Surface Texturing of Cylinder Liners: A Review

Abstract

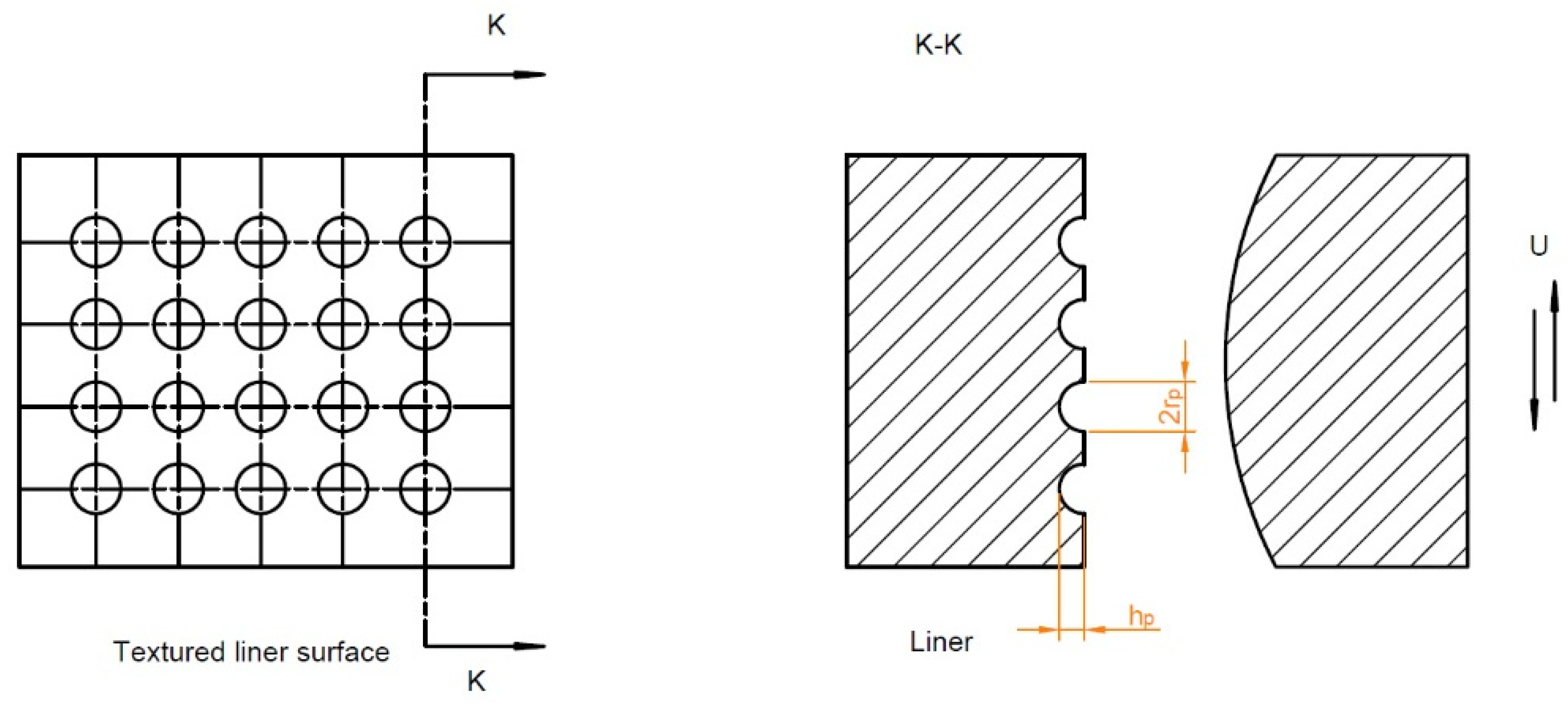

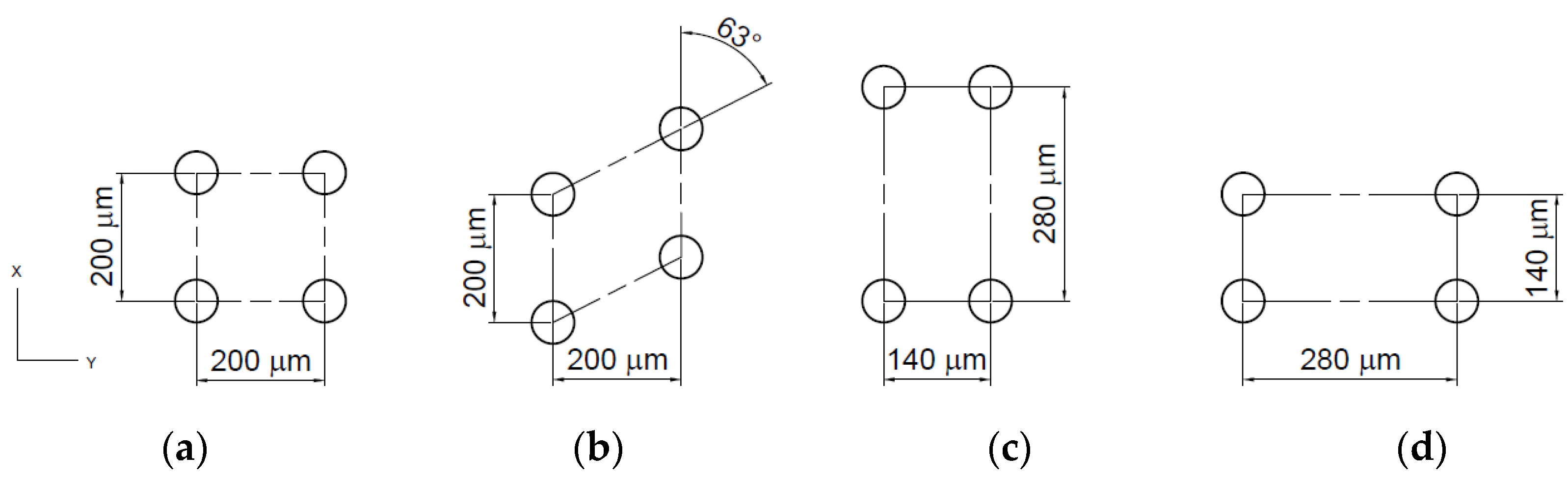

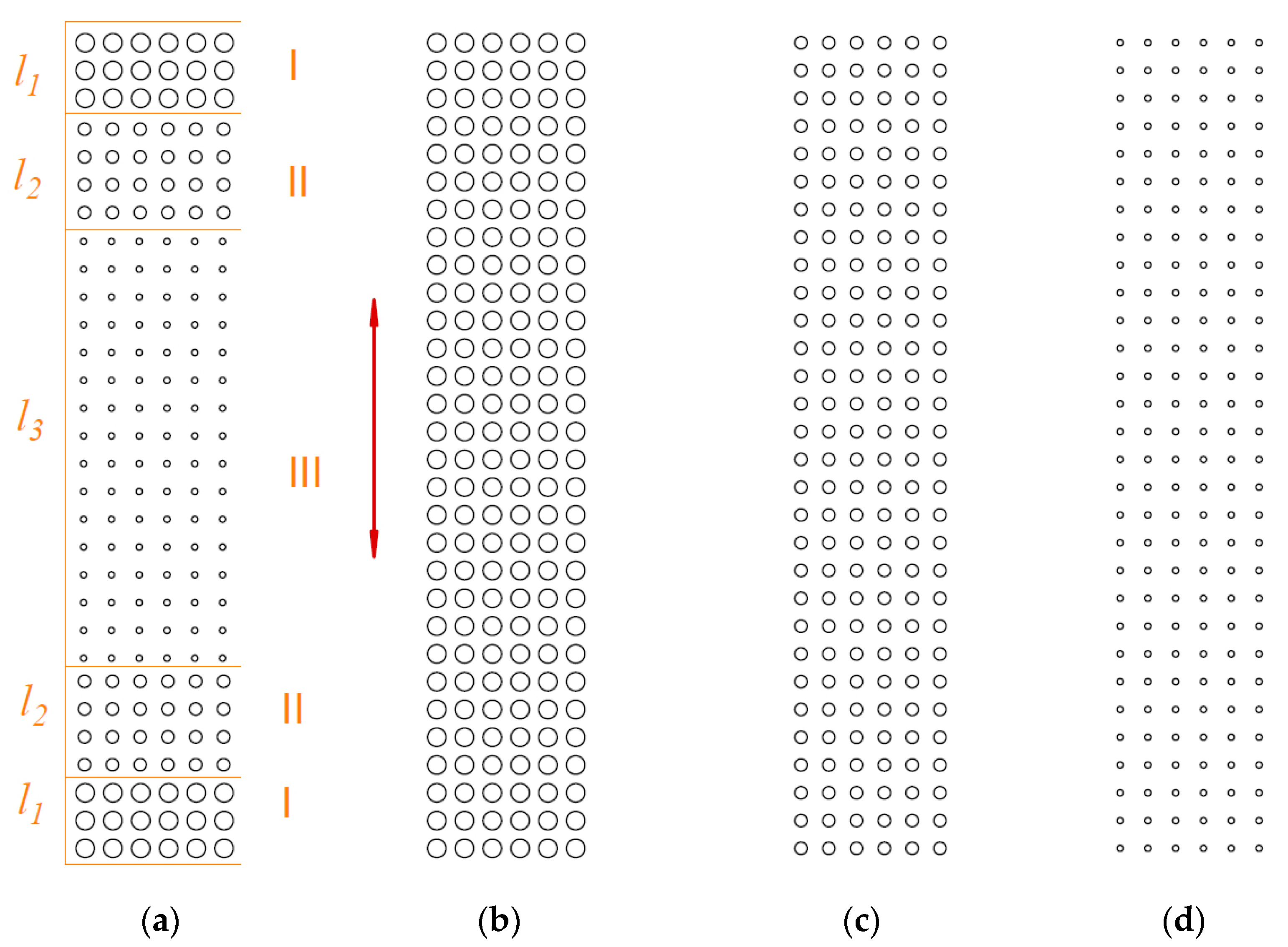

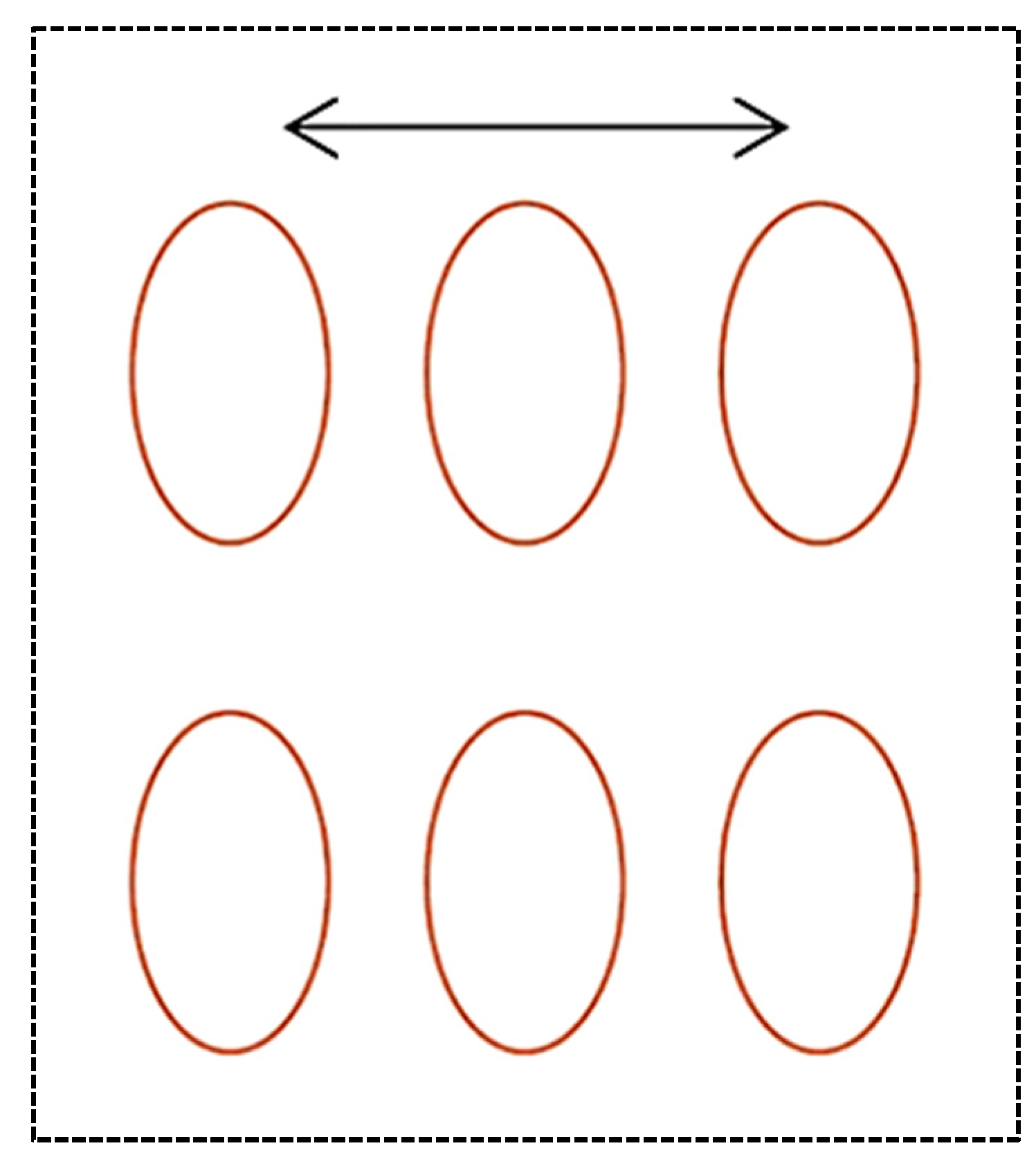

:1. Introduction

2. Functional Performance of Textured Cylinder Liner Surfaces

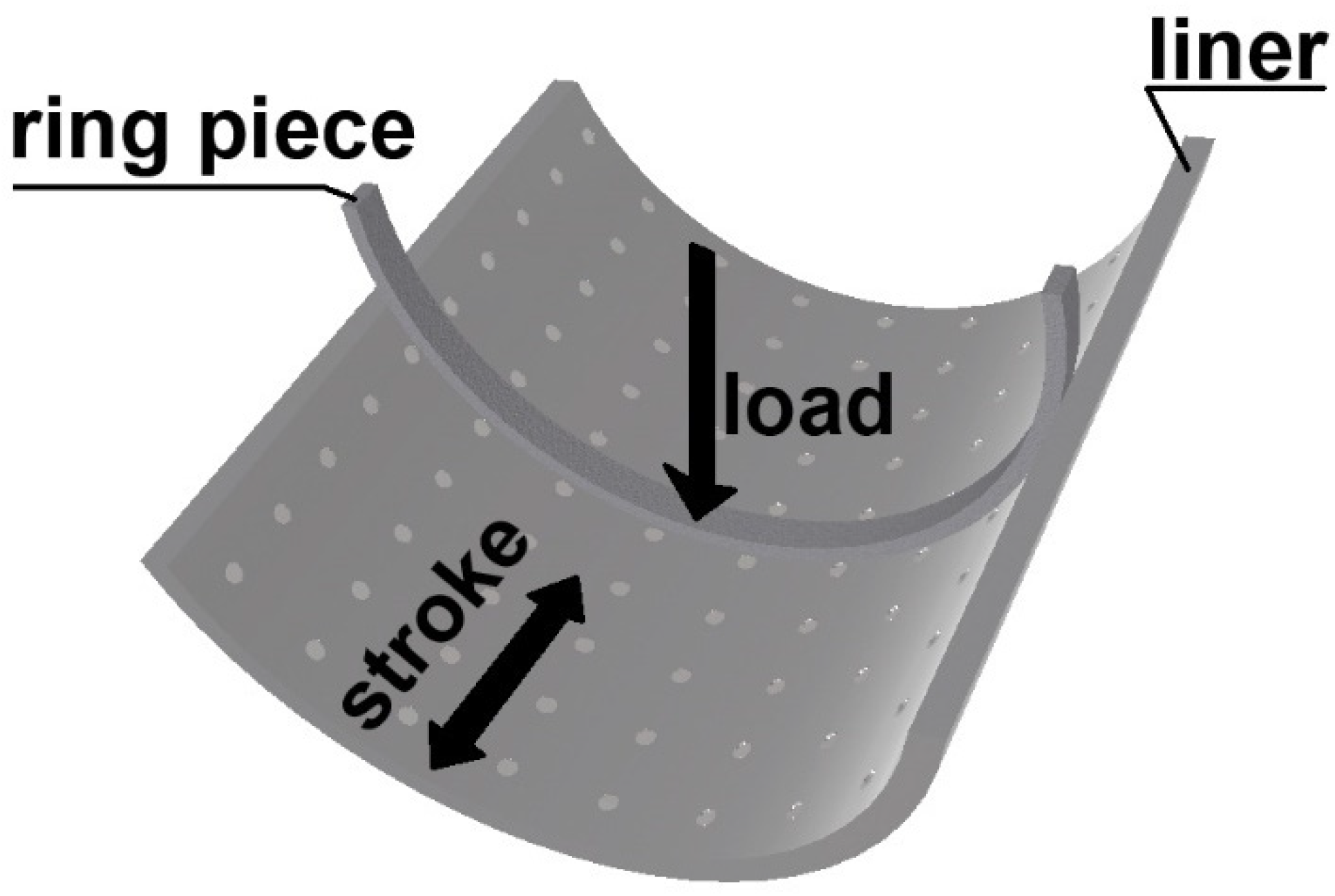

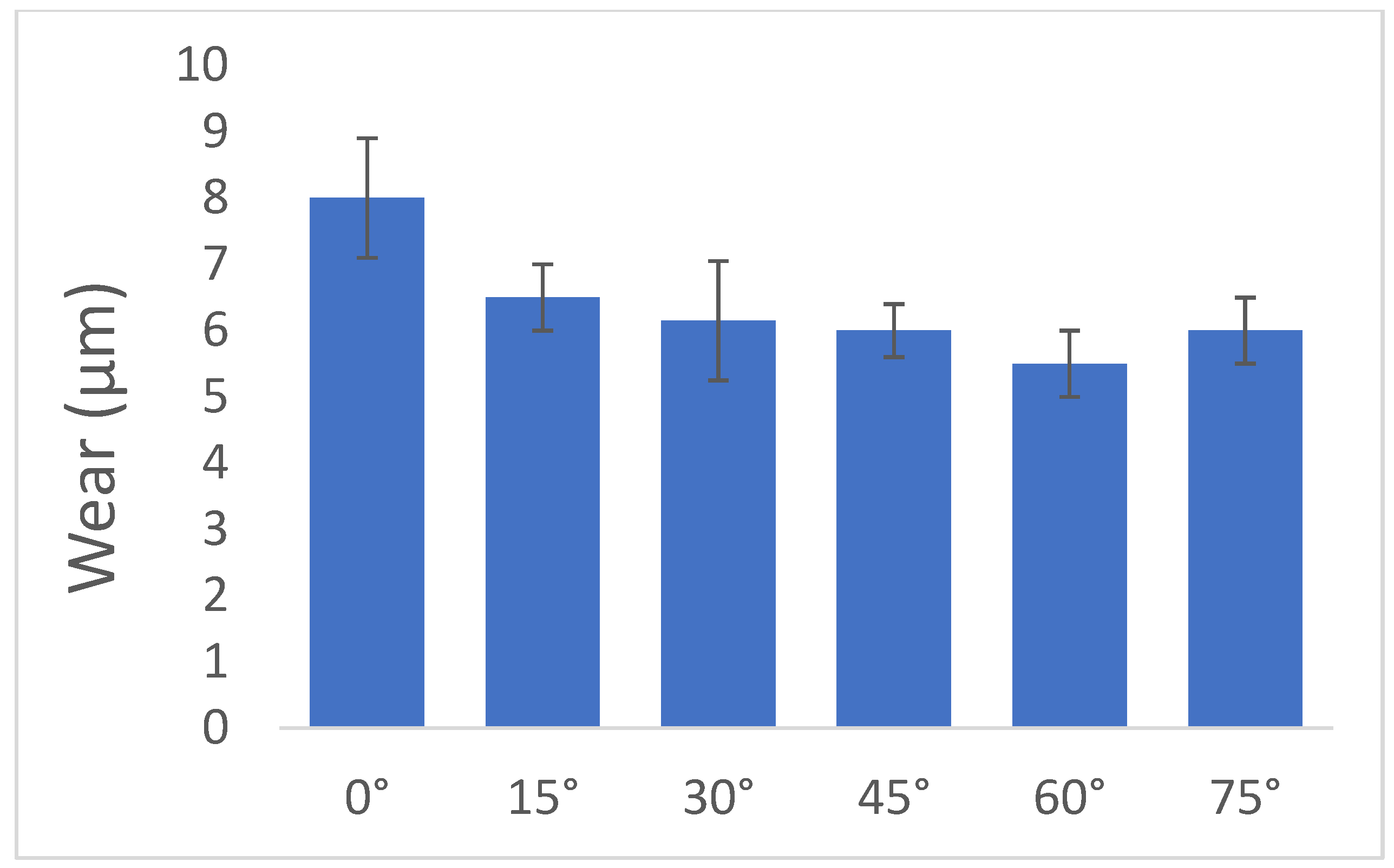

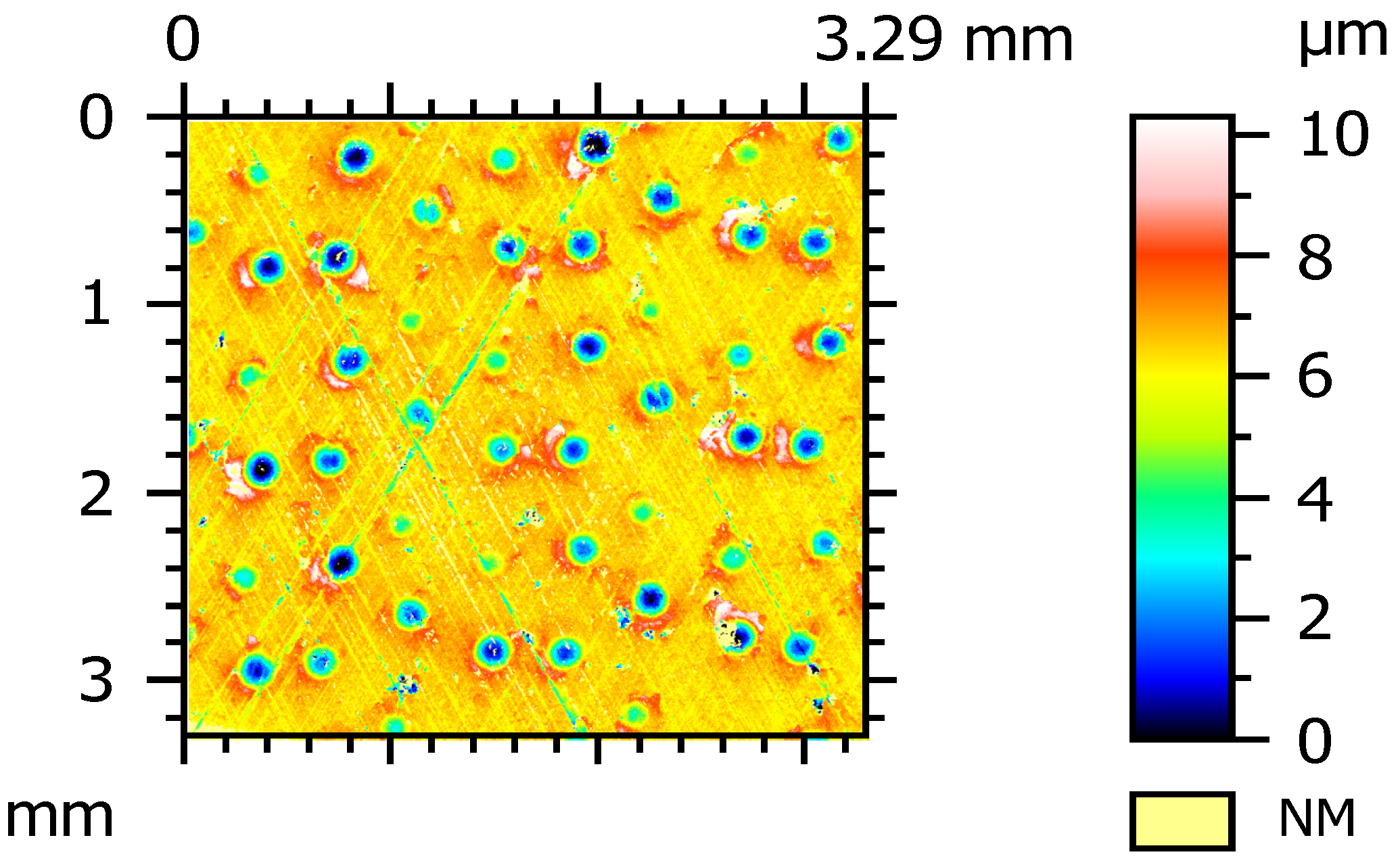

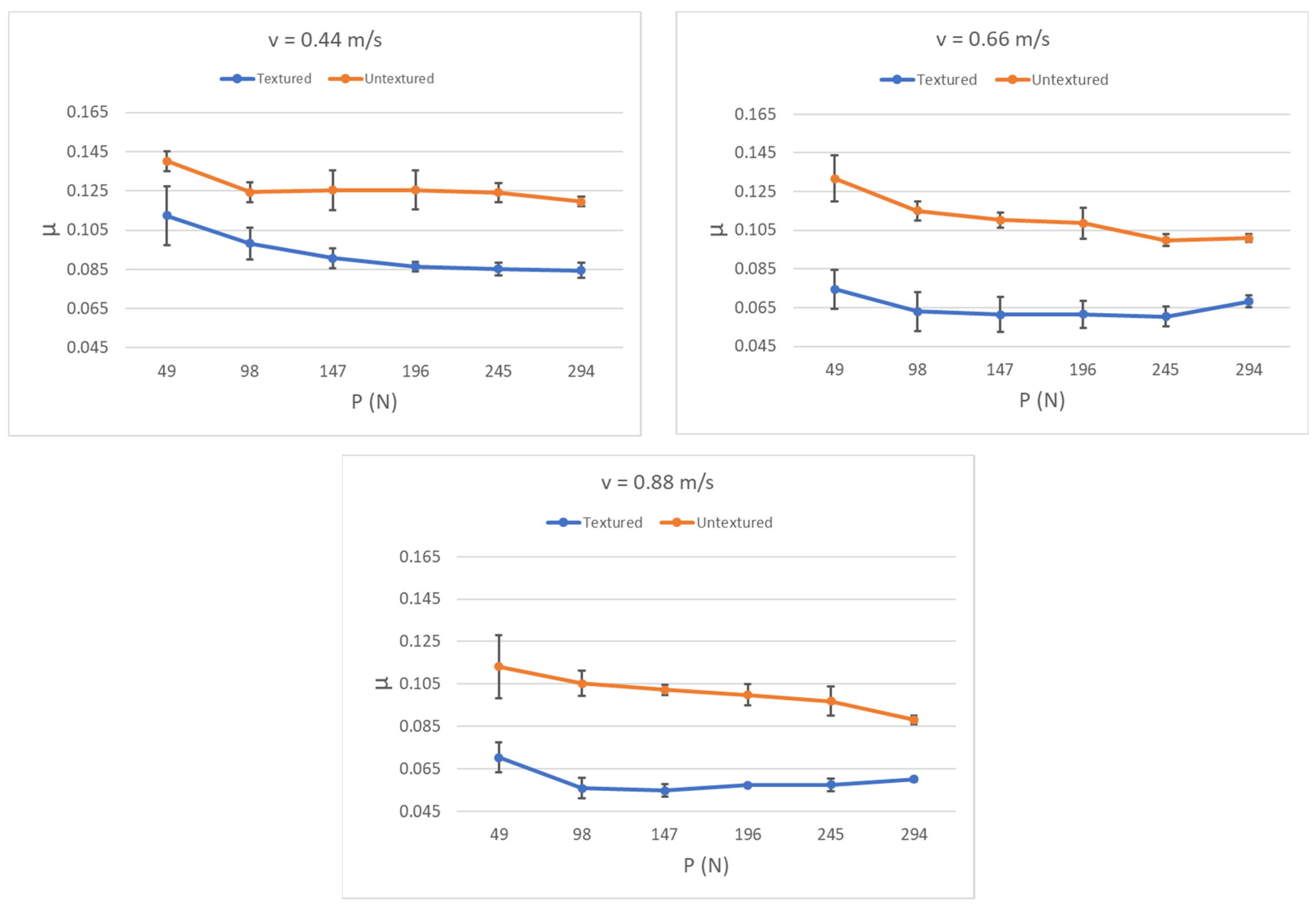

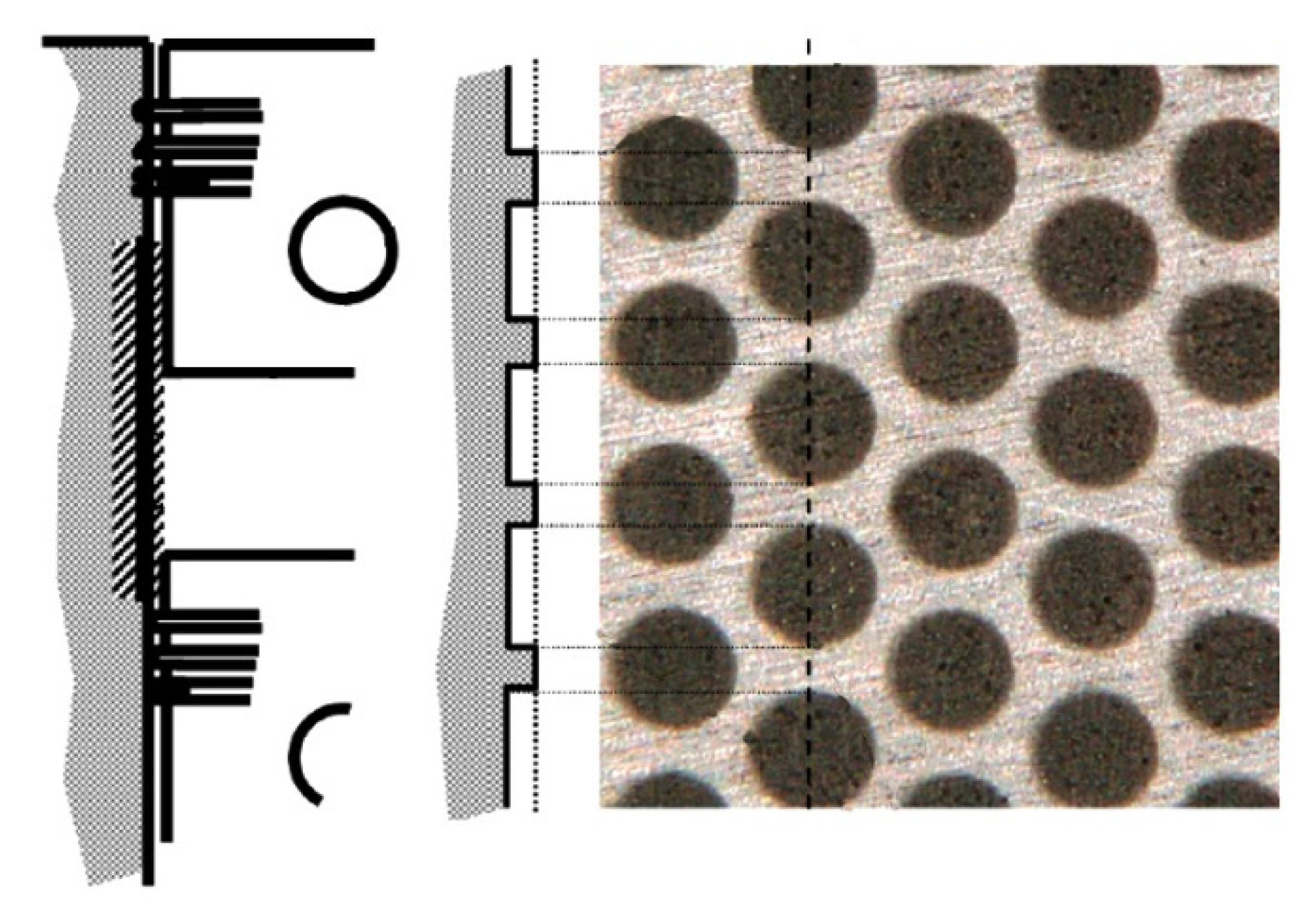

2.1. Laboratory Simulators

2.2. Tests Using a Fired Internal Combustion Engine

2.3. Computer Simulations

3. Discussion

4. Conclusions

- The surface texturing of the cylinder liners improves lubrication between the cylinder liner and the piston ring, especially by increasing the thickness of the oil film near reversal points. Consequently, friction and wear of the co-acting pairs can be reduced. A decrease in the resistance to motion is obviously related to an improvement in engine characteristics, such as a decrease in fuel consumption, and an increase in power and/or torque.

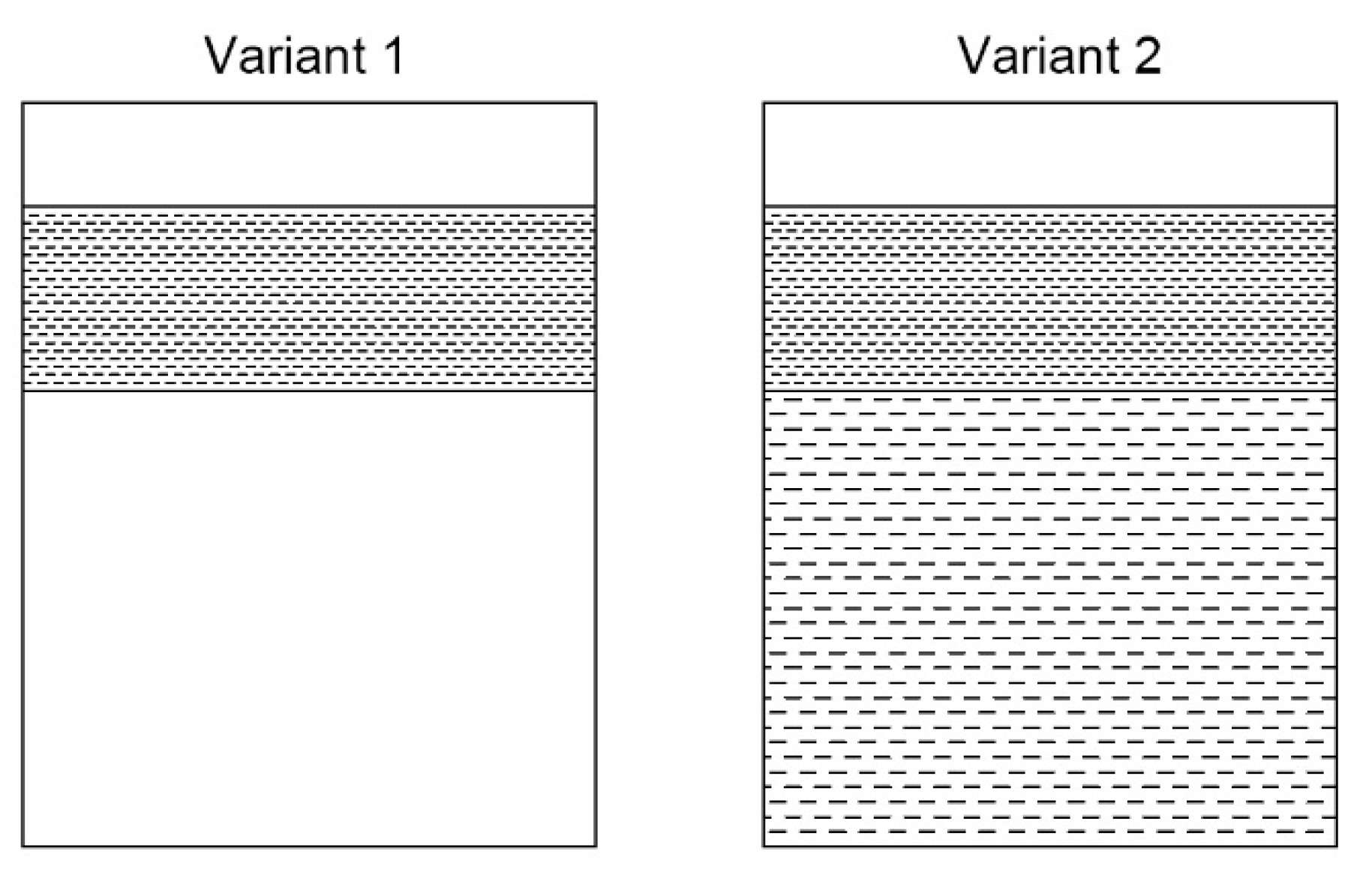

- Correct creation of dimples or grooves on the cylinder surface may lead to a considerable decrease in blow-by and oil consumption compared to plateau-honed cylinder surfaces. This behavior is substantial because smaller oil consumption is related to smaller exhaust emissions. The cylinder surface in the area free of oil pockets should be smooth. Even surface-causing reduced oil consumption can lead to a reduction in fuel consumption. The cylinder liner surface should be additionally textured near the TDC of the piston rings. Texturing the whole cylinder surface or/and too high a depth of oil pockets could cause an increase in oil consumption. An alternative is sparsely texturing the cylinder surface at the midpoint of the stroke. Laser honing also led to a decrease in oil consumption.

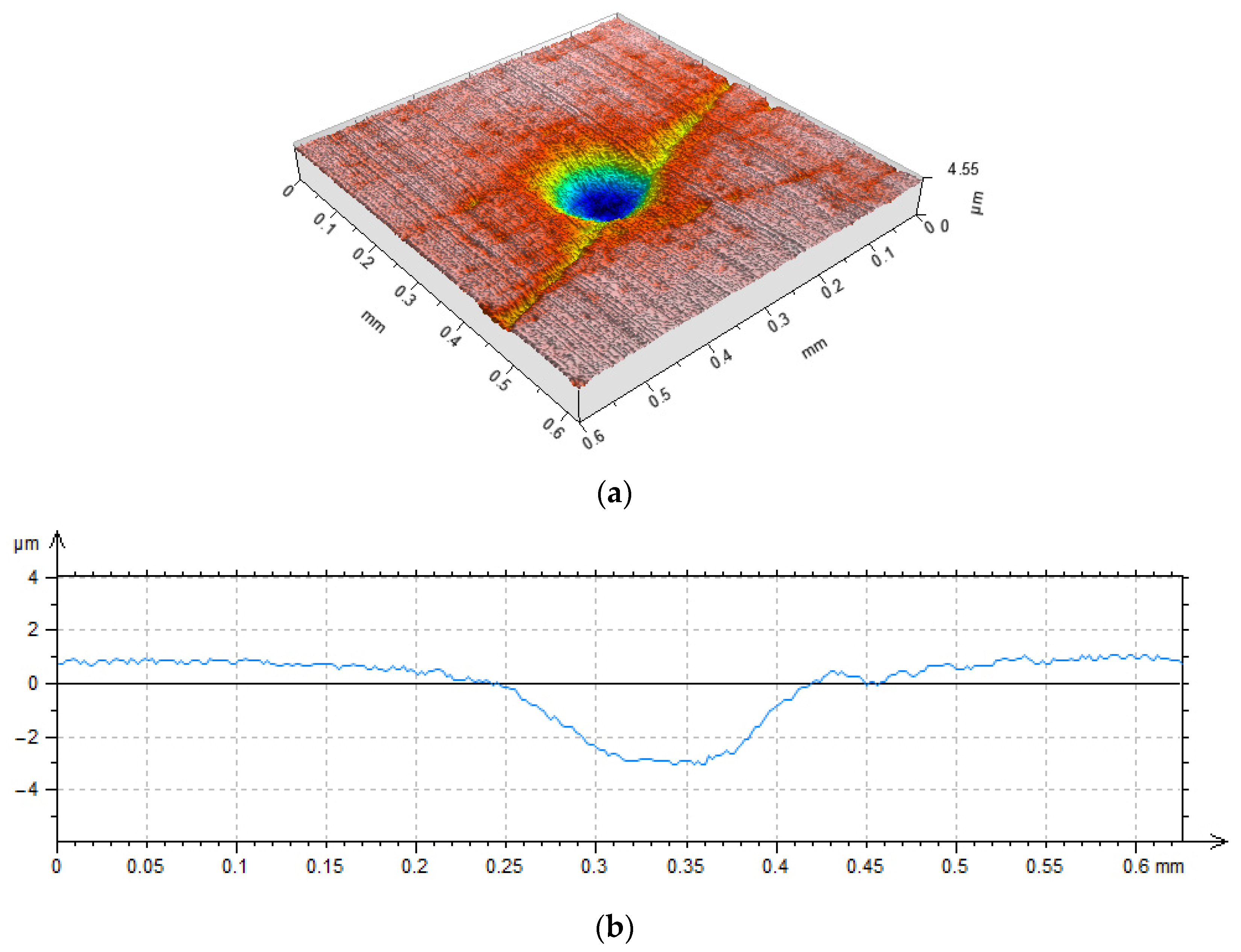

- Circular oil pockets or groves are preferred. Pit area ratio of circular dimples should be between 5 and 15%, the depth of the dimple should be smaller than 10 µm and the ratio of depth to diameter should be less than 0.1. Grooves can be located perpendicularly to the direction of piston ring motion, and of similar depth to dimples, are recommended.

- An alternative solution is the creation of a dimple pattern of small depth (about 2 µm) and large dimple density at the midpoint of the stroke. This caused a reduction in friction, leading to a reduction in fuel consumption. The other possibility is the creation of inclined macro-grooves with nearly 0.2 mm on the cylinder surface of the diesel marine engine. This solution caused reductions in friction, and wear, better sealing performance, smaller emissions of Nox, and violent vibration of the engine.

- In future work, the oil capacity should be included in the description of the textured surface. It is related to oil consumption and resistance to motion. The modeling of co-action between piston rings and cylinder walls should consider the deterministic model of contact and co-action between piston rings and cylinder liner in real engines. Tests using rigs in reciprocation motion should correct simulation conditions of co-action between cylinder liners in piston rings in real engines. More tests should be performed using fired engines using an engine test bench, and the effect of liner texturing on engine performance (power, emission, oil consumption, torque, and fuel consumption) should be analyzed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Nylund, N.-O.; Mäkelä, K.; Erdemir, A. Global energy consumption due to friction in trucks and buses. Tribol. Int. 2014, 78, 94–114. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Grützmacher, P.G.; Gachot, C.; Costa, H.L. Surface Texturing in Machine Elements—A Critical Discussion for Rolling and Sliding Contacts. Adv. Eng. Mater. 2019, 21, 1900194. [Google Scholar] [CrossRef]

- Koszela, W.; Dzierwa, A.; Galda, L.; Pawlus, P. Experimental investigation of oil pockets effect on abrasive wear resistance. Tribol. Int. 2012, 46, 145–153. [Google Scholar] [CrossRef]

- Galda, L.; Dzierwa, A.; Sep, J.; Pawlus, P. The effect of oil pockets shape and distribution on seizure resistance in lubricated sliding. Tribol. Lett. 2010, 37, 301–311. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 761–762. [Google Scholar] [CrossRef]

- Yu, H.; Huang, W.; Wang, X. Dimple patterns design for different circumstances. Lubr. Sci. 2011, 25, 67–78. [Google Scholar] [CrossRef]

- Kouediatouka, A.N.; Ma, Q.; Liu, Q.; Mawignon, F.J.; Rafique, F.; Dong, G. Design Methodology and Application of Surface Texture: A Review. Coatings 2022, 12, 1015. [Google Scholar] [CrossRef]

- Marian, M.; Almqvist, A.; Rosenkranz, A.; Fillon, M. Numerical micro-texture optimization for lubricated contacts—A critical discussion. Friction 2022, 10, 1772–1809. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K. Tribological performance of surface texturing in mechanical applications—A review. Surf. Topogr. Metrol. Prop. 2020, 8, 043001. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef] [Green Version]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Profito, F.J.; Rosenkranz, A. Multi-Scale Surface Texturing in Tribology—Current Knowledge and Future Perspectives. Lubricants 2019, 7, 95. [Google Scholar] [CrossRef] [Green Version]

- Dzyura, V.; Maruschak, P.; Slavov, S.; Dimitrov, D.; Vasileva, D. Experimental research of partial regular microreliefs formed on rotary body face surfaces. Aviation 2021, 25, 268–277. [Google Scholar] [CrossRef]

- Dzyura, V.; Maruschak, P. Optimizing the Formation of Hydraulic Cylinder Surfaces, Taking into Account Their Microrelief Topography Analyzed during Different Operations. Machines 2021, 9, 116. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. Comparing tribological effects of various chevron-based surface textures under lubricated unidirectional sliding. Tribol. Int. 2020, 146, 106205. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. Determination of oil demand for textured surfaces under conformal contact conditions. Tribol. Int. 2016, 93, 602–613. [Google Scholar] [CrossRef]

- Ryk, G.; Kligerman, Y.; Etsion, I. Experimental Investigation of Laser Surface Texturing for Reciprocating Automotive Components. Tribol. Trans. 2002, 45, 444–449. [Google Scholar] [CrossRef]

- Ryk, G.; Kligerman, Y.; Etsion, I.; Shinkarenko, A. Experimental Investigation of Partial Laser Surface Texturing for Piston-Ring Friction Reduction. Tribol. Trans. 2005, 48, 583–588. [Google Scholar] [CrossRef]

- Ryk, G.; Etsion, I. Testing piston rings with partial laser surface texturing for friction reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M.M. Tribological and sealing performance of laser pocketed piston rings in a diesel engine. Tribol. Lett. 2016, 64, 26. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Wu, T.; Xie, Y.-B. Effects of surface texturing on the tribological behavior of piston rings under lubricated conditions. Ind. Lubr. Tribol. 2016, 68, 158–169. [Google Scholar] [CrossRef]

- Ezhilmaran, V.; Vasa, N.J.; Vijayaraghavan, L. Investigation on generation of laser assisted dimples on piston ring surface and influence of dimple parameters on friction. Surf. Coat. Technol. 2018, 335, 314–326. [Google Scholar] [CrossRef]

- Gu, C.; Meng, X.; Xie, Y.; Li, P. A study on the tribological behavior of surface texturing on the nonflat piston ring under mixed lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 230, 452–471. [Google Scholar] [CrossRef]

- Miao, C.; Guo, Z.; Yuan, C. Tribological behavior of co-textured cylinder liner-piston ring during running-in. Friction 2022, 10, 878–890. [Google Scholar] [CrossRef]

- Miao, C.W.; Guo, Z.W.; Yuan, C.Q. An experimental study on tribological properties and air tightness of co-textured cylinder liner-piston ring on an engine tester. Surf. Topogr. Metrol. Prop. 2021, 9, 015005. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.; Guo, Z.; Zhang, X.; Yin, H.; Xu, C.; Yuan, C. Effects of textured cylinder liner piston ring on performances of diesel engine under hot engine tests. Renew. Sustain. Energy Rev. 2021, 146, 111193. [Google Scholar] [CrossRef]

- Mishra, P.; Penchaliah, R. Synergistic effect of surface texturing and coating on the friction between piston ring and cylinder liner contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 1298–1311. [Google Scholar] [CrossRef]

- Atulkar, A.; Pandey, R.K.; Subbarao, P.M.V. Role of textured piston rings/liners in improving the performance behaviours of IC engines: A review with vital findings. Surf. Topogr. Metrol. Prop. 2021, 9, 023002. [Google Scholar] [CrossRef]

- Ahmed, A.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Habibullah, M.; Al Mahmud, K.A.H. An overview of geometrical parameters of surface texturing for piston/cylinder assembly and mechanical seals. Meccanica 2016, 51, 9–23. [Google Scholar] [CrossRef]

- Bathe, R.N.; Padmanabham, G.; Thirumalini, S.; Vaira Vignesh, R. Impact of laser surface texturing (LST) on the tribological characteristics of piston rings and cylinder liners—A review. Part 1: Development of LST technology. Trans. IMF 2021, 99, 231–237. [Google Scholar] [CrossRef]

- Bathe, R.N.; Padmanabham, G.; Thirumalini, S.; Vaira Vignesh, R. Impact of laser surface texturing (LST) on the tribological characteristics of piston rings and cylinder liners—A review. Part 2: Application of the process. Trans. IMF 2022, 100, 119–127. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Żelasko, W. Two-Process Random Textures: Measurement, Characterization, Modeling and Tribological Impact: A Review. Materials 2021, 15, 268. [Google Scholar] [CrossRef] [PubMed]

- Campbell, J.C. Cylinder bore surface roughness in internal combustion engines: Its appreciation and control. Wear 1972, 19, 163–168. [Google Scholar] [CrossRef]

- Santochi, M.; Vignale, M. A study on the functional properties of the honed surface. CIRP Ann. 1982, 31, 431–434. [Google Scholar] [CrossRef]

- Pawlus, P. A study on the functional properties of honed cylinder surface during running-in. Wear 1994, 176, 247–254. [Google Scholar] [CrossRef]

- Pawlus, P. Effects of honed cylinder surface topography on the wear of piston-piston ring-cylinder assemblies under artificially increased dustiness conditions. Tribol. Int. 1993, 26, 49–55. [Google Scholar] [CrossRef]

- Grabon, W.; Pawlus, P.; Wos, S.; Koszela, W.; Wieczorowski, M. Effects of cylinder liner surface topography on friction and wear of liner-ring system at low temperature. Tribol. Int. 2018, 121, 148–160. [Google Scholar] [CrossRef]

- Grabon, W.; Pawlus, P.; Wos, S.; Koszela, W.; Wieczorowski, M. Evolutions of cylinder liner surface texture and tribological performance of piston ring-liner assembly. Tribol. Int. 2018, 127, 545–556. [Google Scholar] [CrossRef]

- Grabon, W.; Pawlus, P.; Sep, J. Tribological characteristics of one-process and two-process cylinder liner honed surfaces under reciprocating sliding conditions. Tribol. Int. 2010, 43, 1882–1892. [Google Scholar] [CrossRef]

- Yin, B.; Zhou, H.; Xu, B.; Jia, H. The influence of roughness distribution characteristic on the lubrication performance of textured cylinder liners. Ind. Lubr. Tribol. 2018, 71, 486–493. [Google Scholar] [CrossRef]

- Barber, G.C.; Ludema, K.C. The break-in stage of cylinder-ring wear: A correlation between fired engines and a laboratory simulator. Wear 1987, 118, 57–75. [Google Scholar] [CrossRef] [Green Version]

- Sato, O.; Takiguchi, M.; Takayuki, A.; Seki, Y.; Fujimura, K.; Tateishi, Y. Improvement of Piston Lubrication in a Diesel Engine by Means of Cylinder Surface Roughness; No. 2004-01-0604; SAE Technical Paper; SAE: Warrendale, PA, USA, 2004. [Google Scholar] [CrossRef]

- Yousfi, M.; Mezghani, S.; Demirci, I.; El Mansori, M. Smoothness and plateauness contributions to the running-in friction and wear of stratified helical slide and plateau honed cylinder liners. Wear 2015, 332–333, 1238–1247. [Google Scholar] [CrossRef]

- Michail, S.K.; Barber, G.C. The Effects of Roughness on Piston Ring Lubrication—Part II: The Relationship between Cylinder Wall Surface Topography and Oil Film Thickness. Tribol. Trans. 1995, 38, 173–177. [Google Scholar] [CrossRef]

- Hill, S.H. Cylinder Bore Finishes and Their Effect on Oil Consumption. SAE Trans. 2001, 110, 1862–1881. [Google Scholar] [CrossRef]

- Spencer, A.; Almqvist, A.; Larsson, R. A numerical model to investigate the effect of honing angle on the hydrodynamic lubrication between a combustion engine piston ring and cylinder liner. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 225, 683–689. [Google Scholar] [CrossRef] [Green Version]

- Hoen, T.; Schmid, J.; Stumpf, W. Less wear and oil consumption through helical slide honing of engines by Deutz. MTZ Worldw. 2009, 70, 46–51. [Google Scholar] [CrossRef]

- Hu, Y.; Meng, X.; Xie, Y.; Fan, J. Study on the frictional performance of slide and plateau honed cylinder liners during running-in. Ind. Lubr. Tribol. 2017, 69, 282–299. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R. Functional importance of honed cylinder liner surface texture: A review. Tribol. Int. 2022, 167, 107409. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Analysis of surface texture of plateau-honed cylinder liner—A review. Precis. Eng. 2021, 72, 807–822. [Google Scholar] [CrossRef]

- Abeln, T.; Flores, G.; Klink, U. Laser structuring—Improvement of tribological properties of surfaces. VDI Ber. 2003, 1810, 227–241. [Google Scholar]

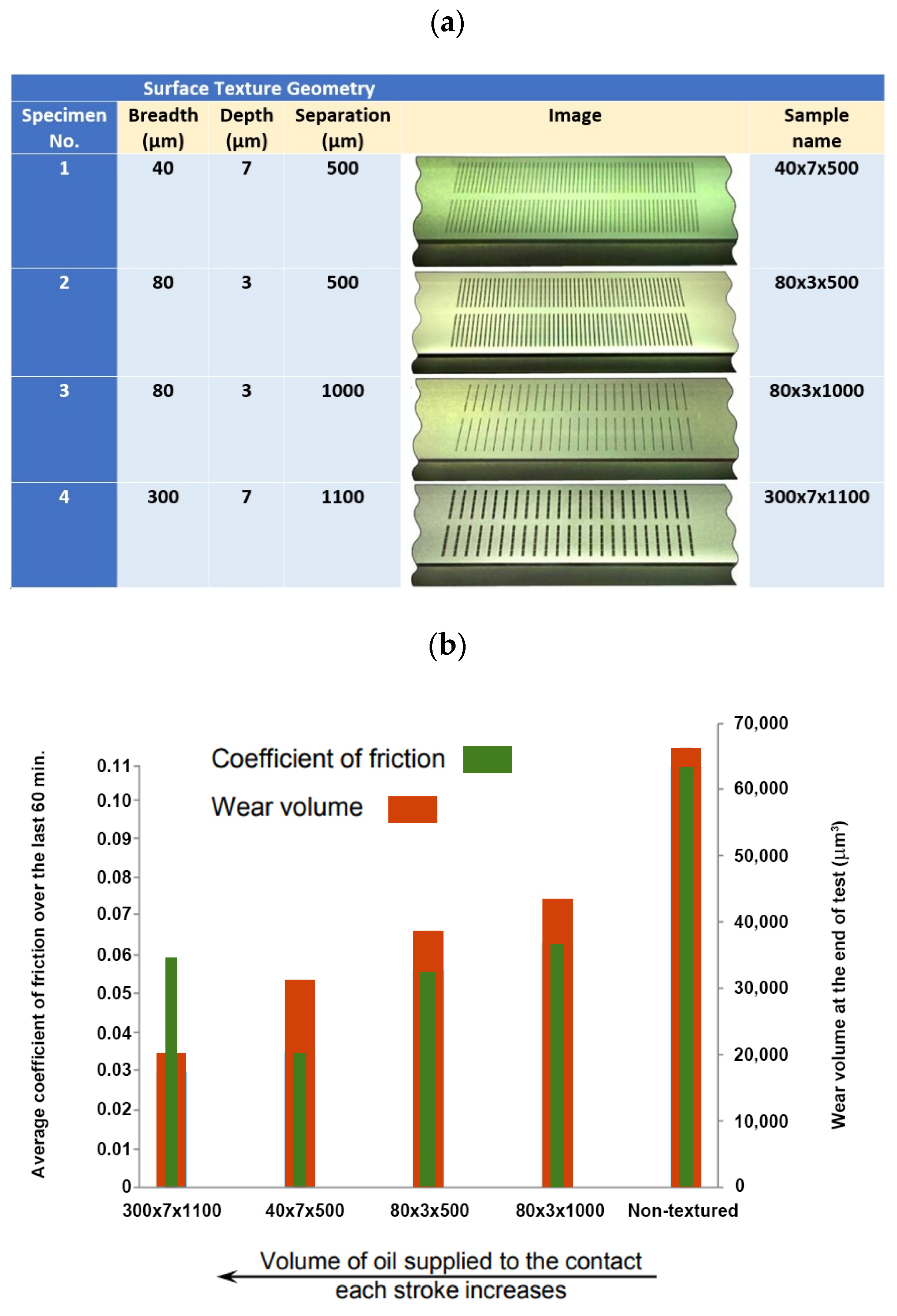

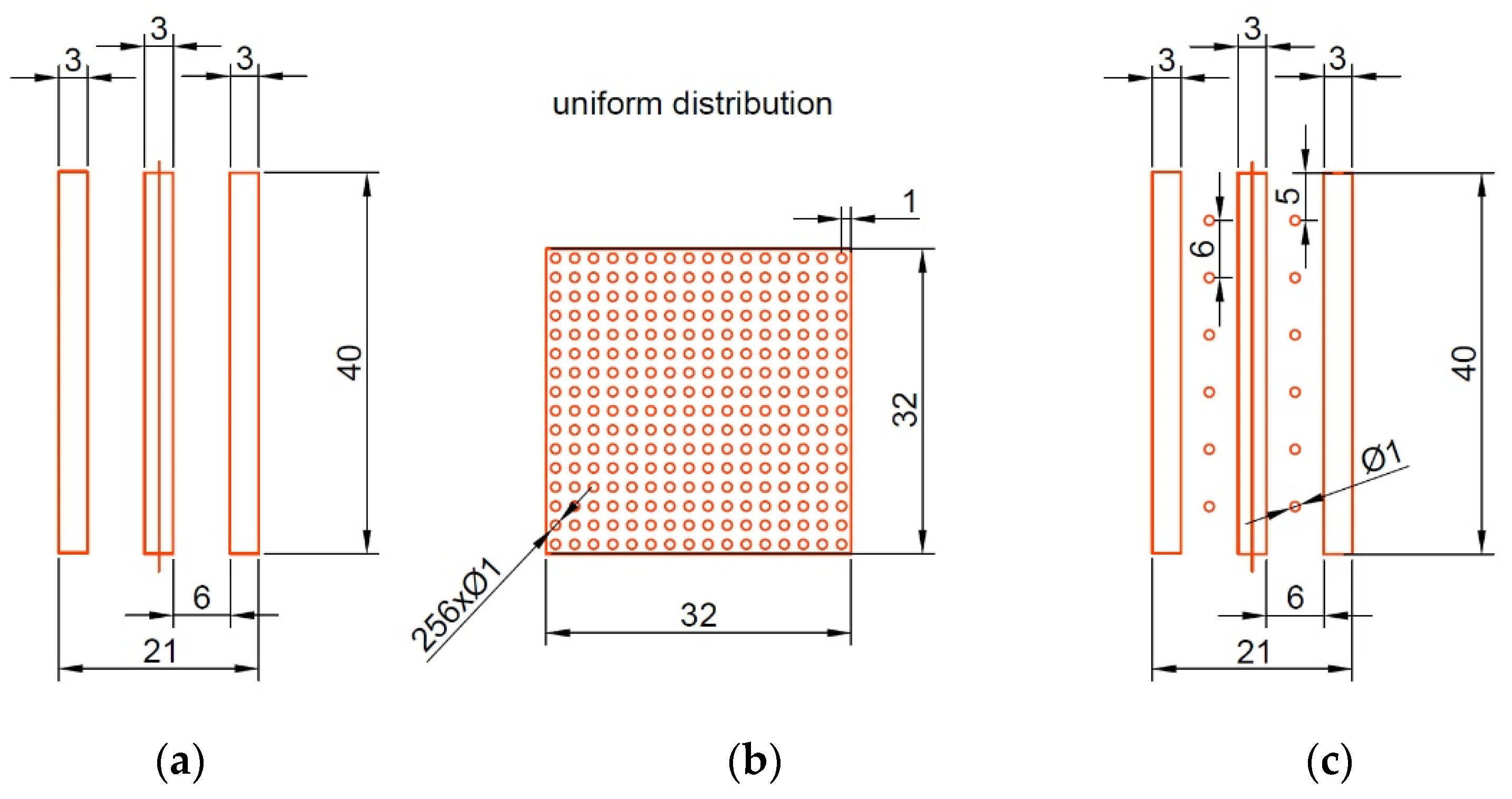

- Wos, S.; Koszela, W.; Dzierwa, A.; Reizer, R.; Pawlus, P. Effects of oil pocket shape and density on friction in reciprocating sliding. Eksploat. Niezawodn. Reliab. Maint. 2022, 24, 338–345. [Google Scholar] [CrossRef]

- Obara, R.B.; Sinatora, A. Quantification of cylinder bores almost ‘zero-wear’. Wear 2016, 364–365, 224–232. [Google Scholar] [CrossRef]

- Obara, R.B. Quantification of wear in cylinder bores based on wear volume profile assessment. J. Tribol. 2018, 140, 051608. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, S.; Prakash, B.; Sethuramiah, A. Assessment of engine liner wear from bearing area curves. Wear 2000, 239, 282–286. [Google Scholar] [CrossRef]

- Duffet, G.; Sallamand, P.; Vannes, A.B. Improvement in friction by cw Nd:YAG laser surface treatment on cast iron cylinder bore. Appl. Surf. Sci. 2003, 205, 289–296. [Google Scholar] [CrossRef]

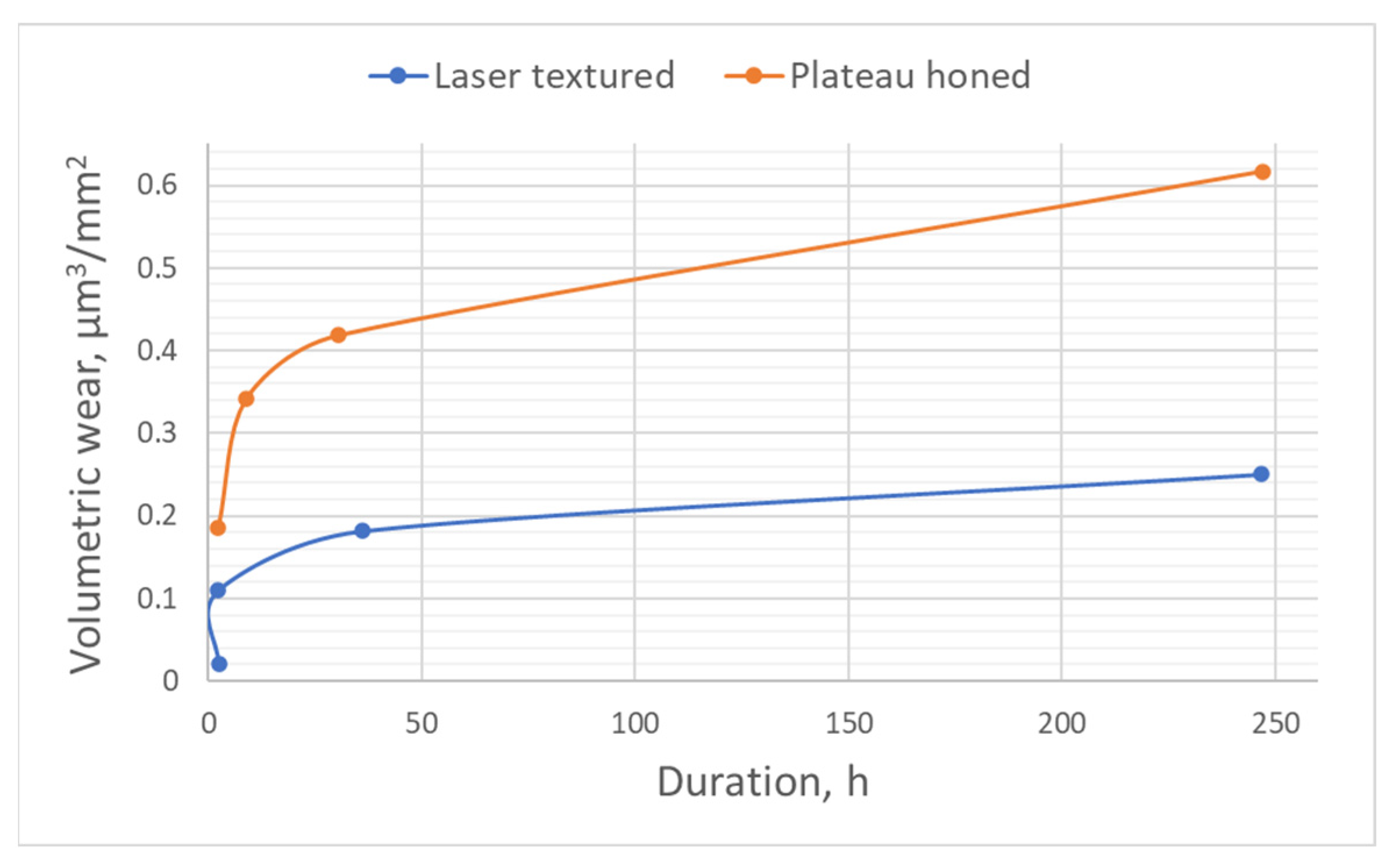

- Tomanik, E. Friction and wear bench tests of different engine liner surface finishes. Tribol. Int. 2008, 41, 1032–1038. [Google Scholar] [CrossRef]

- Zhu, H.; Li, J.Q.; Ma, C.B. Friction reduction effect of micro-round dimple surface texture with variable density in reciprocating. J. Southeast Univ. Nat. Sci. Ed. 2010, 40, 741–745. [Google Scholar] [CrossRef]

- Fan, P.; Zhong, M. Improving the Seizure Resistance of Automobile Engine Liners by Cost Effective ns Fiber Laser Texturing Approach. In Proceedings of the International Summer Session: Lasers and Their Applications, Changchun, China, 31 July–5 August 2011. [Google Scholar] [CrossRef]

- Zhan, J.; Yang, M. Investigation on Dimples Distribution Angle in Laser Texturing of Cylinder—Piston Ring System. Tribol. Trans. 2012, 55, 693–697. [Google Scholar] [CrossRef]

- Zhan, J.; Yang, M. Investigation on the application of YAG laser texturing technology to the cylinder wall of auto engine. Ind. Lubr. Tribol. 2014, 66, 387–392. [Google Scholar] [CrossRef] [Green Version]

- Zhan, J.; Yang, M. The Effects of Dimple Distribution Angle on the Tribology Performance of a Laser Surface Textured Cylinder Piston Ring System. Lasers Eng. 2014, 29, 123–131. [Google Scholar]

- Liu, C.S. Experimental Investigation of Influence of Different Surface Textures on Wear Characteristics of Straight Type Diesel Engine Cylinders. Appl. Mech. Mater. 2013, 443, 141–144. [Google Scholar] [CrossRef]

- Grabon, W.; Koszela, W.; Pawlus, P.; Ochwat, S. Improving tribological behaviour of piston ring–cylinder liner frictional pair by liner surface texturing. Tribol. Int. 2013, 61, 102–108. [Google Scholar] [CrossRef]

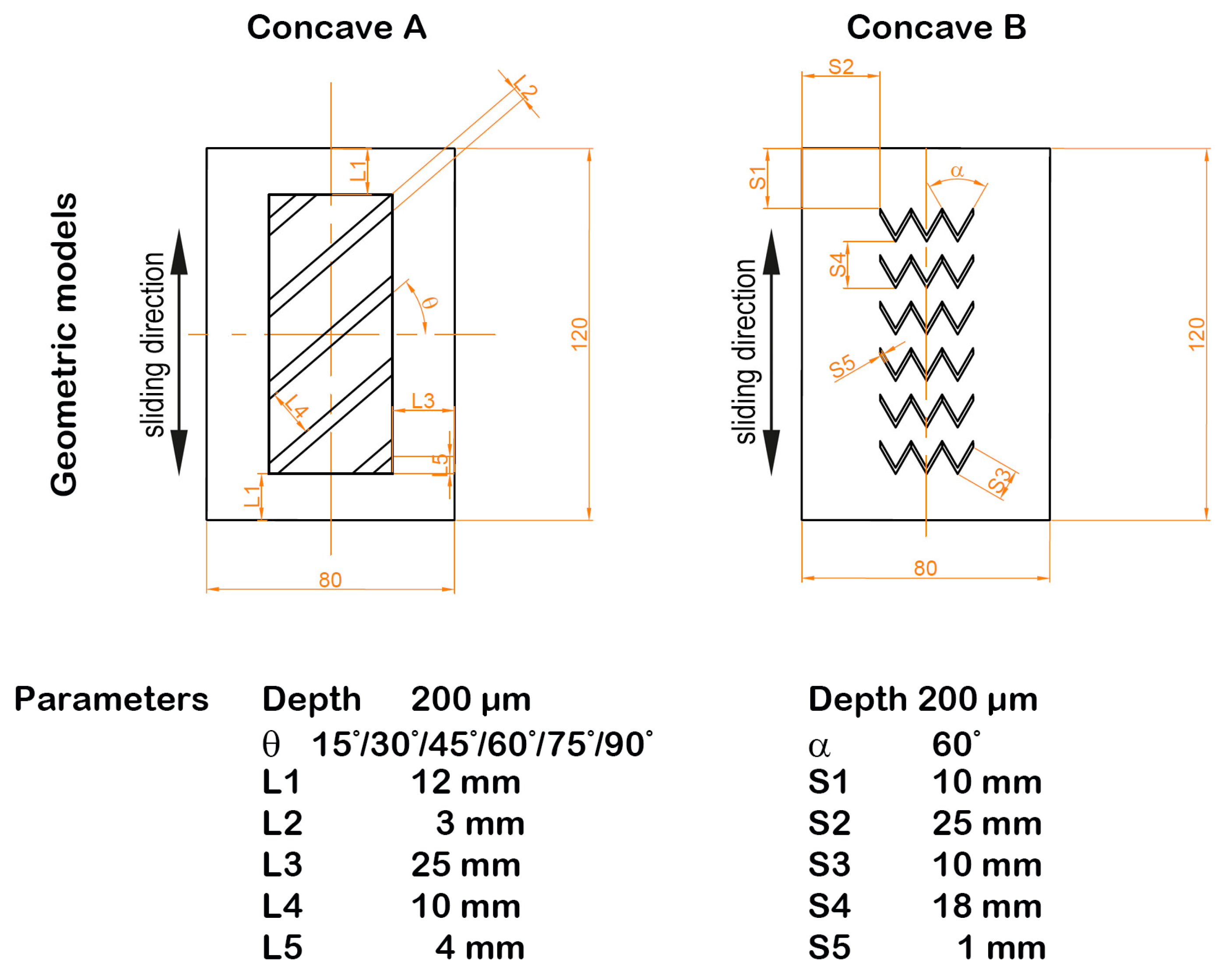

- Morris, N.; Leighton, M.; De la Cruz, M.; Rahmani, R.; Rahnejat, H.; Howell-Smith, S. Combined numerical and experimental investigation of the micro-hydrodynamics of chevron-based textured patterns influencing conjunctional friction of sliding contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 229, 316–335. [Google Scholar] [CrossRef]

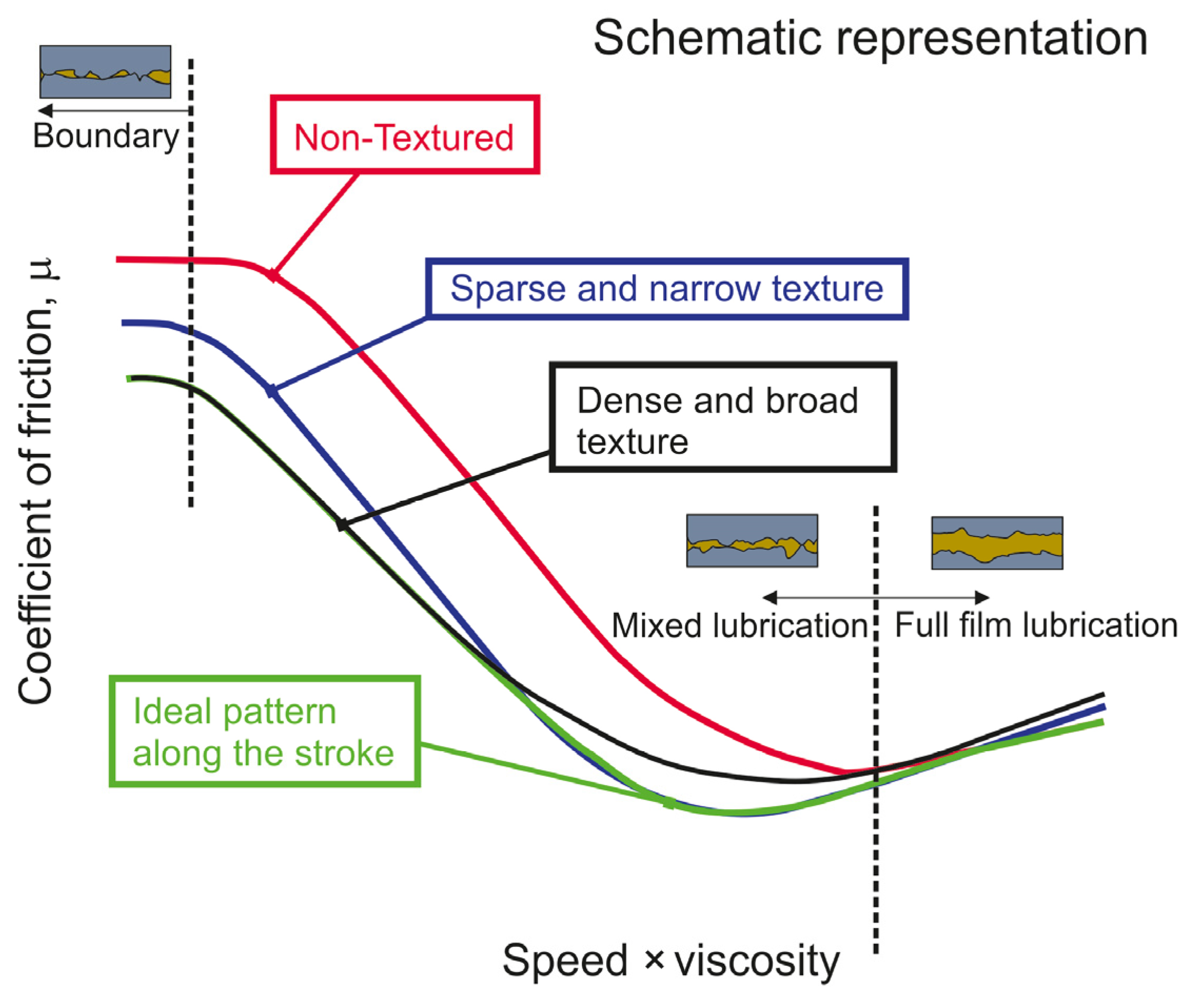

- Costa, H.L.; Hutchings, I.M. Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 2007, 40, 1227–1238. [Google Scholar] [CrossRef]

- Vlădescu, S.-C.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. The effects of surface texture in reciprocating contacts—An experimental study. Tribol. Int. 2014, 82, 28–42. [Google Scholar] [CrossRef] [Green Version]

- Vlădescu, S.-C.; Medina, S.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. Lubricant film thickness and friction force measurements in a laser surface textured reciprocating line contact simulating the piston ring–liner pairing. Tribol. Int. 2016, 98, 317–329. [Google Scholar] [CrossRef] [Green Version]

- Vlădescu, S.-C.; Medina, S.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. The Transient Friction Response of a Laser-Textured, Reciprocating Contact to the Entrainment of Individual Pockets. Tribol. Lett. 2016, 62, 19. [Google Scholar] [CrossRef]

- Vlădescu, S.-C.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. Combined friction and wear reduction in a reciprocating contact through laser surface texturing. Wear 2016, 358–359, 51–61. [Google Scholar] [CrossRef] [Green Version]

- Vlădescu, S.-C.; Ciniero, A.; Tufail, K.; Gangopadhyay, A.; Reddyhoff, T. Looking into a laser textured piston ring-liner contact. Tribol. Int. 2017, 115, 140–153. [Google Scholar] [CrossRef]

- Fowell, M.; Olver, A.V.; Gosman, A.D.; Spikes, H.A.; Pegg, I. Entrainment and Inlet Suction: Two Mechanisms of Hydrodynamic Lubrication in Textured Bearings. J. Tribol. 2007, 129, 336. [Google Scholar] [CrossRef]

- Vlădescu, S.-C.; Ciniero, A.; Tufail, K.; Gangopadhyay, A.; Reddyhoff, T. Optimization of Pocket Geometry for Friction Reduction in Piston–Liner Contacts. Tribol. Trans. 2017, 61, 522–531. [Google Scholar] [CrossRef]

- Profito, F.J.; Vlădescu, S.-C.; Reddyhoff, T.; Dini, D. Experimental Validation of a Mixed-Lubrication Regime Model for Textured Piston-Ring-Liner Contacts. Mater. Perform. Charact. 2017, 6, 112–129. [Google Scholar] [CrossRef]

- Ma, R.; Mohamad, S.A.; Lu, X.; Li, W. Numerical Analysis and Experimental Evaluation of Cylinder Liner Macro-Scale Surface Texturing. In Proceedings of the ASME 2015 Internal Combustion Engine Division Fall Technical Conference, Houston, TX, USA, 8–11 November 2015; Volume 2. [Google Scholar] [CrossRef]

- Yousfi, M.; Mezghani, S.; Demirci, I.; El Mansori, M. Tribological performances of elliptic and circular texture patterns produced by innovative honing process. Tribol. Int. 2016, 100, 255–262. [Google Scholar] [CrossRef] [Green Version]

- Johansson, S.; Nilsson, P.H.; Ohlsson, R.; Rosén, B.-G. A Novel Approach to Reduction of Frictional Losses in a Heavy-Duty Diesel Engine by Reducing the Hydrodynamic Frictional Losses. Adv. Tribol. 2017, 2017, 9240703. [Google Scholar] [CrossRef] [Green Version]

- Guo, Z.-W.; Yuan, C.-Q.; Bai, X.-Q.; Yan, X.-P. Experimental Study on Wear Performance and Oil Film Characteristics of Surface Textured Cylinder Liner in Marine Diesel Engine. Chin. J. Mech. Eng. 2018, 31, 52. [Google Scholar] [CrossRef] [Green Version]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Functional importance of surface texture parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.; Guo, Z.; Yuan, C. Influence of Surface Groove Width on Tribological Performance for Cylinder Liner–Piston Ring Components. Tribol. Trans. 2019, 62, 239–248. [Google Scholar] [CrossRef]

- Miao, J.; Li, Y.; Rao, X.; Zhu, L.; Guo, Z.; Yuan, C. Effects of different surface grooved cylinder liner on the tribological performance for cylinder liner-piston ring components. Ind. Lubr. Tribol. 2020, 72, 581–588. [Google Scholar] [CrossRef]

- Fu, J.; Xu, C.; Ma, D.; Zhu, X.; Cheng, D.; Yan, Z.; Ma, C.; Liu, G.; Fu, Y. Tribological properties and releasing behavior of solid lubricant WS2 in the dimples on cylinder liner surface of diesel engine. Tribol. Int. 2021, 158, 106936. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. The effect of both surfaces textured on improvement of tribological properties of sliding elements. Tribol. Int. 2017, 113, 182–188. [Google Scholar] [CrossRef]

- Yin, B.; Xu, B.; Jia, H.; Hua, X.; Fu, Y. Experimental research on the frictional performance of real laser-textured cylinder liner under different lubrication conditions. Int. J. Engine Res. 2021, 23, 693–704. [Google Scholar] [CrossRef]

- Xu, Y.; Peng, Y.; Dearn, K.D.; You, T.; Geng, J.; Hu, X. Fabrication and tribological characterization of laser textured boron cast iron surfaces. Surf. Coat. Technol. 2017, 313, 391–401. [Google Scholar] [CrossRef] [Green Version]

- Stoeterau, R.L.; Silveira, N.S.; Lima, M.S.F.; Batalha, G. Performance analysis of laser structured surfaces like-honing. In Proceedings of the Euspen’s 17th International Conference & Exhibition, Hannover, Germany, 29 May–2 June 2017. [Google Scholar]

- Shen, Y.; Lv, Y.; Li, B.; Huang, R.; Yu, B.; Wang, W.; Li, C.; Xu, J. Reciprocating electrolyte jet with prefabricated-mask machining micro-dimple arrays on cast iron cylinder liner. J. Mater. Process. Technol. 2019, 266, 329–338. [Google Scholar] [CrossRef]

- Xu, B.; Yin, B.; Jia, H.; Hua, X.; Wei, M. Effects of liner surface textures on the tribological performance of different production piston rings. Lubr. Sci. 2022, 34, 356–368. [Google Scholar] [CrossRef]

- Nakano, M.; Korenaga, A.; Korenaga, A.; Miyake, K.; Murakami, T.; Ando, Y.; Usami, H.; Sasaki, S. Applying Micro-Texture to Cast Iron Surfaces to Reduce the Friction Coefficient Under Lubricated Conditions. Tribol. Lett. 2007, 28, 131–137. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Sedlaček, M.; Podgornik, B.; Vižintin, J.; Babnik, A.; Možina, J. Surface texturing by pulsed Nd:YAG laser. Tribol. Int. 2009, 42, 1496–1504. [Google Scholar] [CrossRef]

- Podgornik, B.; Vilhena, L.M.; Sedlaček, M.; Rek, Z.; Žun, I. Effectiveness and design of surface texturing for different lubrication regimes. Meccanica 2012, 47, 1613–1622. [Google Scholar] [CrossRef]

- Saeidi, F.; Meylan, B.; Hoffmann, P.; Wasmer, K. Effect of surface texturing on cast iron reciprocating against steel under starved lubrication conditions: A parametric study. Wear 2016, 348–349, 17–26. [Google Scholar] [CrossRef] [Green Version]

- Fang, S.; Klein, S.; Hsu, C.-J.; Llanes, L.; Gachot, C.; Bähre, D. Fabrication and tribological performance of a laser-textured hardmetal guiding stone for honing processes. Int. J. Refract. Met. Hard Mater. 2019, 84, 105034. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. The Friction Reducing Effect of Square-Shaped Surface Textures under Lubricated Line-Contacts—An Experimental Study. Lubricants 2016, 4, 26. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. A Novel Surface Texture Shape for Directional Friction Control. Tribol. Lett. 2018, 66, 51. [Google Scholar] [CrossRef] [Green Version]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. The use of anisotropic texturing for control of directional friction. Tribol. Int. 2017, 113, 169–181. [Google Scholar] [CrossRef] [Green Version]

- Wos, S.; Koszela, W.; Dzierwa, A.; Pawlus, P. Effects of operating conditions and pit-area ratio on the coefficient of friction of textured assemblies in lubricated reciprocating sliding. Materials 2022, 15, 7199. [Google Scholar] [CrossRef]

- Guo, Z.; Yuan, C.; Liu, P.; Peng, Z.; Yan, X. Study on Influence of Cylinder Liner Surface Texture on Lubrication Performance for Cylinder Liner–Piston Ring Components. Tribol. Lett. 2013, 51, 9–23. [Google Scholar] [CrossRef]

- Peng, E.; Huang, S. Wear performance of cylinder liner surface texturing on cylinder liner–piston ring assembly. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 291–306. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.; Guo, Z.; Yuan, C. Effects of thread groove width in cylinder liner surface on performances of diesel engine. Wear 2019, 426–427, 1296–1303. [Google Scholar] [CrossRef]

- Yin, B.; Xu, B.; Jia, H.; Zhou, H.; Fu, Y.; Hua, X. Effects of the array modes of laser-textured micro-dimples on the tribological performance of cylinder liner–piston ring. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 232, 871–881. [Google Scholar] [CrossRef]

- Urabe, M.; Takakura, T.; Metoki, S.; Yanagisawa, M.; Murata, H. Mechanism of and Fuel Efficiency Improvement by Dimple Texturing on Liner Surface for Reduction of Friction between Piston Rings and Cylinder Bore; No. 2014-01-1661; SAE Technical Paper; SAE: Warrendale, PA, USA, 2014; p. 1661. [Google Scholar] [CrossRef]

- Ergen, O.R.; Kurnaz, G.; Soydemir, N.G.; Akalin, O. Reduced Oil Consumption by Laser Surface Texturing on Cylinders. SAE Int. J. Commer. Veh. 2009, 1, 446–453. [Google Scholar] [CrossRef]

- Hegemier, T.; Stewart, M. Some Effects of Liner Finish on Diesel Engine Operating Characteristics. SAE Trans. 1993, 102, 958–967. [Google Scholar] [CrossRef]

- Hill, S.H.; Kantola, T.C.; Brown, J.R.; Hamelink, J.C. An Experimental Study of the Effect of Cylinder Bore Finish on Engine Oil Consumption. SAE Trans. 1995, 104, 1568–1576. [Google Scholar] [CrossRef]

- Willcock, M.; Tidmarsh, D.H.; Foss, P. An evaluation of the influence of cylinder liner finish and synthetic lubricating oil on exhaust hydrocarbon species from an SI engine. J. Synth. Lubr. 1997, 14, 47–61. [Google Scholar] [CrossRef]

- Davis, F.A.; Eyre, T.S. The effect of a friction modifier on piston ring and cylinder bore friction and wear. Tribol. Int. 1990, 23, 163–171. [Google Scholar] [CrossRef]

- Al-Khalidi, G.F.; Eyre, T.S. Bore polishing—Identification and simulation. Tribol. Int. 1987, 20, 18–24. [Google Scholar] [CrossRef]

- Dong, W.P.; Davis, E.J.; Butler, D.L.; Stout, K.J. Topographic features of cylinder liners—An application of three-dimensional characterization techniques. Tribol. Int. 1995, 28, 453–463. [Google Scholar] [CrossRef]

- Grabon, W.; Pawlus, P.; Koszela, W.; Reizer, R. Proposals of methods of oil capacity calculation. Tribol. Int. 2014, 75, 117–122. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M.; Krolczyk, G. Material ratio curve as information on the state of surface topography—A review. Precis. Eng. 2020, 65, 240–258. [Google Scholar] [CrossRef]

- Hua, X.; Fu, Y.; Wang, X.; Yuan, R.; Zhang, Y.; Lan, C. Experimental research on laser honing of engine cylinder bore. China Mech. Eng. 2007, 18, 2989–2992. [Google Scholar]

- Hua, X.; Sun, J.; Zhang, P.; Ge, H.; Yonghong, F.; Jinghu, J.; Yin, B. Research on discriminating partition laser surface micro-texturing technology of engine cylinder. Tribol. Int. 2016, 98, 190–196. [Google Scholar] [CrossRef]

- Kang, Z.; Fu, Y.; Zhou, D.; Wu, Q.; Chen, T.; He, Y.; Su, X. Reducing engine oil and fuel consumptions by multidimensional laser surface texturing on cylinder surface. J. Manuf. Process. 2021, 64, 684–693. [Google Scholar] [CrossRef]

- Brinkman, S.; Bodschwinna, H. Characterisation of Automotive Engine Bore Performance Using 3D Surface Metrology. In Advanced Techniques for Assessment Surface Topography; Butterworth–Heinemann: Oxford, UK, 2003; pp. 307–322. [Google Scholar] [CrossRef]

- Golloch, R.; Merker, G.P.; Kessen, U.; Brinkmann, S. Functional properties of microstructured cylinder liner surfaces for internal combustion engines. Tribotest 2005, 11, 307–324. [Google Scholar] [CrossRef]

- Rahnejat, H.; Balakrishnan, S.; King, P.D.; Howell-Smith, S. In-Cylinder Friction Reduction Using a Surface Finish Optimization Technique. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2006, 220, 1309–1318. [Google Scholar] [CrossRef] [Green Version]

- Yin, B. Theoretical and Experimental Research on Lubrication Performance of Laser Surface Texturing Cylinder Liner. Chin. J. Mech. Eng. 2012, 48, 91–96. [Google Scholar] [CrossRef]

- Howell-Smith, S.; Rahnejat, H.; King, P.D.; Dowson, D. Reducing in-cylinder parasitic losses through surface modification and coating. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 391–402. [Google Scholar] [CrossRef] [Green Version]

- Koszela, W.; Pawlus, P.; Reizer, R.; Liskiewicz, T. The combined effect of surface texturing and DLC coating on the functional properties of internal combustion engines. Tribol. Int. 2018, 127, 470–477. [Google Scholar] [CrossRef]

- Fu, Y.H.; Ye, Y.X.; Zhang, Y.K.; Cai, L. The Technology of Laser Honing Applied in Distinctively Improving the Lubrication of Frictional Units. Key Eng. Mater. 2001, 202–203, 265–270. [Google Scholar] [CrossRef]

- Zhang, Y.K.; Yang, C.J.; Fu, Y.H.; Zhou, J.Z.; Hua, X.J.; Ji, J.H. Surface Texturing Technology by Laser Honing Based on Hydrodynamic Lubrication. Key Eng. Mater. 2007, 359–360, 340–343. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Greenwood, I.; Tripp, J.H. The contact of nominally flat surfaces. Proc. Inst. Mech. Eng. 1971, 185, 625–633. [Google Scholar] [CrossRef]

- Organisciak, M.; Cavallaro, G.; Lubrecht, A.A. Starved Hydrodynamic Lubrication of the Piston Ring Cylinder Liner Contact: Preliminary Study of the Influence of Surface Texturing. Tribol. Interface Eng. Ser. 2005, 48, 573–583. [Google Scholar] [CrossRef]

- Takata, R.; Li, Y.; Wong, V.W. Effects of Liner Surface Texturing on Ring/Liner Friction in Large-Bore IC Engines. In Proceedings of the ASME 2006 Internal Combustion Engine Division Fall Technical Conference (ICEF2006), Sacramento, CA, USA, 5–8 November 2006. [Google Scholar] [CrossRef]

- Caciu, C.; Decencière, E.; Jeulin, D. Parametric Optimization of Periodic Textured Surfaces for Friction Reduction in Combustion Engines. Tribol. Trans. 2008, 51, 533–541. [Google Scholar] [CrossRef]

- Yin, B. Research on Tribological Performance of Cylinder Liner by Micro-Laser Surface Texturing. J. Comput. Theor. Nanosci. 2011, 4, 1318–1324. [Google Scholar] [CrossRef]

- Yin, B.; Li, X.; Fu, Y.; Yun, W. Effect of laser textured dimples on the lubrication performance of cylinder liner in diesel engine. Lubr. Sci. 2012, 24, 293–312. [Google Scholar] [CrossRef]

- Yin, B.; Sun, S.; Wang, B.; Qian, Y. Numerical Research on Tribological Performance of Textured Liner Surface under Different Combustion Modes. J. Eng. Gas Turbines Power 2016, 139, 011504. [Google Scholar] [CrossRef]

- Yin, B.; Xu, B.; Qian, Y.; Ji, J.; Fu, Y. Lubrication adaptability to the variations of combustion modes by texturing cylinder liner in engines. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 232, 946–957. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, H.; Tang, W.; Ma, C.; Zhang, W. Development of the theoretical model for the optimal design of surface texturing on cylinder liner. Tribol. Int. 2012, 52, 1–6. [Google Scholar] [CrossRef]

- Tomanik, E. Modelling the hydrodynamic support of cylinder bore and piston rings with laser textured surfaces. Tribol. Int. 2013, 59, 90–96. [Google Scholar] [CrossRef]

- Checo, H.M.; Ausas, R.F.; Jai, M.; Cadalen, J.-P.; Choukroun, F.; Buscaglia, G.C. Moving textures: Simulation of a ring sliding on a textured liner. Tribol. Int. 2014, 72, 131–142. [Google Scholar] [CrossRef]

- Elrod, H.; Adams, M. A Computer Program for Cavitation and Starvation Problems. In 1st Leeds Lyon Symposium on Cavitation and Related Phenomena in Lubrication; Dowson, D., Ed.; Technical Report 190; Institution of Mechanical Engineers: London, UK, 1974; Volume 103, p. 354. [Google Scholar]

- Mohamad, S.A.; Lu, X.; Zheng, Q. Numerical modeling of lubrication of piston ring of two-stroke marine diesel engine considering the effect of multi-scale grooves on the cylinder liner. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 989–1002. [Google Scholar] [CrossRef]

- Mohamad, S.A.; Zheng, Q.; Lu, X.Q. Improving Tribological Behavior of 2-Stroke Marine Diesel Engine Piston Ring by Cylinder Liner Surface Texturing. Appl. Mech. Mater. 2014, 620, 278–284. [Google Scholar] [CrossRef]

- Mohamad, S.A.; Kamel, M.A. Optimization of cylinder liner macro-scale surface texturing in marine diesel engines based on teaching–learning-based optimization algorithm. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 329–342. [Google Scholar] [CrossRef]

- Zavos, A.; Nikolakopoulos, P.G. Simulation and modeling of friction for honed and wave-cut cylinder bores of marine engines. Simul. Model. Pract. Theory 2014, 49, 228–244. [Google Scholar] [CrossRef]

- Biboulet, N.; Lubrecht, A.A. Analytical solution for textured piston ring—Cylinder liner contacts (1D analysis). Tribol. Int. 2016, 96, 269–278. [Google Scholar] [CrossRef]

- Gu, C.; Meng, X.; Xie, Y.; Yang, Y. Effects of surface texturing on ring/liner friction under starved lubrication. Tribol. Int. 2016, 94, 591–605. [Google Scholar] [CrossRef]

- Morris, N.; Rahmani, R.; Rahnejat, H.; King, P.D.; Howell-Smith, S. A Numerical Model to Study the Role of Surface Textures at Top Dead Center Reversal in the Piston Ring to Cylinder Liner Contact. J. Tribol. 2016, 138, 021703. [Google Scholar] [CrossRef]

- Profito, F.J.; Vlădescu, S.C.; Reddyhoff, T.; Dini, D. Transient experimental and modelling studies of laser-textured microgrooved surfaces with a focus on piston-ring cylinder liner contacts. Tribol. Int. 2017, 113, 125–136. [Google Scholar] [CrossRef]

- García, C.P.; Rojas, J.P.; Abril, S.O. Analysis of the Influence of Textured Surfaces and Lubrication Conditions on the Tribological Performance between the Compression Ring and Cylinder Liner. Lubricants 2021, 9, 51. [Google Scholar] [CrossRef]

- Jang, S. Computational study on the frictional power loss reduction of piston ring with laser surface texturing on the cylinder liner. Int. J. Automot. Technol. 2022, 23, 855–865. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M.M. Numerical optimization of texture shape for parallel surfaces under unidirectional and bidirectional sliding. Tribol. Int. 2015, 82, 1–11. [Google Scholar] [CrossRef]

- Priest, M.; Taylor, C. Automobile engine tribology—Approaching the surface. Wear 2000, 241, 193–203. [Google Scholar] [CrossRef]

- Morina, A.; Lee, P.M.; Priest, M.; Neville, A. Challenges of simulating “fired engine” ring-liner oil additive/surface interactions in ring-liner bench tribometer. Tribol. Mater. Surf. Interfaces 2011, 5, 25–33. [Google Scholar] [CrossRef]

- Lee, P.M.; Chittenden, R.J. Consideration of Test Parameters in Reciprocating Tribometers Used to Replicate Ring-on-Liner Contact. Tribol. Lett. 2010, 39, 81–89. [Google Scholar] [CrossRef]

| Type of Research | Texturing Effects | |||

|---|---|---|---|---|

| Laboratory simulators | Friction | Wear | ||

| Test rigs | [27,59,60,61,64,66,67,68,70,71,72,73,74,76,77,78,79,80,81,84,85,87,88,89,90,91] | [27,59,60,62,63,64,65,66,67,71,73,80,81,83,85,88] | ||

| Engine simulators | [43,103,104,105] | [101,102] | ||

| Tests of fired engines | Oil consumption | Wear | Parameters (torque, power, fuel consumption) | |

| [106,115,116,117,118,119,121,124,125] | [29,118,119,124] | [105,120,121,122,123] | ||

| Modeling | Friction, oil film thickness | |||

| [43,64,68,77,78,104,121,128,129,130,132,133,134,135,136,137,139,140,141,142,143,144,145,146,147] | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pawlus, P.; Koszela, W.; Reizer, R. Surface Texturing of Cylinder Liners: A Review. Materials 2022, 15, 8629. https://doi.org/10.3390/ma15238629

Pawlus P, Koszela W, Reizer R. Surface Texturing of Cylinder Liners: A Review. Materials. 2022; 15(23):8629. https://doi.org/10.3390/ma15238629

Chicago/Turabian StylePawlus, Pawel, Waldemar Koszela, and Rafal Reizer. 2022. "Surface Texturing of Cylinder Liners: A Review" Materials 15, no. 23: 8629. https://doi.org/10.3390/ma15238629

APA StylePawlus, P., Koszela, W., & Reizer, R. (2022). Surface Texturing of Cylinder Liners: A Review. Materials, 15(23), 8629. https://doi.org/10.3390/ma15238629