How Wood Fuels’ Quality Relates to the Standards: A Class-Modelling Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Physical Characterization of Wood Chips

2.2. Statistical Analysis

3. Results and Discussion

3.1. Changes of Wood Chips Quality over the Years and According to the Standards

3.2. Multivariate SIMCA models

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Energy Agency (IEA). CO2 Emissions from Fuel Combustion. 2016 Edition. Available online: http://www.iea.org/publications/freepublications/publication/KeyCO2EmissionsTrends.pdf (accessed on 18 July 2017).

- Bentley, R.W.; Mannan, S.A.; Wheeler, S.J. Assessing the date of the global oil peak: The need to use 2P reserves. Energy Policy 2007, 35, 6364–6382. [Google Scholar] [CrossRef]

- Pierobon, F.; Zanetti, M.; Grigolato, S.; Sgarbossa, A.; Anfodillo, T.; Cavalli, R. Life Cycle Environmental Impact of Firewood Production—A Case Study in Italy. Appl. Energy 2015, 150, 185–195. [Google Scholar] [CrossRef]

- Bacenetti, J.; Bergante, S.; Facciotto, G.; Fiala, M. Woody Biofuel Production from Short Rotation Coppice in Italy: Environmental-impact Assessment of Different Species and Crop Management. Biomass Bioenergy 2016, 94, 209–219. [Google Scholar] [CrossRef]

- Dunnet, A.J.; Shah, N. Prospects for bioenergy. J. Biobased Mater. Bioenergy 2007, 1, 289–300. [Google Scholar] [CrossRef]

- Murphy, F.; Devlin, G.; Kevin McDonnell, K. Forest Biomass Supply Chains in Ireland: A Life Cycle Assessment of GHG Emissions and Primary Energy Balances. Appl. Energy 2014, 116, 1–8. [Google Scholar] [CrossRef]

- Thornley, P.; Gilbert, P.; Shackley, S.; Hammond, J. Maximizing the Greenhouse Gas Reductions from Biomass: The Role of Life Cycle Assessment. Biomass Bioenergy 2015, 81, 35–43. [Google Scholar] [CrossRef]

- Proto, A.R.; Bacenetti, J.; Macrì, G.; Zimbalatti, G. Roundwood and Bioenergy Production from Forestry: Environmental Impact Assessment Considering Different Logging Systems. J. Clean. Prod. 2017, 165, 1485–1498. [Google Scholar] [CrossRef]

- Morrison, B.; Goden, J.S. Life Cycle Assessment of Co-firing Coal and Wood Pellets in the Southeastern United States. J. Clean. Prod. 2017, 150, 188–196. [Google Scholar] [CrossRef]

- Lovarelli, D.; Bacenetti, J. Bridging the Gap Between Reliable Data Collection and the Environmental Impact for Mechanised Field Operations. Biosyst. Eng. 2017, 160, 109–123. [Google Scholar] [CrossRef]

- EN ISO 16559:2014. Solid Biofuels—Terminology, Definitions and Descriptions; ISO: Geneva, Switzerland, 2014.

- Kuptz, D.; Hartmann, H. The Effect of Raw Material and Machine Setting on Chipping Performance and Fuel Quality—A German Case Study. Int. J. For. Eng. 2015, 26, 60–70. [Google Scholar] [CrossRef]

- Sgarbossa, A.; Costa, C.; Menesatti, P.; Antonucci, F.; Pallottino, F.; Zanetti, M.; Grigolato, S.; Cavalli, R. Colorimetric Patterns of Wood Pellets and Their Relations with Quality and Energy Parameters. Fuel 2014, 137, 70–76. [Google Scholar] [CrossRef]

- EN 14961-1:2010. Solid Biofuels. Fuel Specifications and Classes. Part 1: General Requirements; CEN: Brussels, Belgium, 2010.

- EN ISO 17225-1:2014. Solid Biofuel. Fuel Specifications and Classes. Part 1: General Requirements; ISO: Geneva, Switzerland, 2014.

- Duca, D.; Pizzi, A.; Mancini, M.; Rossini, G.; Mengarelli, C.; Ilari, A.; Lucesoli, G.; Toscano, G.; Pedretti, E.F. Fast Measurement by Infrared Spectroscopy as Support to Woody Biofuels Quality Determination. J. Agric. Eng. 2016, 47, 17–21. [Google Scholar] [CrossRef]

- Lehtikangas, P. Quality Properties of Pelletised Sawdust, Logging Residues and Bark. Biomass Bioenergy 2001, 20, 351–360. [Google Scholar] [CrossRef]

- Dias, J.; Costa, M.; Azevedo, J.L.T. Test of Small Domestic Boiler Using Different Pellets. Biomass Bioenergy 2004, 27, 531–539. [Google Scholar] [CrossRef]

- Jirjis, R. Effects of Particle Size and Pile Height on Storage and Fuel Quality of Comminuted Salix viminalis. Biomass Bioenergy 2005, 28, 193–201. [Google Scholar] [CrossRef]

- Werkelin, J.; Skrifvars, B.J.; Zevenhoven, M.; Holmbom, B.; Hupa, M. Chemical Forms of Ash-forming Elements in Woody Biomass Fuels. Fuel 2010, 89, 481–493. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbaş, A.; Hossain, M.S.; Mekhilef, S. A Review on Biomass as a Fuel for Boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Spinelli, R.; Nati, C.; Sozzi, L.; Magagnotti, N.; Picchi, G. Physical Characterization of Commercial Woodchips on the Italian Energy Market. Fuel 2011, 90, 2198–2202. [Google Scholar] [CrossRef]

- Abdallah, R.; Auchet, S.; Méausoone, P.J. Experimental Study about the Effects of Disc Chipper Settings on the Distribution of Wood Chip Size. Biomass Bioenergy 2011, 35, 843–852. [Google Scholar] [CrossRef]

- Serrano, C.; Portero, H.; Monedero, E. Pine Chips Combustion in a 50 kW Domestic Biomass Boiler. Fuel 2013, 111, 564–573. [Google Scholar] [CrossRef]

- Cerasino, L.; La Porta, N. Allocation of Five Macroelements and Quality of Fuels Derived from Norway Spruce Wood Obtained by Thinning Operations. Biomass Bioenergy 2014, 70, 553–556. [Google Scholar] [CrossRef]

- Fournel, S.; Palacios, J.H.; Morissette, R.; Villeneuve, J.; Godbout, S.; Heitz, M.; Savoie, P. Influence of Biomass Properties on Technical and Environmental Performance of a Multi-fuel Boiler During on-farm Combustion of Energy Crops. Appl. Energy 2015, 141, 247–259. [Google Scholar] [CrossRef]

- Manzone, M. Energy Consumption and CO2 Analysis of Different Types of Chippers Used in Wood Biomass Plantations. Appl. Energy 2015, 156, 686–692. [Google Scholar] [CrossRef]

- Krzyzaniak, M.; Stolarski, M.J.; Niksa, D.; Tworkowski, J.; Szczukowski, S. Effect of Storage Methods on Willow Chips Quality. Biomass Bioenergy 2016, 92, 61–69. [Google Scholar] [CrossRef]

- EN 14691-4:2011. Solid Biofuels. Fuel Specifications and Classes. Part 4: Wood Chips Non-Industrial Use; CEN: Brussels, Belgium, 2011.

- EN ISO 17225-4:2014. Fuel Specifications and Classes. Part 4: Graded Wood Chips; ISO: Geneva, Switzerland, 2014.

- Associazione Italiana Energie agroforestali (AIEL); Ente Nazionale Meccanizzazione Agricola (ENAMA). Manuale per la Certificazione di Qualità dei Biocombustibili Legnosi. Parte Speciale per la Certificazione del Cippato. 2015. Available online: http://www.enama.it/fileGallery/36/files/Handbook%20CIPPATO.pdf (accessed on 4 July 2017).

- Negrin, M. Qualità, tracciabilità e sostenibilità, i pilastri della certificazione Biomassplus per cippato, legna da ardere e bricchette. Agriforenergy 2015, 3, 27–29. [Google Scholar]

- Wold, S.; Sjöström, M. SIMCA, a method for analysing chemical data in terms of similarity and analogy. In Chenometrics: Theory and Application; Kowalsky, B.R., Ed.; American Chemical Society: Washington, DC, USA, 1977; p. 243. [Google Scholar]

- Vanden Branden, K.; Hubert, M. Robust Classification in High Dimensions Based on the SIMCA Method. Chemometr. Intell. Lab. Syst. 2005, 79, 10–21. [Google Scholar] [CrossRef]

- Casale, M.; Armanino, C.; Casolino, C.; Forina, M. Combining Information from Headspace Mass Spectrometry and Visible Spectroscopy in the Classification of the Ligurian Olive Oils. Anal. Chim. Acta 2007, 589, 89–95. [Google Scholar] [CrossRef] [PubMed]

- Hall, G.J.; Kenny, J.E. Estuarine Water Classification Using EEM Spectroscopy and PARAFAC SIMCA. Anal. Chim. Acta 2007, 581, 118–124. [Google Scholar] [CrossRef] [PubMed]

- Forina, M.; Oliveri, P.; Casale, M.; Lanteri, S. Multivariate Range Modeling, a New Technique for Multivariate Class Modeling: The Uncertainty of the Estimates of Sensitivity and Specificity. Anal. Chim. Acta 2008, 622, 85–93. [Google Scholar] [CrossRef] [PubMed]

- Forina, M.; Oliveri, P.; Lanteri, S.; Casale, M. Class-modeling Techniques, Classic and New, for Old and New Problems. Chemometr. Intell. Lab. Syst. 2008, 93, 132–148. [Google Scholar] [CrossRef]

- Aguzzi, J.; Costa, C.; Antonucci, F.; Company, J.B.; Menesatti, P.; Sarda, F. Influence of Diel Behaviour in the Morphology of Decapod Natantia. Biol. J. Linn. Soc. 2009, 96, 517–532. [Google Scholar] [CrossRef]

- Menesatti, P.; Antonucci, F.; Pallottino, F.; Bucarelli, F.M.; Costa, C. Spectrophotometric Qualification of Italian Pasta Produced by Traditional or Industrial Production Parameters. Food Bioprocess Tech. 2014, 7, 1364–1370. [Google Scholar] [CrossRef]

- EN 14778:2011. Solid Biofuel. Sampling; CEN: Brussels, Belgium, 2011.

- EN 14474-1:2009. Solid Biofuels. Determination of Moisture Content. Oven Dry Method. Part 1: Total Moisture—Reference Method; CEN: Brussels, Belgium, 2009.

- EN ISO 18134-1:2015. Solid Biofuels. Determination of Moisture Content. Oven Dry Method. Part 1: Total Moisture—Reference Method; ISO: Geneva, Switzerland, 2015.

- EN 15103:2010. Solid Biofuels. Determination of Bulk Density; CEN: Brussels, Belgium, 2010.

- EN ISO 17828:2015. Solid Biofuels. Determination of Bulk Density; ISO: Geneva, Switzerland, 2015.

- EN 15149-1: 2011. Solid Biofuels. Determination of Particle Size Distribution. Part 1: Oscillating Screen Method Using Sieve Apertures of 1 mm and above; CEN: Brussels, Belgium, 2011.

- EN ISO 17827-1:2016. Solid Biofuels. Determination of Particle Size Distribution for Uncompressed Fuels. Part 1: Oscillating Screen Method Using Sieves with Apertures of 3.15 mm and above; ISO: Geneva, Switzerland, 2016.

- EN 14775:2010. Solid Biofuels. Determination of Ash Content; CEN: Brussels, Belgium, 2010.

- EN ISO 18122:2015. Solid Biofuels. Determination of Ash Content; ISO: Geneva, Switzerland, 2015.

- EN 14918:2009. Solid Biofuels. Determination of Calorific Value; CEN: Brussels, Belgium, 2009.

- EN ISO 3310-2: 2013. Test Sieves. Technical Requirements and Testing. Part 2: Test Sieves of Perforated Metal Plate; ISO: Geneva, Switzerland, 2013.

- Kennard, R.W.; Stone, L.A. Computer Aided Design of Experiments. Technometrics 1969, 11, 137–148. [Google Scholar] [CrossRef]

- Sgarbossa, A.; Costa, C.; Menesatti, P.; Antonucci, F.; Pallottino, F.; Zanetti, M.; Grigolato, S.; Cavalli, R. A Multivariate SIMCA Index as Discriminant in Wood Pellet Quality Sssessment. Renew. Energy 2015, 76, 258–263. [Google Scholar] [CrossRef]

- Demirbaş, A. Biomass Resource Facilities and Biomass Conversion Processing for Fuels and Chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- McKendry, P. Energy Production from Biomass (part 1): Overview of Biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

| Wood Chips Properties | Standards | |

|---|---|---|

| European | International | |

| Moisture content (MC) | EN 14474-1 [42] | ISO 18134-1 [43] |

| Bulk density (BD) | EN 15103 [44] | ISO 17828 [45] |

| Particle size distribution (P) | EN 15149-1 [46] | ISO 17827-1 [47] |

| Ash content (A) | EN 14775 [48] | ISO 18122 [49] |

| High Heating Value as received (HHVar) | EN 14918 [50] | NA |

| High heating Value dry basis ash free (HHVdaf) | EN 14918 [50] | NA |

| Variable | Abbreviation | Unit | Limit Value for EN 14961-4 | Limit Values for ISO 17225-4 and Biomassplus (A1+) | |||||

|---|---|---|---|---|---|---|---|---|---|

| A1 | A2 | B | A1 | A2 | B | A1+ | |||

| Moisture Content | MC | % | ≤10 | ≤35 | * | ≤10 | ≤35 | ** | ≤10 |

| ≤25 | ≤25 | ||||||||

| Bulk Density | BD | kg m−3 | ≥150 ≥200 | ≥150 ≥200 | * | ≥150 ≥200 | ≥150 ≥200 | ** | ≥150 ≥200 ≥250 |

| Particle size distribution class | P | mm | P16A P16B P31, 5 P45 | P16A P16B P31, 5 P45 | P16A P16B P31, 5 P45 | P16S P31S P45S | P16S P31S P45S | P16S P31S P45S | P16S P31S P45S |

| Fines a | F | % | 12 to 8 | 12 to 8 | 12 to 8 | 15 to 10 | 15 to 10 | 15 to 10 | 6 to 5 |

| Ash on dry basis | A | % | ≤1.0 | ≤1.5 | ≤ 3.0 | ≤1.0 | ≤1.5 | ≤3.0 | ≤1.0 |

| High Heating Value as received | HHVar | MJ kg−1 | ≥13.0 | ≥11.0 | * | *** | *** | *** | ≥16.0 |

| High Heating Value b dry basis and ash free | HHVdaf | MJ kg−1 | * | * | * | * | * | * | * |

| Statistical Parameter | HHVar (MJ kg−1) | HHVdaf (MJ kg−1) | F (%) | MC (%) | BD (kg mc−1) | A (%) |

|---|---|---|---|---|---|---|

| mean | 13.66 | 19.89 | 5.31 | 23.33 | 237 | 1.30 |

| stdev | 2.63 | 0.60 | 5.56 | 12.22 | 49.46 | 1.70 |

| max | 20.09 | 23.91 | 49.40 | 65.45 | 430 | 23.07 |

| min | 4.88 | 17.90 | 0.05 | 2.68 | 100 | 0.10 |

| Quality Parameters | HHVar (MJ kg−1) | HHVdaf (MJ kg−1) | F (%) | MC (%) | BD (kg m−3) | A (%) |

|---|---|---|---|---|---|---|

| HHVar (MJ kg−1) | 1.00 | 0.15 | −0.21 | −0.98 | −0.64 | −0.26 |

| HHVdaf (MJ kg−1) | 0.15 | 1.00 | −0.18 | 0.02 | −0.08 | −0.41 |

| F (%) | −0.21 | −0.18 | 1.00 | 0.18 | 0.20 | 0.40 |

| MC (%) | −0.98 | 0.02 | 0.18 | 1.00 | 0.64 | 0.20 |

| BD (kg m−3) | −0.64 | −0.08 | 0.20 | 0.64 | 1.00 | 0.19 |

| Ash (%) | −0.26 | −0.41 | 0.40 | 0.20 | 0.19 | 1.00 |

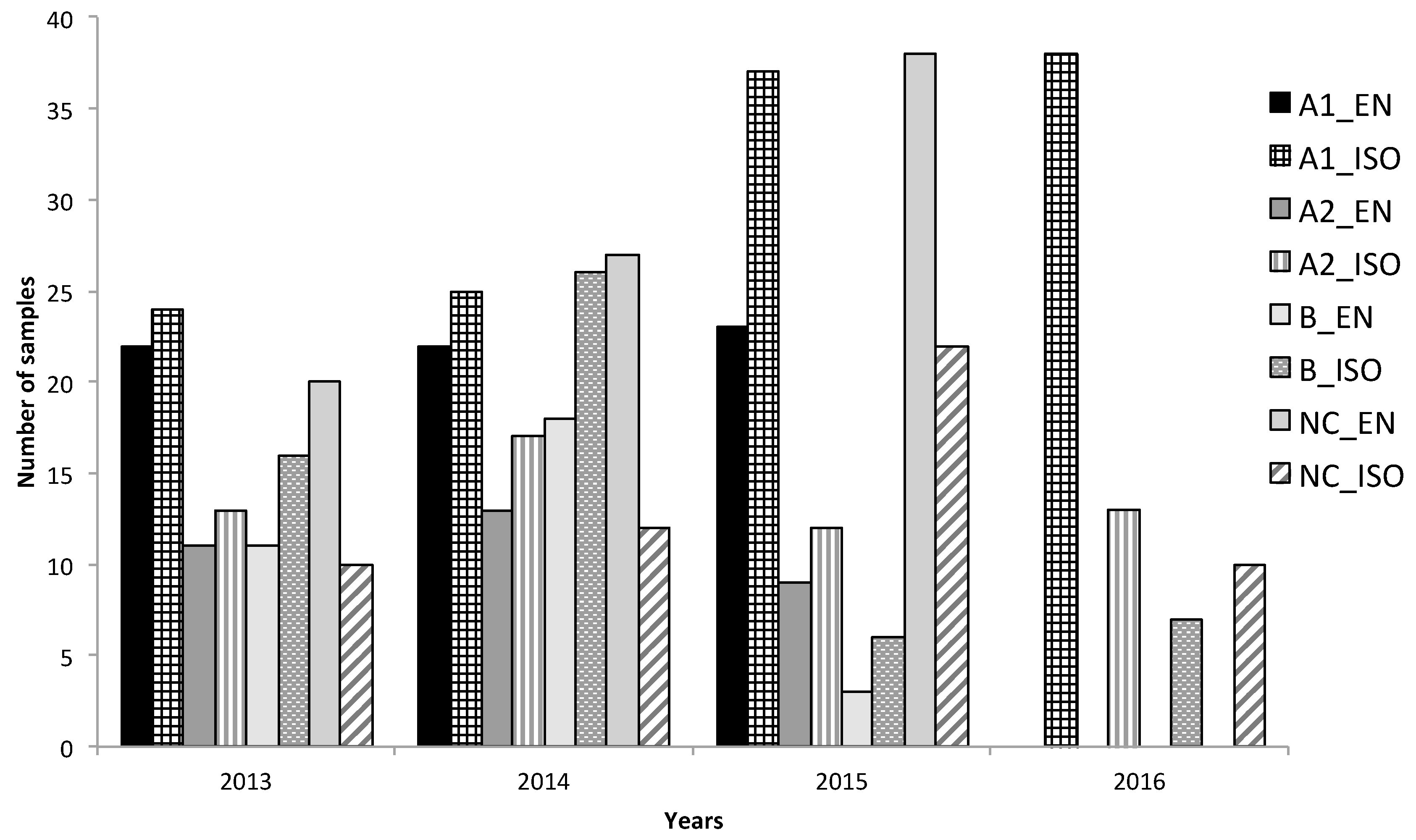

| Standard | Year | Samples | Quality Classes | Total | χ2 Values and Probabilities Threshold | ||||

|---|---|---|---|---|---|---|---|---|---|

| A1 | A2 | B1 | NC | ||||||

| EN 14961-4 | 2013 | Observed | 22 | 11 | 11 | 20 | 64 | ||

| Expected | 19.76 | 9.73 | 9.44 | 25.07 | - | ||||

| Freeman-Tukey transforms | 0.540 | 0.462 | 0.556 | −1.009 | - | ||||

| 2014 | Observed | 22 | 13 | 18 | 27 | 80 | |||

| Expected | 24.70 | 12.17 | 11.80 | 31.34 | - | 15.018 | |||

| Freeman-Tukey transforms | −0.504 | 0.300 | 1.660 | −0.753 | - | P(χ20.05,6) = | 0.020 | ||

| 2015 | Observed | 23 | 9 | 3 | 38 | 73 | |||

| Expected | 22.54 | 11.10 | 10.76 | 28.59 | - | ||||

| Freeman-Tukey transforms | 0.147 | −0.576 | −2.906 | 1.668 | - | ||||

| Total | 217 | ||||||||

| ISO 17225-4 | 2013 | Observed | 24 | 13 | 16 | 10 | 63 | ||

| Expected | 27.13 | 12.03 | 12.03 | 11.81 | - | ||||

| Freeman-Tukey transforms | −0.565 | 0.338 | 1.114 | −0.467 | - | ||||

| 2014 | Observed | 25 | 17 | 26 | 12 | 80 | |||

| Expected | 34.44 | 15.28 | 15.28 | 15.00 | - | ||||

| Freeman-Tukey transforms | −1.681 | 0.485 | 2.414 | −0.741 | - | ||||

| 2015 | Observed | 37 | 12 | 6 | 22 | 77 | |||

| Expected | 33.15 | 14.70 | 14.70 | 14.44 | - | 12.934 | |||

| Freeman-Tukey transforms | 0.688 | −0.665 | −2.639 | 1.821 | - | P(χ20.05,9) = | 0.166 | ||

| 2016 | Observed | 38 | 13 | 7 | 10 | 68 | |||

| Expected | 29.28 | 12.99 | 12.99 | 12.75 | - | ||||

| Freeman-Tukey transforms | 1.542 | 0.071 | −1.802 | −0.732 | - | ||||

| Total | 288 | ||||||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zanetti, M.; Costa, C.; Greco, R.; Grigolato, S.; Ottaviani Aalmo, G.; Cavalli, R. How Wood Fuels’ Quality Relates to the Standards: A Class-Modelling Approach. Energies 2017, 10, 1455. https://doi.org/10.3390/en10101455

Zanetti M, Costa C, Greco R, Grigolato S, Ottaviani Aalmo G, Cavalli R. How Wood Fuels’ Quality Relates to the Standards: A Class-Modelling Approach. Energies. 2017; 10(10):1455. https://doi.org/10.3390/en10101455

Chicago/Turabian StyleZanetti, Michela, Corrado Costa, Rosa Greco, Stefano Grigolato, Giovanna Ottaviani Aalmo, and Raffaele Cavalli. 2017. "How Wood Fuels’ Quality Relates to the Standards: A Class-Modelling Approach" Energies 10, no. 10: 1455. https://doi.org/10.3390/en10101455

APA StyleZanetti, M., Costa, C., Greco, R., Grigolato, S., Ottaviani Aalmo, G., & Cavalli, R. (2017). How Wood Fuels’ Quality Relates to the Standards: A Class-Modelling Approach. Energies, 10(10), 1455. https://doi.org/10.3390/en10101455