Dynamic Matrix Control for the Thermal Power of MHTGR-Based Nuclear Steam Supply System

Abstract

:1. Introduction

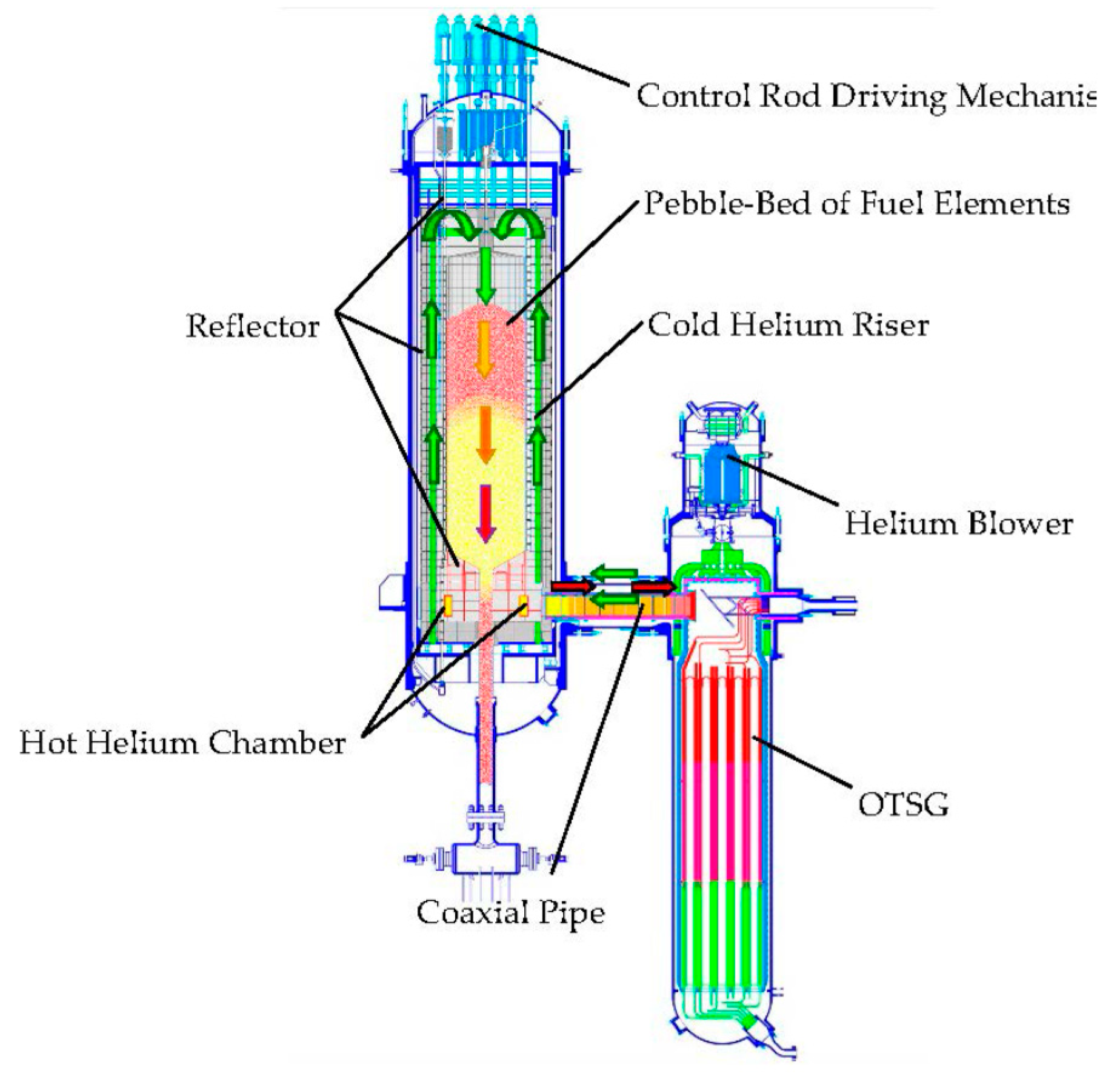

2. MHTGR-Based NSSS

2.1. System Description

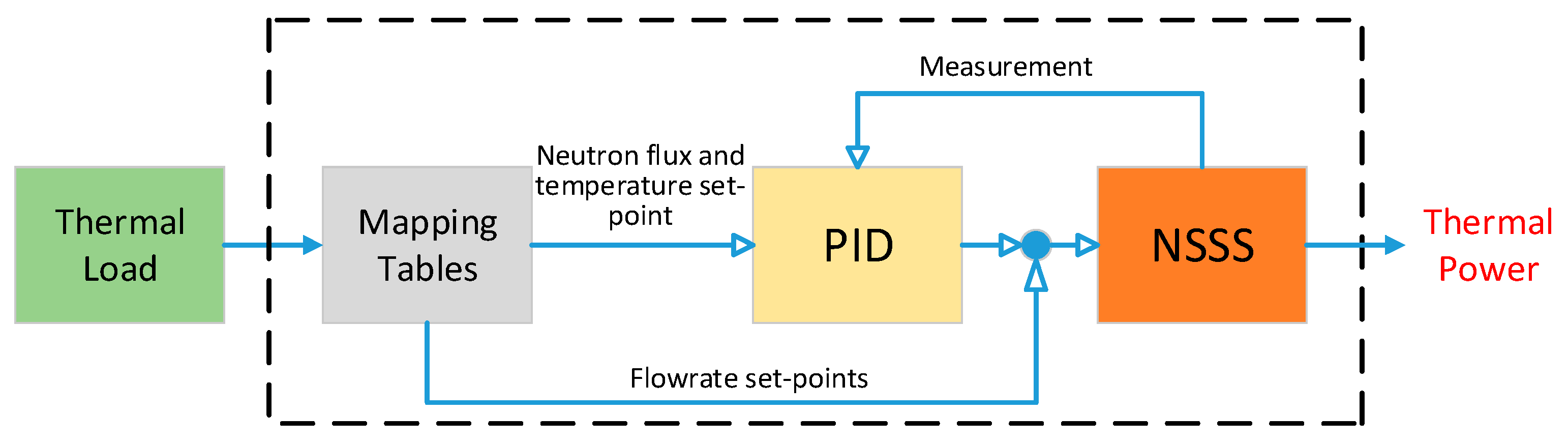

2.2. Inner Loop Control Scheme

2.3. Problem Formulation

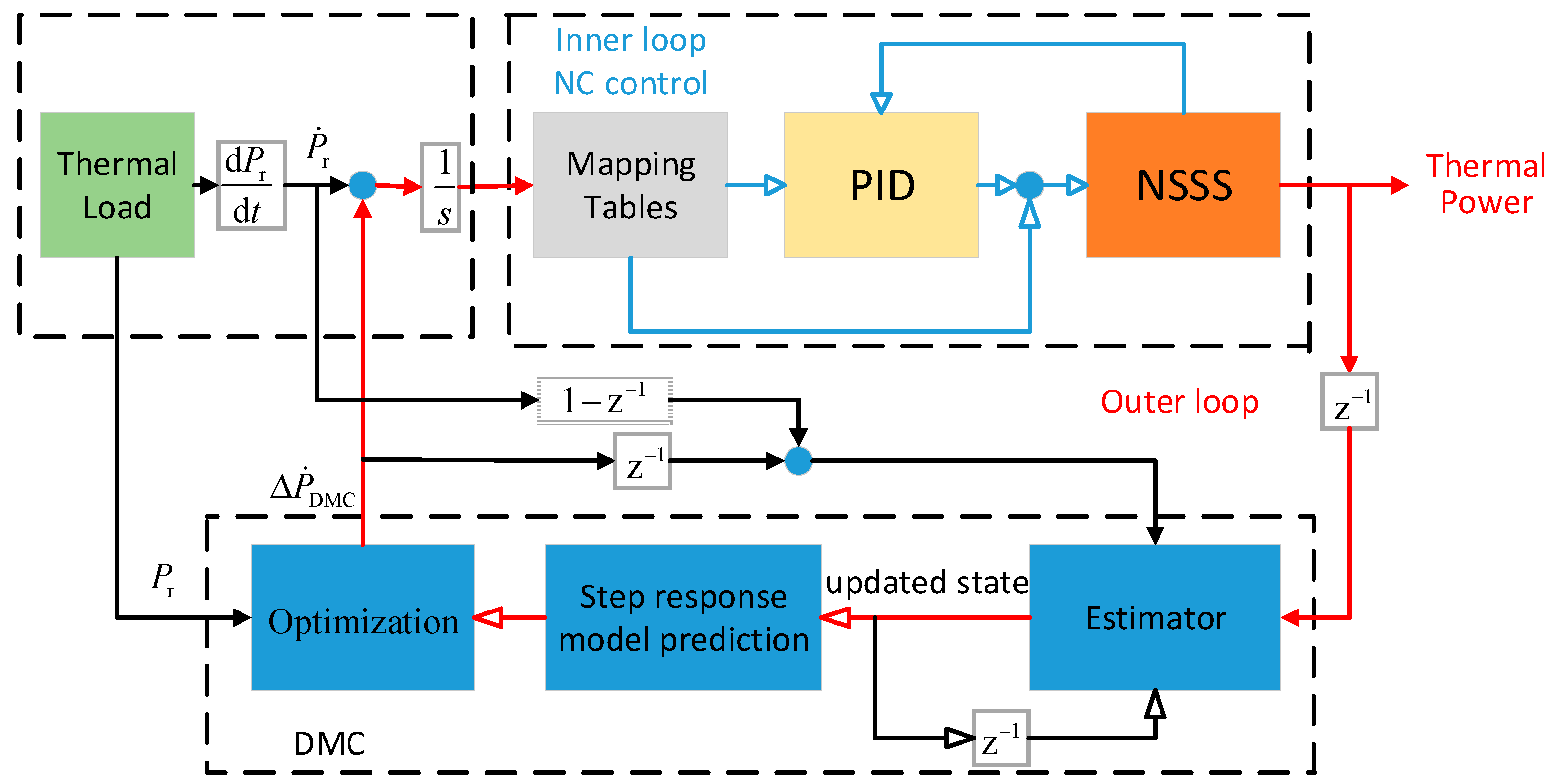

3. Dynamic Matrix Control for Thermal Power

3.1. Cascade Control Scheme

3.2. Step Response Model

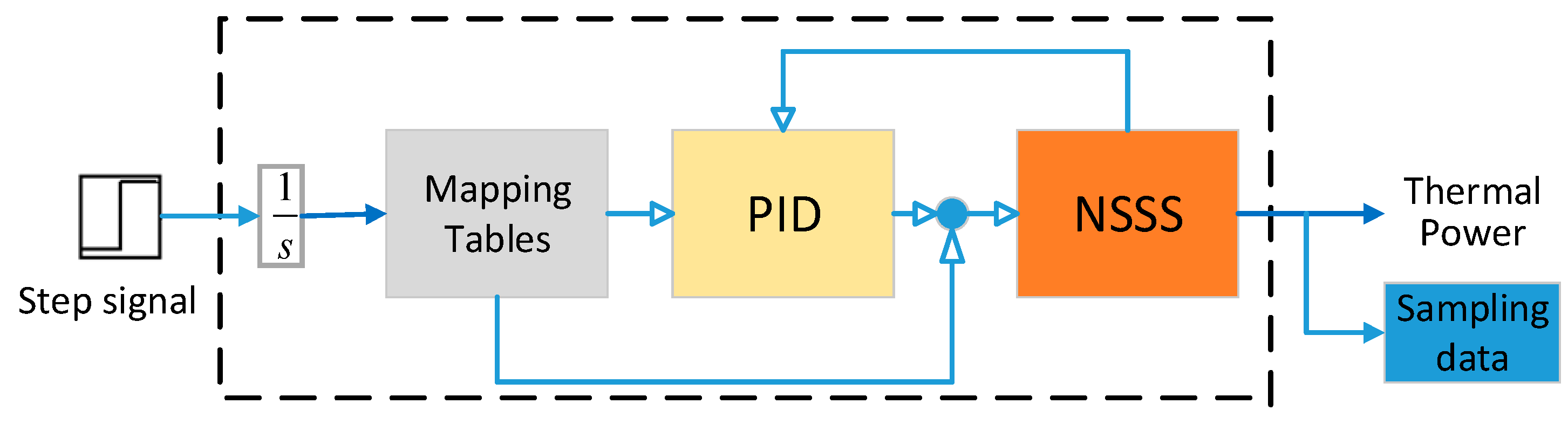

3.2.1. Step Signal Test

3.2.2. State Space Model

3.3. Optimization

3.4. Estimator

3.5. Tuning of the DMC

- large value adds the cost of using large values of the derivative revision signal, to the cost of missing a small amount of the thermal power tracking. Since the step response coefficient matrix is sampled around a specified operating point, the inevitable model error makes it meaningless to tune the parameter aggressively by solving the QP.

- By solving Equation (9), small value of may result in a large . From Equation (13), a large causes large variation in estimator error, and hence should be avoided.

4. Application to NSSS Thermal Power Control

4.1. Implementation of DMC

4.2. Simulation Setting and Results

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lanning, D.D. Modularized high-temperature gas-cooled reactor systems. Nucl. Technol. 1989, 88, 139–156. [Google Scholar] [CrossRef]

- Wu, Z.; Lin, D.; Zhong, D. The design features of the HTR-10. Nucl. Eng. Des. 2002, 218, 25–32. [Google Scholar] [CrossRef]

- Dong, Z.; Zhang, Z.; Dong, Y.; Huang, X. Multi-layer perception based model predictive control for the thermal power of nuclear superheated-steam supply systems. Energy 2018, 151, 116–125. [Google Scholar] [CrossRef]

- Shtessel, Y.B. Enhanced Sliding mode control of the space nuclear reactor system. IEEE Trans. Aero. Electron. Syst. 1998, 34, 579–589. [Google Scholar] [CrossRef]

- Huang, Z.; Edwards, R.M.; Lee, K.Y. Fuzzy-adapted recursive sliding-mode controller design for a nuclear power plant control. IEEE Trans. Nucl. Sci. 2004, 51, 256–266. [Google Scholar] [CrossRef]

- Qaiser, S.H.; Bhatti, A.I.; Iqbal, M.; Samar, R.; Qadir, J. Model validation and higher order sliding mode controller design for a research reactor. Ann. Nucl. Energy 2009, 36, 37–45. [Google Scholar] [CrossRef]

- Ansarifar, G.R.; Rafiei, M. Higher order sliding mode controller design for a research nuclear reactor considering the effect of xenon concentration during load following operation. Ann. Nucl. Energy 2015, 75, 728–735. [Google Scholar] [CrossRef]

- Dong, Z. Physically-based power-level control for modular high temperature gas-cooled reactors. IEEE Trans. Nucl. Sci. 2012, 59, 2531–2549. [Google Scholar] [CrossRef]

- Dong, Z.; Pan, Y.; Zhang, Z.; Dong, Y.; Huang, X. Model-free adaptive control for nuclear superheated-steam supply systems. Energy 2017, 135, 53–67. [Google Scholar] [CrossRef]

- Eom, M.; Chwa, D.; Baang, D. Robust disturbance observer-based feedback linearization control for a research reactor considering a power change rate constraint. IEEE Trans. Nucl. Sci. 2015, 62, 1301–1312. [Google Scholar] [CrossRef]

- Han, S.; Sun, L.; Shen, J.; Pan, L.; Lee, K.Y. Optimal Load-Tracking Operation of Grid-Connected Solid Oxide Fuel Cells through Set Point Scheduling and Combined L1-MPC Control. Energies 2018, 11, 801. [Google Scholar] [CrossRef]

- Kong, X.B.; Liu, X.J.; Lee, Y.K. Nonlinear multivariable hierarchical model predictive control for boiler-turbine system. Energy 2015, 93, 309–322. [Google Scholar] [CrossRef]

- Na, M.G.; Shin, S.H.; Kim, W.C. A model predictive controller for nuclear reactor power. Nucl. Eng. Technol. 2003, 35, 399–411. [Google Scholar] [CrossRef]

- Na, M.G.; Upadhyaya, B.R. Application of model predictive control strategy based on fuzzy identification to an SP-100 space reactor. Ann. Nucl. Energy 2006, 33, 1467–1478. [Google Scholar] [CrossRef]

- Na, M.G.; Hwang, I.J.; Lee, Y.J. Design of a fuzzy model predictive power controller for pressurized water reactors. IEEE Trans. Nucl. Sci. 2006, 53, 1504–1514. [Google Scholar] [CrossRef]

- Etchepareborda, A.; Lolich, J. Research reactor power controller design using an output feedback nonlinear receding horizon control method. Nucl. Eng. Des. 2007, 237, 268–276. [Google Scholar] [CrossRef]

- Eliasi, H.; Menhaj, M.B.; Davilu, H. Robust nonlinear model predictive control for a PWR nuclear power plant. Prog. Nucl. Energy 2012, 54, 177–185. [Google Scholar] [CrossRef]

- Mayne, D.Q.; Rawlings, J.B.; Rao, C.V.; Scokaert, P.O.M. Constrained model predictive control: Stability and optimality. Automatica 2000, 36, 789–814. [Google Scholar] [CrossRef]

- Vajpayee, V.; Mukhopadhyay, S.; Tiwari, A.P. Data-Driven Subspace Predictive Control of a Nuclear Reactor. IEEE Trans. Nucl. Sci. 2018, 65, 666–679. [Google Scholar] [CrossRef]

- Moon, U.C.; Lee, K. Step-response model development for dynamic matrix control of a drum-type boiler-turbine system. IEEE Trans. Energy Convers. 2009, 24, 423–430. [Google Scholar] [CrossRef]

- Moon, U.C.; Lee, Y.; Lee, K.Y. Practical dynamic matrix control for thermal power plant coordinated control. Control Eng. Pract. 2018, 71, 154–163. [Google Scholar] [CrossRef]

- Qin, S.; Badgwell, T. A survey of industrial model predictive control technology. Control Eng. Pract. 2003, 11, 733–764. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Wu, Z.; Wang, D.; Xu, Y.; Sun, Y.; Li, F.; Dong, Y. Current status and technical description of Chinese 2 × 250 MWth HTR-PM demonstration plant. Nucl. Eng. Des. 2009, 239, 2265–2274. [Google Scholar] [CrossRef]

- Mercorelli, P. Trajectory tracking using MPC and a velocity observer for flat actuator systems in automotive applications. In Proceedings of the 2008 IEEE International Symposium on Industrial Electronics, Cambridge, UK, 30 June–2 July 2008; pp. 1138–1143. [Google Scholar]

- Morari, M.; Ricker, N.L. Model Predictive Control Toolbox—For Use with MATLAB, 2nd ed.; The MathWorks, Inc.: Natick, MA, USA, 1995. [Google Scholar]

- Dong, Z.; Pan, Y.; Zhang, Z.; Dong, Y.; Huang, X. Dynamical modeling and simulation of the six-modular high temperature gas-cooled reactor plant HTR-PM600. Energy 2016, 155, 971–991. [Google Scholar] [CrossRef]

| Parameters | Unit | Value |

|---|---|---|

| Thermal power of reactor module | MWth | 250 |

| Core power density | MW/m3 | 3.22 |

| Electricity efficiency | % | 42 |

| Core diameter/height | m | 3/11 |

| Helium pressure | MPa | 7 |

| Helium temperature at reactor inlet/outlet | °C | 250/750 |

| Helium flowrate | kg/s | 96 |

| Steam pressure | MPa | 13.24 |

| Steam temperature | °C | 576 |

| Steam flowrate | kg/s | 96 |

| Module | Input | Output |

|---|---|---|

| MHTGR | Rod speed | Neutron flux |

| OTSG | Helium flowrate | Helium temperature |

| Feedwater flow | Live steam temperature |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, D.; Dong, Z.; Liu, M.; Huang, X. Dynamic Matrix Control for the Thermal Power of MHTGR-Based Nuclear Steam Supply System. Energies 2018, 11, 2651. https://doi.org/10.3390/en11102651

Jiang D, Dong Z, Liu M, Huang X. Dynamic Matrix Control for the Thermal Power of MHTGR-Based Nuclear Steam Supply System. Energies. 2018; 11(10):2651. https://doi.org/10.3390/en11102651

Chicago/Turabian StyleJiang, Di, Zhe Dong, Miao Liu, and Xiaojin Huang. 2018. "Dynamic Matrix Control for the Thermal Power of MHTGR-Based Nuclear Steam Supply System" Energies 11, no. 10: 2651. https://doi.org/10.3390/en11102651