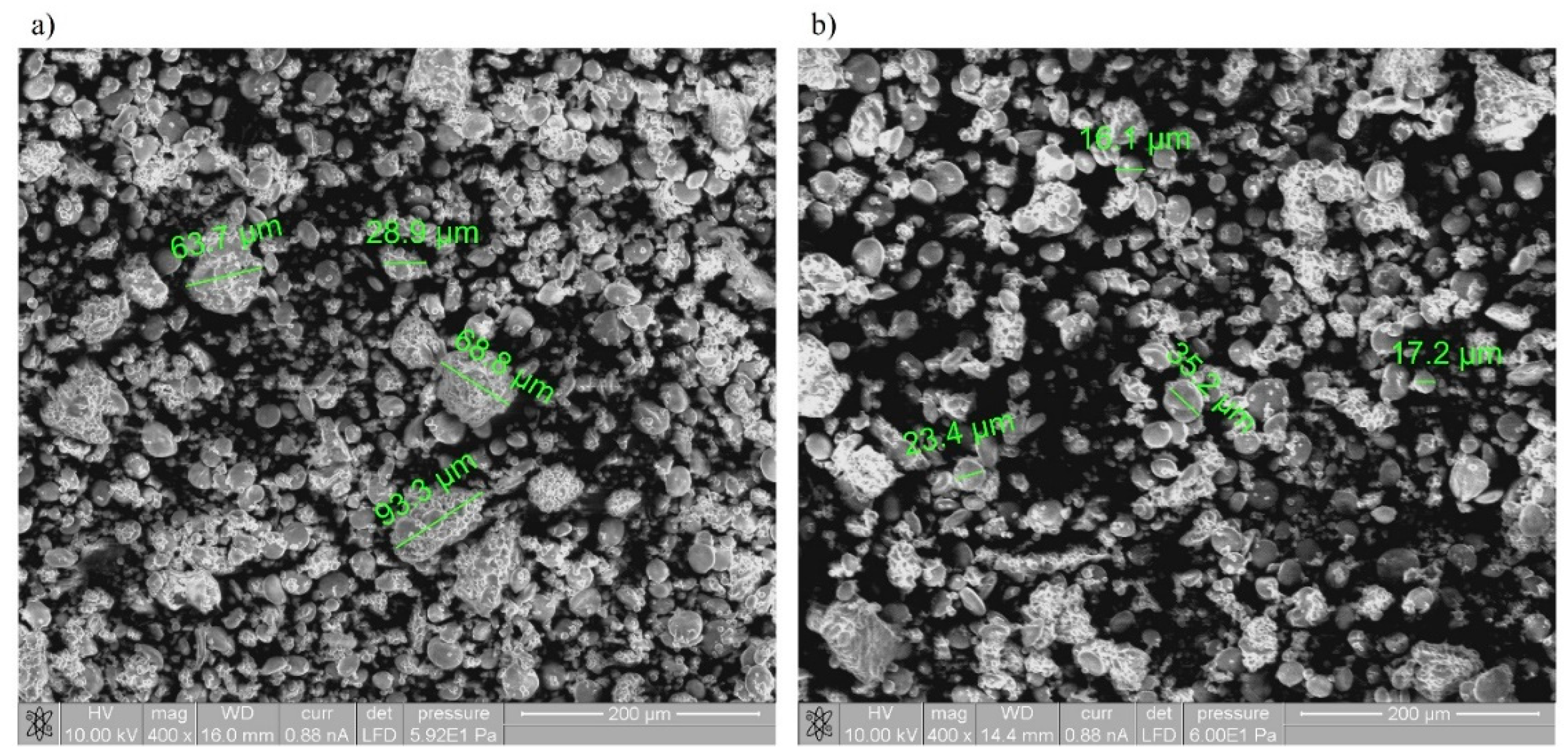

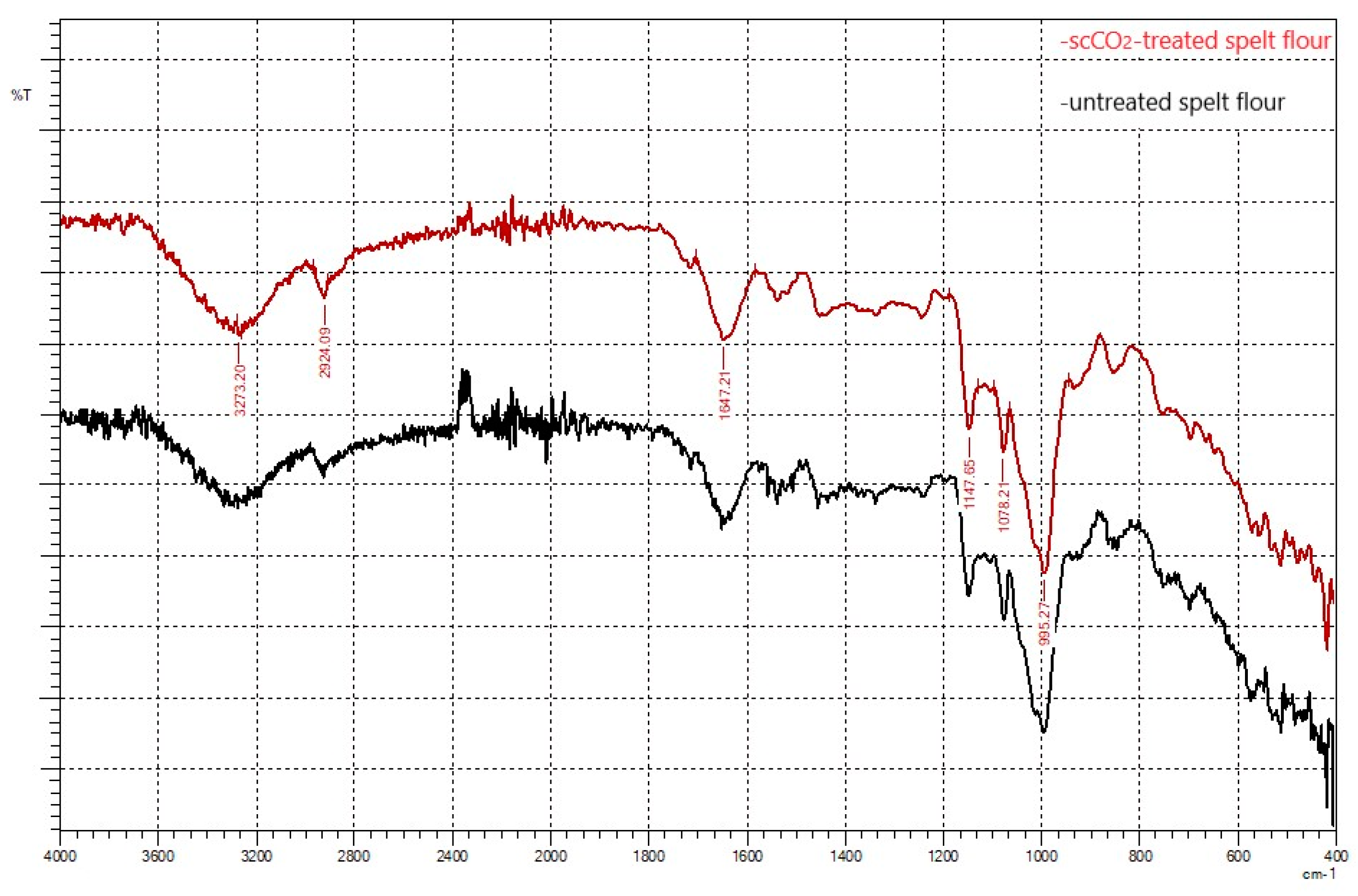

3.2. SEM and FTIR Characteristics of Spelt Flour

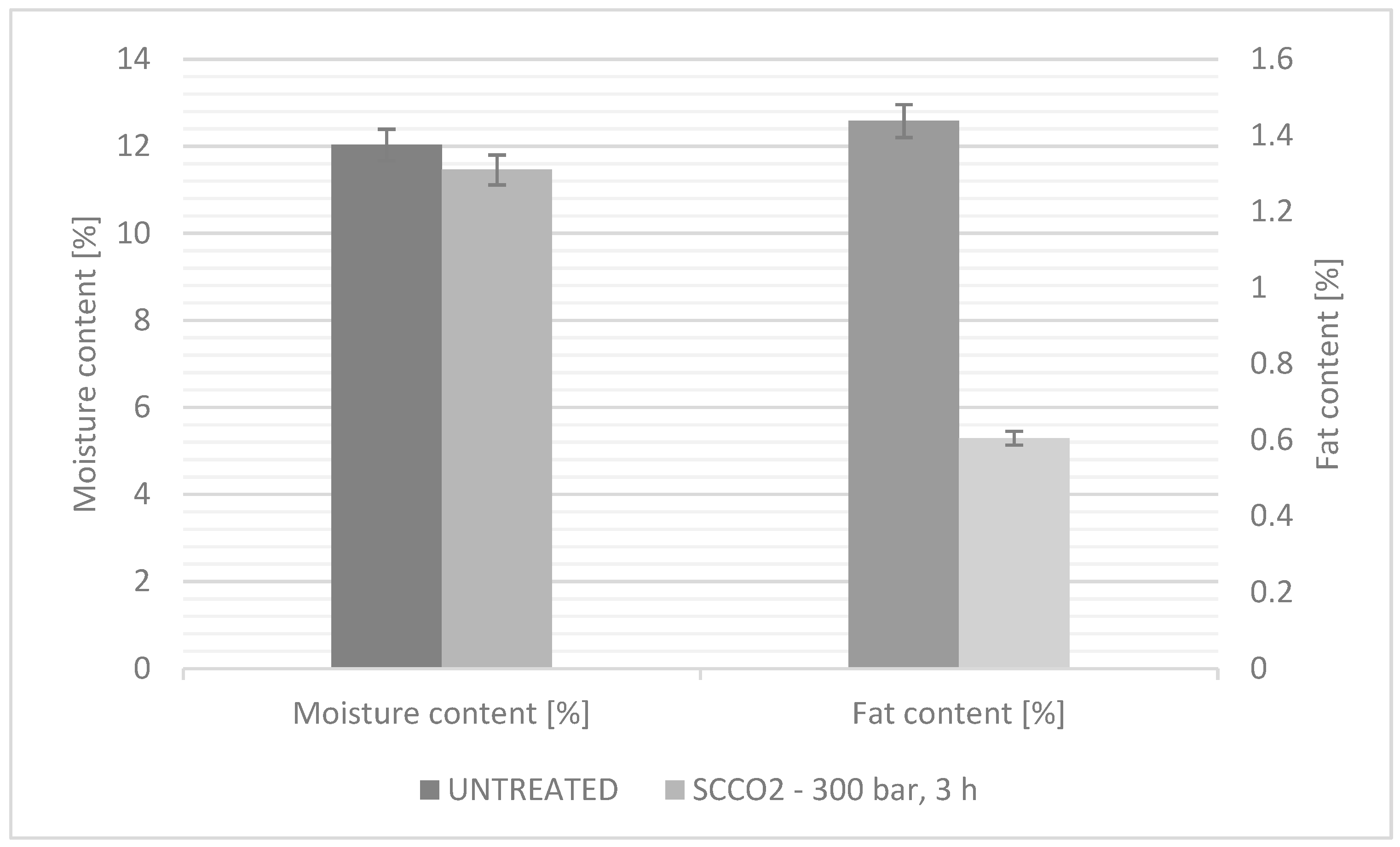

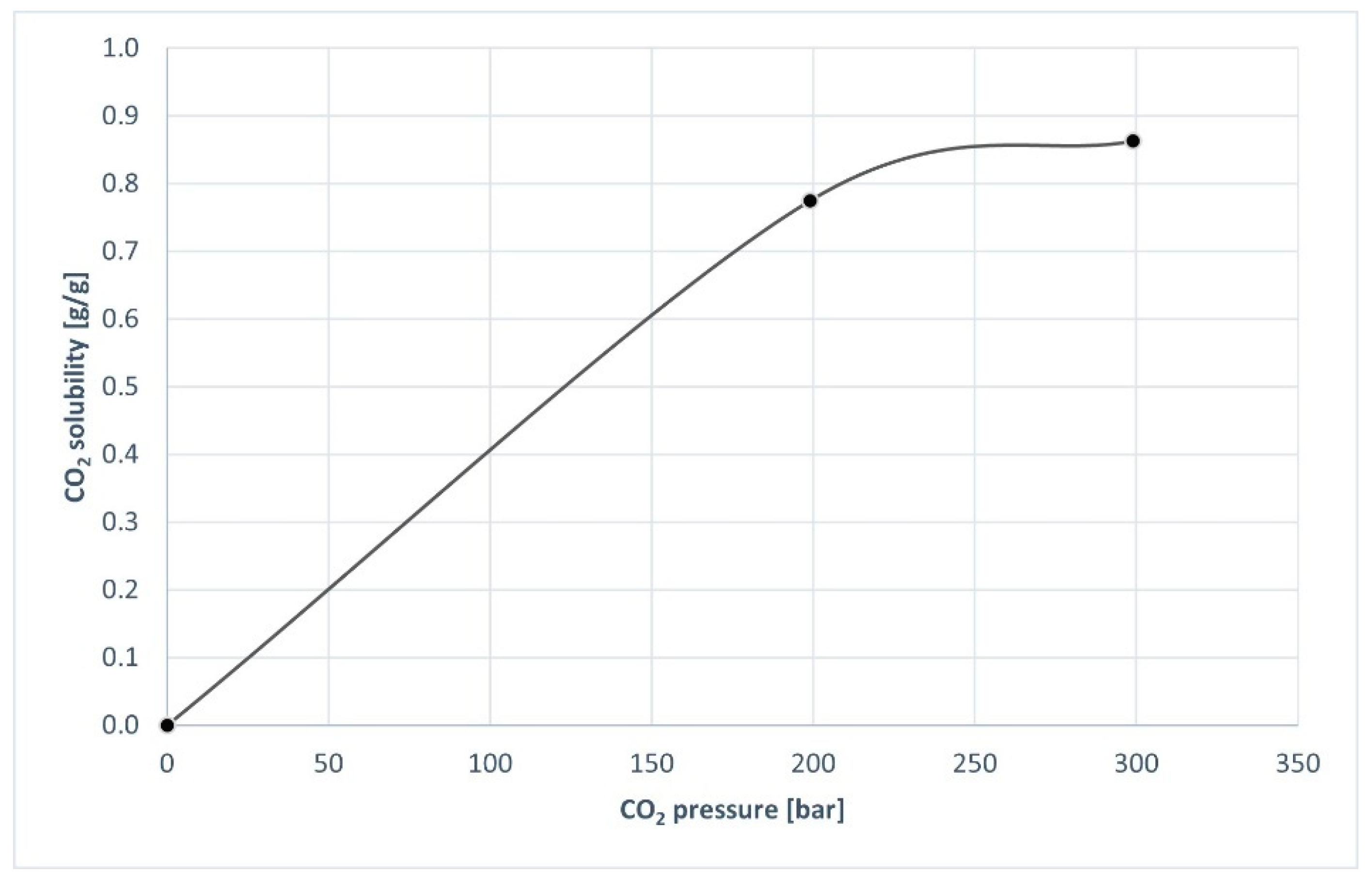

3.3. Chemical Composition Measurement of Spelt Flour

3.4. Breadmaking

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Corato, U. Improving the Shelf-Life and Quality of Fresh and Minimally-Processed Fruits and Vegetables for a Modern Food Industry: A Comprehensive Critical Review from the Traditional Technologies into the Most Promising Advancements. Crit. Rev. Food Sci. Nutr. 2020, 60, 940–975. [Google Scholar] [CrossRef] [PubMed]

- Roobab, U.; Shabbir, M.A.; Khan, A.W.; Arshad, R.N.; Bekhit, A.E.-D.; Zeng, X.-A.; Inam-Ur-Raheem, M.; Aadil, R.M. High-Pressure Treatments for Better Quality Clean-Label Juices and Beverages: Overview and Advances. LWT 2021, 149, 111828. [Google Scholar] [CrossRef]

- Škegro, M.; Putnik, P.; Bursać Kovačević, D.; Kovač, A.P.; Salkić, L.; Čanak, I.; Frece, J.; Zavadlav, S.; Ježek, D. Chemometric Comparison of High-Pressure Processing and Thermal Pasteurization: The Nutritive, Sensory, and Microbial Quality of Smoothies. Foods 2021, 10, 1167. [Google Scholar] [CrossRef] [PubMed]

- Tomić, J.; Torbica, A.; Belović, M.; Popović, L.; Knežević, N. Biochemical Quality Indicators and Enzymatic Activity of Wheat Flour from the Aspect of Climatic Conditions. Available online: https://www.hindawi.com/journals/jfq/2018/5187841/ (accessed on 14 November 2019).

- Rani, K.U.; Prasada Rao, U.J.S.; Leelavathi, K.; Haridas Rao, P. Distribution of Enzymes in Wheat Flour Mill Streams. J. Cereal Sci. 2001, 34, 233–242. [Google Scholar] [CrossRef]

- Poudel, R. Enzymatic Activities and Compostional Properties of Whole Wheat Flour. Ph.D. Thesis, University of Nebraska-Lincoln, Lincoln, NE, USA, 2018; pp. 1–135. [Google Scholar]

- Austin, D.L. Chapter 10—Enzymes: Extending Shelf Life and Eating Quality of Tortillas. In Tortillas; Rooney, L.W., Serna-Saldivar, S.O., Eds.; AACC International Press: St. Paul, MN, USA, 2015; pp. 201–214. ISBN 978-1-891127-88-5. [Google Scholar]

- Casas, L.; Mantell, C.; Rodríguez, M.; Torres, A.; Macías, F.A.; Martínez de la Ossa, E. Extraction of Natural Compounds with Biological Activity from Sunflower Leaves Using Supercritical Carbon Dioxide. Chem. Eng. J. 2009, 152, 301–306. [Google Scholar] [CrossRef]

- Silva, E.K.; Meireles, M.A.A.; Saldaña, M.D.A. Supercritical Carbon Dioxide Technology: A Promising Technique for the Non-Thermal Processing of Freshly Fruit and Vegetable Juices. Trends Food Sci. Technol. 2020, 97, 381–390. [Google Scholar] [CrossRef]

- Yu, T.; Niu, L.; Iwahashi, H. High-Pressure Carbon Dioxide Used for Pasteurization in Food Industry. Food Eng. Rev. 2020, 12, 364–380. [Google Scholar] [CrossRef]

- Knez, Ž.; Leitgeb, M.; Primožič, M. Biochemical Reactions in Supercritical Fluids. In Functional Food Ingredients and Nutraceuticals; CRC Press: Boca Raton, FL, USA, 2015; pp. 127–158. ISBN 978-1-4822-4064-1. [Google Scholar]

- Clodoveo, M.L.; Muraglia, M.; Fino, V.; Curci, F.; Fracchiolla, G.; Corbo, F.F.R. Overview on Innovative Packaging Methods Aimed to Increase the Shelf-Life of Cook-Chill Foods. Foods 2021, 10, 2086. [Google Scholar] [CrossRef]

- Wang, W.; Rao, L.; Wu, X.; Wang, Y.; Zhao, L.; Liao, X. Supercritical Carbon Dioxide Applications in Food Processing. Food Eng. Rev. 2021, 13, 570–591. [Google Scholar] [CrossRef]

- Jiang, Y.; Duan, X.; Qu, H.; Zheng, S. Browning: Enzymatic Browning. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 508–514. ISBN 978-0-12-384953-3. [Google Scholar]

- Ceni, G.; Fernandes Silva, M.; Valério, C., Jr.; Cansian, R.L.; Oliveira, J.V.; Dalla Rosa, C.; Mazutti, M.A. Continuous Inactivation of Alkaline Phosphatase and Escherichia Coli in Milk Using Compressed Carbon Dioxide as Inactivating Agent. J. CO2 Util. 2016, 13, 24–28. [Google Scholar] [CrossRef]

- Leitgeb, M.; Čolnik, M.; Primožič, M.; Zalar, P.; Cimerman, N.G.; Knez, Ž. Activity of Cellulase and α-Amylase from Hortaea Werneckii after Cell Treatment with Supercritical Carbon Dioxide. J. Supercrit. Fluids 2013, 78, 143–148. [Google Scholar] [CrossRef]

- Senyay-Oncel, D.; Yesil-Celiktas, O. Characterization, Immobilization, and Activity Enhancement of Cellulase Treated with Supercritical CO2. Cellulose 2015, 22, 3619–3631. [Google Scholar] [CrossRef]

- dos Santos, P.; Rezende, C.A.; Martínez, J. Activity of Immobilized Lipase from Candida Antarctica (Lipozyme 435) and Its Performance on the Esterification of Oleic Acid in Supercritical Carbon Dioxide. J. Supercrit. Fluids 2016, 107, 170–178. [Google Scholar] [CrossRef]

- Tedjo, W.; Eshtiaghi, M.N.; Knorr, D. Impact of Supercritical Carbon Dioxide and High Pressure on Lipoxygenase and Peroxidase Activity. J. Food Sci. 2000, 65, 1284–1287. [Google Scholar] [CrossRef]

- Murtaza, A.; Iqbal, A.; Linhu, Z.; Liu, Y.; Xu, X.; Pan, S.; Hu, W. Effect of High-Pressure Carbon Dioxide on the Aggregation and Conformational Changes of Polyphenol Oxidase from Apple (Malus domestica) Juice. Innov. Food Sci. Emerg. Technol. 2019, 54, 43–50. [Google Scholar] [CrossRef]

- Marszałek, K.; Krzyżanowska, J.; Woźniak, Ł.; Skąpska, S. Kinetic Modelling of Polyphenol Oxidase, Peroxidase, Pectin Esterase, Polygalacturonase, Degradation of the Main Pigments and Polyphenols in Beetroot Juice during High Pressure Carbon Dioxide Treatment. LWT—Food Sci. Technol. 2017, 85, 412–417. [Google Scholar] [CrossRef]

- Ferrentino, G.; Spilimbergo, S. Non-Thermal Pasteurization of Apples in Syrup with Dense Phase Carbon Dioxide. J. Food Eng. 2017, 207, 18–23. [Google Scholar] [CrossRef]

- Gui, F.; Wu, J.; Chen, F.; Liao, X.; Hu, X.; Zhang, Z.; Wang, Z. Inactivation of Polyphenol Oxidases in Cloudy Apple Juice Exposed to Supercritical Carbon Dioxide. Food Chem. 2007, 100, 1678–1685. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, S.; Ji, H.; Zhang, C.; Deng, C.; Cao, W.; Mao, W.; Gao, J. Inactivation of Polyphenol Oxidase from Pacific White Shrimp by Dense Phase Carbon Dioxide. Innov. Food Sci. Emerg. Technol. 2011, 12, 635–641. [Google Scholar] [CrossRef]

- Marszałek, K.; Doesburg, P.; Starzonek, S.; Szczepańska, J.; Woźniak, Ł.; Lorenzo, J.M.; Skąpska, S.; Rzoska, S.; Barba, F.J. Comparative Effect of Supercritical Carbon Dioxide and High Pressure Processing on Structural Changes and Activity Loss of Oxidoreductive Enzymes. J. CO2 Util. 2019, 29, 46–56. [Google Scholar] [CrossRef]

- Marszałek, K.; Skąpska, S.; Woźniak, Ł.; Sokołowska, B. Application of Supercritical Carbon Dioxide for the Preservation of Strawberry Juice: Microbial and Physicochemical Quality, Enzymatic Activity and the Degradation Kinetics of Anthocyanins during Storage. Innov. Food Sci. Emerg. Technol. 2015, 32, 101–109. [Google Scholar] [CrossRef]

- Marszałek, K.; Woźniak, Ł.; Barba, F.; Skapska, S.; Lorenzo Rodriguez, J.M.; Zambon, A.; Spilimbergo, S. Enzymatic, Physicochemical, Nutritional and Phytochemical Profile Changes of Apple (Golden delicious L.) Juice under Supercritical Carbon Dioxide and Long-Term Cold Storage. Food Chem. 2018, 268, 279–286. [Google Scholar] [CrossRef] [PubMed]

- Primo, M.S.; Ceni, G.C.; Marcon, N.S.; Antunes, O.A.C.; Oliveira, D.; Oliveira, J.V.; Dariva, C. Effects of Compressed Carbon Dioxide Treatment on the Specificity of Oxidase Enzymatic Complexes from Mate Tea Leaves. J. Supercrit. Fluids 2007, 43, 283–290. [Google Scholar] [CrossRef]

- Hossain, M.S.; Nik Norulaini, N.A.; Banana, A.A.; Mohd Zulkhairi, A.R.; Ahmad Naim, A.Y.; Mohd Omar, A.K. Modeling the Supercritical Carbon Dioxide Inactivation of Staphylococcus Aureus, Escherichia Coli and Bacillus Subtilis in Human Body Fluids Clinical Waste. Chem. Eng. J. 2016, 296, 173–181. [Google Scholar] [CrossRef]

- Piechowiak, T.; Józefczyk, R.; Balawejder, M. Impact of Ozonation Process of Wheat Flour on the Activity of Selected Enzymes. J. Cereal Sci. 2018, 84, 30–37. [Google Scholar] [CrossRef]

- Bradford, M.M. A Rapid and Sensitive Method for the Quantitation of Microgram Quantities of Protein Utilizing the Principle of Protein-Dye Binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef] [PubMed]

- Hojnik Podrepšek, G.; Knez, Ž.; Leitgeb, M. Development of Chitosan Functionalized Magnetic Nanoparticles with Bioactive Compounds. Nanomaterials 2020, 10, 1913. [Google Scholar] [CrossRef]

- Hojnik Podrepšek, G.; Knez, Ž.; Leitgeb, M. The Influence of Supercritical Carbon Dioxide on Graham Flour Enzyme Polyphenol Oxidase Activity. Molecules 2020, 25, 5981. [Google Scholar] [CrossRef]

- Primožič, M.; Čolnik, M.; Knez, Ž.; Leitgeb, M. Advantages and Disadvantages of Using SC CO2 for Enzyme Release from Halophilic Fungi. J. Supercrit. Fluids 2019, 143, 286–293. [Google Scholar] [CrossRef]

- Hubbard, J.D.; Downing, J.M.; Ram, M.S.; Chung, O.K. Lipid Extraction from Wheat Flour Using Supercritical Fluid Extraction. Cereal Chem. 2004, 81, 693–698. [Google Scholar] [CrossRef]

- Kravanja, G.; Primožič, M.; Knez, Ž.; Leitgeb, M. Transglutaminase Release and Activity from Novel Poly(ε-Caprolactone)-Based Composites Prepared by Foaming with Supercritical CO2. J. Supercrit. Fluids 2020, 166, 105031. [Google Scholar] [CrossRef]

- Thirumdas, R.; Annapure, U.S. Chapter 7—Enzyme Inactivation in Model Systems and Food Matrixes by Cold Plasma. In Advances in Cold Plasma Applications for Food Safety and Preservation; Bermudez-Aguirre, D., Ed.; Academic Press: London, UK, 2020; pp. 229–252. ISBN 978-0-12-814921-8. [Google Scholar]

- Omar, A.K.M.; Tengku Norsalwani, T.L.; Asmah, M.S.; Badrulhisham, Z.Y.; Easa, A.M.; Omar, F.M.; Hossain, M.S.; Zuknik, M.H.; Nik Norulaini, N.A. Implementation of the Supercritical Carbon Dioxide Technology in Oil Palm Fresh Fruits Bunch Sterilization: A Review. J. CO2 Util. 2018, 25, 205–215. [Google Scholar] [CrossRef]

- Fleury, C.; Savoire, R.; Harscoat-Schiavo, C.; Hadj-Sassi, A.; Subra-Paternault, P. Optimization of Supercritical CO2 Process to Pasteurize Dietary Supplement: Influencing Factors and CO2 Transfer Approach. J. Supercrit. Fluids 2018, 141, 240–251. [Google Scholar] [CrossRef]

- Dijkstra, Z.J.; Merchant, R.; Keurentjes, J.T.F. Stability and Activity of Enzyme Aggregates of Calb in Supercritical CO2. J. Supercrit. Fluids 2007, 41, 102–108. [Google Scholar] [CrossRef]

- Chen, Y.; Eder, S.; Schubert, S.; Gorgerat, S.; Boschet, E.; Baltensperger, L.; Städeli, C.; Kuster, S.; Fischer, P.; Windhab, E. Influence of Amylase Addition on Bread Quality and Bread Staling. ACS Food Sci. Technol. 2021, 2021, 1143–1150. [Google Scholar] [CrossRef]

- Suzuki, T.; Mukasa, Y.; Morishita, T.; Woo, S.; Kim, S.-J.; Noda, T.; Takigawa, S.; Yamauchi, H. Possible Roles of Lipase, Lipoxygenase and Peroxidase in Buckwheat Flour and Noodles. Eur. J. Plant Sci. Biotechnol. 2012, 2012, 43–49. [Google Scholar]

- Jaynaqov, M.S.; Shavkat, Y. Activity of Peroxidase Enzyme in Grains of Some Varieties of Soybeans Grown in Uzbekistan. Am. J. Plant Sci. 2020, 11, 1270–1275. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, L.; Liu, Q.; Liu, W.; Hu, H. Rheological Behaviors and Physicochemical Changes of Doughs Reconstituted from Potato Starch with Different Sizes and Gluten. Food Res. Int. 2021, 145, 110397. [Google Scholar] [CrossRef]

- Kuhnen, S.; Ogliari, J.B.; Dias, P.F.; Boffo, E.F.; Correia, I.; Ferreira, A.G.; Delgadillo, I.; Maraschin, M. ATR-FTIR Spectroscopy and Chemometric Analysis Applied to Discrimination of Landrace Maize Flours Produced in Southern Brazil. Int. J. Food Sci. Technol. 2010, 45, 1673–1681. [Google Scholar] [CrossRef]

- Solaesa, Á.G.; Villanueva, M.; Beltrán, S.; Ronda, F. Characterization of Quinoa Defatted by Supercritical Carbon Dioxide. Starch Enzymatic Susceptibility and Structural, Pasting and Thermal Properties. Food Bioprocess Technol. 2019, 12, 1593–1602. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Xu, D.; Sang, S.; Jin, Y.; Xu, X.; Cui, B. Effect of Superheated Steam Treatment on the Structural and Digestible Properties of Wheat Flour. Food Hydrocoll. 2021, 112, 106362. [Google Scholar] [CrossRef]

- Lin, J.; Gu, Y.; Bian, K. Bulk and Surface Chemical Composition of Wheat Flour Particles of Different Sizes. J. Chem. 2019, 2019, e5101684. [Google Scholar] [CrossRef]

- Sujka, K.; Koczoń, P.; Ceglińska, A.; Reder, M.; Ciemniewska-Żytkiewicz, H. The Application of FT-IR Spectroscopy for Quality Control of Flours Obtained from Polish Producers. J. Anal. Methods Chem. 2017, 2017, 4315678. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Liu, T.; Zhao, L.; Yuan, W. Experimental Measurements and Modeling of Solubility and Diffusivity of CO2 in Polypropylene/Micro- and Nanocalcium Carbonate Composites. Ind. Eng. Chem. Res. 2013, 52, 5100–5110. [Google Scholar] [CrossRef]

- Wang, X.; Pei, D.; Teng, Y.; Liang, J. Effects of Enzymes to Improve Sensory Quality of Frozen Dough Bread and Analysis on Its Mechanism. J. Food Sci. Technol. 2018, 55, 389–398. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leitgeb, M.; Knez, Ž.; Hojnik Podrepšek, G. Effect of Green Food Processing Technology on the Enzyme Activity in Spelt Flour. Foods 2022, 11, 3832. https://doi.org/10.3390/foods11233832

Leitgeb M, Knez Ž, Hojnik Podrepšek G. Effect of Green Food Processing Technology on the Enzyme Activity in Spelt Flour. Foods. 2022; 11(23):3832. https://doi.org/10.3390/foods11233832

Chicago/Turabian StyleLeitgeb, Maja, Željko Knez, and Gordana Hojnik Podrepšek. 2022. "Effect of Green Food Processing Technology on the Enzyme Activity in Spelt Flour" Foods 11, no. 23: 3832. https://doi.org/10.3390/foods11233832