Abstract

As one of the most widely used units in water cooling systems, the closed wet cooling towers (CWCTs) have two typical counter-flow constructions, in which the spray water flows from the top to the bottom, and the moist air and cooling water flow in the opposite direction vertically (parallel) or horizontally (cross), respectively. This study aims to present a simplified calculation method for conveniently and accurately analyzing the thermal performance of the two types of counter-flow CWCTs, viz. the parallel counter-flow CWCT (PCFCWCT) and the cross counter-flow CWCT (CCFCWCT). A simplified cooling capacity model that just includes two characteristic parameters is developed. The Levenberg–Marquardt method is employed to determine the model parameters by curve fitting of experimental data. Based on the proposed model, the predicted outlet temperatures of the process water are compared with the measurements of a PCFCWCT and a CCFCWCT, respectively, reported in the literature. The results indicate that the predicted values agree well with the experimental data in previous studies. The maximum absolute errors in predicting the process water outlet temperatures are 0.20 and 0.24 °C for the PCFCWCT and CCFCWCT, respectively. These results indicate that the simplified method is reliable for performance prediction of counter-flow CWCTs. Although the flow patterns of the two towers are different, the variation trends of thermal performance are similar to each other under various operating conditions. The inlet air wet-bulb temperature, inlet cooling water temperature, air flow rate, and cooling water flow rate are crucial for determining the cooling capacity of a counter-flow CWCT, while the cooling tower effectiveness is mainly determined by the flow rates of air and cooling water. Compared with the CCFCWCT, the PCFCWCT is much more applicable in a large-scale cooling water system, and the superiority would be amplified when the scale of water distribution system increases. Without multiple iterative calculations and extensive experimental data, the simplified method could be used to effectively analyze the thermal performance of counter-flow CWCTs in operation. It is useful for optimization operation of counter-flow CWCTs such that to improve the energy efficiency of the overall cooling water system.

1. Introduction

As one of the commonly used units in cooling water systems, the closed wet cooling tower (CWCT) is essentially combining a closed-circuit heat exchanger (usually tubular serpentine coil bundles) and a direct-contact evaporative cooling tower into a compact device [1]. The process water inside the serpentine tubes is indirectly cooled by evaporative heat and mass transfer process between the spray water and the moist air flowing outside the tubes. In two typical CWCTs with different counter-flow constructions, the spray water flows from the top to the bottom, and the moist air and cooling water flow in the opposite direction vertically (parallel) or horizontally (cross), respectively. As compared to an open cooling tower, a CWCT is usually more expensive because the tubular heat exchangers consume a substantial amount of metallic materials [2]. However, the integration of CWCT into chillers can keep the cooling water clean and make the chiller setup more convenient [3]. Meanwhile, CWCT has been increasingly applied in the refrigeration and air conditioning industry in recent years due to its better thermal performance and lower energy consumption [4].

To predict and/or evaluate the cooling tower performance, many numerical and analytical models have been developed on the basis of heat and mass transfer theory with suitable assumptions. Xia et al. [2] reported a novel designed CWCT and developed a one-dimensional transient distributed-parameter model to evaluate the cooling tower performance under different operating conditions. Khan et al. [5] used a detailed model to investigate the characteristics of a counter-flow wet cooling tower and reported the cooling tower performance variation along the height of the tower. Hajidavalloo et al. [6] adopted a conventional mathematical model to predict the thermal behavior of an existing cross-flow tower under various wet-bulb temperatures. Hasan and Sirén [7] presented theoretical analysis and computational modeling of CWCTs. A difference of less than 1% was found between the model output and the design data in terms of power consumption. Moreover, Computational Fluid Dynamics (CFD) is a suitable tool for performance prediction of CWCTs. For example, Sarker et al. [8] used the commercial CFD software FLUENT to devise the most suitable experimental condition based on the optimum performance of a hybrid closed circuit cooling tower with the bare-type copper coil. Gan et al. [9] adopted the CFD technology for optimizing the design and operation of CWCTs for chilled ceilings. Kang and Strand [10] studied the main physical phenomenon of simultaneous heat and mass transfer within passive downdraft evaporative cooling towers with the FLUENT platform. However, the detailed models usually needed computation codes and high-performance computers [9]. Meanwhile, these models and codes required a certain degree of specialization and consumed considerable computing time due to iterative computation [11].

As an alternative to theoretical and analytical modeling methods, the artificial neural network (ANN) approach can be applied and achieve high accuracy and reliability for the performance prediction of a cooling tower when sufficient experimental data is available. For example, Wu, et al. [12] developed a three-layer (5-11-9) ANN model based on back-propagation (BP) algorithm to effectively predict the performance characteristics of a reversible used cooling tower for heat pump device in winter. Gao, et al. [13] proposed a three-layer (5-6-3) BP network model to predict the thermal performance of natural draft counter-flow wet cooling tower under cross-wind conditions. The combination of wavelet analysis and neural network can also be used effectively for predicting the performance characteristics of a shower cooling tower under various operating conditions [14]. However, the results predicted by ANN models could not provide any physical knowledge for [15]. Meanwhile, the extensive field experimental works, which were carried out on a real size cooling tower to gather enough data for training and verifying the ANN model, were costly and time-consuming.

Although mathematical modeling and ANN approach are quite popular in the research field of cooling towers, it is never an easy job to accurately and conveniently predict and/or evaluate the cooling tower performance with several experimental data inputs. Therefore, a simplified method without iterative computation and extensive experiment data inputs is urgently needed because the simplified model based on an overall approach provides as good or even better results as those based on finite differences methods [11]. The previous study showed that a mechanical cooling tower model [16], in which three characteristic parameters were determined by the Levenberg–Marquardt method, could be simply used to predict the real-time operating performance of an open cooling tower when the operating point condition changed. Based on this mathematical model, the operating performance of counter-flow wet cooling towers can be optimized, so as to minimize the total energy consumption of the condenser water loop in a centralized heating, ventilation, and air conditioning (HVAC) system [17]. As for a simple model of CWCT, Stabat and Marchio [18] presented a cooling capacity model for analyzing the combined heat and mass transfer in indirect cooling towers on the basis of Merkel’s theory, which assumed that the Lewis number was equal to unity and the losses due to water evaporation were negligible. The results showed that a good agreement between the model and the manufacturers’ data was achieved for a wide range of operation conditions. However, there are still two major problems in engineering applications. The first one is that the cooling capacity model is not suitable for predicting the heat rejection rate of a counter-flow CWCT because it introduces two pairs of input–output variables, including the inlet and outlet wet-bulb temperatures of moist air, and the inlet and outlet temperatures of hot water. Meanwhile, the fictitious specific heat of the saturated air and the water viscosity in the model can not be determined directly due to the lack of corresponding theoretical or empirical formulas. Therefore, under some suitable assumptions and reasonable approximations, the cooling capacity model can be further simplified for engineering application in predicting the performance of counter-flow CWCTs. The other problem is that the model should be validated by real-time experimental data of CWCTs rather than the data from manufacturers.

This study aims to develop a simplified calculation method for predicting the performance of counter-flow CWCTs accurately and conveniently. Under suitable assumptions, a simplified cooling capacity model with two characteristic parameters inputting is derived by making some necessary approximations to a combination of theoretical and empirical formulas. The Levenberg–Marquardt method is employed to determine the two parameters via curve fitting of the real-time experiment data. A parallel counter-flow CWCT (PCFCWCT) and a cross counter-flow CWCT (CCFCWCT) are selected as the study objects in this work. Based on the proposed model and new parameters, the predicted outlet temperatures of process water are compared with the experimental data presented in the previous literature. Then, the effects of the operating conditions on the two performance indicators, viz. cooling capacity and cooling tower effectiveness, of both towers are analyzed.

2. Methodology and Modeling

2.1. Description of the Two Typical Counter-Flow CWCTs

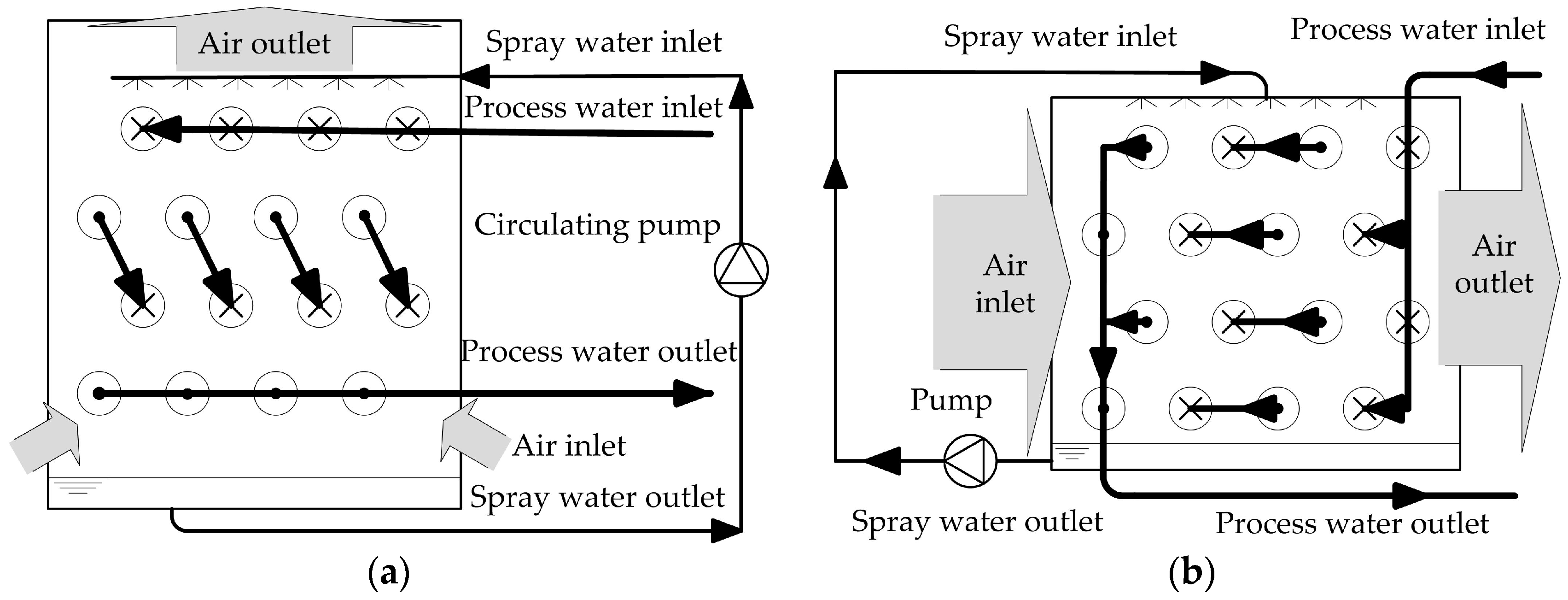

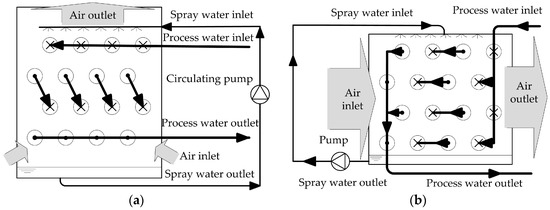

For a typical CWCT unit, a heat exchanger is incorporated into a conventional direct contact evaporative cooling tower, in which three working fluids conduct heat and mass transfer. Process water runs inside the serpentine tubes, while moist air and spray water flow outside the tube bundles. According to the situation of relative movement between air and process water, cooling towers can be categorized as cross-flow and counter-flow [19]. In this study, two typical counter-flow CWCTs with distinct flow constructions are selected as the research objects. As shown in Figure 1a, a force-draught CWCT with parallel counter-flow construction is designated as PCFCWCT in this study. As the best one-dimensional flow pattern of CWCT [20], the majority of flow patterns [7,9,11,18,21,22,23,24] were that cooling water and spray water parallel flowed from the top to the bottom, while air flowed in the opposite direction. As shown in Figure 1b, the other one with cross counter-flow construction is designated as CCFCWCT, in which spray water flows from the top to the bottom, while process water and counter air flow in the horizontal direction.

Figure 1.

Schematic diagrams of the two typical counter-flow CWCTs with different constructions: (a) parallel counter-flow (PCFCWCT) and (b) cross counter-flow (CCFCWCT).

2.2. Assumptions and Simplifications

The major assumptions to derive the simplified modeling equations are summarized as follows:

- (1)

- The heat and mass transfer processes occur under steady-state conditions [23,25].

- (2)

- Water and air specific heats are constant [2,23,25,26,27]. The heat and mass transfer coefficients are constant [25].

- (3)

- Heat transfer from the tower fans to air or water streams is negligible [26], and the heat exchange between the wall of CWCT and the surroundings is negligible [2,3,25,26].

- (4)

- The spray water flow rate is sufficient to wet all surfaces of the tubes [2,3,4,7]. Mass of spray water taken away by the airflow per unit time is much smaller compared to the mass flow rate of spray water. Therefore, the mass flow rate of the spray water is constant [3], which means the reduction of the water flow rate by evaporation (generally 1%–3% of the water mass flow rate) is neglected in mass balance [6,16,28]. The spray water outlet temperature is equal to the spray water inlet temperature because the heat exchange between the circulating pipe and the surroundings is negligible.

- (5)

- Process water and air are in counter-flow [23].

Before modeling the cooling tower performance, we make approximations to the fictitious specific heat of the saturated air and the dynamic viscosity coefficient of process water as follows based on the existing empirical formulas. Through an analogy to the specific heat of water, the fictitious specific heat of the saturated air is defined as the ratio of the enthalpy difference to the temperature difference between the inlet and outlet wet-bulb temperatures, which is given as [18]:

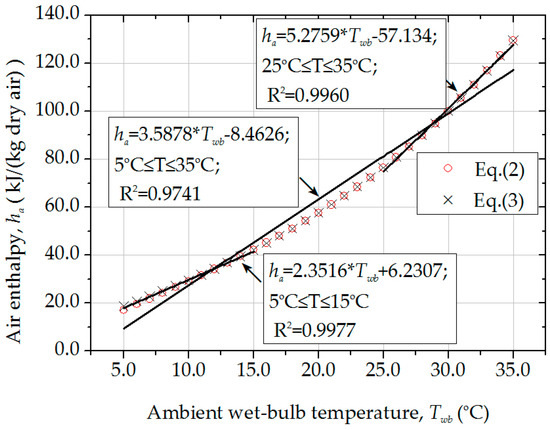

The enthalpy of the saturated air is a single function of the wet-bulb temperature and can be determined by the following equation [29]:

The enthalpy of the saturated air can also be calculated by an empirical correlation [30] as follows:

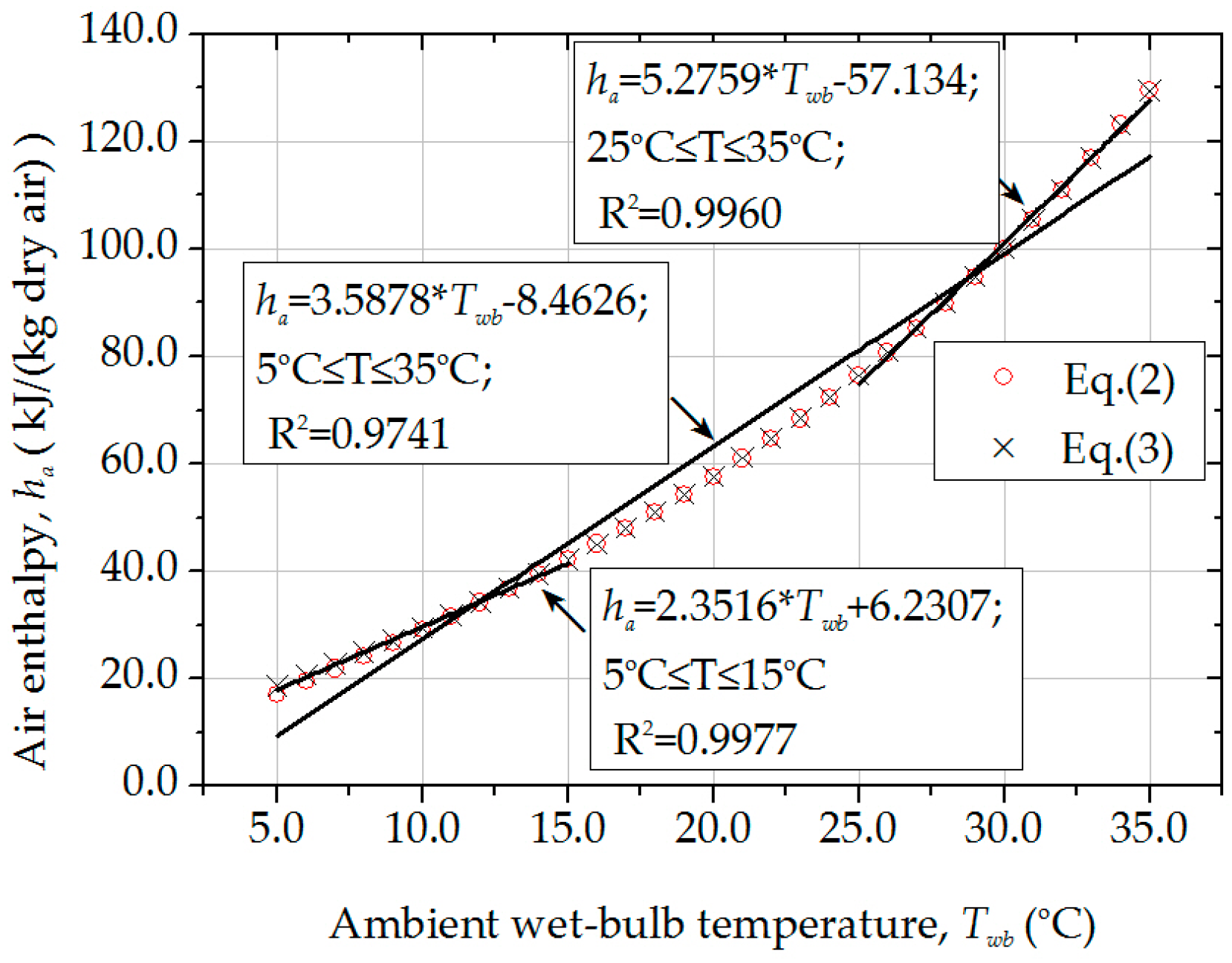

The saturated enthalpy is approximately linear with respect to wet-bulb temperature [16]. As shown in Figure 2, the fictitious specific heat of air is almost constant, 3.5878 kJ/(kg·°C), when the wet-bulb temperature ranges from 5 to 35 °C. In contrast, the other two fictitious specific heats, 2.3516 kJ/(kg·°C) and 5.2759 kJ/(kg·°C), are also assigned to the saturated air with the temperature ranging from 5 to 15 °C and 25 to 35 °C, respectively.

Figure 2.

Air enthalpy vs. wet-bulb temperature.

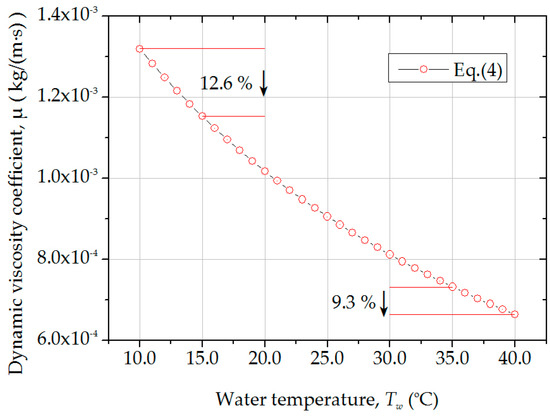

The correlation between the dynamic viscosity and the temperature of water can be calculated by the following empirical formula [31]:

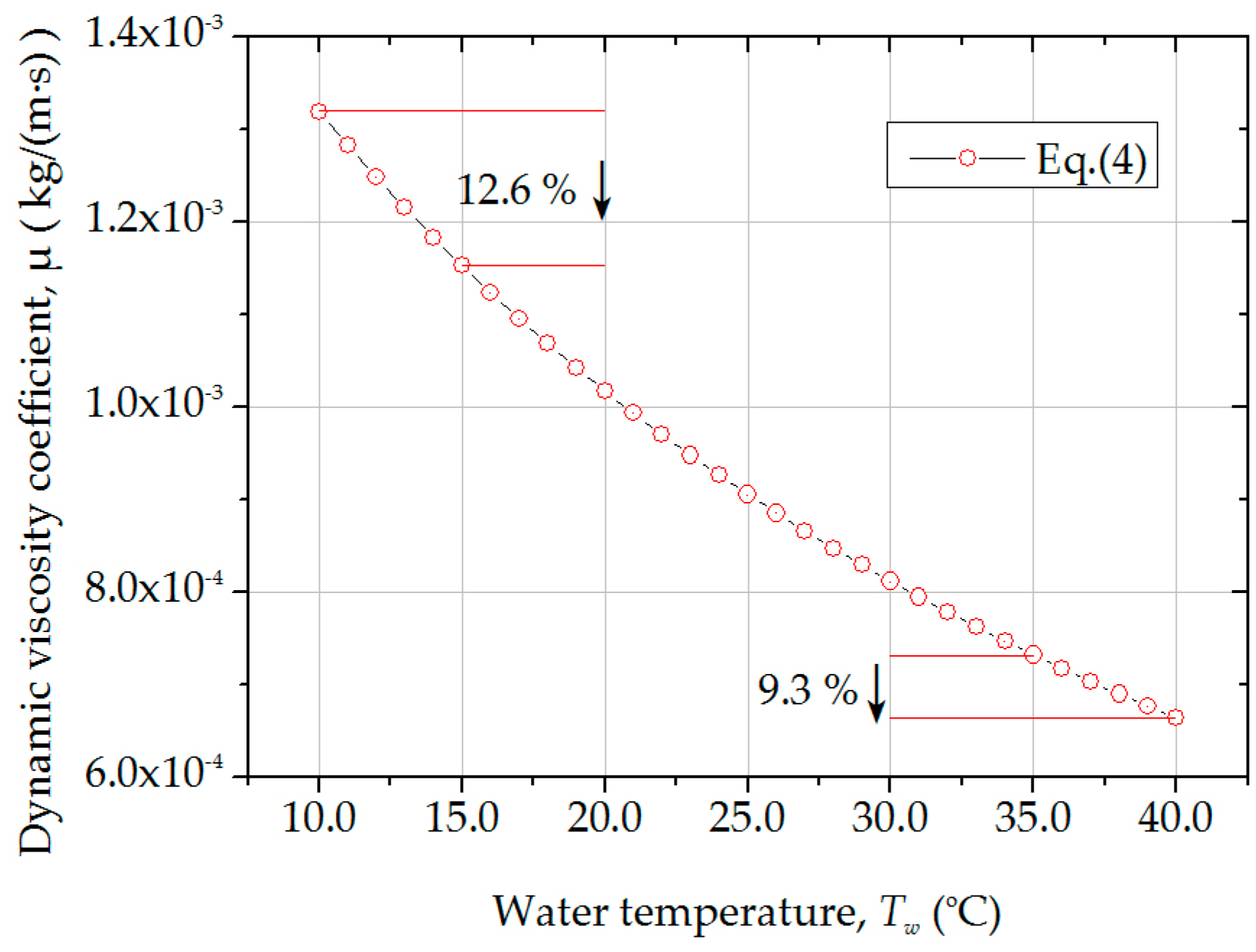

The design temperature difference between the inlet and outlet cooling water of CWCTs is usually 5 °C for residential and commercial buildings. As shown in Figure 3, the relative errors of water viscosity coefficient within the design temperature difference is less than 12.6% when the outlet temperature of process water is 10 °C. Therefore, the viscosity coefficient at the inlet temperature of process water can be used as a reliable substitute representation from the inlet to the outlet temperature of process water, which can meet the accuracy of the viscosity coefficient.

Figure 3.

Water dynamic viscosity coefficient vs. water temperature.

2.3. Thermal Performance Analysis

Under the aforementioned assumptions for a steady state, steady-flow processes, the cooling capacity and the cooling tower effectiveness are adopted as indicators to evaluate the performance of counter-flow CWCTs and the calculation and analysis are described as follows. According to the Merkel approach, the cooling capacity of a CWCT is expressed as follows [22,32]:

The process water outlet temperature of a counter-flow CWCT can be determined by rewriting Equation (5) as:

Based on the above assumptions, the air side energy balance equation can be determined approximately by [8]:

When 12 ≤ dext ≤ 40 mm, 0.7 < Γ/dext ≤ 5.5 kg/(m2·s), 2500 ≤ Rea ≤ 14,000, 50 ≤ Resw ≤ 240, 2500 ≤ Rew ≤ 10,000 and 3 ≤ Prw ≤ 8 (15 ≤ Tw,i ≤ 60 °C), the cooling capacity model developed for counter-flow CWCTs can also be expressed as [18]:

where UA and ΔTLM, can be calculated by the following equations:

where βext is a constant that depends on the thermal properties of air and the coil’s geometry, and βint is a constant that is influenced by the coil’s geometry and the constant water-properties.

When ∆Tmax/∆Tmin < 2, the logarithmic mean temperature difference can be simplified as follows [33]:

Substituting Equations (3)–(11) into Equation (1), the simplified cooling capacity model for counter-flow CWCTs is obtained:

Based on well-established experimental data under quasi-steady-state conditions, the two characteristic parameters, βext and βint, can be determined by curve fitting of experimental data with the Levenberg–Marquardt method using the Statistic Package for Social Science (SPSS) tool.

Substituting Equation (12) into Equation (6), the predicted outlet temperature of process water is obtained:

By analogy to the effectiveness of a classical heat exchanger, the cooling tower effectiveness, which is defined as the ratio of actual temperature drop to the maximum temperature drop of the inlet process water, is expressed as follows:

Substituting Equation (13) into Equation (14), the cooling tower effectiveness is determined as follows:

3. Results and Discussion

3.1. Model Validation

Model validation was carried out for predicting the performance of a PCFCWCT [34] and a CCFCWCT [35]. Moreover, the predicted outlet temperatures of process water were compared with the measurements for both towers.

3.1.1. Validation with a Parallel Counter-Flow CWCT

The PCFCWCT [34] selected in this study was a forced-draught cooling tower with a dimension of 1.2 m × 0.6 m × 1.55 m, in which the smooth circular tubes were used as a heat exchanger. Its performance was tested at the University of Porto. The key experimental data of the cooling tower are listed in Table 1. The mass flow rates of spray water were 1.23 and 1.38 kg/s, respectively. The spray water temperature ranged from 13.6 to 18.1 °C. Table 1 presents a comparison between the predicted thermal performance and the measurements for the tower. As shown in Table 1, as we assigned three different values, viz. 2.3516, 3.5878, and 5.2759, to the fictitious specific heat of air, two new parameters (βext, βint) of this model were determined as the corresponding values, viz. (0.803, 0.565), (0.416, 0.697), and (0.283, 0.697), respectively. In these scenarios, the predicted outlet temperatures of process water agreed well with the measurements. The maximum temperature difference was only 0.20 °C. It means that the model can be used to forecast the outlet temperature of the process water under different operating conditions for counter-flow CWCTs.

Table 1.

Comparison between the predicted thermal performance and the measurements of the PCFCWCT.

3.1.2. Validation with a Cross Counter-Flow CWCT

In addition to the example of a PCFCWCT, the simplified model with new input parameters was also verified by a CCFCWCT, which was reported in previous literature [35]. This tower was a forced-draught CWCT with dimensions of 0.57 m × 0.31 m × 0.18 m, in which the fin-tube structure was employed to expand the heat and mass transfer area, and the discontinuous louvers were also used on the fins. Its performance was tested in an environmental chamber. Table 2 shows the experimental data of the tower. The mass flow rates of the spray water varied from 0.06 to 0.13 kg/s, and its temperature ranged from 24.4 to 27.9 °C. Comparison between the predicted and measured outlet temperatures of the process water is presented in Table 2. When three different values, viz. 2.3516, 3.5878, and 5.2759, were assigned to the fictitious specific heat of air, the two new parameters (βext, βint) of the simplified model were obtained correspondingly, viz. (3.461, 0.085), (1.205, 0.089), and (0.638, 0.092), respectively. In these scenarios, the predicted outlet temperatures of the process water were consistent with the measurements, and the maximum absolute error of the temperature difference was 0.24 °C. This means the proposed model with new parameters is reliable for predicting the outlet temperature of process water of the CCFCWCT.

Table 2.

Comparison of the predicted thermal performance versus the measurements for the CCFCWCT.

Validation results indicated that the models with new input parameters were accurate enough for predicting the thermal performance of the two typical counter-flow CWCTs. The predicted outlet temperatures of the process water were almost independent of the fictitious specific heat of air. Therefore, the fictitious specific heat of saturated air was set to be 3.5878 kJ/(kg·°C) for the following analysis. Moreover, due to the effect of pollution on the cooling tower performance, the characteristic parameters of the simplified model should be updated periodically by inputting the latest performance and operating data to guarantee the model’s prediction accuracy. A similar phenomenon also existed in another simplified cooling capacity model for an open cooling tower [16].

3.2. Effects of Different Factors on Cooling Capacity and Cooling Tower Effectiveness

Based on the above results analysis, the cooling capacities and effectiveness values of both towers could be predicted by the proposed model with new parameters under different operating conditions because it was difficult for the limited experimental data to thoroughly reveal the performance. The effects of different factors, including the inlet parameters of three kinds of working fluids, on the cooling tower performance were investigated.

3.2.1. Effects of Spray Water Flow Rate and Inlet Water Temperature

Obviously, the cooling capacity predicted by Equation (12) was not influenced by the change of spray water flow rate, even though it was derived and simplified under the assumption of a constant spray water flow rate [18]. This phenomenon is probably the consequence of joint contributions of the spray water, the spray, and the splash. When the external surface of the heat exchanger is fully wetted by the spray water, an increase of spray water flow rate does not significantly improve the thermal performance, which is consistent with the results reported by Facão [11], Zheng [21], and Yoo [22]. The spray water temperature is a dependent variable, which is mainly determined by the status of air and process water [34,35]. Thus, no further study is needed to investigate the effect of the spray water parameters on the thermal performance of a CWCT.

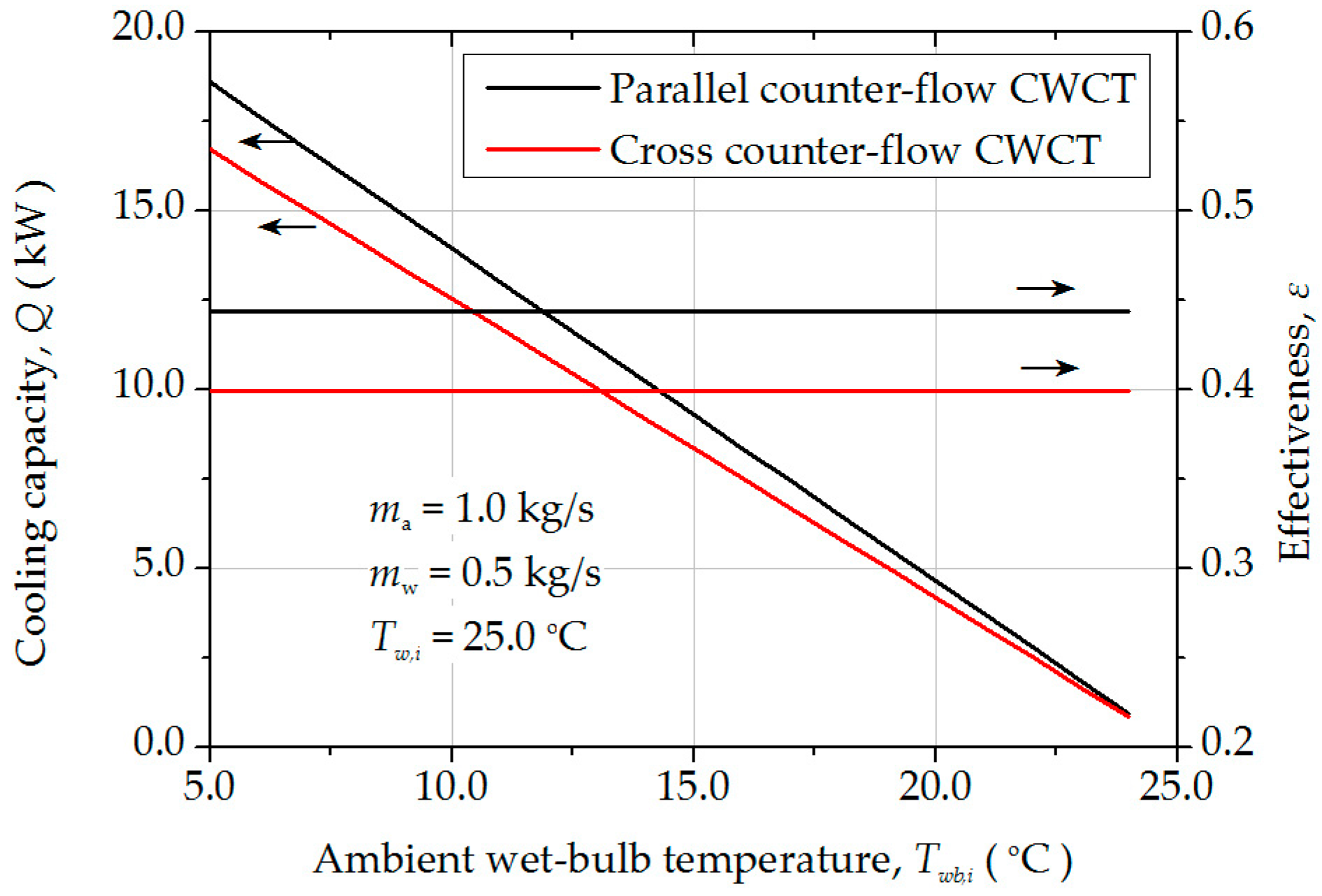

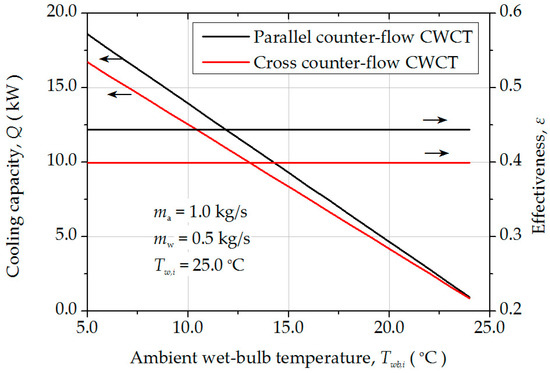

3.2.2. Effect of Ambient Wet-Bulb Temperature

The ambient wet-bulb temperature is a key factor that influences the thermal performance of a CWCT. When ma = 1.0 kg/s, mw = 0.5 kg/s, and Tw,i = 25.0 °C, the cooling capacities and effectiveness values of both towers were investigated with the ambient wet-bulb temperature increasing from 5.0 to 24.0 °C. As shown in Figure 4, the two indicators of the two towers vary with the ambient wet-bulb temperatures significantly. A decrease of ambient wet-bulb temperature is beneficial to improve the cooling capacity of a CWCT because the temperature difference between the air and the cooling water is increasing. This indicates that the cooling water outlet temperature has a strong positive correlation with the ambient wet-bulb temperature, which is consistent with the findings of Zheng [4], Yoo [22], and Sarker [32]. The cooling tower effectiveness was not considerably affected by the ambient wet-bulb temperature in this study, which was consistent with the results reported by Facão [11].

Figure 4.

Cooling capacity and effectiveness versus ambient wet-bulb temperature (the arrows indicate the variable axes).

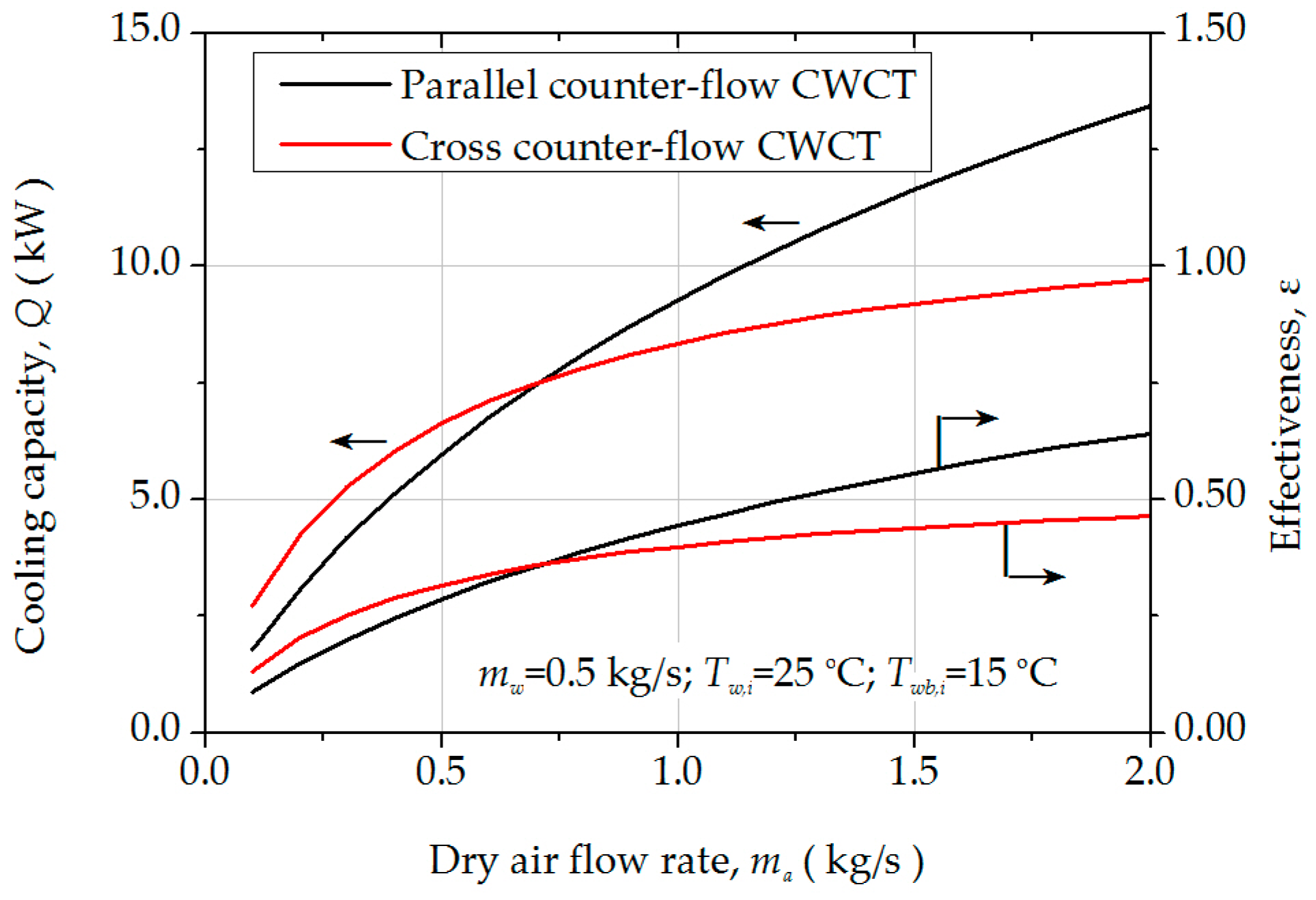

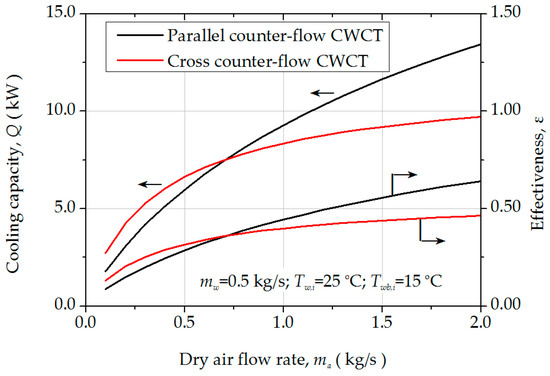

3.2.3. Effect of Air Flow Rate

When ma = 0.1–2.0 kg/s, mw = 0.5 kg/s, Tw,i = 25.0 °C, and Twb,i = 15.0 °C, the effects of dry air mass flow rate on the thermal performance of the two counter-flow CWCTs are shown in Figure 5. Apparently, the rise of air flow rate promotes the heat and mass transfer between the air and the spray water [7], which contributes to improving the thermal performance of CWCTs. Similar results were reported in [2,11,22,32,35]. However, the bigger the air flow rate, the larger the fan energy consumption. Thus, a trade-off between the cooling tower performance and the fan energy consumption should be considered in both the initial design phase and the operating period.

Figure 5.

Variations of the cooling capacity and the effectiveness with air flow rate (the arrows indicate the variable axes).

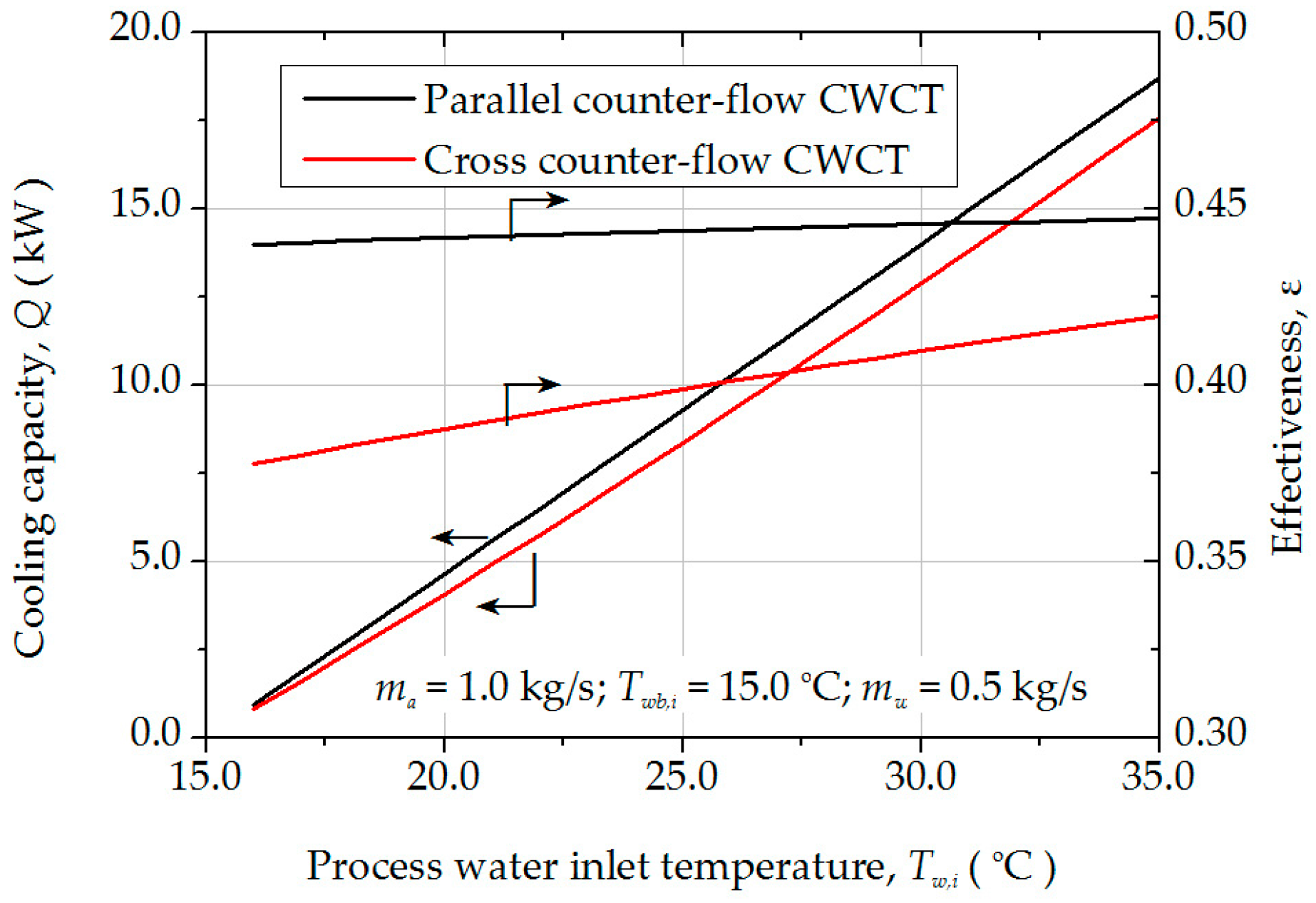

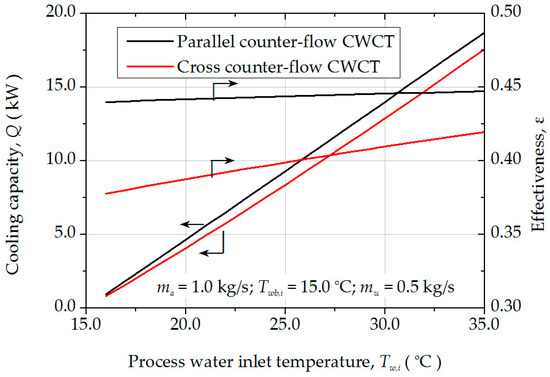

3.2.4. Effects of Inlet Water Temperature

As shown in Figure 6, the inlet cooling water temperatures make obvious influences on the cooling capacity and the cooling tower effectiveness while ma = 1.0 kg/s, mw = 0.5 kg/s, Tw,i = 16–25.0 °C, and Twb,i = 15.0 °C. The cooling capacity increases almost linearly with the increase of the cooling water inlet temperature due to the increase of heat and mass transfer driving forces among the working fluids, which is consistent with findings by Jiang [35]. However, the cooling tower effectiveness increases slightly with the temperature increase, which indicates that the influence of water inlet temperatures on the tower’s thermal efficiency is negligible within a narrow range of inlet temperature for process water. Similar results were also reported in [11].

Figure 6.

Cooling capacity and cooling tower effectiveness versus process water inlet temperature (the arrows indicate the variable axis).

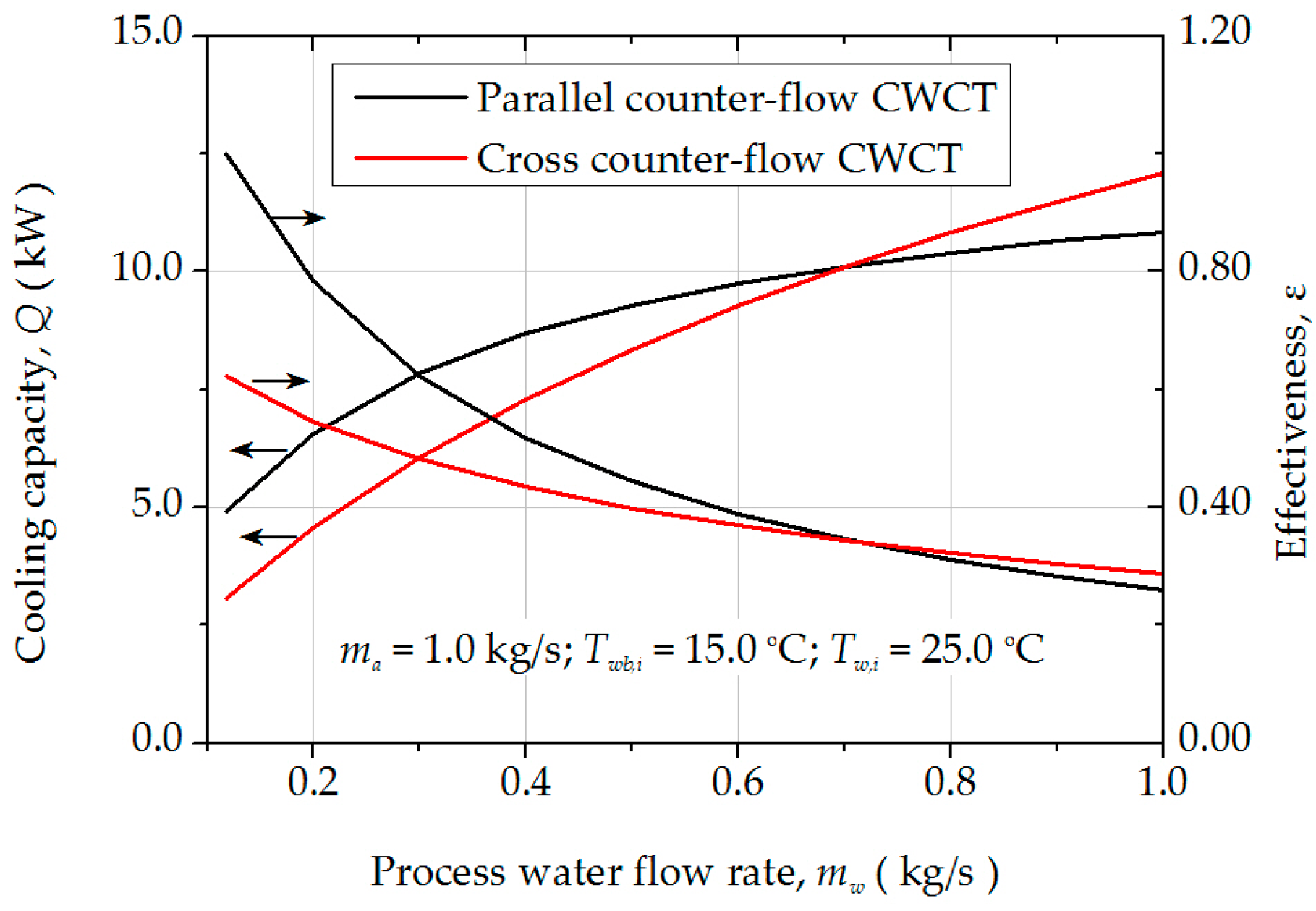

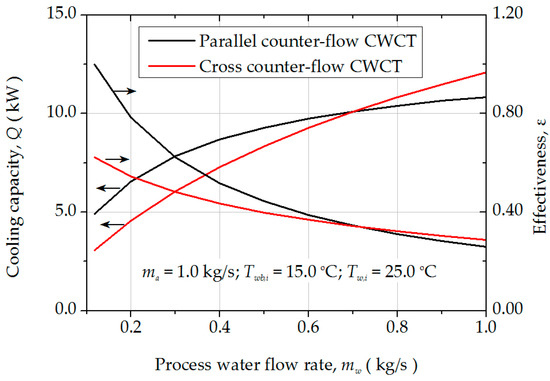

3.2.5. Effects of Process Water Flow Rate

As shown in Figure 7, when ma = 1.0 kg/s, Tw,i = 25.0 °C, and Twb,i = 15.0 °C, the performance indicators of the two cooling tower vary with the cooling water flow rate increasing from 0.1 to 1.0 kg/s. The results show that the cooling capacity of a counter-flow CWCT increases with the increase of cooling water flow rate, while the effectiveness is in contrast, which are consistent with the results reported by Xia [2]. This indicates that the increase of cooling water flow rate would strengthen the heat transfer process between the spray water and the process water. Therefore, a larger cooling water flow helped to release more heat to the atmosphere [35]. However, the greater the cooling water flow rate, the larger the pump energy consumption. On the other hand, to obtain a high thermal efficiency, the process water flow rate should be minimized. Therefore, a balance between the CWCT performance and the cooling water flow rate should be achieved to achieve a better solution for optimizing the daily operation of a CWCT with parallel or cross counter-flow construction.

Figure 7.

Cooling capacity and effectiveness versus process water flow rate (the arrows indicate the variable axes).

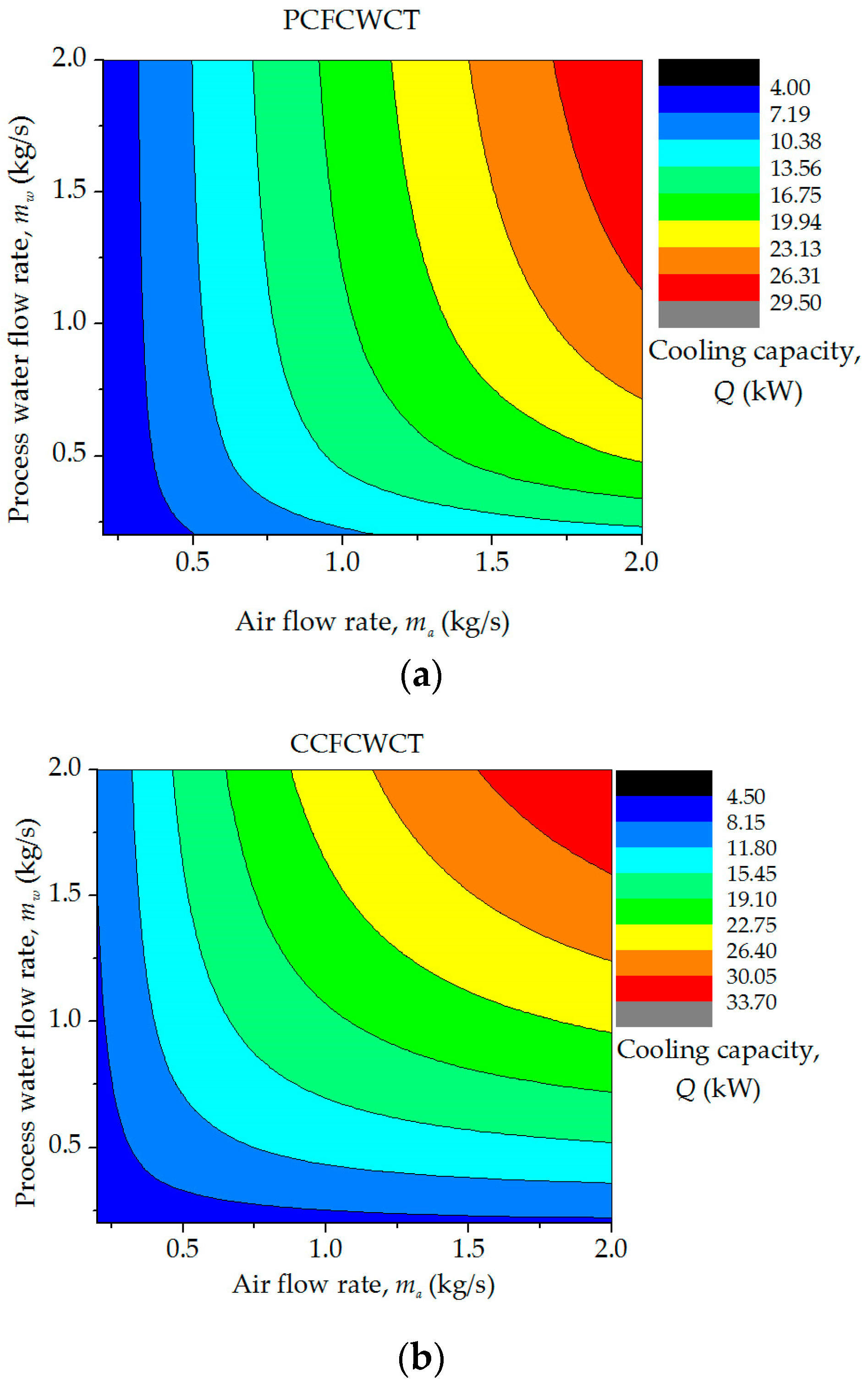

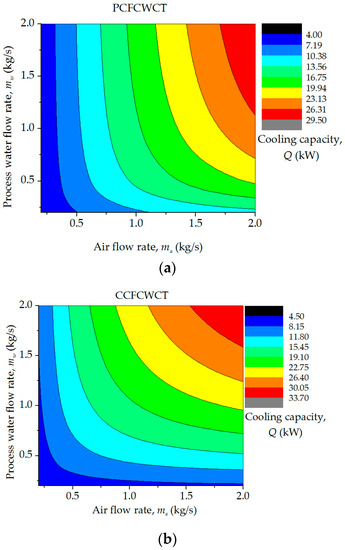

3.2.6. Effects of the Mass Flow Rates of Air and Process Water

During cooling tower operation, the ambient wet-bulb temperature is a non-controllable variable. As mentioned above, in this study, the mass flow rate of spray water was remained constant such that the external surface of the heat exchanger was thoroughly wetted by the spray water. Therefore, the effects of the two controllable factors, viz. the mass flow rates of air and process water, on the cooling capacity and effectiveness of both towers were investigated under given conditions, viz. at an ambient wet-bulb temperature of 15 °C and a process water inlet temperature of 30 °C.

The cooling capacities of both towers were investigated by varying the mass flow rates of air and process water in Equation (12). As shown in Figure 8, the air flow rate has more impact on the cooling capacity of PCFCWCT than the process water flow rate, while the process water flow rate affects the cooling capacity of CCFCWCT almost as much as the air flow rate does. This can be explained by the fact that, compared with PCFCWCT, the CCFCWCT can achieve more uniform heat and mass transfer driving forces in most of the apparatus, which is consistent with the findings by Jiang [35]. The results indicate that the optimum ranges of air flow rate and water flow rate can be detected in Figure 8 to maximize the cooling capacity. These optimum ranges vary within a lower water flow rate and a higher air flow rate for PCFCWCT, and higher flow rates of air and water for CCFCWCT, respectively. This means that the CWCT with parallel counter-flow construction is much more applicable than the one with cross counter-flow construction in the large-scale cooling water system, and the superiority would be amplified when the scale of the water distribution system increases. The reason might be that the minor reductions in energy consumption of circulating water pumps would be enough to offset the increase of energy consumption of fans.

Figure 8.

Cooling capacity of both towers versus different mass flow rates of process water and air: (a) PCFCWCT and (b) CCFCWCT.

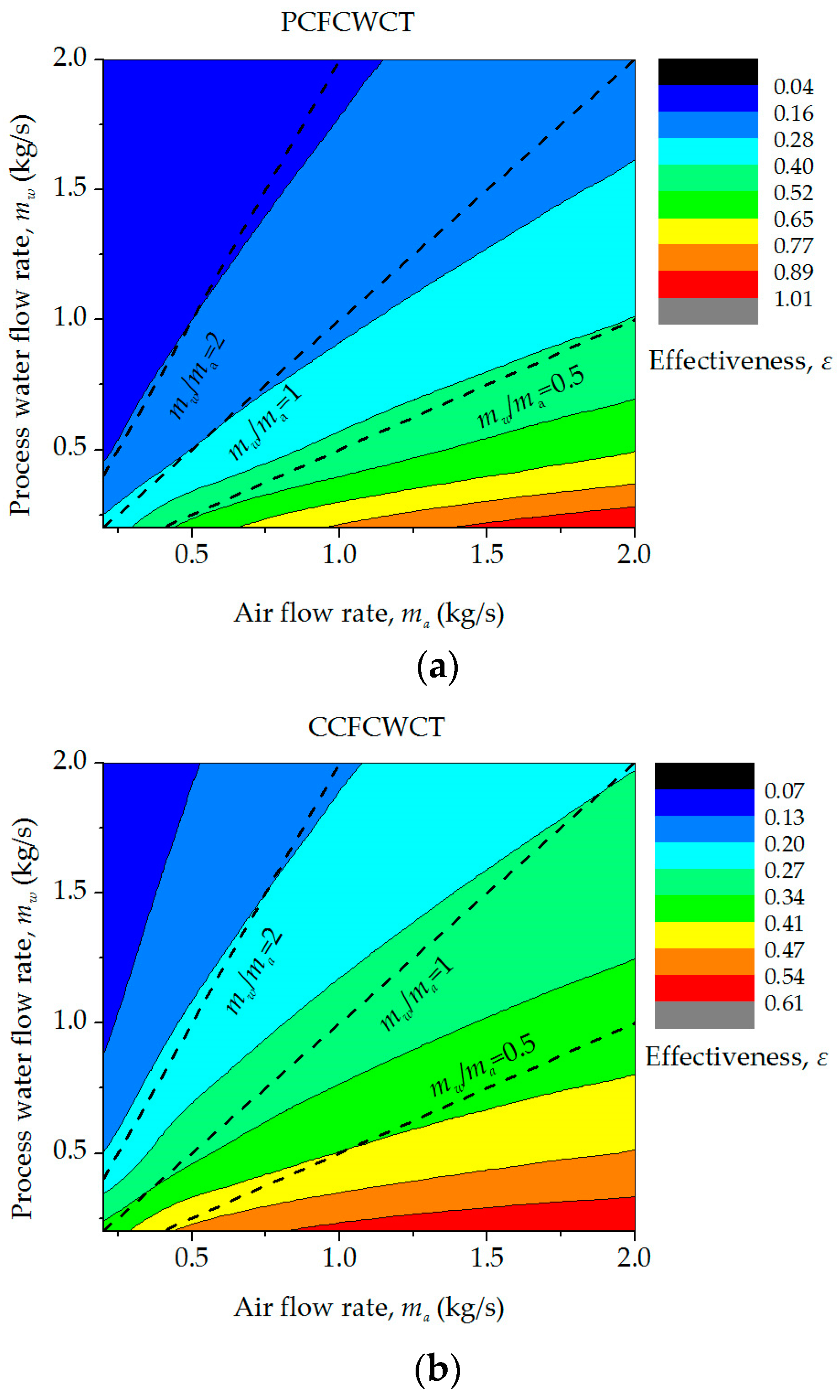

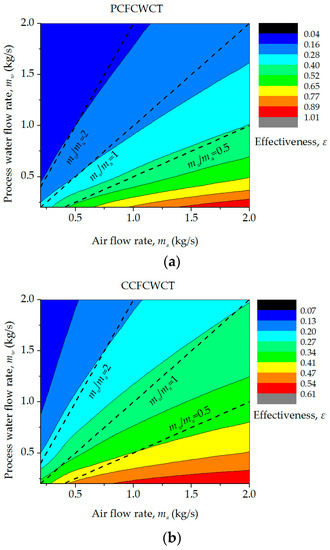

The cooling tower effectiveness values of both towers were investigated by varying the mass flow rates of air and process water in Equation (15). As shown in Figure 9, the air flow rate has more influence on the effectiveness of both cooling towers than the process water flow rate. When the ratio of water to air flow rate is constant, the effectiveness of both towers decreases with the process water flow rate increases. For instance, when the water/air (mw/ma) flow ratio equals 1, the effectiveness ranges decrease by 22% and 21% for PCFCWCT and CCFCWCT, respectively, with the process water flow rate increasing from 0.5 to 2.0 kg/s. This indicates that the effectiveness values of both towers have similar variation tendencies.

Figure 9.

Effectiveness of both towers versus different mass flow rates of process water and air: (a) PCFCWCT and (b) CCFCWCT.

4. Conclusions

Two typical closed water cooling towers (CWCTs) with different counter-flow constructions, viz. one with the parallel counter-flow and the other with the cross counter-flow, were selected as the study objects in this work. A simplified model and calculation method were presented for performance prediction of counter-flow CWCTs. Based on the proposed cooling capacity model with new input parameters, the outlet temperatures of the process water were compared with the measurements. Furthermore, the cooling capacity and cooling tower effectiveness of both towers were investigated and compared, respectively, under given operating conditions. The key findings are summarized as follows:

- (1)

- A simplified cooling capacity model with two characteristic parameters inputting was developed and the two parameters were determined by curve fitting of real-time experimental data using the Levenberg–Marquardt method.

- (2)

- The predicted outlet temperatures of the process water were in good agreement with the experimental data. The maximum absolute errors between the predicted values and the measurements were 0.20 and 0.24 °C for the parallel counter-flow CWCT (PCFCWCT) and the cross counter-flow CWCT (CCFCWCT), respectively. These results indicated that the simplified method was reliable for performance prediction and analysis for counter-flow CWCTs.

- (3)

- Although the flow patterns of both types of counter-flow CWCTs were different, the effects of the main influencing factors on their performance indicators were similar. The inlet parameters of cooling water and air were crucial for determining the cooling capacity of a counter-flow CWCT, while the effectiveness was mainly determined by the flow rates of air and cooling water.

- (4)

- The PCFCWCT is much more applicable than the CCFCWCT in a large-scale cooling water system, and the superiority would be amplified when the scale of water distribution system increases.

The simplified method proposed in this paper provided a convenient way to accurately predict and evaluate the thermal performance of a counter-flow CWCT without iterative computation and a large number of experiments. It could make the systematical performance study and the optimization operation of the whole water cooling system more convenient and easier.

Acknowledgments

The study has been supported by the China National Key R&D Program “Solutions to heating and cooling of buildings in the Yangtze River region” (Grant No. 2016YFC0700305). The authors also appreciated the financial support from National Natural Science Foundation of China (No. 51578220).

Author Contributions

All authors conceived the research idea and the framework of this study. Xiaoqing Wei, Jianlin Cheng, Jinhua Hu, and Meng Wang collected the relevant data. Xiaoqing Wei analyzed the data and wrote the paper. Nianping Li and Jinqing Peng were responsible for revising this paper and language editing.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| m | mass flow rate, kg/s |

| T | temperature, °C |

| h | enthalpy, kJ/kg |

| c | specific heat, kJ/(kg·°C) |

| cw | specific heat of cooling water at constant pressure, 4.1868 kJ/(kg·°C) |

| cpsat | the fictitious specific heat of saturated air at constant pressure, kJ/(kg·°C) |

| d | diameter, m |

| F | a composite indicator, kW |

| Re | Reynolds number |

| Pr | Prandtl number |

| Q | cooling capacity, kW |

| U | heat transfer coefficient, kW/(m2·°C) |

| A | area, m2 |

| ∆TLM | logarithmic mean temperature difference, °C |

| Greek Symbols | |

| μ | dynamic viscosity coefficient of water at the temperatures T, kg/(m·s) |

| μo | dynamic viscosity coefficient of water at 0 °C, 1.792 × 10−3 kg/(m·s) |

| βint | a constant which is influenced by the coil’s geometry and constant water-properties |

| βext | a constant which depends on the thermal properties of air and on the coil’s geometry |

| ε | effectiveness or efficiency coefficient |

| Γ | spray water load, equal to spray mass flow divided by tower section, kg/(m·s) |

| Subscripts | |

| a | air |

| pre | predicted |

| sw | spray water |

| w | process water |

| i | inlet |

| o | outlet |

| wb | ambient wet-bulb |

| ew | evaporated water |

References

- American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE). ASHRAE Handbook—2008 HVAC Systems and Equipment; ASHRAE: Atlanta, GA, USA, 2008. [Google Scholar]

- Xia, Z.Z.; Chen, C.J.; Wang, R.Z. Numerical simulation of a closed wet cooling tower with novel design. Int. J. Heat Mass Transf. 2011, 54, 2367–2374. [Google Scholar] [CrossRef]

- Chen, C.J.; Wang, R.Z.; Xia, Z.Z.; Kiplagat, J.K. Study on a silica gel-water adsorption chiller integrated with a closed wet cooling tower. Int. J. Therm. Sci. 2010, 49, 611–620. [Google Scholar] [CrossRef]

- Zheng, W.Y.; Zhu, D.S.; Zhou, G.Y.; Wu, J.F.; Shi, Y.Y. Thermal performance analysis of closed wet cooling towers under both unsaturated and supersaturated conditions. Int. J. Heat Mass Transf. 2012, 55, 7803–7811. [Google Scholar] [CrossRef]

- Khan, J.U.R.; Yaqub, M.; Zubair, S.M. Performance characteristics of counter flow wet cooling towers. Energy Convers. Manag. 2003, 44, 2073–2091. [Google Scholar] [CrossRef]

- Hajidavalloo, E.; Shakeri, R.; Mehrabian, M.A. Thermal performance of cross flow cooling towers in variable wet bulb temperature. Energy Convers. Manag. 2010, 51, 1298–1303. [Google Scholar] [CrossRef]

- Hasan, A.; Sirén, K. Theoretical and computational analysis of closed wet cooling towers and its applications in cooling of buildings. Energy Build. 2002, 34, 477–486. [Google Scholar] [CrossRef]

- Sarker, M.M.A.; Kim, E.; Moon, C.G.; Yoon, J.I. Performance characteristics of the hybrid closed circuit cooling tower. Energy Build. 2008, 40, 1529–1535. [Google Scholar] [CrossRef]

- Gan, G.; Riffat, S.B. Numerical simulation of closed wet cooling towers for chilled ceiling systems. Appl. Therm. Eng. 1999, 19, 1279–1296. [Google Scholar] [CrossRef]

- Daeho, K.; Strand, R.K. Modeling of simultaneous heat and mass transfer within passive down-draft evaporative cooling (PDEC) towers with spray in FLUENT. Energy Build. 2013, 62, 196–209. [Google Scholar]

- Facão, J.; Oliveira, A.C. Thermal behaviour of closed wet cooling towers for use with chilled ceilings. Appl. Therm. Eng. 2000, 20, 1225–1236. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, G.; Zhang, Q.; Zhou, J.; Wang, Y. Artificial neural network analysis of the performance characteristics of a reversibly used cooling tower under cross flow conditions for heat pump heating system in winter. Energy Build. 2011, 43, 1685–1693. [Google Scholar] [CrossRef]

- Gao, M.; Sun, F.Z.; Zhou, S.J.; Shi, Y.T.; Zhao, Y.B.; Wang, N.H. Performance prediction of wet cooling tower using artificial neural network under cross-wind conditions. Int. J. Therm. Sci. 2009, 48, 583–589. [Google Scholar] [CrossRef]

- Qi, X.; Liu, Y.; Guo, Q.; Yu, S.; Yu, J. Performance prediction of a shower cooling tower using wavelet neural network. Appl. Therm. Eng. 2016, 108, 475–485. [Google Scholar] [CrossRef]

- Wang, J.G.; Shieh, S.S.; Jang, S.S.; Wu, C.W. Discrete model-based operation of cooling tower based on statistical analysis. Energy Convers. Manag. 2013, 73, 226–233. [Google Scholar] [CrossRef]

- Jin, G.Y.; Cai, W.J.; Lu, L.; Lee, E.L.; Chiang, A. A simplified modeling of mechanical cooling tower for control and optimization of HVAC systems. Energy Convers. Manag. 2007, 48, 355–365. [Google Scholar] [CrossRef]

- Lu, L.; Cai, W.; Soh, Y.C.; Xie, L.; Li, S. HVAC system optimization––Condenser water loop. Energy Convers. Manag. 2004, 45, 613–630. [Google Scholar] [CrossRef]

- Stabat, P.; Marchio, D. Simplified model for indirect-contact evaporative cooling-tower behaviour. Appl. Energy 2004, 78, 433–451. [Google Scholar] [CrossRef]

- Mohiuddin, A.K.M.; Kant, K. Knowledge base for the systematic design of wet cooling towers. Part I: Selection and tower characteristics. Int. J. Refrig. 1996, 19, 43–51. [Google Scholar] [CrossRef]

- Ren, C.Q.; Yang, H.X. An analytical model for the heat and mass transfer processes in indirect evaporative cooling with parallel/counter flow configurations. Int. J. Heat Mass Transf. 2006, 46, 617–627. [Google Scholar]

- Zheng, W.Y.; Zhu, D.S.; Song, J.; Zeng, L.D.; Zhou, H.J. Experimental and computational analysis of thermal performance of the oval tube closed wet cooling tower. Appl. Therm. Eng. 2012, 35, 233–239. [Google Scholar] [CrossRef]

- Yoo, S.Y.; Kim, J.H.; Han, K.H. Thermal performance analysis of heat exchanger for closed wet cooling tower using heat and mass transfer analogy. J. Mech. Sci. Technol. 2010, 24, 893–898. [Google Scholar] [CrossRef]

- Papaefthimiou, V.D.; Rogdakis, E.D.; Koronaki, I.P.; Zannis, T.C. Thermodynamic study of the effects of ambient air conditions on the thermal performance characteristics of a closed wet cooling tower. Appl. Therm. Eng. 2012, 33–34, 199–207. [Google Scholar] [CrossRef]

- Ala, H.; Gan, G.H. Simplification of analytical models and incorporation with CFD for the performance prediction of closed-wet cooling towers. Int. J. Energy Res. 2002, 26, 1161–1174. [Google Scholar]

- Bourouni, K.; Bassem, M.M.; Chaibi, M.T. Numerical study of coupled heat and mass transfer in geothermal water cooling tower. Energy Convers. Manag. 2008, 49, 988–994. [Google Scholar] [CrossRef]

- Lucas, M.; Martínez, P.J.; Viedma, A. Experimental study on the thermal performance of a mechanical cooling tower with different drift eliminators. Energy Convers. Manag. 2009, 50, 490–497. [Google Scholar] [CrossRef]

- Marques, C.A.X.; Fontes, C.H.; Embirucu, M.; Kalid, R.A. Efficiency control in a commercial counter flow wet cooling tower. Energy Convers. Manag. 2009, 50, 2843–2855. [Google Scholar] [CrossRef]

- He, S.; Gurgenci, H.; Guan, Z.; Hooman, K.; Zou, Z.; Sun, F. Comparative study on the performance of natural draft dry, pre-cooled and wet cooling towers. Appl. Therm. Eng. 2016, 99, 103–113. [Google Scholar] [CrossRef]

- Costelloe, B.; Finn, D.P. Heat transfer correlations for low approach evaporative cooling systems in buildings. Appl. Therm. Eng. 2009, 29, 105–115. [Google Scholar] [CrossRef]

- Serna-González, M.; Ponce-Ortega, J.M.; Jimenez-Gutierrez, A. MINLP optimization of mechanical draft counter flow wet-cooling towers. Chem. Eng. Res. Des. 2010, 88, 614–625. [Google Scholar] [CrossRef]

- Du, G.S. Engineering Fluid Mechanics; China Electric Power Press: Beijing, China, 2007. (In Chinese) [Google Scholar]

- Sarker, M.M.A.; Shim, G.J.; Lee, H.S.; Moon, C.G.; Yoon, J.I. Enhancement of cooling capacity in a hybrid closed circuit cooling tower. Appl. Therm. Eng. 2009, 29, 3328–3333. [Google Scholar] [CrossRef]

- Lian, Z.W.; Zhang, Y.P.; Chen, B.M.; Cao, D.X. Heat and Mass Transfer Principles and Equipment; China Architecture & Building Press: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Gan, G.; Riffat, S.B.; Shao, L.; Doherty, P. Application of CFD to closed-wet cooling towers. Appl. Therm. Eng. 2001, 21, 79–92. [Google Scholar] [CrossRef]

- Jiang, J.J.; Liu, X.H.; Jiang, Y. Experimental and numerical analysis of a cross-flow closed wet cooling tower. Appl. Therm. Eng. 2013, 61, 678–689. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).