5.1. Open-Loop Step Responses at Different Plant Flue Gas Capacities

A power plant operated in a power market with a high penetration of renewables will most likely be operated in load-following mode [

7,

63]. This means that the power plant with PCC will be operated during a significant amount of its lifetime at part loads. In the case of a natural gas combined cycle power plant with post-combustion CO

2 capture it means that, at part-load operation, the gas turbine (GT) load will be reduced, generating a reduced mass flow rate of flue gas that would be conducted to the PCC unit. The purpose of this case study is to investigate the transient performance of the PCC pilot plant via dynamic process simulation by implementing open-loop step changes to the dynamic process model, and to compare the response of the plant at different part-load operating points, defined by different mass flow rates of flue gas to be treated. The analysis will assess the transient response of the plant to multiple and non-simultaneous step changes in three key inputs to the plant, namely (i) flue gas flow rate

Fgas (ii) solvent flow rate

Fsolv; and (iii) reboiler duty

, at different flue gas mass flow rate capacities of the plant. In order to define the part-load operating points, a decentralized control structure was utilized, in which reboiler duty was the manipulated variable to control stripper bottom temperature

Tstr to 120.9 °C, and the solvent flow rate was the manipulated variable to control CO

2 capture ratio

Cap to 0.85, as defined in Equation (13). When operating the plant at different flue gas mass flow rates, corresponding to 100%, 80% and 60% of nominal mass flow rate, this results in the three steady-state operating points presented in

Table 5 and

Table 6. The control structure is defined as control structure A in

Table 7.

The open-loop response was studied for the process variables (i) CO2 absorbed CO2,abs, in Equation (11); (ii) CO2 desorbed CO2,des (or Fprod); (iii) lean CO2 loading Ll at the inlet of the absorber; and (iv) rich CO2 loading Lr at the outlet of the absorber. To characterize the transient response, dead time θ, settling time ts, total stabilization time tt, and relative change (RC) were calculated:

Dead time θ: it is the time that takes before a process variable starts to change from the initial steady-state conditions as a response to the disturbance or input.

Settling time: The 10% settling time ts is the time taken from when the process variable begins to respond to the input change (dead time) until it remains within an error band described by 10% of the change in the process variable Δy and the final steady-state value of the process variable y∞, i.e.: −0.1 Δy + y∞ < y∞ < 0.1 Δy + y∞.

Total stabilization time: the sum of the dead time θ and the settling time ts is the resulting total stabilization time tt.

Relative change RC: Change in the observed process variable from initial steady-state conditions y0 to the final steady-state conditions; refer to Equation (14).

The detailed results of the process simulations are presented in

Table A1,

Table A2 and

Table A3 in

Appendix A.

Figure 8 shows the total stabilization times for the selected process variables at the three operating points, for step changes in solvent flow rate and reboiler duty. The responses for step changes in flue gas flow rate are not presented, since it is shown in

Table A1 that the relative change

RC in the output process variables is very small or negligible (

RC ranges from −0.81% to 0.21%). This can be explained by the highly diluted nature of the CO

2 in the flue gas (ca. 3.5 vol%). The results show the non-linear behavior of the plant, with different transient responses to step change set-point increase and decrease in key plant inputs, and at different loads of the plant.

Figure 8a shows the total stabilization time for lean CO

2 loading

Ll at the inlet of the absorber, which ranges from 25 to 45 min in all cases. The results show that the required time for total stabilization increases when the plant is operated at lower loads. As shown in

Appendix A (

Table A1 and

Table A2), a general trend was that the dead time

θ in the response of

Ll to step changes in reboiler duty and rich solvent mass flow rate increases at part-load points. This could be explained by the fact that at lower loads the solvent mass flow rate is smaller (refer to

Fsolv in

Table 6), resulting in longer residence times of the solvent through each equipment hold-up, piping, and recycle loop, this is, larger circulation time. This can also explain why dead times are generally larger when decreasing solvent flow rate than when increasing it; refer to

Table A2 in

Appendix A.

Figure 8b shows the total stabilization times for rich CO

2 loading

Lr at the outlet of the absorber sump. In this case, the stabilization times range from 60 to 450 min. It should be mentioned that the relative change

RC in rich CO

2 loading is also small or negligible for the disturbances studied (see

Appendix A), due to the fact that the solvent is operated close to its maximum loading capacity of 0.51 mol/mol CO

2 loading. The total stabilization times of the responses of rich CO

2 loading

Lr to disturbances in solvent flow rate and reboiler duty are larger at lower plant loads. At 60% flue gas capacity, a very slow response is found in

Lr when the solvent flow rate is decreased by a −10% step change; however, the relative change

RC of

Lr in this process variable is negligible for this plant disturbance; refer to

Table A2 in

Appendix A.

The total stabilization times for CO

2 absorbed

CO2,abs response to disturbances in rich solvent mass flow rate

Fsolv and reboiler duty

reb are shown in

Figure 8c. Total stabilization times range from 55 to 135 min. When the rich solvent mass flow rate is increased by 10%, this results in an increase in CO

2 absorbed with a relative change

RC of 0.35% to 4.18% (refer to

Table A2), due to the increased L/G ratio in the absorber column. However, since the reboiler duty is kept constant, the lean loading will increase (see

RC values of

Ll in

Table A2). Due to the residence time in the hot solvent piping, lean/rich heat exchanger and lean amine cooler of the recycle loop, it takes time for the solvent to be distributed towards the inlet of the absorber. A dead time in CO

2 lean loading

Ll at the inlet of the absorber of 11 to 22 min is observed (see

Table A2). This results in it taking a long time for the

CO2,abs to stabilize. When the rich solvent mass flow rate is decreased by 10%, it is observed that the CO

2 absorbed

CO2,abs decreases (relative change

RC between −3.14% and −5.59% in

Table A2). This is a result of the combination of the reduction in L/G ratio and the decrease in lean loading

Ll. CO2,abs requiring time for stabilization (stabilization time of 65 to 69 min). When reboiler duty

reb is increased by 10%, the lean loading

Ll is decreased significantly (

RC ranging from 6.75 to 8.59%), which results in increase of

CO2,abs (relative change

RC of 4.0% to 6.07%). The change in lean loading

Ll is observed at the absorber inlet with a dead time of 13 to 23 min (due to circulation time of the solvent in the recycle loop), and the total stabilization time for

CO2,abs for increase in reboiler duty ranges from 76 to 99 min. When reboiler duty

reb is decreased by 10%, the solvent lean loading increases (

RC of 6.63% to 8.46%), resulting in less CO

2 being absorbed. Relatively slower response in

CO2,abs to disturbances in solvent flow rate and reboiler duty were found when the PCC was operated at lower loads (55 to 99 min). An exception is found for the case when the solvent flow rate is increased at 100% mass flow rate operating conditions of the plant.

Figure 8d shows the stabilization times for CO

2 desorbed

CO2,des. For disturbances in rich solvent flow rate and reboiler duty, the desorbed CO

2 stabilizes slightly faster at lower loads (ranging from 2 to 100 min). In general, it was found that the desorption rate stabilized faster than the absorption rate

CO2,abs for the disturbances in solvent flow rate and reboiler duty applied to the process. When solvent flow rate is decreased, this results in smaller L/G ratio in the absorber column and less CO

2 being desorbed in the stripper column. Since the rich CO

2 loading does not change significantly (

RC in

Lr from 0 to 0.08%), the CO

2 desorbed

CO2,des stabilizes faster than the CO

2 absorbed (circulation time through the recycle loop is not affecting the stabilization of

CO2,des). When the reboiler duty

reb is increased by 10%, the relative change in CO

2 desorbed is large (4 to 6.07% in

Table A3), and with fast total stabilization time (2 to 3 min in

Table A3). A change in reboiler duty results in a fast response in the produced stripping vapors, which also results in a fast response in CO

2 product flow rate (CO

2 desorbed). The longest stabilization time for CO

2 desorbed is found when the solvent flow rate is increased at 100% operating conditions. It is notable that there is a big difference in total stabilization times for solvent flow rate increase at different loads of the plant.

5.2. Decentralized Control Structures

In this section, four control structures for the TCM DA amine plant were tested via dynamic process model simulations. The scenario considers realistic load changes on the power plant, by changing flue gas flow rate feed to the absorber column. From a control analysis perspective, flue gas flow rate change can be considered as a disturbance applied to the PCC process. A load change event would result in a significant change in flue gas flow rate, at a ramp rate given by GT operation and controls. Fast ramp rates are the goal of power plant operators, since a fast power plant can respond to the variability in costs in a day-ahead power market [

7,

64]. For a NGCC power plant, a fast ramp rate is considered to be around 10%/min GT load [

4,

65]. Two tests were considered and simulated:

Test 1: Ramping down flue gas flow rate from 100 to 70% in 3 min. The transient event starts at t0 = 0 min, and sufficient simulation time is allowed for the plant to reach the new steady-state.

Test 2: Flue gas flow rate is ramped up from 70 to 100% in 3 min. The transient event starts at t0 = 0 min, and sufficient simulation time is allowed for the plant to reach the new steady-state.

The supervisory or advanced control layer of the TCM DA amine plant has three main degrees of freedom, consisting of set point of flue gas volumetric flow rate

Fgas, set point of rich pump solvent flow rate

Fsolv, and steam flow rate to feed the reboiler duty

; refer to FT1, FT5 and FT4, respectively in

Figure 1. Under normal and stable operation of the pilot plant at TCM DA, such degrees of freedom are changed manually by the operators to bring the plant to different operating conditions. If flue gas flow rate is considered to be a disturbance, there are two degrees of freedom left for operation. Note that here we do not consider the degrees of freedom available to the operators in the stabilizing or regulatory control layer, or for other auxiliary operations of the plant, or start-up procedures. Several studies in the literature suggest that keeping the capture ratio

Cap and a temperature in the stripper column constant can lead to efficient operation of the process for varying loads of the PCC absorber-desorber process [

13]. In this analysis, four control structures were tested, as presented in

Table 7. All the feedback control loops are PI controllers, and were tuned with the simple internal model control (SIMC) tuning rules [

66].

Control structure A uses

Fsolv to control capture ratio at the top of the absorber

Cap defined by Equation (13) to the set point of 0.85, and reboiler duty

reb to control the solvent temperature at the stripper bottom

Tstr to the set point of 120.9 °C. This control structure has been previously proposed in the literature in different studies including [

14,

16], where it shows a fast response and the capability to reject disturbances.

Control structure B uses

Fsolv to control the solvent temperature at the stripper bottom

Tstr to the set point of 120.9 °C, and reboiler duty

reb to control capture ratio at the top of the absorber

Cap to the set point of 0.85. Note that changes in reboiler duty result in a big change in solvent lean CO

2 loading (large relative change

RC; see

Appendix A). A similar version was suggested by Panahi and Skogestad [

14], where it was found that this control structure showed similar dynamic behavior, in response to disturbances in flue gas flow rate, compared with a model predictive control scheme (MPC).

Control structure C utilizes solvent flow rate

Fsolv to control the mass-based L/G ratio in the absorber column at the same value as that in the close-to-design-point operating conditions. This control structure has been studied previously in [

12,

15]. This control loop is implemented via ratio control. In addition, reboiler duty is manipulated to control

Tstr to 120.9 °C. The control structure leads to different final steady-state operating conditions when ramping down the plant load than the other three alternatives.

Control structure D is a modification of control structure A. In this control structure, the solvent flow rate set point is changed via a feed forward (FF) action to control the capture ratio Cap at 0.85; in addition, the stripper bottom temperature is controlled by manipulating the reboiler duty. The feed forward controller is implemented by a set-point ramp change in the solvent flow rate with the same total duration as the flue gas flow rate ramp change, to the final value that gives a Cap of 0.85 under final steady-state conditions.

Figure 9 shows the simulated time input trajectories during the test with flue gas flow rate reduction. The manipulated variables

Fsolv and

are shown for the different control structures evaluated.

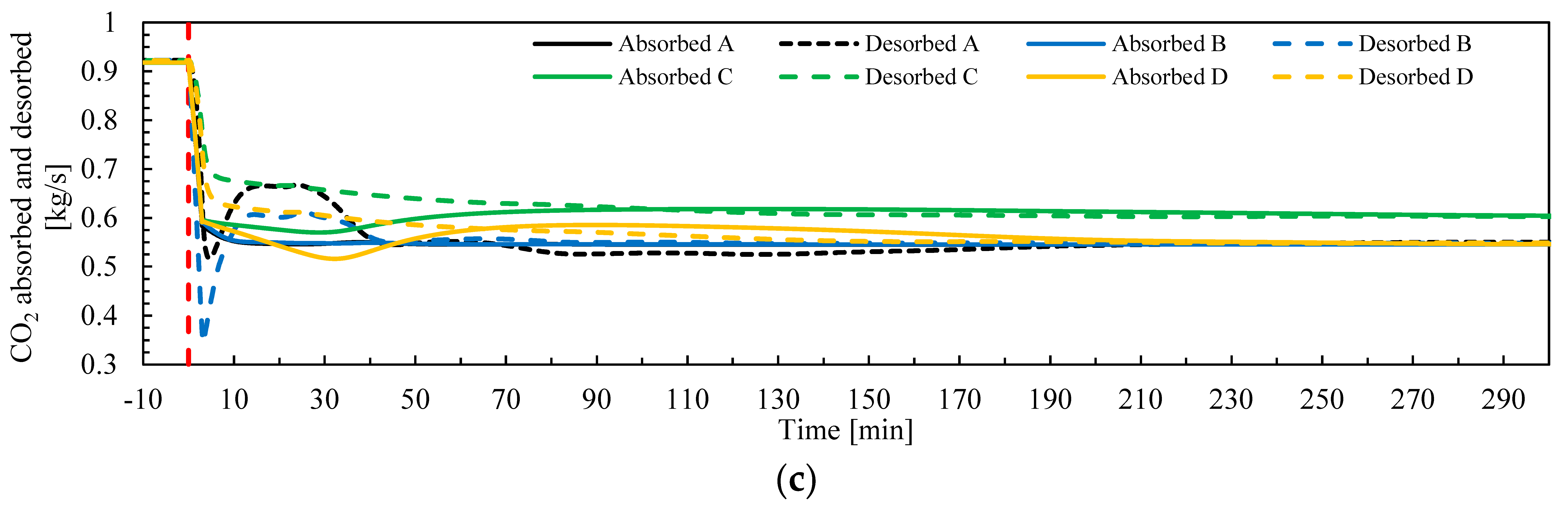

Figure 10 shows the output trajectories of CO

2 capture ratio

Cap, desorption ratio

Des, CO

2 absorbed and CO

2 desorbed for the transient tests of flue gas flow rate reduction.

Figure 11 shows the trajectories of lean loading

Ll and stripper bottom solvent temperature

Tstr for flue gas flow rate reduction. In addition,

Figure 12 shows the simulated time input trajectories during the test with flue gas flow rate increase.

Figure 13 shows the output trajectories of CO

2 capture ratio

Cap, desorption ratio

Des, CO

2 absorbed and CO

2 desorbed for the transient tests of flue gas flow rate increase, and

Figure 14 shows the trajectories of lean loading

Ll and stripper bottom solvent temperature

Tstr for flue gas flow rate increase. In order to compare the different control structure performances during transient load change, the total stabilization times of the selected process variables are shown in

Table 8. These will indicate how fast the plant achieves stabilization of the different floating (not controlled) process variables when moving from one operating condition to the next one. In addition, three transient performance indicators have been considered and presented in

Table 9. Note that, for this analysis auxiliary consumptions of the plant are not considered.

Accumulated reboiler energy input Qreb (MJ): see Equation (15). This is calculated by integration of the

trajectory under the transient event, from the initial time

t0 = 0 min to the final time

tf = 480 min (8 h). The final time was defined to ensure that the plant was already under steady-state conditions at the final operating point. This value

Qreb represents the main energy consumption of the process during the transient event of load change. In addition, the consumption of an ideal static plant is included for comparison (see

Table 9). The ideal static plant is assumed to change from initial to the final steady-state operating conditions instantaneously at time

t0, and would operate until

tf. The static plant value represents the minimum value when ramping down and a maximum value when ramping up.

Accumulated CO2 emitted CO2,em (tons): see Equation (16). This is calculated by integration of the

trajectory under the transient event, from the initial time

t0 = 0 min to the final time

tf = 480 min; this represents the CO

2 emitted at the absorber stack. The final time was defined to ensure that the plant was already under steady-state conditions at the final operating point. This measure represents the CO

2 emitted during the transient event of load change. For comparison, the CO

2 emitted by an ideal static plant is calculated (considered as the maximum value when ramping down and a minimum value when ramping up), shown in

Table 9.

Accumulated CO2 captured CO2,cap (tons): see Equation (17). This is calculated by integration of the CO

2 absorbed

CO2,abs trajectory (Equation (12)) under the transient event, from the initial time

t0 = 0 min to the final time

tf = 480 min. The final time was defined to ensure that the plant was already under steady-state conditions at the final operating point. This measure represents the CO

2 captured during the transient event of load change. For comparison, the CO

2 captured by an ideal static plant is calculated (considered as the minimum value when ramping down and a maximum value when ramping up), shown in

Table 9.

Figure 10 shows that the CO

2 capture ratio

Cap had similar trajectories for control structures A and B during Test 1 (flue gas ramp-down), and that

Cap reached stabilization conditions faster (20–50 min) than control structures C and D (around 270 min).

Cap had also larger excursions from the set point than when control structures A and B are utilized. The same trends are found for Test 2 with flue gas flow rate ramp-up (

Figure 13). When ramping up, control structures C and D stabilize faster (around 160 min) than when ramping down. This showed that the utilization of close-loop feedback control (structures A and B) allows shorter stabilization times to be reached for the controlled variable CO

2 capture ratio

Cap. The desorption ratio

Des trajectories in

Figure 10 show that the plant requires the shortest stabilization time for this process variable when employing control structure B (around 60 min), followed by control structure A and C (around 200 min). This can be explained by the fact that for a change in reboiler duty the response of CO

2 desorbed has a fast total stabilization time and a large static relative change

RC (where

RC ranges from 4 to 6.29% and total stabilization time range from 2.2 to 3.5 min for a +10% step in reboiler duty); refer to

Table A3. When it comes to the stabilization time required for

Des for Test 1, structures C and D presented a poorer performance as the trajectories for

Cap and

Des deviate from the set point significantly. For control structure A,

Des showed slow performance for Test 2 (around 210 min total stabilization time) with significant oscillations around set point; refer to

Figure 13.

When ramping down the plant, CO

2 absorbed and CO

2 desorbed require similar stabilization times for control structures A and B (around 3 min for

CO2,abs and 36 min for

CO2,des), while the control structures C and D require longer stabilization times for CO

2 desorbed (around 50 to 57 min); refer to

Table 8. The trajectory of CO

2 lean loading again shows shorter stabilization time for control structure B. This can be explained by the large static relative change

RC of the response of CO

2 lean loading to changes in reboiler duty (where

RC ranges from −6.29% to −4.97% and total stabilization time range from 22.7 to 39.2 min for a +10% step in reboiler duty); refer to

Table A3. This contributes to the tight control of CO

2 capture ratio

Cap achieved by control structure B, since the CO

2 lean loading

Ll is a key process variable that connects the operation of the stripper and the absorber columns via the recycle loop. In addition, control structure B shows the shortest stabilization times and smaller excursions of the stripper bottom temperature

Tstr (around 15 to 30 min), in

Figure 11 and

Figure 14.

When the plant load is ramped up from 70 to 100% (Test 2), the control structure B in general showed a faster dynamic performance with significantly shorter stabilization times required for the floating process variables considered (5.2 min for

CO2,abs, 27.5 min for

CO2,des and 46.7 min for

Ll), see

Table 9; followed by C, D and A. Note that control structure B presented a faster dynamic performance towards stabilization while ramping up (

Ll stabilizes in 46.7 min) than when ramping down the process (

Ll stabilizes in 68.2 min). Control structures A, C and D required shorter stabilization times for CO

2 absorption and CO

2 desorption when ramping down the process load, while CO

2 lean loading stabilized faster when ramping up the plant load; refer to the stabilization time values in

Table 9. When the plant is operated under control structure C, the optimum solvent flow rate

Fsolv and lean loading

Ll are not reached at the 70% absorber capacity steady-state operating conditions; refer to time >250 min in

Figure 9a and

Figure 11a, and time <0 min in

Figure 12a and

Figure 14a. This leads to a higher

Cap than specified (refer time t > 290 min in

Figure 10a and time t < 0 min in

Figure 13a), and therefore higher reboiler duty (time t > 290 min in

Figure 9b and time t < 0 min in

Figure 12b), even though the stripper bottom temperature

Tstr criterion is satisfied.

During the ramp-down transient event of the plant (i.e., period of 8 h from the time change was implemented), the least energy-intensive performance measured by

Qreb in

Table 9 was observed for control structure B. In addition, this structure shows the largest CO

2 emissions during the transient event, albeit still lower than the ideal static plant. The fast stabilization time of the plant process variables achieved by control structure B provides a transient performance that is the closest to the ideal static plant. Control structures C and D showed the largest CO

2 captured during the transient event. However, when ramping down the plant load, this means that the plant is emitting less CO

2 during the transient event with control structures A, B, C and D than that established by the operational objective and represented by the ideal static plant case. Consequently, when ramping down the plant load, CO

2 emissions will always be lower than those of the equivalent ideal static plant. In addition, the plant is capturing more CO

2 than the ideal static plant.

Figure 10a shows how there are periods of time in which the capture ratio

Cap is above the target of 0.85, leading to more CO

2 being captured than the ideal static plant during the transient event. Control structures A and B showed the largest CO

2 emitted when compared with the ideal static case. Despite control structure A presenting a similar amount of CO

2 emitted during the transient event, it requires a larger amount of energy input during this period than control structure B. Therefore, control structure B shows the best performance in terms of energy consumption and CO

2 emissions during the transient load change event of ramping down the PCC plant load. When ramping up the plant load the most energy-intensive control structure is control structure B. However CO

2 emissions are the lowest, being closer to the minimum established by the static plant. This means that, when ramping up the plant load, CO

2 emissions will always be higher than those of the equivalent ideal static plant. While control structure D is the least energy-intensive process during the transient event of load change increase, it is the control structure with the largest CO

2 emissions during this transient event.