Near Wellbore Hydraulic Fracture Propagation from Perforations in Tight Rocks: The Roles of Fracturing Fluid Viscosity and Injection Rate

Abstract

:1. Introduction

2. Sample Preparation

2.1. Casting Cement Samples

2.2. Preparing Cased Perforated Samples

3. Experimental Set-Up

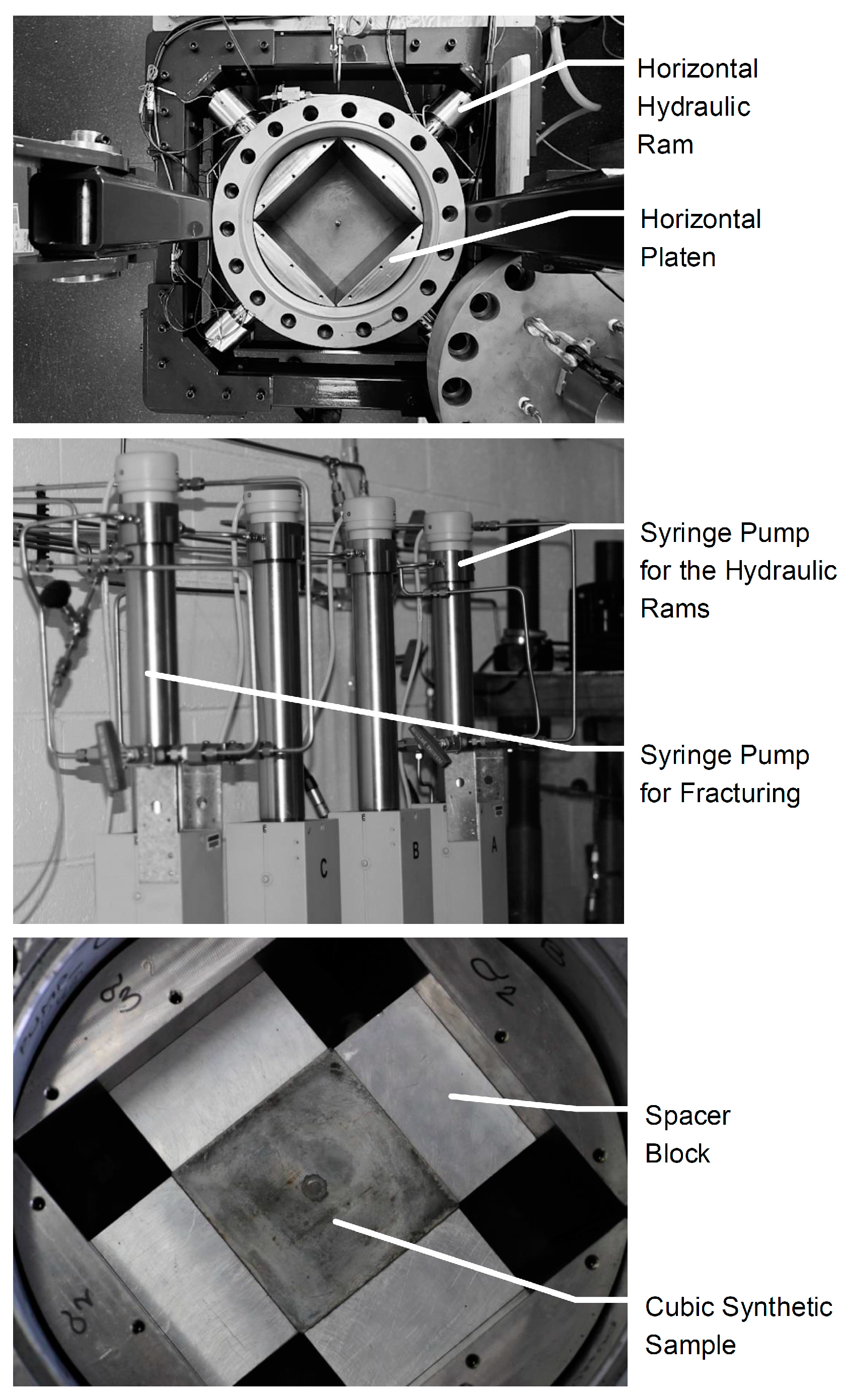

3.1. True Tri-Axial Stress Cell (TTSC)

3.2. Fracturing Fluid Injection

4. Scaling Analysis

5. Results and Discussion

5.1. Predicting Fracture Propagation Time

5.2. Cement Sheath Strength Effect

5.3. The Effects of Viscosity and Flow Rate

5.3.1. Fracturing Pressures

5.3.2. Fracture Geometry

5.3.3. Casing Effect

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Cleary, M.; Johnson, D.; Kogsb, H.; Owens, K.; Perry, K.; Pater, C.; Alfred, S.; Holger, S.; Mauro, T. Field implementation of proppant slugs to avoid premature screen-out of hydraulic fractures with adequate proppant concentration. In Proceedings of the Low Permeability Reservoirs Symposium, Denver, CO, USA, 26–28 April 1993.

- Davidson, B.; Saunders, B.; Robinson, B.; Holditch, S. Analysis of abnormally high fracture treating pressures caused by complex fracture growth. In Proceedings of the SPE Gas Technology Symposium, Calgary, AB, Canada, 28–30 June 1993.

- Aud, W.; Wright, T.; Cipolla, C.; Harkrider, J. The effect of viscosity on near-wellbore tortuosity and premature screenouts. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 25–28 September 1994.

- Lehman, L.; Brumley, J. Etiology of multiple fractures. In Proceedings of the SPE Production Operations Symposium, Oklahoma City, OK, USA, 9–11 March 1997.

- Behrmann, L.; Elbel, J. Effect of perforations on fracture initiation. J. Pet. Technol. 1991, 43, 608–615. [Google Scholar] [CrossRef]

- Abass, H.; Brumley, J.; Venditto, J. Oriented perforations-a rock mechanics view. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 25–28 September 1994.

- Gulrajani, S.N.; Romero, J. Evaluation and modification of fracture treatments showing near-wellbore effects. In Proceedings of the European Petroleum Conference, Milan, Italy, 22–24 October 1996.

- Behrmann, L.; Nolte, K. Perforating requirements for fracture stimulations. SPE Drill. Complet. 1999, 14, 228–234. [Google Scholar] [CrossRef]

- Hossain, M.; Rahman, M.; Rahman, S. Hydraulic fracture initiation and propagation: Roles of wellbore trajectory, perforation and stress regimes. J. Pet. Sci. Eng. 2000, 27, 129–149. [Google Scholar] [CrossRef]

- Atkinson, C.; Eftaxiopoulos, D. Numerical and analytical solutions for the problem of hydraulic fracturing from a cased and cemented wellbore. Int. J. Solids Struct. 2002, 39, 1621–1650. [Google Scholar] [CrossRef]

- Fallahzadeh, S.H.; Shadizadeh, R.S.; Pourafshary, P. Dealing with the challenges of hydraulic fracture initiation in deviated-cased perforated boreholes. In Proceedings of the SPE Trinidad and Tobago Energy Resources Conference, Port of Spain, Trinidad, 27–30 June 2010.

- Fallahzadeh, S.; Rasouli, V.; Sarmadivaleh, M. An investigation of hydraulic fracturing initiation and near-wellbore propagation from perforated boreholes in tight formations. Rock Mech. Rock Eng. 2015, 48, 573–584. [Google Scholar] [CrossRef]

- Romero, J.; Mack, M.; Elbel, J. Theoretical model and numerical investigation of near-wellbore effects in hydraulic fracturing. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 22–25 October 1995.

- Daneshy, A. Experimental investigation of hydraulic fracturing through perforations. J. Pet. Technol. 1973, 25, 1201–1206. [Google Scholar] [CrossRef]

- Van de Ketterij, R.G. Optimisation of the Near-Wellbore Geometry of Hydraulic Fractures Propagating from Cased Perforated Completions. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2001. [Google Scholar]

- Van Ketterij, R.; De Pater, C. Impact of perforations on hydraulic fracture tortuosity. SPE Prod. Facil. 1999, 14, 117–130. [Google Scholar] [CrossRef]

- Perkins, T.; Weingarten, J. Stability and failure of spherical cavities in unconsolidated sand and weakly consolidated rock. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 2–5 October 1988.

- Fallahzadeh, S.H.; Rasouli, V.; Sarmadivaleh, M. Experimental investigation of hydraulic fracturing in vertical and horizontal perforated boreholes. In Proceedings of the 47th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 23–26 June 2013.

- Mindess, S.; Young, J.F.; Darwin, D. Concrete; Prentice Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Fallahzadeh, S.; Rasouli, V. The impact of cement sheath mechanical properties on near wellbore hydraulic fracture initiation. In Proceedings of the ISRM International Symposium-EUROCK, Stockholm, Sweden, 28–30 May 2012.

- Rasouli, V. A true triaxial stress cell (ttsc) used for simulations of real field operations in the lab. True Triaxial Test. Rocks 2012, 4, 311. [Google Scholar]

- Min, S.; Sastry, S.; Balasubramaniam, V. Compressibility and density of select liquid and solid foods under pressures up to 700 mpa. J. Food Eng. 2010, 96, 568–574. [Google Scholar] [CrossRef]

- Bunger, A.P. Near-surface hydraulic fracture. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 2005. [Google Scholar]

- De Pater, C.; Weijers, L.; Cleary, M.; Quinn, T.; Barr, D.; Johnson, D. Experimental verification of dimensional analysis for hydraulic fracturing. SPE Prod. Facil. 1994, 9, 230–238. [Google Scholar] [CrossRef]

- Weijers, L. The Near-Wellbore Geometry of Hydraulic Fractures Initiated from Horizontal and Deviated Wells. Available online: http://repository.tudelft.nl/islandora/object/uuid:44f71145-b331-43af-a3d5-32916fd7333c/datastream/OBJ/view (accessed on 21 November 2016).

- Lhomme, T.P.Y. Initiation of Hydraulic Fractures in Natural Sandstones. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2005. [Google Scholar]

- Mack, M.G.; Warpinski, N. Mechanics of hydraulic fracturing. In Reservoir Stimulation; Wiley: New York, NY, USA, 2000. [Google Scholar]

- Detournay, E. Propagation regimes of fluid-driven fractures in impermeable rocks. Int. J. Geomech. 2004, 4, 35–45. [Google Scholar] [CrossRef]

- Bourgoyne, A.T.; Millheim, K.K.; Chenevert, M.E.; Young, F. Applied Drilling Engineering; Society of Petroleum Engineers: Richardson, TX, USA, 1986. [Google Scholar]

- Nelson, E.B. Well Cementing; Elsevier Science: Amsterdam, NY, USA, 1990. [Google Scholar]

- Fjar, E.; Holt, R.M.; Raaen, A.; Risnes, R.; Horsrud, P. Petroleum Related Rock Mechanics; Elsevier: Amsterdam, NY, USA, 2008. [Google Scholar]

| Mechanical Properties | Value | Unit | Testing Methodology | |

|---|---|---|---|---|

| UCS | Uni-axial compressive strength | 79.5 | MPa | Unconfined compression test * |

| To | Tensile strength | 3.5 | MPa | Brazilian tensile test * |

| KIC | Fracture Toughness | 0.78 | MPam0.5 | Semi-Circular bend test * |

| Elastic Properties | ||||

| ν | Poisson’s ratio | 0.19 | - | Unconfined compression test * |

| E | Young’s Modulus | 27.74 | GPa | Unconfined compression test * |

| Adhesives Shear Strength | ||||

| τo | Selleys Liquid Nails | 1.1 | MPa | Sandblasted aluminum lap shear ** |

| τo | Super Strength Araldite | 26 | MPa | Sandblasted aluminum lap shear ** |

| Physical Properties | ||||

| ρb | Bulk density | 2047 | Kg/m3 | Density measurement test |

| ρg | Grain density | 2500 | Kg/m3 | Density measurement test |

| φ | Porosity | 13.5 | % | Two Boyle’s cells |

| K | Permeability | 0.019 | mD | Transient gas flooding |

| Fracturing Fluid | Viscosity (Pa.s) | Specific Density | Compressibility (1/psi) | Maximum Frictional Pressure Loss (MPa) *** |

|---|---|---|---|---|

| Honey | 20 | 1.36 ** | 1.00 × 10−4 ** | 0.18 |

| Poly DMS-T51 | 97.7 * | 0.977 | <9.43 × 10−5 | 0.4 |

| Poly DMS-T56 | 586.8 * | 0.978 | <9.43 × 10−5 | 1.04 |

| Fracturing Fluid | Viscosity (Pa.s) | Flow Rate (cc/min) | Dimensionless Toughness (κ) |

|---|---|---|---|

| Honey | 20 | 1 | 0.65 |

| Honey | 20 | 2 | 0.58 |

| Honey | 20 | 5 | 0.49 |

| Poly DMS-T51 | 97.7 | 0.05 | 0.69 |

| Poly DMS-T51 | 97.7 | 0.1 | 0.61 |

| Poly DMS-T51 | 97.7 | 1 | 0.42 |

| Poly DMS-T56 | 586.8 | 0.1 | 0.37 |

| Poly DMS-T56 | 586.8 | 1 | 0.25 |

| Test No. | Fluid Viscosity (cP) | Injection Rate (cc/min) | Initiation Pressure (MPa) | Breakdown Pressure (MPa) | Propagation Time (s) |

|---|---|---|---|---|---|

| H-1 | 20,000 | 1.00 | 8.96 | 9.10 | ---- |

| H-2 | 20,000 | 1.00 | 12.82 | 14.19 | 320 |

| H-3 | 20,000 | 2.00 | 10.69 | 11.41 | 669 |

| H-4 | 20,000 | 5.00 | 15.24 | 18.68 | 636 |

| SL-1 | 97,700 | 1.00 | 18.40 | 19.96 | 340 |

| SL-2 | 97,700 | 0.10 | 17.44 | 18.19 | 936 |

| SL-3 | 97,700 | 0.05 | 7.98–14.37 | 8.16–14.65 | 499 |

| SH-1 | 586,800 | 1.00 | 32.75 | 35.65 | 364 |

| SH-2 | 586,800 | 0.10 | 28.27 | 32.72 | 460 |

| Test No. | Test Description and Fracture Geometry |

|---|---|

| H-1 | The fracturing Fluid (honey) created several fractures in the solid adhesive, which had filled the annulus between the casing and the wellbore. Eventually, the fractures reached the bottom of the annulus and the fluid leaked out. |

| H-2 | This sample was initially intended to be fractured by a flow rate of 1 cc/min; however, after 3100 s of injection, no fracture was initiated. Therefore, the flow rate was then increased to 2 cc/min. Consequently, the wellbore pressure increased and eventually a vertical, almost planar, fracture perpendicular to the direction of minimum stress was initiated and propagated from each perforation tunnel. The two fractures did not link up at the vicinity of the wellbore, probably due to high stress concentration around the wellbore. |

| H-3 | From each perforation a two-wing fracture was propagated along the perforation axis. However, the initiated fractures were not vertical at the perforation wall, and had an angle of about 35° with respect to the vertical plane. Both fractures propagated downwards and upwards in the sample in a curved path, and in a distance away from the wellbore they turned towards the vertical plane (PFP). |

| H-4 | Similar to the previous test, curved fractures were initiated from the perforations, and then turned towards the PFP. The lower wing of the fracture in this test made an angle of about 80° with respect to the vertical plane; however, it turned towards a plane where less normal stress was applied. |

| SL-1 | Almost similar to the two previous tests, from each perforation a two-wing fracture was created in an angle of 65° with respect to the vertical plane. Then, in some distance away from the wellbore, the fractures turned towards the PFP. |

| SL-2 | An almost planar fracture, making an angle of 3° with respect to PFP, was developed from both perforations, and propagated mostly towards the bottom of the sample. |

| SL-3 | This test exhibited multiple fracturing. In addition, a two-wing fracture was developed almost against the maximum stress, initiating from one of the perforations. Then one of its wings propagated and changed its direction towards a vertical plane, which was nearly perpendicular to the minimum stress. The other perforation just initiated a small fracture. |

| SH-1 | A two-wing fracture was developed almost against the maximum stress, initiating from one of the perforations. Then one of its wings propagated and turned towards the PFP. |

| SH-2 | An almost planar vertical fracture, making an angle of 25° with respect to PFP, was propagated from one of the perforations. The other perforation created a fracture which also developed towards the vertical plane and perpendicular to the minimum stress direction. |

| Test No. | Injection Rate (m3/s) ×10−8 | Fluid Viscosity (Pa.s) | Q × μ (Fracturing Energy) (N.m) ×10−10 | Pressurization Time (s) | Fracturing Power (N.m/s) ×10−10 | Fracture Initiation Angle (°) | Fracture Propagation Geometry |

|---|---|---|---|---|---|---|---|

| H-2 | 1.67 | 20.0 | 3763 | 3100 | 1.2 | 5 | Planar |

| H-3 | 3.33 | 20.0 | 6667 | 900 | 7.4 | 35 | Curved |

| H-4 | 8.33 | 20.0 | 16,667 | 70 | 238.1 | 80 | Curved |

| SL-1 | 1.67 | 97.7 | 16,283 | 500 | 32.6 | 65 | Curved |

| SL-2 | 0.17 | 97.7 | 1628 | 3200 | 0.5 | 3 | Planar |

| SL-3 | 0.08 | 97.7 | 814 | 14,000 | 0.06 | 0 to 70 | Curved |

| SH-1 | 1.67 | 586.8 | 97,800 | 700 | 139.7 | 75 | Curved |

| SH-2 | 0.17 | 586.8 | 9780 | 4400 | 2.2 | 25 | Almost Planar |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fallahzadeh, S.H.; Hossain, M.M.; James Cornwell, A.; Rasouli, V. Near Wellbore Hydraulic Fracture Propagation from Perforations in Tight Rocks: The Roles of Fracturing Fluid Viscosity and Injection Rate. Energies 2017, 10, 359. https://doi.org/10.3390/en10030359

Fallahzadeh SH, Hossain MM, James Cornwell A, Rasouli V. Near Wellbore Hydraulic Fracture Propagation from Perforations in Tight Rocks: The Roles of Fracturing Fluid Viscosity and Injection Rate. Energies. 2017; 10(3):359. https://doi.org/10.3390/en10030359

Chicago/Turabian StyleFallahzadeh, Seyed Hassan, Md Mofazzal Hossain, Ashton James Cornwell, and Vamegh Rasouli. 2017. "Near Wellbore Hydraulic Fracture Propagation from Perforations in Tight Rocks: The Roles of Fracturing Fluid Viscosity and Injection Rate" Energies 10, no. 3: 359. https://doi.org/10.3390/en10030359

APA StyleFallahzadeh, S. H., Hossain, M. M., James Cornwell, A., & Rasouli, V. (2017). Near Wellbore Hydraulic Fracture Propagation from Perforations in Tight Rocks: The Roles of Fracturing Fluid Viscosity and Injection Rate. Energies, 10(3), 359. https://doi.org/10.3390/en10030359