Abstract

The massive and continuous development of renewable energy systems is making it possible to achieve the European goals regarding environment and sustainability. On the other hand, it leads to the progression of significant problems such as low renewable energy density (i), social acceptability (ii), and non-programmability of renewable energy sources (iii). The rural architecture, which is largely present in the countryside of central Italy, is generally equipped with several annexes such as dovecotes (i), grain stores (ii), and tobacco drying kilns (iii). Nowadays, those towers appear in decay because of the decline of agricultural activities, although they are classed as Environmental and Historical Heritage sites. The present work aims to propose a methodology for improving the energy grid in the countryside, while reusing abandoned buildings by modifying their function and maintaining their aspect as much as possible. The proposed workflow was applied to a rural silo, which has fallen into disuse, in Sant’Apollinare (Marsciano, Perugia) by converting it into a mini-biogas plant. The function of the annex which was chosen as the case study changes from agricultural use to energy production: it becomes an on-site renewable energy-based electric grid that can produce clean energy from agricultural and forestry residues. The project turns out to be sustainable not only in terms of energy and the environment, but also from an economic point of view as a result of the recent regulations and incentives for renewable energy production.

1. Introduction

The development of energy plants based on Renewable Energy Sources (RES) can significantly contribute to achieving the European goals of environmental sustainability and reduction of carbon emissions, as indicated in the recent dispositions [1,2] upgraded to 2030 and 2050 [3,4]. The increasing use of RES plants has inevitably introduced new relevant problems to the territory [5]: generally, they are characterized by low energy density and face difficulties in social acceptance, while their energy production is non-programmable such as in solar and wind plants. In order to generate continuous energy, some solutions were proposed such as power-to-gas technologies [6] and energy-from-waste exploitation [7], but none of them provides a solution to the problem of social acceptance. Regarding the problems related to non-continuous energy production, they can be easily overcome by applying the concept of smart grids which allows the integration of several RES and the use of specific systems for matching energy demand and supply. The former criticisms caused by RES plants’ spread could be solved, in part, by recovering ancient and abandoned buildings, better if characterized by vertical extension, in order to increase energy density.

The rural landscape is packed with service-annexes such as dovecotes and silos [8], which were commonly used a few decades ago for agricultural applications such as silage and forage storage, and organic waste recovery. They were built according to local traditional masonry so that, nowadays, they have a great visual as well as architectural value, which is preserved by local regulations. The recent reconversion of micro economies from agriculture to other activities contributed to the abandonment of those annexes, leading them to slow and continue degradation caused by weather and seismic events. At this point, they have lost their agriculturally based function, but the research described in this paper aims to propose a reconversion process which should lead to their reuse and promotion: they could be reused as nodes on the energy grid for the production of thermal and electric energy based on RES by using plants integrated mainly into the vertical buildings’ volume [9]. This proposal could overcome the social acceptability issue and permit recovery of precarious rural buildings [10].

2. The Energy Rural Silo (ERS)

The smart city concept represents a topic largely investigated in the last few decades due to the increasing interest in urban growth and increasing energy consumption. A city could be defined as ‘smart’ if it is able to reach a high level of efficiency, flexibility, and responsiveness by increasing the quality of the services offered to its citizens such as energy supply, traffic, information control, and waste management [11,12]. They are managed by considering the district as a sequence of overlapping layers, each one with a grid structured in cells, edges, and nodes. In that regard, the energy smart grid is a system composed of smart and optimized elements which aims to generate as many autonomous grids as possible with really low environmental footprints. According to this schematic and simplified representation, the nodes stand for energy sources such as photovoltaic plants or biomass power stations; cells and their edges respectively represent final users and supply systems. The CIRIAF Research Centre has recently developed research projects on the integration of renewable energy sources, in order to solve the criticisms of grid-connected plants [13,14,15].

2.1. Methodology

The present work aims to propose a methodology for improving the energy grid in the countryside, while reusing abandoned buildings by modifying their function and maintaining their aspect as much as possible. In this section, the proposal is explained in a few points which describe each step of the process.

- Survey of the defined rural area in order to identify the annexes to be recovered and classification to classify them by type;

- Definition of the most adequate energy technology for RES production which could be applied to the previously selected rural buildings;

- Construction of a virtual model of the proposed solution in order to evaluate the plant functional scheme and visual impact of the proposal;

- Analysis of the proposal’s sustainability by evaluating its economic and environmental impacts.

2.2. The Concept of Energy Rural Silo

The Energy Rural Silo (ERS) is a project proposal for a sustainable energy tower that could be applied to the nodes of the rural energy grid. In moving from suburban areas to the countryside, rural annexes such as silos, dovecotes and grain stores appear as tall buildings which have fallen into disuse and are commonly unstable and unsafe [16]. In that regard, the main aim of the ERS proposal is the recovery and enhancement of these buildings by turning them into small plants fed with biomass residues and byproducts from agricultural and zootechnical activities. Currently, there are numerous structures that have been abandoned for longer periods of time because their functions are no longer necessary; this has contributed to architects’ preference for reusing existent buildings instead of erecting new ones. The High Line in New York City (USA) [17], the Danish National Maritime Museum in Helsingør (Denmark) [18], and the Gasometer in Wien [19] are some evident examples about how degraded and functionless spaces can still have an important role on urban strategies. The former was an urban railroad turned into a linear park where citizens can practice sports or just spend their free time in a healthy space; the second was a dry dock which has been turned into a museum. The latter was a gasometer which has been redesigned as a residence for students. Moreover, the modification of something already existent in the territory is easily accepted by citizens and that might solve the social acceptability issue related to renewable energy exploitation.

The ERS project represents an efficient application of the Circular Economy approach: this theory promotes greater resource productivity aiming at reducing waste and avoiding environmental pollution [20]. In this case, the ‘waste’ is not only represented by the disused buildings and the materials they are made of, but also by the aforementioned biomass residues which are converted into renewable energy. According to the proposal, heat and electricity could be produced through mini biomass plants, widespread in the countryside and installed within rural silos. Therefore, the ERS may satisfy rural energy needs and considerably reduce the distance between plants and users. It could also guarantee a very low environmental impact thanks to the use of biomass residues and their conversation into renewable energy.

2.3. Rural Buildings in Umbria

The economy of central Italy is mainly based on agriculture and livestock thanks to the advantageous climate conditions. Over the last century, the population began to move from urban areas towards the surrounding countryside which therefore gave a sudden impulse to the construction of new buildings where families lived and worked. According to their functions, those rural structures were able to take advantage of both local materials and traditional technologies allowing them to live in symbiosis with the environment. From this point of view, rural buildings could be considered an elementary example of bioclimatic architecture [21,22].

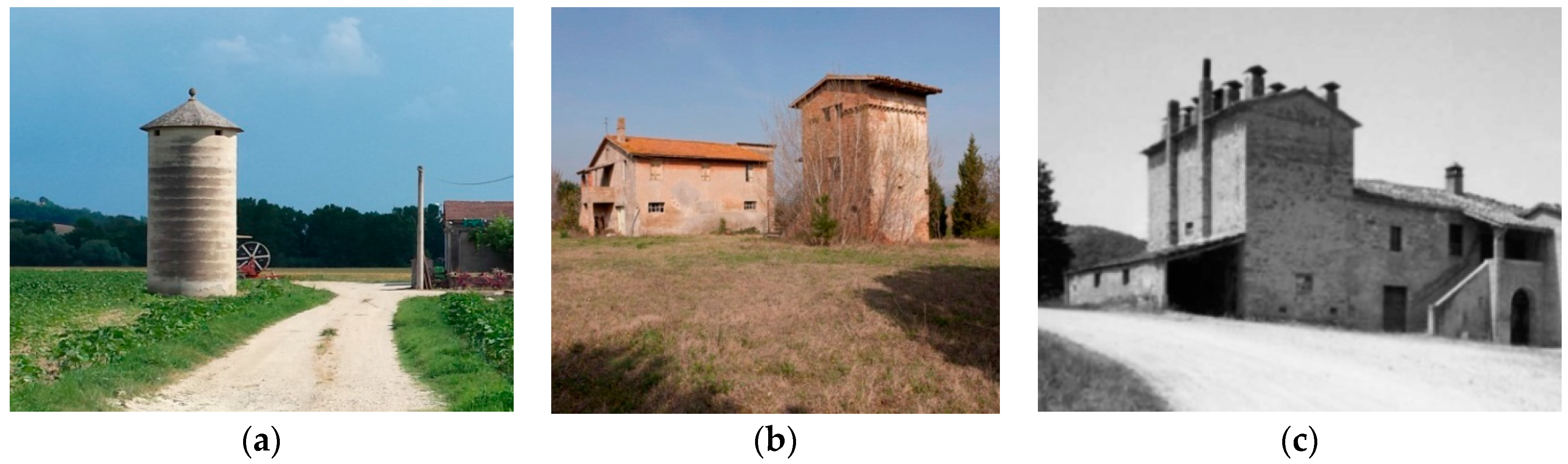

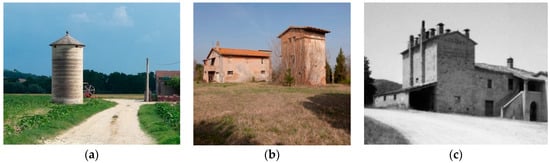

Depending on the supply chain and products, those rural buildings were equipped with adequate annexes such as dovecotes towers (i), grain store silos (ii), and tobacco drying kilns (iii) [23] (Figure 1). The first buildings were defensive outposts during the colonization period and their function has been later changed into a sort of aviary for doves. Although some dovecotes could appear in isolation, they were usually absorbed by nearby dwellings, which were built as elements of parasitic architecture. As for the dovecotes, grain stores were tower-shaped annexes constructed using brick or structural concrete depending on their age and localization. They were seven meters high at the most and they were placed on the farms nearby. In contrast to the former, those silos are commonly isolated to the rural landscape. Due to its function, this type of building turns out to be the most widespread during the last century in the countryside of the central Italy. The third building type, tobacco drying kilns were usually built in the northern part of the region Umbria and they were characterized by the presence of numerous chimneys located on their roofs that, nowadays, make them easy to identify [24].

Figure 1.

Rural buildings in central Italy, from the left: (a) a grain store silo; (b) a dovecotes tower; (c) a tobacco drying kiln.

Even if those elements of rural architecture have recently been classed as Environmental and Historical Heritage sites, the buildings seem to be in decay because of the decline of the agricultural activities. Hence, their reuse and promotion turns out to be particularly important considering the strategic planning defined by policies from the Italian Ministry for Agriculture, Food and Forestry: the ministry aims at promoting the re-introduction of new knowledge and technologies on the primary sector of the economy until 2020 in order to pursue sustainable development in terms of productivity, profitability, and efficiency [25]. In particular, the planning highlights the need of reducing both energy demand and waste production by realizing new plants with a low impact on the surroundings, as with the proposed ERSs’.

2.4. Mini Biogas in Umbria

The state of art of biogas exploitation as a renewable energy source in the region Umbria in central Italy highlights that bioenergy production in 2014 was about 223.5 GWh. It was approximately the 2.4% of the Italian gross bioenergy production, which actually is around 18,732.4 GWh according to the Statistic Report on Energy from Renewable Sources elaborated by the Italian Manager of Public Energy (GSE) [26].

Umbria bioenergy production seems to be mainly attributable to biogas plants (47%); while the remaining part mainly represents the energy deriving from solid biomass combustion (40%). Bioenergy from waste is not developed in Umbria and there is a small percentage of energy from bioliquids (13%). Moreover, the report shows that in recent years (2013–2014) an increment of about 7.4% of green energy produced from bio products was registered. In conclusion, biogas plants’ contribution to the local energy balance seems to already be significant, although there is still ample room for improvement.

3. Description of the Case Study

3.1. Building Survey and Modeling

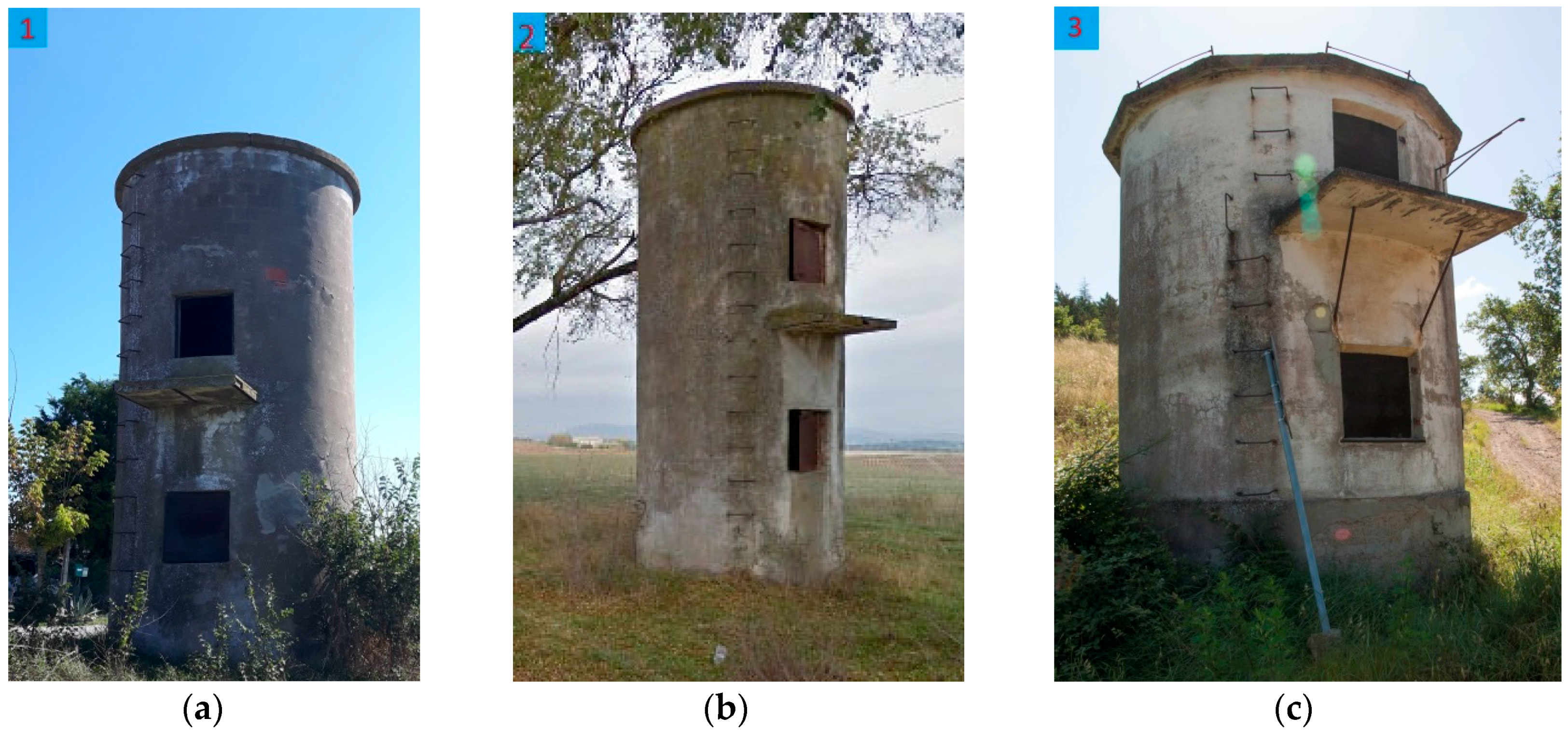

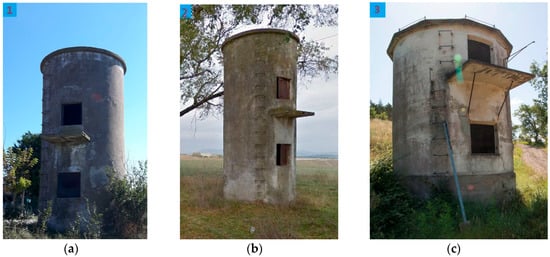

The case study is an abandoned silo, located in the rural area of Sant’Apollinare (Marsciano, Perugia). There are several rural ancient buildings in that area, as reported in the map on Figure 2. For the present study, one rural tower was chosen (the number 3 in Figure 2 and Figure 3) because of its proximity to the Sant’Apollinare fortress. The fortress hosts a milling plant for vegetable oil production from seeds and there is a vocational tradition for oil production. Several decades ago, the crops all around the site were dedicated to sunflower and rapeseed cultivation in order to produce oleaginous seeds. The recent crisis of the agricultural activities resulted in the abandonment of fields and rural buildings.

Figure 2.

Localization of the main silos on the countryside near Sant’Apollinare (Marsciano, Perugia).

Figure 3.

Pictures of the silos reported in the previous orthophoto of Sant’Apollinare area. (a) Silo Le Masse; (b) Silo Via Settevalli; (c) Silo Sant’Apollinare.

The silos were built for grain storage from the oil supply chain; so, they are ideal for conversion into locations for a renewable energy-based electric grid for producing green energy from agricultural and forestry residues.

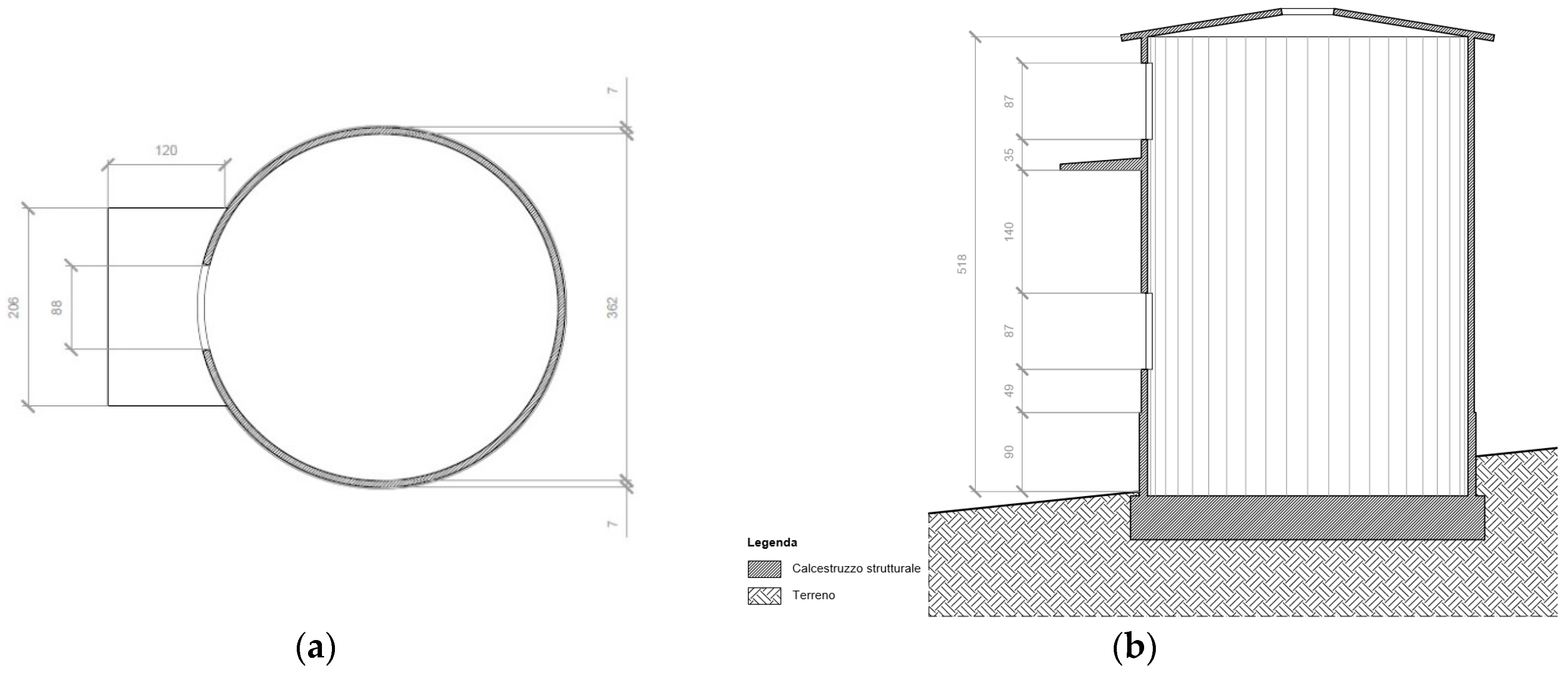

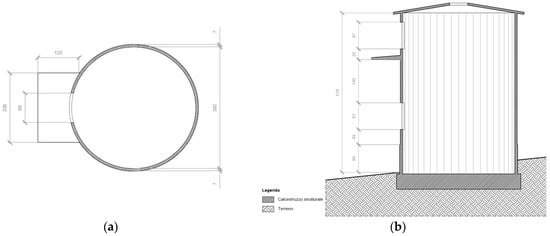

The silo located in Sant’Apollinare was probably built during the 1950s by the Agrarian Foundation of Perugia. In particular, the geometric survey of the architectural object reported that the cylinder which forms the envelope is made of structural concrete 7 cm thick: so, it would not collapse under loads caused by stored grain and wind flow. The single layer wall is characterized by high thermal conduction; therefore, indoor and outdoor temperatures are more or less the same. The external diameter is 376 cm, while its height to the eaves is 518 cm. There are two windows, placed at different heights, and an opening on the ceiling so it could be filled. None of those openings are closed—there is a window or a trapdoor—and the building turns out to not be insulated from the outdoor environment. Both windows are 88 cm in length and 87 cm in height. The silo’s lower part is reinforced with a concrete base 90 cm in height that is 3 cm thicker than the wall. This description is also reported in Figure 4 by the plan (Figure 4a) and section (Figure 4b).

Figure 4.

Survey and measurement process of silo’s geometry, base, and profile: (a) Plan; (b) Section. The dimensions are expressed in meters.

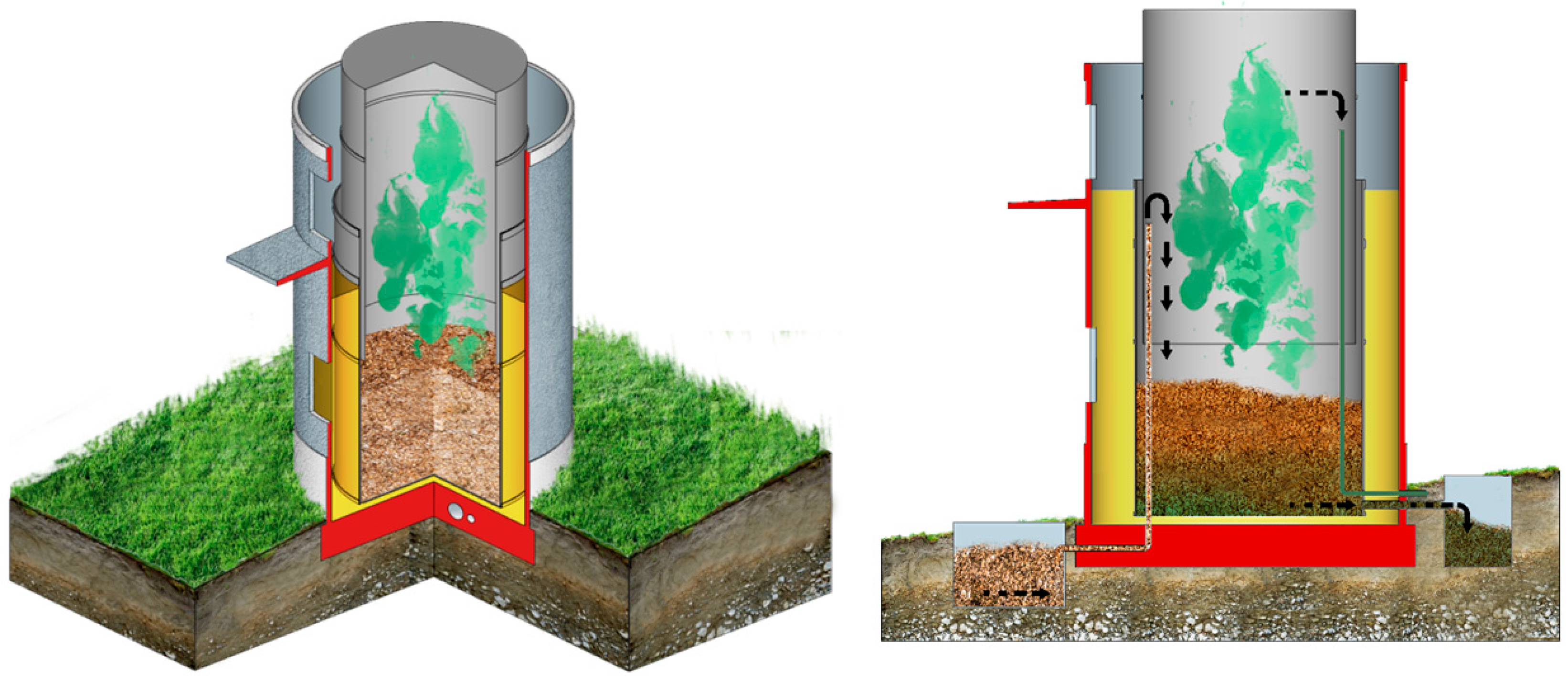

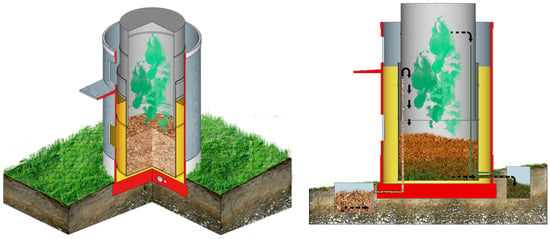

Furthermore, a 3D model was realized in order to evaluate the biomass system’s impact on the visual perception of the rural building. Indeed, those heritage sites are protected by their historical value as key elements of the original landscape, therefore they cannot be demolished and their envelope’s original appearance should be maintained as much as possible. The model, shown in Figure 5, highlights how the installation of a biogas plant does not impact the appearance of the landscape or countryside: it demonstrates how an ERS could reduce social acceptability problems caused by RES plant installation.

Figure 5.

An overview of the small-scale biogas plant integrated within the silo.

3.2. Biogas and Plant Design

The case study consists of an abandoned silo located in the rural area of Sant’Apollinare (Marsciano, Perugia, Italy). In the following paragraphs, the main Energy Rural Silo’s characteristics are reported by discussing the reasons which led toward the resulting plant design. Furthermore, the main elements which compose the small-scale biogas system are listed below and pictured in Figure 5.

The components are described as follows:

- Loading system, a tank that can store up to 12 m3 of different biomasses, and a specific submerged pump can stir them and make the mixture homogeneous; a regulation valve can dose the quantity of biomass to be loaded to the reactor;

- Anaerobic digester, the biomass based mixture remains in the digester for 15 days by getting warmer through a coil;

- Gasometer, while the digestion process is underway, the resulting biogas is stored in the floating bell with a volume up to 13.5 m3 that corresponds to a maximum height increment of 2 m;

- Biogas cogeneration engine, the engine is fueled by the biogas stored in the upper part of the digester; the electric power can range from 10 to 30 kW, with a corresponding biogas flow rate of respectively 7 and 9 m3/h (at least 65% methane content in biogas) and a thermal power which ranges from 50 to 70 kW;

- Digested matter storage tank, a part of produced heat is transferred towards this tank to ensure drying the digested matter is dried.

3.2.1. Plant Technology

The available technologies for biogas plants are mainly classified based on the direction of the biomass flow through the reactor where the biological transformation occurs: there are digesters with horizontal or vertical biomass flow or a combination thereof. According to the biomass feeding capacity, digesters can be structured in one stage; in fact, two or more stages are required if biomass load is over 50,000–90,000 t/year, in order to reduce the volumes of reactors and to assure an adequate retention time. In conclusion, two other parameters affect the dynamics of the biological process for biogas production: the total solid content (<20% in wet conditions, >20% in dry ones) and the operating temperature (mesophile at about 35 °C; thermophile at least 55 °C) [27].

Due to the necessity of fitting the reactor inside the building, the chamber must be single-stage based. The anaerobic digestion occurs in the chamber with a mesophilic process and a solid content less than 20% (wet conditions). The required technology with the underlined characteristics is produced by AAT Abwasser- und Abfalltechnik GmbH [28] and it is currently applied to some plants such as PFIEL, realized in Austria in 2003 and fed with energy crops; and BOSCH AG, realized in Switzerland in 2004 fed with butchery residues [29].

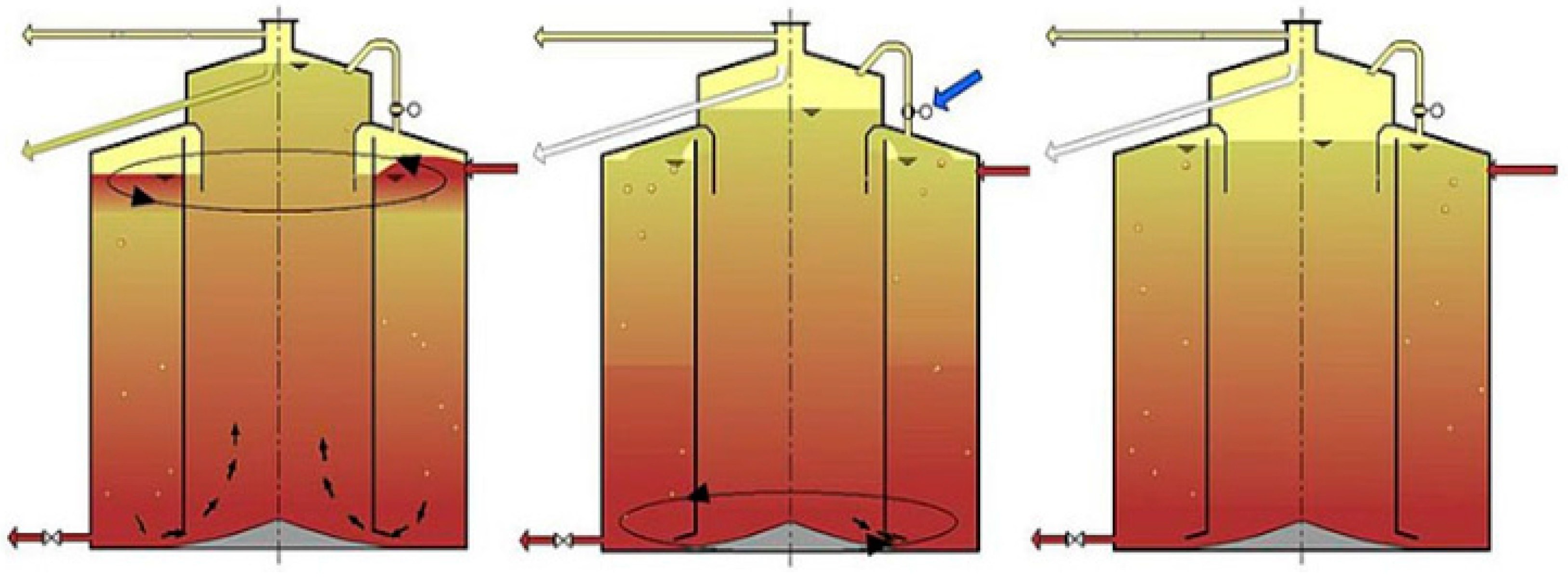

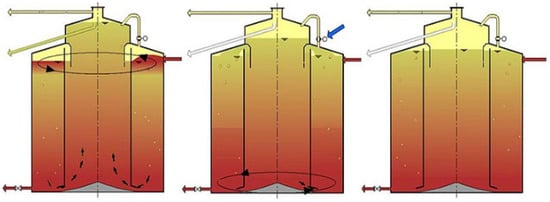

The system provides an arrangement with two digestion rooms and an independent hydraulic mixing. The dual-chamber system consists of two passages connected together in a series that prevents short-circuit flows. The products that are difficult to digest (floating and heavy substances) are accumulated in a special compartment. Those products can be excluded and extracted from the digester through special extraction systems to prevent clogging and deposit risks (Figure 6). Autonomous hydraulic mixing and the pumping system which works as the agitator allow both the mixing and extraction of the digested substrate [30]. In a plant characterized by low quantities of digested matter as in this case, this mixing system is efficient and allows the plant features to be simplified. This process enables the treatment of substrates with high concentrations of organic matter (liquid manure with a content up to 12% of dry matter).

Figure 6.

A schematic section of the digester plant, from the left: before, during and after mixing.

This conformation of the hydraulic digester permits greater reliability of the process and the system to be achieved, while reducing management costs for both energy and maintenance costs [27].

3.2.2. Insulation Layer’s Properties

An important step for the definition of the plant layout is the design of the insulation layer: it can reduce the heat losses through the tower’s envelope and prevent alteration of the inner chemical reactions. The silo’s insulation is divided into three main parts: facade (i); basement (ii), and floating gas-holder (iii).

Regarding the facade, two different solutions, which are stone wool and expanded perlite, were assessed and compared in order to select the best one in terms of costs and performance. They were chosen among the available insulating materials because of their low rigidity which makes them perfect for application as insulation layers in cavities between walls, or between the existing silos and the digester in this case. Despite the lower cost due to raw material and installation, which is 25 €/m2 for expanded perlite and 30 €/m2 for stone wool [31], expanded perlite has been discarded: stone wool seems to be the most adequate for filling a cavity 0.44 m thick. Therefore, considering a thermal conductivity (λstone wool) of 0.044 W/mK, the consequent thermal transmittance (Ustone wool) guaranteed by mineral wool is about 0.10 W/m2K, while the thermal flow (Φstone wool) should be up to 137.9 W.

Otherwise, only cellular glass has been evaluated as the insulation material for the basement due to its higher density (120 kg/m3) and its better compressive strength (7 kg/cm3) if compared to the aforementioned insulating materials. According to the standard UNI EN ISO 13370 [32], the thermal flow (Φcellular glass) toward the ground was calculated and its value is 115.4 W.

Finally, the thermal dispersion was evaluated through the floating gas-holder made of a steel layer (λsteel = 0.12 W/mK) without any insulation layer because of its function. Considering the same adduction coefficient for air and biogas (hair = hbiogas = 2.5 W/m2K) [33], the thermal transmittance and the thermal flow were respectively calculated as 10.34 W/m2K and 8733.16 W. In conclusion, summing up the three thermal flows related to the three main parts of the silo (facade, basement and floating gas-holder as reported in Table 1, the Φtotal is up to 9 kW and this quantity should be counterbalanced by thermal gains from a heat exchanger connected to the whole plant.

Table 1.

A thermal characterization of the building components.

3.2.3. Coil Heat Exchanger

The coil heat exchanger system, which allows to maintain the mesophilic conditions (from 38 °C to 40 °C) as constantly as is possible, is located in the digester, attached to its internal iron surface. The system was designed from a few considered hypotheses about the biomass mixture’s density and the slurry’s specific heat capacity and density. In particular, the biomass mixture’s density, calculated as weighted mean of the material densities (on the percentage composition in biomass) is 925 kg/m3, while the slurry’s specific heat capacity has been set at 7500 J/kgK.

Therefore, considering the coil is made of copper with a water flow of 0.5 m3/h, the thermal flows gained by slurry and due to the heat exchanger is 790 kW. In conclusion, the pipe that forms the coil heat exchanger should be about 525.8 m long in order to accomodate the mesophilic conditions needed for biological processes.

3.2.4. Biogas Cogeneration Engine

Once the biogas has been produced, it is ready to be turned into energy through an Internal Combustion Engine (ICE), provided with a Combined Heat and Power (CHP) system. Currently, the plant stands alone and no connection to the grid has been established.

The engine’s model is a Tedom T30 AP-biogas that is 1700 mm long, 760 mm deep and 1600 mm high. It weighs 1.100 kg and its container reduces noise up to 60 dB. In Table 2 below, the main features of this plant are reported [34].

Table 2.

Basic technical specifications.

3.3. Biomass Pathway and Biogas Production

In order to improve the sustainability of the biogas supply pathway and the integration of the construction intervention with the surrounding rural area, an innovative and promising sustainable crop has been recently studied by the CIRIAF Research Centre: the cardoon (Cynara cardunculus). Some experimental crops were planted in Sant’ Apollinare di Marsciano (Figure 7).

Figure 7.

A recent cardoon crop in Sant’ Apollinare.

Cardoon is a multi-year crop and, after its second year, the seeds can be easily harvested (1.5–2 t/ha) and milled in a squeezing plant to produce vegetable oil. The cultivar is sustainable because (i) it grows in marginal lands, avoiding competition with food crops and (ii) it does not need to be irrigated and fertilized (spontaneous crop).

The cardoon oil is involved in the biobased product pathway [35]; the squeezing residue can be recovered and used as a food supplement for the production of animal feed [36]. Due to the great quantity of produced by squeezing residue, the CIRIAF investigated its application as feeding matter for biogas, in co-digestion with other local biomass through a mini biogas plant. Some laboratory tests were conducted in order to regulate the different kind of biomass to define the best biogas yield of the proposed biomass. An experimental campaign was conducted using one-liter batch reactors in a biogas laboratory and with percentages of cardoon squeezing residue of 15%, 18%, and 21%. The restraints on the composition of biomass in co-digestion were defined by anaerobic process conditions: 39°C mesophilic conditions temperature, 10%–15% of solid contents in biomass, pH 6.8–7.2 [37], carbon/nitrogen ratio 15 [38]. The best biogas yield is about 63 m3 biogas/tons wet based, with a content of 18% in cardoon dry matter, corresponding to about 5% wet matter [36].

In the mini biogas plant, integrated within the ERS, the biogas production from squeezing residue was combined with the seeds milling activity and the biogas plant operation lasted about eight months. The total ERS volume for biogas plant is about 13.5 m3; according to the total biomass mixture density of 925 kg/m3, the total weight of inlet biomass to fill the digestion chamber is 12.5 t. The equivalent weight of the cardoon residue fraction is 0.6 t; for the total duration of the biogas production tests, the total cardoon residue needed was about 10 t, which was easily stored in big bags.

The required quantities of fields for the cultivation of cardoon are about 10 hectares and the seed production is about 17 tons.

The produced biogas was about 788 m3 within 15 days and its composition was about 70% methane, as determined by experimental tests in laboratory [39]. During the eight months of plant operation, the total biogas production was more than 13,000 m3 and the energy production by the cogenerator described previously, was 25,000 kWh in electrical production; 56,000 kWh in thermal energy.

3.4. Economical and Environmental Sustainability

The total costs, both OPEX (OPerating EXpenditure) and CAPEX (CAPital EXpenditure), and the revenues of the mini biogas plant integrated in ERS are shown in the present paragraph of the paper in order to investigate the economical sustainability of the proposed intervention.

The source of revenue is represented by the incentive of selling the produced electric energy. The yearly incentive from the electric energy production can be estimated according to the recent regulation and depending on the electrical output (<300 kW), the kind of biomass in co-digestion (byproducts from agriculture and zootechnical slurry), and the absorbed energy for auxiliary units (11%) [40]. The feed-in tariff is 0.233 €/kWh and total revenue is about 5,500 €/year.

In Table 3, CAPEX are shown in detail.

Table 3.

CAPEX for ERS application.

The OPEX total costs refer to the whole cardoon pathway: the milling plant is just labor; the manpower employed for the oil station can also be improved in the ERS biogas plant due to the high automation level of the biogas plant. The OPEX attributable to the oil plant is represented by: fuel and engine maintenance. The fuel is necessary to feed the tractor to transfer and load the plant with animal slurry and cardoon squeezing residue, its cost should be about 1000 €/year. On the other hand, the maintenance costs of the biogas engine should be at most 2000 €/year.

The carbon footprint of the working proposed biogas plant can be evaluated according to the renewable electric energy produced by the plant and injected to the grid. The avoided CO2 emissions are about 15.5 tons/year, considering an emission factor equal to 0.5 kgCO2/kWh [41].

3.5. Application of Solid Oxide Fuel Cells (SOFC) Stack

Solid Oxide Fuel Cells (SOFC) systems are among the most promising energy generators, due to their high electrical efficiency (>50%) [7]. This kind of technology can be considered for application to the ERS prototype because of its comparable OPEX. Furthermore, both the ICE and the SOFC stack are characterized by low pollutant emissions [42]; in fact, the produced carbon dioxide from a biomass pathway does not contribute to the greenhouse effect.

The application of the SOFC systems to the ERS prototype makes the installation of a system for the pre-treatment of dirty gases necessary in order to obtain a high quality feeding biogas. A scientific literature survey has been improved in order to define the best systems for cleaning biogas and removing trace compounds [43].

4. Conclusions

The spread of biogas plants in Umbria has slowed down over the years due to their low energy density, difficulties in social acceptance and the non-programmability of the energy production. All these issues can be easily overcome by employing innovative technologies with really low environmental impacts. In that regard, the CIRIAF Research Centre has designed an intervention about the installation of a little sized anaerobic digester (power around 30 kW) in the historical area of Sant’Apollinare. That area is involved in an agricultural plan for revitalizing the local economy based on agriculture, through the installation of a new sustainable crop: cardoon.

Therefore, the proposed plant is fed with local biomass and residue from agricultural activities. It converts them into electric and thermal energy. Creating a grid of small-scale plants, perfectly integrated on rural landscape, may overcome the mentioned issues.

The Energy Rural Silo concept comes from this idea: small biogas plants integrated with buildings, which are classed as Environmental and Historical Heritage sites by the local authority in order to promote and recover them. Thus, the concept can be easily applied to other rural sites, especially in Umbria, coupling low cost with a high performance level. A basic estimation shows a census of about 200 abandoned rural silos in the region Umbria [23,24] and their recovery is strongly encouraged by law [25].

The biogas potential of squeezing residue from cardoon seeds was assessed in this research to define an approximate scheme of the pathway and to optimize the device organization. The environmental benefits related to biogas consumption have been estimated; the economics of the proposal may be evaluated considering the whole cardon pathway, including the milling of the seeds, oil storage and the final energy consumptions. Therefore, the economic benefits produced by biogas can cover all the expenditure for the recovery and the conversion of the silo and its maintenance.

Author Contributions

Mattia Manni operated the survey of the ERS; Andrea Nicolini, Valentina Coccia and Alessandro Petrozzi designed the experimental activities in order to design the energy interventions in biogas plant integration; Gianluca Cavalaglio designed the engine and the features.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| RES | Renewable Energy Sources |

| GSE | Manager of Public Energy |

| ERS | Energy Rural Silo |

| ICE | Internal Combustion Engine |

| CHP | Combined Heat and Power |

| OPEX | Operating Expenditure |

| CAPEX | Capital Expenditure |

| SOFC | Solid Oxide Fuel Cells |

References

- European Union. Directive 2010/31/EU on the Energy Performance of Buildings (Recast)—19 May 2010; European Union: Brussels, Belgium, 2010. [Google Scholar]

- Edenhofer, O.; Madruga, R.P.; Sokona, Y.; Seyboth, K.; Matschoss, P.; Kadner, S.; Zwickel, T.; Eickemeier, P.; Hansen, G.; Schlömer, S.; et al. Renewable Energy Sources and Climate Change Mitigation: Special Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Marrakech Action Proclamation for Our Climate and Sustainable Development; UNFCCC: Marrakech, Morocco, 2016. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Report of the Conference of the Parties on Its Twenty-Second Session; UNFCCC: Marrakech, Morocco, 2016. [Google Scholar]

- Lovins Amory, B. Renewable Energy’s ‘Footprint’ Myth. Electr. J. 2011, 24, 40–47. [Google Scholar] [CrossRef]

- Lewandowska-Bernat, A.; Desideri, U. Opportunities of Power-to-Gas technology. Energy Procedia 2017, 105, 4569–4574. [Google Scholar] [CrossRef]

- Papurello, D.; Lanzini, A.; Tognana, L.; Silvestri, S.; Santarelli, M. Waste to energy: Exploitation of biogas from organic waste in a 500 Wel solid oxide fuel cell (SOFC) stack. Energy 2015, 85, 145–158. [Google Scholar] [CrossRef]

- Agostini, S. Architettura Rurale: La via del Recupero. Alternative di Intervento Sull’esistente; Franco Angeli Editore: Rome, Italy, 1999. [Google Scholar]

- Cotana, F.; Belardi, P.; Tamagnini, C.; Materazzi, A.L.; Fornaciari, M.; Petrozzi, A.; Pisello, A.L.; Cavalaglio, G.; Coccia, V.; Pagnotta, G.; et al. TIAR: Renewable energy production, storage and distribution; a new multidisciplinary approach for the design of rural facility. Energy Procedia 2014, 45, 323–332. [Google Scholar] [CrossRef]

- Pisello, A.L.; Petrozzi, A.; Castaldo, V.L.; Cotana, F. On an innovative integrated technique for energy refurbishment of historical buildings: Thermal-energy, economic and environmental analysis of a case study. Appl. Energy 2014, 162, 1313–1322. [Google Scholar] [CrossRef]

- IEC-International Electrotechnical Commission. Grid Integration of Large-Capacity Renewable Energy Source and Use of Large-Capacity Electrical Energy Storage; White Papers; International Electrotechnical Commission (IEC) Market Strategy Board: Rome, Italy, 2001. [Google Scholar]

- Mosannenzadeh, F.; Bisello, A.; Vaccaro, R.; D’Alonzo, V.; Hunter, G.W.; Vettorato, D. Smart energy city development: A story told by urban planners. Cities 2017, 64, 54–65. [Google Scholar] [CrossRef]

- Rossi, F.; Nicolini, A. A cylindrical small size molten carbonate fuel cell: Experimental investigation on materials and improving performance solutions. Fuel Cells 2009, 9, 170–177. [Google Scholar] [CrossRef]

- Rossi, F.; Nicolini, A. Experimental investigation on a novel electrolyte configuration for cylindrical molten carbonate fuel cells. J. Fuel Cell Sci. Technol. 2011, 8, 051012. [Google Scholar] [CrossRef]

- Cotana, F.; Rossi, F.; Nicolini, A. A new geometry high performance small power MCFC. J. Fuel Cell Sci. Technol. 2004, 1, 25–29. [Google Scholar] [CrossRef]

- Bonamente, E.; Pelliccia, L.; Merico, M.C.; Rinaldi, S.; Petrozzi, A. The multifunctional environmental energy tower: Carbon footprint and land use analysis of an integrated renewable energy plant. Sustainability 2015, 7, 13564–13584. [Google Scholar] [CrossRef]

- King, E.A.; Bourdeau, E.P.; Zheng, X.Y.K.; Pilla, F. A combined assessment of air and noise pollution on the High Line, New York City. Transp. Res. Part D Transp. Environ. 2016, 42, 91–103. [Google Scholar] [CrossRef]

- Maritime Museum in Helsingør, Denmark. Available online: http://mfs.dk/en/ (accessed on 12 February 2017).

- Gasometer in Wien. Available online: http://www.gasometer.at/de/ (accessed on 25 June 2017).

- European Commission (COM614). Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Bruxelles, Belgium, 2013. [Google Scholar]

- Agenzia nazionale per le nuove tecnologie, l'energia e lo sviluppo economico sostenibile (ENEA). Architettura Bioclimatica; De Luca Editore: Rome, Italy, 1983. [Google Scholar]

- Martelli, R. I Materiali e gli Elementi Costruttivi Nella Casa Rurale; Olschki Ed.: Florence, Italy, 1969. [Google Scholar]

- Pagnotta, G. Umbria Architettura Tradizione. Rilievo e Catalogazione Dell’architettura rurale in Umbria. Ph.D. Thesis, University of Perugia, Perugia, Italy.

- Bonasera, F.; Desplanques, H.; Fondi, M.; Poeta, A. La Casa Rurale Nell'umbria. C.N.R., Ricerche Sulle Dimore Rurali in Italia; Olschki Ed.: Florence, Italy, 1955. [Google Scholar]

- Ministero delle Politiche Agricole, Alimentari e Forestali (MIPAAF). Piano Strategico per l’innovazione e la Ricerca nel Settore Agricolo Alimentare e Forestale (2014–2020); MIPAAF: Rome, Italy, 2014. [Google Scholar]

- Gestore dei Servizi Energetici (GSE). Statistic Report on Energy from Renewable Sources; GSE: Rome, Italy, 2014. [Google Scholar]

- California Integrated Waste Management Board. Current Anaerobic Digestion Technologies Used for Treatment of Municipal Organic Solid Waste; Public Affairs Office; Publications Clearinghouse: Sacramento, CA, USA, 2008.

- Administrative Appeals Tribunal (AAT). Abwasser- und Abfalltechnik GmbH Technology for Biogas. Available online: http://www.aat-biogas.at/it/esibizioni-profilo/sistemi-di-digestori/ (accessed on 25 February 2017).

- Costruire un impianto di biogas: Dal Nord Italia all’Abruzzo. In Proceedings of the Administrative Appeals Tribunal (AAT) Conference, Pescara, Italy, 23 February 2010.

- Sarikaya, E.; Demirer, G.N. Biogas production from broiler manure, wastewater treatment plant sludge, and greenhouse waste by anaerobic co-digestion. J. Renew. Sustain. Energy 2013, 5. [Google Scholar] [CrossRef]

- Insulating Materials. Available online: https://tirichiamo.it/page/Ristrutturazioni/Isolamento-Termico/Insufflaggio-Intercapedine-Prezzi-Costi-e-Consigli.aspx (accessed on 14 August 2017).

- Italian Standards, UNI EN ISO 13370. Heat Transfer toward the Ground; UNI—Ente Nazionale Italiano di Unificazione: Milan, Italy, 2001. [Google Scholar]

- Beretta Caldaie. Prontuario Tecnico; Hoepli Editore: Lecco, Italy, 2014. [Google Scholar]

- Tedom Biogas Engine. Available online: http://en.tedomengines.com/ (accessed on 10 March 2017).

- Novamont Mater-Bi. Available online: http://www.novamont.com/mater-bi (accessed on 10 March 2017).

- Cavalaglio, G.; Petrozzi, A.; Coccia, V.; D’Antonio, S.; Cotana, S. Mass and energy flows of cardoon oil in a prototype system for seeds milling and vegetable oil treatment and cogeneration. Energy Procedia 2015, 82, 681–685. [Google Scholar]

- Castelli, S.; Negri, M. La Digestione Anaerobica: Processo e Parametri di Controllo. Biomasse ed Energia. Produzione, Gestione e Processi di Trasformazione; Maggioli Editore: Rimini, Italy, 2011; pp. 163–181. [Google Scholar]

- Adani, F.; Schievano, A.; D’Imporzano, G. I fattori che rendono ottimale la razione per il digestore. L'Informatore Agrario 2008, 40, 19–22. [Google Scholar]

- Petrozzi, A.; Cavalaglio, G.; Coccia, V.; Nicolini, A.; Barbanera, M.; Cotana, F. Energy Enhancement of the Residues from the Cardoon Seeds Milling: Preliminary Experimentation in a Small Size Biogas Plant. Energy Procedia 2016, 101, 440–447. [Google Scholar] [CrossRef]

- Ministero dello Sviluppo Economico, Ministero dell’Ambiente. Decreto del 23 Giugno 2016: Incentivazione dell’energia elettrica prodotta da fonti rinnovabili diverse dal fotovoltaico; Gazzetta Ufficiale: Rome, Italy, 2016.

- Bruno, I. La Valutazione Delle Emissioni Evitate; Unità Studi GSE: Rome, Italy, 2013. [Google Scholar]

- Papurello, D.; Soukoulis, C.; Schuhfried, E.; Cappellin, L.; Gasperi, F.; Silvestri, S.; Santarelli, M.; Biasioli, F. Monitoring of volatile compound emissions during dry anaerobic digestion of the Organic Fraction of Municipal Solid Waste by Proton Transfer Reaction Time-of-Flight Mass Spectrometry. Bioresour. Technol. 2012, 126, 254–265. [Google Scholar] [CrossRef] [PubMed]

- Papurello, D.; Tomasi, L.; Silvestri, S.; Santarelli, M. Evaluation of the Wheeler-Jonas parameters for biogas trace compounds removal with activated carbons. Fuel Process. Technol. 2016, 152, 93–101. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).