Control of Variable Speed Wind Turbines with Doubly Fed Asynchronous Generators for Stand-Alone Applications

Abstract

:1. Introduction

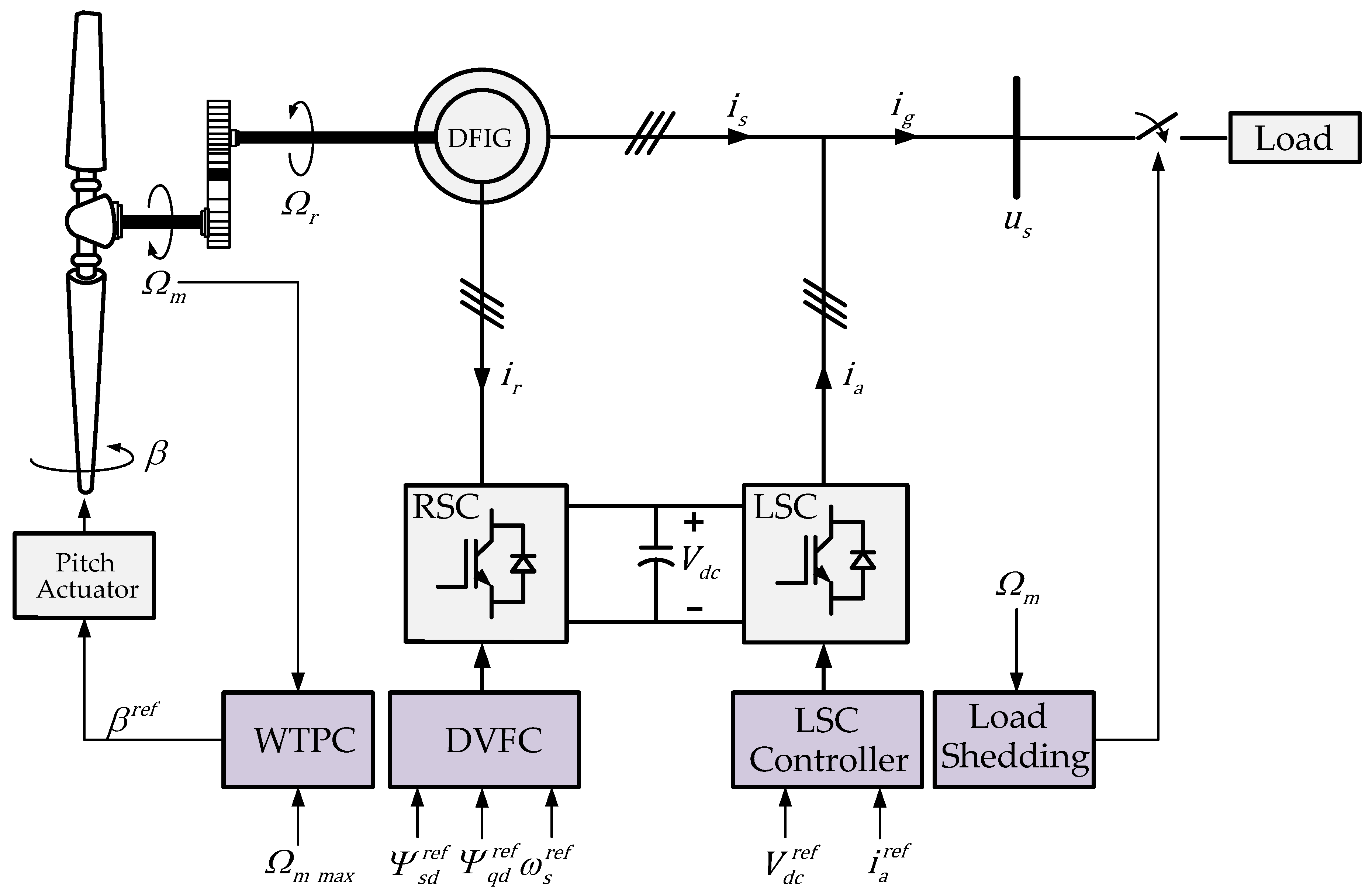

2. Stand-Alone DFIG Based Variable Speed Wind Turbine

2.1. Wind Turbine Model

2.2. DFIG Model

3. System Control and Operation

3.1. Direct Voltage and Frequency Control (DVFC)

3.2. Line Side Converter (LSC) Control

3.3. Wind Turbine Power Control (WTPC)

3.4. Load Shedding

4. Simulation Results

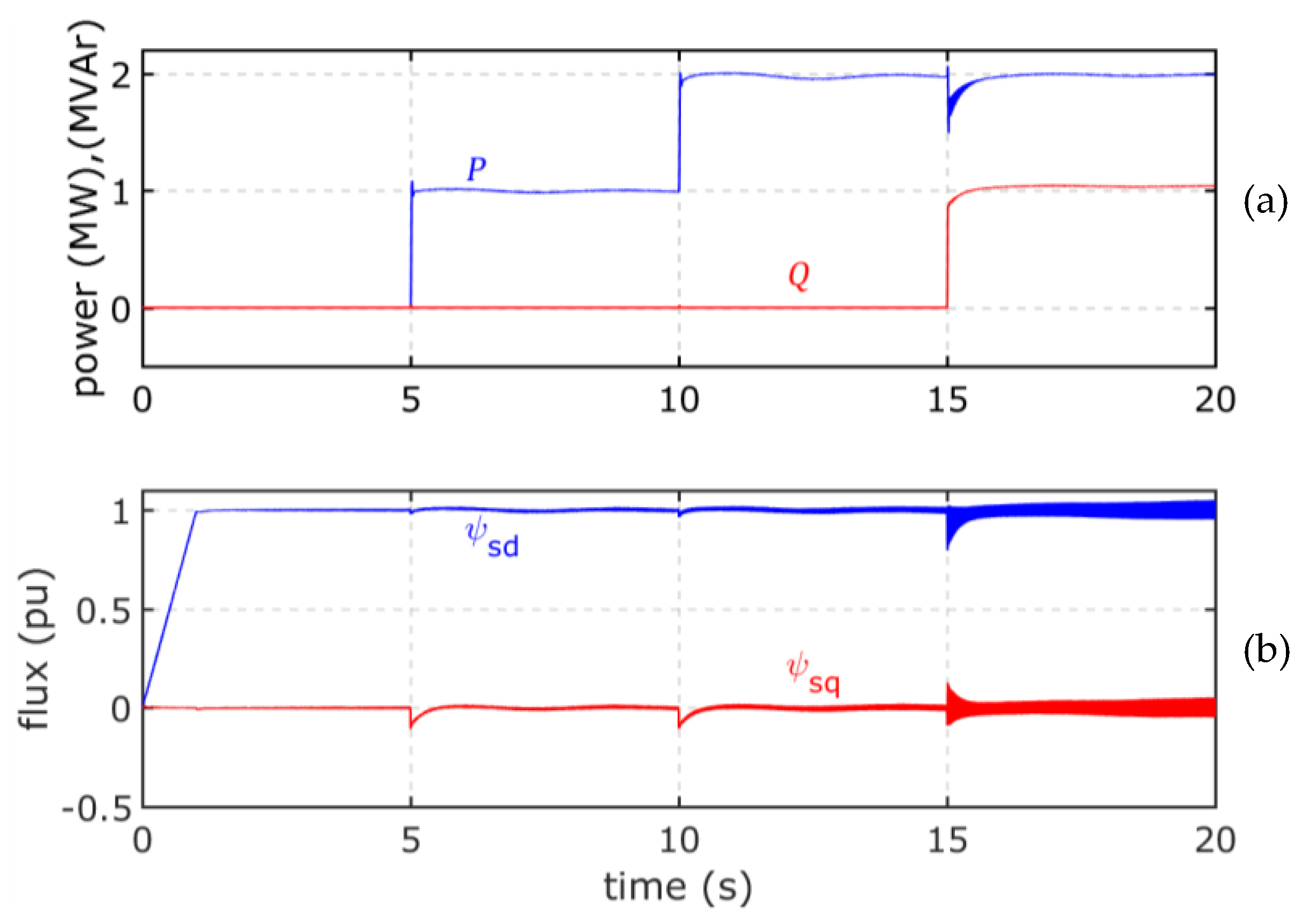

4.1. Results With Constant Wind Speed and Variable Load

4.2. Results with Variable Wind Speed and Constant Load

4.3. Results Under a Change in the Reference Signals with Constant Wind Speed and Constant Load

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Θ | encoder angle |

| θs, θr, θsp | stator, rotor, and slip voltage angle |

| Subscripts | |

| d, q | synchronous dq axis |

| s, r | stator, rotor |

| g, l, m | generator, load, wind turbine |

| B | base values |

| Superscripts | |

| ref | reference value |

| Acronyms | |

| VSC | Voltage-sourced converter |

| LCC | Line-commutated converter |

| HVdc | High-voltage direct current |

| WT | Wind turbine |

| DFIG | Doubly-fed induction generator |

| DVFC | Direct voltage and frequency control |

| WTPC | Wind turbine power control |

| LSC | Line side converter |

| RSC | Rotor side converter |

Appendix

- Rated power Pn = 2.0 MW

- Maximum rotational speed nm max = 20 rpm

- Base wind speed vB = 10.5 m/s

- Rated wind speed vn = 12 m/s

- Rotor radius R = 38 m

- Cpmax = 0.48

- λB = 8.1

- β range 0°–45°

- β rate range ± 10 degrees/s

- Pitch servo gain, kb = 2

- Pitch servo time constant, τb = 0.2 s

- Gear ratio nr/nm = 100

- Inertia J = 7 × 104 kg·m2

- Friction coefficient D = 0.06 Nm·s

- Rated stator power Pns = 2.25 MVA

- f = 50 Hz

- Synchronous speed ns = 1500 rpm (4 poles)

- Rated stator voltage UgB = 690 V

- Rotor blocked rotor voltage Ur0 = 2070 V

- Base stator flux ΨsB = 85.8 V·s

- Ns/Nr = 0.333

- Stator resistance Rs = 2.48 mΩ

- Rotor resistance (referred to stator) Rr = 2.72 mΩ

- Stator leakage inductance Lσs = 86.5 μH

- Rotor leakage inductance Lσr (referred to stator) = 86.5 μH

- Magnetizing inductance Lm = 2.50 mH

References

- Tsili, M.; Papathanassiou, S. A review of grid code technical requirements for wind farms. IET Renew. Power Gener. 2009, 3, 308–332. [Google Scholar] [CrossRef]

- Rocabert, J.; Luna, A.; Blaabjerg, F.; Rodriguez, P. Control of power converters in ac microgrids. IEEE Trans. Power Electron. 2012, 27, 4734–4749. [Google Scholar] [CrossRef]

- Ribeiro, L.; Saavedra, O.; Lima, S.; Matos, J.; Bonan, G. Making isolated renewable energy systems more reliable. Renew. Energy 2012, 45, 221–231. [Google Scholar] [CrossRef]

- Jiayi, H.; Chuanwen, J.; Rong, X. A review on distributed energy resources and MicroGrid. Renew. Sustain. Energy Rev. 2008, 12, 2472–2483. [Google Scholar] [CrossRef]

- Xiang, D.; Ran, L.; Bumby, J.R.; Tavner, P.J.; Yang, S. Coordinated control of an HVDC link and doubly fed induction generators in a large offshore wind farm. IEEE Trans. Power Deliv. 2006, 21, 463–471. [Google Scholar] [CrossRef]

- Erlich, I.; Feltes, C.; Shewarega, F.Y. Enhanced voltage drop control by VSC-HVDC systems for improving wind farm fault Ridethrough capability. IEEE Trans. Power Deliv. 2014, 29, 378–385. [Google Scholar] [CrossRef]

- Lujano-Rojas, J.M.; Monteiro, C.; Dufo-López, R.; Bernal-Agustín, J. Optimum load management strategy for wind/diesel/battery hybrid power systems. Renew. Energy 2012, 44, 288–295. [Google Scholar] [CrossRef]

- Kanellos, F.D.; Hatziargyriou, N.D. Control of Variable Speed Wind Turbines in Islanded Mode of Operation. IEEE Trans. Energy Convers. 2008, 23, 535–543. [Google Scholar] [CrossRef]

- Paiva, J.E.; Carvalho, A.S. Controllable hybrid power system based on renewable energy sources for modern electrical grids. Renew. Energy 2013, 53, 271–279. [Google Scholar] [CrossRef]

- Ackermann, T. Wind Power in Power Systems; John Wiley & Sons: Chichester, UK, 2005; pp. 480–504. [Google Scholar]

- Li, H.; Chen, Z. Overview of different wind generator systems and their comparisons. IET Renew. Power Gener. 2008, 2, 123–138. [Google Scholar] [CrossRef]

- Xu, L.; Cartwright, P. Direct active and reactive power control of DFIG for wind energy generation. IEEE Trans. Energy Convers. 2006, 21, 750–758. [Google Scholar] [CrossRef]

- Müller, S.; Deicke, M.; De Donker, R.W. Doubly Fed Induction Generator Systems for Wind Turbines. IEEE Ind. Appl. Mag. 2002, 8, 26–33. [Google Scholar] [CrossRef]

- Peña, R.; Cardenas, R.; Asher, G. Overview of control systems for the operation of DFIGs in wind energy applications. In Proceedings of the 39th Annual Conference of the IEEE Industrial Electronics Society, IECON 2013, Vienna, Austria, 10–13 November 2013; pp. 88–95. [Google Scholar]

- Peña, R.; Clare, J.C.; Asher, G.M. A doubly fed induction generator using back to back PWM converters supplying an isolated load from a variable speed wind turbine. Proc. IEE Electr. Power Appl. 1996, 143, 380–387. [Google Scholar] [CrossRef]

- Cárdenas, R.; Peña, R.; Asher, G.; Clare, J. MRAS observer for sensorless control of standalone doubly fed induction generators. IEEE Trans. Energy Convers. 2005, 20, 710–718. [Google Scholar] [CrossRef]

- Ataji, A.B.; Miura, Y.; Ise, T.; Tanaka, H. Direct Voltage Control with Slip Angle Estimation to Extend the Range of Supported Asymmetric Loads for Stand-Alone DFIG. IEEE Trans. Power Electron. 2016, 31, 1015–1025. [Google Scholar] [CrossRef]

- Abdoune, F.; Aouzellag, D.; Ghedamsi, K. Terminal voltage build-up and control of a DFIG based stand-alone wind energy conversion system. Renew. Energy 2016, 97, 468–480. [Google Scholar] [CrossRef]

- Shukla, R.D.; Tripathi, R.K. A novel voltage and frequency controller for standalone DFIG based Wind Energy Conversion System. Renew. Sustain. Energy Rev. 2014, 37, 69–89. [Google Scholar] [CrossRef]

- Iwanski, G.; Koczara, W. Autonomous power system for island or grid-connected wind turbines in distributed generation. Eur. Trans. Electr. Power 2008, 18, 658–673. [Google Scholar] [CrossRef]

- Touaiti, B.; Azza, H.B.; Jemli, M. Direct voltage control of stand-alone DFIG in wind energy applications. In Proceedings of the IEEE 16th International Conference on Sciences and Techniques of Automatic Control and Computer Engineering (STA), Monastir, Tunisia, 21–23 December 2015; pp. 672–677. [Google Scholar]

- Abad, G.; López, J.; Rodríguez, M.A.; Marroyo, L.; Iwanski, G. Doubly Fed Induction Machine: Modeling and Control for Wind Energy Generation; IEEE Press and John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Akhmatov, V. Variable-speed wind turbines with doubly-fed induction generator. Part I: Modeling in dynamic simulation tools. Wind Eng. 2002, 26, 85–108. [Google Scholar] [CrossRef]

- Moura, S.P.; de Alemeida, A.T. The role of demand-side management in the grid integration of wind power. Appl. Energy J. 2010, 87, 2581–2588. [Google Scholar] [CrossRef]

- PSIM Accelerates Your Pace of Innovation. Available online: https://powersimtech.com (accessed on 27 November 2017).

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arnaltes, S.; Rodriguez-Amenedo, J.L.; Montilla-DJesus, M.E. Control of Variable Speed Wind Turbines with Doubly Fed Asynchronous Generators for Stand-Alone Applications. Energies 2018, 11, 26. https://doi.org/10.3390/en11010026

Arnaltes S, Rodriguez-Amenedo JL, Montilla-DJesus ME. Control of Variable Speed Wind Turbines with Doubly Fed Asynchronous Generators for Stand-Alone Applications. Energies. 2018; 11(1):26. https://doi.org/10.3390/en11010026

Chicago/Turabian StyleArnaltes, Santiago, Jose Luis Rodriguez-Amenedo, and Miguel E. Montilla-DJesus. 2018. "Control of Variable Speed Wind Turbines with Doubly Fed Asynchronous Generators for Stand-Alone Applications" Energies 11, no. 1: 26. https://doi.org/10.3390/en11010026

APA StyleArnaltes, S., Rodriguez-Amenedo, J. L., & Montilla-DJesus, M. E. (2018). Control of Variable Speed Wind Turbines with Doubly Fed Asynchronous Generators for Stand-Alone Applications. Energies, 11(1), 26. https://doi.org/10.3390/en11010026