1. Introduction

Solar power is one of the most promising renewable energy technologies for producing electricity as part of the shift away from fossil fuels. Common approaches employ photovoltaic (PV) panels. These use semiconductors to produce electric potential, on the basis of the photoelectric effect, when exposed to sunlight. Very high PV cell conversion efficiency of 43.5% have been demonstrated in laboratory measurement condition [

1]. However, such efficiency comes with a very high fabrication cost, because of the need to manufacture multi-junction solar cells. Using highly efficient solar cells, such as multi-junction solar cells, with a flat PV panel base can achieve higher efficiency, but it is expensive because of the large number of solar cells needed to cover a large area. Concentrated photovoltaic (CPV) systems, which utilize highly efficient PV cells under concentrated solar radiation, are solutions for reduction of the solar electricity cost. The main purpose of CPVs is the utilization of low-cost concentrating optical components that dramatically reduce the required cell area, allowing for the replacing of low-electricity-conversion-efficiency solar cells by expensive but high-efficiency cells [

2,

3]. A CPV system that can achieve an efficiency of 38.9% at standard test conditions has been demonstrated by the Soitec Company (Bernin, France) recently [

4]. Some commercial CPV systems have exceeded an efficiency of 30% [

5]. A CPV system is composed of three main components: the sunlight concentrator, a sun-tracking system, and solar cells. In conventional CPV systems, there are two mechanisms to concentrate solar radiation: solar concentrator base on refraction such as Fresnel lenses or converging lenses, and concentrator based on reflection such as compound parabolic concentrators (CPC) or parabolic mirrors. Long focal distance of solar concentrator makes CPV system become complex and bulky. Furthermore, conventional CPV systems require sun tracking systems to precisely rotate system and align its surface normal to sunlight direction. These sun tracking systems are usually cumbersome, require a pedestal, and must be mechanically stable against wind-loading forces [

6,

7]. These problesms of concentrators and sun-tracking systems inhibit the use of CPV systems on roofs, which is where the majority of solar panels throughout the world are installed.

Flat CPVs with lateral displacement tracking have been proposed to enable CPV installation on rooftops [

8,

9]. Some types of flat solar concentrators with various translation-based sun-tracking strategies have been designed to reduce the complex of CPV system. Jared et al. [

10] explored an alternate approach using a sandwich structure. high-efficiency micro solar cells are sandwiched between a two layer of lenslet arrays to demonstrate quasi-static concentrating PV panels less than 1 cm thick that accomplish full-day tracking through a small lateral translation at a fixed latitude tilt. Fabian et al. proposed a CPV system in the context of mobile freeform optics, in which the positions of the PV cells are varied laterally with respect to multiple concentrator optics [

6]. The planar micro-optic solar concentrator by Justin et al. used a combination of planar waveguide and lenslet array. Sunlight is concentrated by lenslet array then be coupled to waveguide by small reflective facets at the focal point of each lenslet [

7]. This design also allows a lateral displacement mechinsm of sun tracking. However, general difficulties among these approaches include complexity and a very small scale.

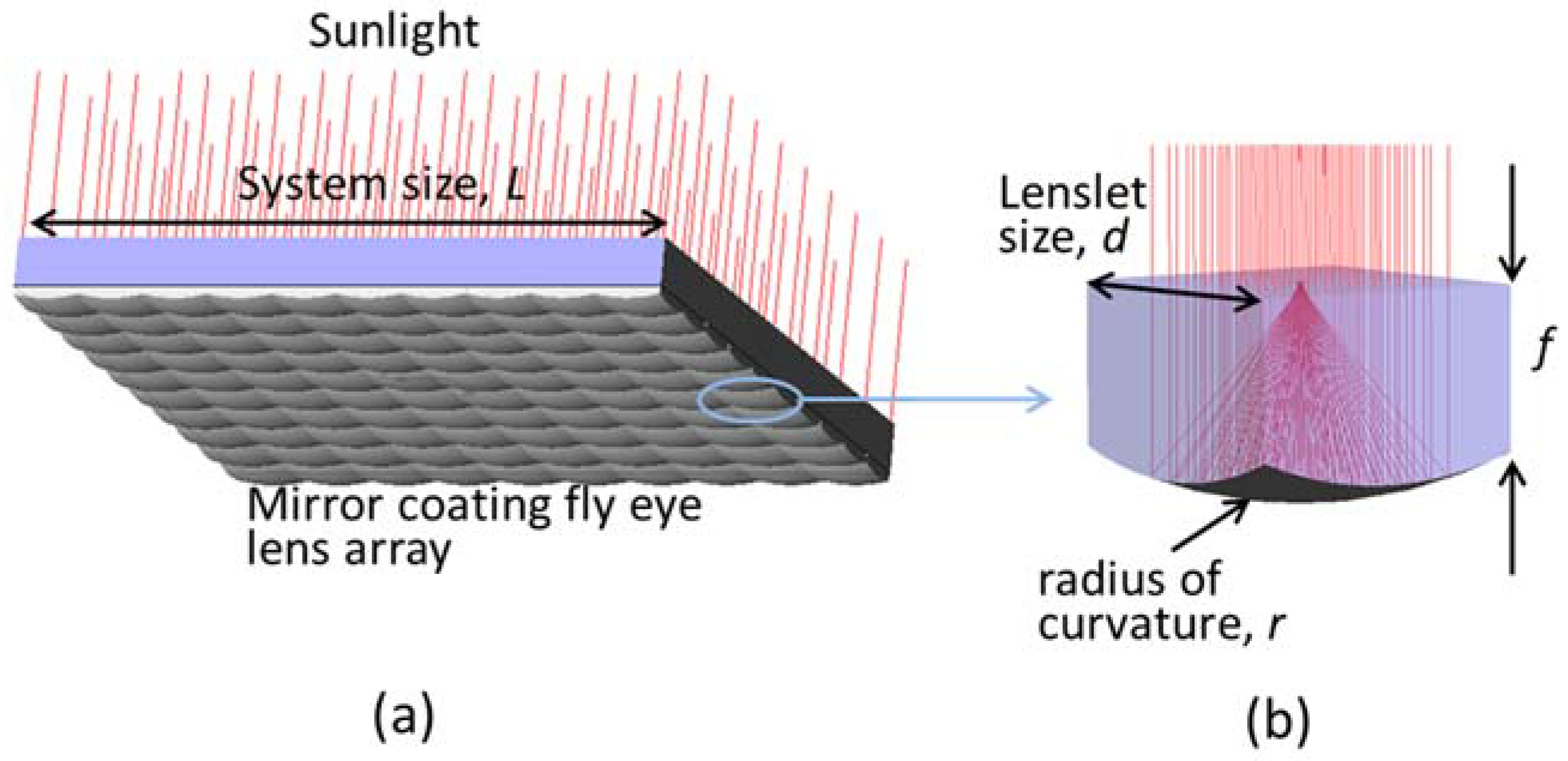

In this study, we introduce an alternative approach for a large-scale, flat CPV system comprised of an array of large-scale lenslets with mirror coating at the bottom and an array of solar cells integrated on a transparent substrate. The principles of CPV systems based on lenslet arrays are proposed in [

5,

8,

11]; however, distance from lenslet to the focal point is long in comparison with its diameter. As shown in

Figure 1a, in a larger-scale CPV system using an array of large-size lenslets, the system becomes very thick. The exaggerated part of

Figure 1a shows the orbit of the focal point of each lenslet when the sunlight direction changes. The orbit of focal point of each lenslet is a arc. This does not allow for the use of a lateral displacement-tracking mechanism. Here, we propose a novel CPV system using amirror coated lenslet array. The mechanism of a solar concentrator based on mirror coated lenslet array is shown in

Figure 1b. With this specialist design, sunlight is focused by a reflection mechanism instead of refraction in the conventional designs. The focal length can be sufficiently small, and the orbits of focal points are in a straight line (as shown in the exaggerated part of

Figure 1b) instead of an arc (as in the exaggerated part of

Figure 1a). With this design, the complex CPV system with cumbersome sunlight concentrator and rotation sun tracking mechanism could be replaced by a flat concentrator with lateral sun tracking mechanism. The aim of this research was to design and analyze a compact solar concentrator based on a mirror-coated lenslet array that might contribute to developing a high-efficiency, low-cost CPV system suitable for rooftop installation, thus facilitating the mass production and commercialization of cost-effective CPV systems.

The remainder of the paper is organized as follows:

Section 2 discusses in detail the design of the proposed flat CPV system based on a mirror-coated lenslet array. In

Section 3, the proposed system has been modeled using LightTools software (Synopsys, Inc., San Diego, CA, USA) to evaluate its performance. The requirements for lateral displacement and tolerance of sun-tracking systems are also discussed. Detailed discussion, technical issues, and cost factors are presented in

Section 4. Finally, brief concluding remarks and possibilities for future research are presented in

Section 5.

4. Discussion

Providing a cost-effective system is the major challenge for achieving the wider adoption of CPVs. As discussed in the introduction, to be competitive, a CPV system must be fabricated using a low-cost process. Accordingly, they must be manufactured using plastic materials. The use of plastic allows the lenslet array to be molded, thereby providing a low-cost solution for mass production. Reducing the use of materials will also contribute to reducing the costs of manufacturing, supplier management, and recycling. In our system design, the receiver and concentrator are made of a single material—PMMA.

Our proposed system has a lower concentration ratio (

Cgeo = 50×) in comparison with typical Fresnel-based CPV systems (

Cgeo is from 300× to 1000×), thereby requiring a larger solar cell area. Nevertheless, despite this comparative cost increase for additional solar cells, the declining unit cost of solar cell production means the system cost remains acceptable. On the other hand, the high concentration ratio of conventional designs requires very high-quality optical devices and sun-tracking systems. Very close alignment is also required between optical components, and these can rapidly become misaligned when operating under outdoor conditions [

12,

14]. Heat is also a problem in high-concentration systems, the remediation of which involves an additional cost. The highly condensed and non-uniform profile of light at the focused area in conventional systems requires a complicated and lossy optical system for the redistribution of light, which results in a lower efficiency and higher cost. Because of a lower concentration ratio in our proposed design, the heat problem becomes the minority.

As discussed in the introduction part, to be competitive, the flat CPV system must be efficient and must be fabricated using a low-cost process. The concentrator, which is an array of lenses, can be manufactured by a simple molding process. The fabrication of the receiver part, which is composed of a solar cell array integrated on a transparent sheet, seems not to be easy. We suggest using transparent light-emitting diode (LED) display technology; however, the LED chips will be replaced by solar cells. The LED display on a glass substrate was commercialized with a low cost and has been widely applied for decorative lighting or displays recently [

15].

Figure 11 shows the structure of a receiver constructed on the basis of this technology. The receiver is composed of indium tin oxide (ITO) conductive glass, solar cells and a glass panel. ITO coated glass is often used for displays and touch screens. The solar cell array is glued onto a conductive glass. The solar cells on the conductive glass are electrified through the method of laser ablation. No electrical wire is utilized in this method; hence the shadow of the electric wire is eliminated. A glass plate is placed on the upper to protect the degradation under outdoor conditions. Two layers are glued together using a polyvinyl butyral (PVB) film, which is a resin mostly used for adhesion to many surfaces. In [

16], the thermal conductivity of the ITO layer is 4–5.86 W/mK, while the thermal conductivity of the glass is 0.8 W/mK and of the PMMA is 0.167–0.25 W/mK; thus this ITO layer also plays the role of a heat dissipation layer. Because the solar cells are placed on the top of the CPV system, we propose coating a thin layer of silver as an additional heat sink.

Because of the simplicity of the proposed flat CPV system in terms of its shape, weight, operating principle, and cost, it can easily be installed on rooftops. The adoption of flat CPVs for rooftop installation will address the apparent huge demand for commercialization [

17]. The aim of the present research is to design a flat CPV system suitable for residential rooftops; therefore, a brief comparison between our proposed system and widely used PV panels is essential. Most PV panels have an electricity conversion efficiency of 18–20% as a result of using Si solar cells with a multi-crystalline structure. Our proposed system utilizes single-crystalline Si solar cells with an efficiency of 25%; considering optical losses (~10%), the overall system efficiency is approximately 22.5%. Unlike traditional or more conventional flat-panel systems, our proposed flat CPV system is much less expensive to produce, as each cell requires much less semiconductor material than conventional solar cells, which also makes the system more environmentally friendly. Sunlight has two components: direct normal irradiance (DNI) and diffuse horizontal irradiance (DHI). As for most concentration systems, our proposed flat CPV system is unable to collect diffuse irradiation. This is a drawback in comparison with flat PV systems. There have recently been rapid developments in transparent solar cell technology. A transparent solar panel can absorb both the ultra violet and infrared parts of the solar spectrum to generate electricity. This type of solar cell is transparent to the visible spectrum. We suggest that the transparent PMMA sheet used in the receiver part of our proposed system might be replaced by a transparent solar panel and the solar cell arrays be replaced by double-junction solar cells baed on GaInP/GaInAs, which have the highest conversion efficiencies within the visible spectrum. This would allow the non-visible components of both DNI and DHI to be collected and converted to electricity, and visible irradiation—the largest portion of solar energy—will be concentrated and converted by high-conversion-efficiency solar cells. The approach of combining with transparent solar cells, as discussed here, may provide a new path for efficient, compact, and inexpensive PV power.