The performance of the proposed recursive method has been fully evaluated through the following two case studies. The two test systems are the commonly used RBTS-BUS6 [

31] and a practical industrial distribution system in Henan province, China [

32].

5.1. RBTS-BUS6

As a typical mixed rural/urban distribution network with residential, commercial and agricultural customers, RBTS-BUS6 consists of 4 feeders, 40 load points, 82 lines, 40 fuses and 28 transformers, 9 breakers and 17 disconnect switches [

31]. Normally, the tie-switch connecting feeder 1 and feeder 2 is assumed to be opened and other switches are set to be closed. The peak load and average load of this system are 20 MW and 10.72 WM, respectively. The reliability parameters for protective devices are given in

Table 1, other system parameters and the network topology are referred to in Reference [

31].

In order to comprehensively explore the benefits of the proposed method, three different cases have been considered:

Case 1: The operation time of all tie-switches is set to 1.5 h and that of other disconnect switches is set to 1 h. In addition, the fuses, breakers and relays are assumed to be 100% reliable, i.e., they belongs to ideal protective devices;

Case 2: All the fuses, breakers and relays are assumed to be 90% reliable and other conditions are set as the same with case 1;

Case 3: An AS has been installed at the terminal of feeder 4, and other conditions are set as the same with case 2.

Based on the reliability parameters presented in

Table 1, the reliability performance of all LPs can be calculated using the proposed recursive method. The results are partly listed in

Table 2. The experiment reveals that the results obtained from the proposed recursive method are completely consistent with the results obtained from FMEA/RNEA/ST/SPM in all three cases. Thus, it can be readily conferred that the system reliability performances obtained from the proposed method are also consistent with the system performance obtained from FMEA, RNEA, ST and SPM, which demonstrates the computation accuracy of the proposed method.

In addition, the results in

Table 2 also demonstrate that the operation state of protective devices can more or less affect the reliability performances for each LP since the reliability results in case 2 are worse than the results in case 1. Moreover, with reference to case 1–3 or case 2–3, it can be concluded that ASs could largely improve the reliability performance for related LPs since they can shorten the interruptions via service restoration.

The significance of the proposed recursive method is its element-by-element equivalent principles, which result in computation efficiency improvement. In References [

9,

33], the efficiency of the distribution system is measured by calculation events. One unit of calculation event is defined as the time taken for calculating both

λ and

r once. The calculation event neglects the differences of each computing platform, i.e., the hardware and software aspects, and thus the efficiency of the reliability algorithm can be expressed more relatively. Considering case 3, the calculation events for FMEA, RNEA, ST, SPM and the proposed recursive method are tabulated in

Table 3. It can be found that the calculation events of the overall system using the proposed method amount to 496, and are 21.02% of that required by FMEA, 39.02% of RNEA, 49.11% of ST, and 36.31% of the SPM, which indicates the proposed method exhibits the highest computation efficiency.

Moreover, considering case 3, the run time using FMEA, RNEA, ST, SPM and the recursive algorithm for the overall system are listed in

Table 4, as to make the conclusion concerning the efficiency of the proposed method more convincing. The simulations are carried out with an Intel(R) Core i7-3612QM 2.1-GHz CPU and 16.00 GB of RAM. From

Table 4, it can be seen that the execution time of the recursive method is 1.1564 s, which is 21.92% of that required by FMEA, 39.30% of RNEA, 34.08% of ST, and 47.73% of the SPM. This also indicates that the proposed recursive method exhibits the highest calculation efficiency amongst these listed algorithms. In addition, the execution time using ST takes 0.3393 s, which is 64.30% of that executed by FMEA. This is consistent with the conclusion in Reference [

9] that ST takes 76.3% of the time using FMEA, considering the base case of RBTS-Bus6.

5.2. An Industrial Distribution System

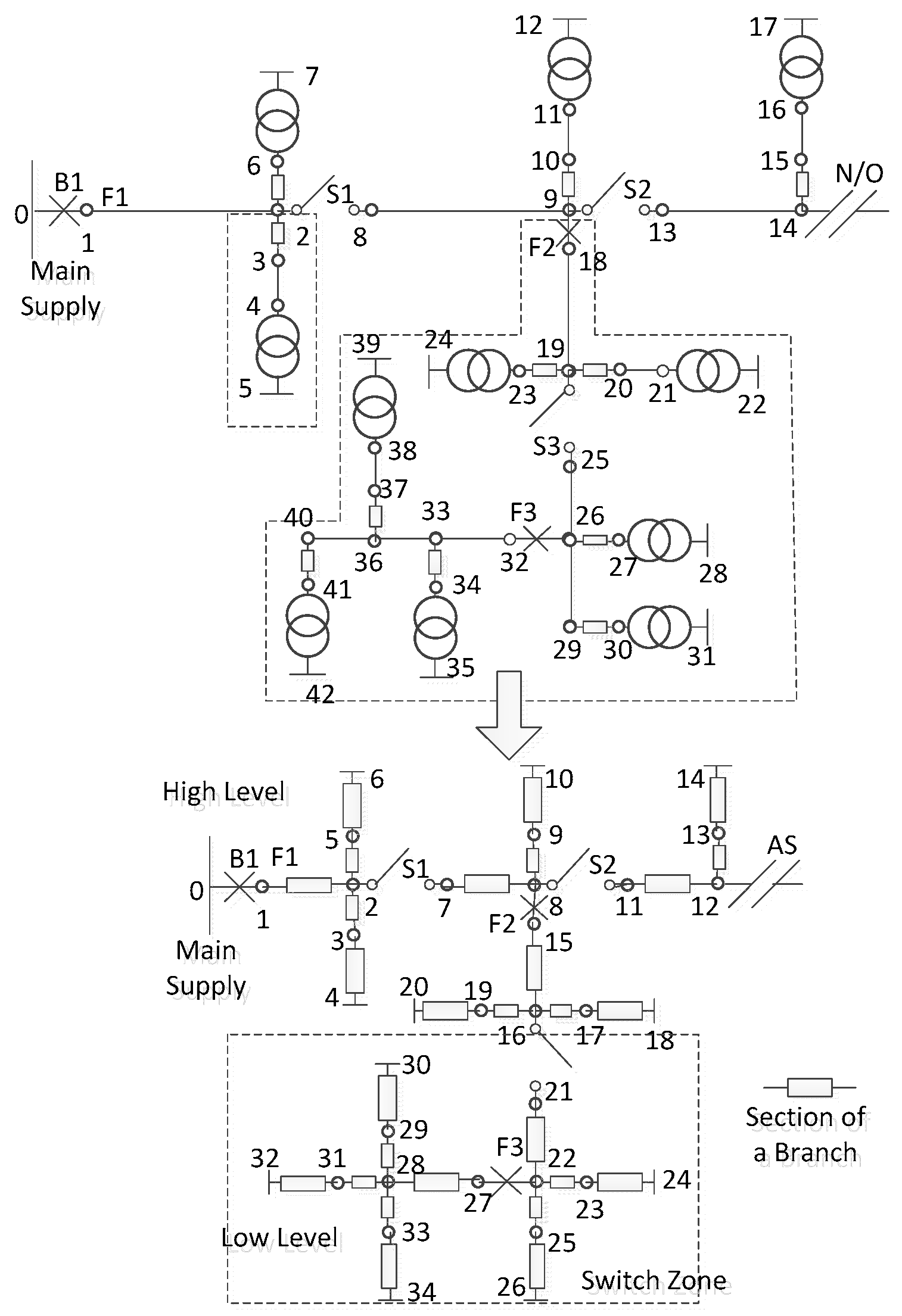

For an in-depth investigation into the efficiency benefits of the proposed recursive method, a practical 362-bus urban distribution system newly upgraded in Henan province [

31], China, is adopted as the benchmark system. The distribution system, shown in

Figure 5, consists of five 10-kV feeders, 242 branches and 186 load transformers. In addition, many types of protective devices, such as 98 normally closed disconnect switches, 5 normally opened tie-switches, 21 fuse cutouts and 14 circuit breakers, are also contained in the system. The length and capacity for feeders F1–F5 are 7.242 km & 3.5 MVA, 15.806 km & 26.1 MVA, 5.502 km & 2.9 MVA, 6.654 km & 5.7 MVA, and 7.441 km & 6.3 MVA, respectively. Each feeder contains industrial, office building, government, residential and commercial customers. The reliability data for the circuit equipment is listed in

Table 5 and

Table 6. Based on the reliability data for circuit equipments, the reliability performance for each feeder can be calculated.

Similarly, three different cases are simulated to demonstrate the benefits of the proposed recursive algorithm, described as follows,

Case 1: All types of protective devices, such as fuses, breakers and fuse cutouts are assumed to be 100% reliable.

Case 2: All types of protective devices are assumed to be 80% reliable.

Case 3: The operation time of all tie-switch is set to 1.5 h, and other conditions are set as the same as case 2.

The reliability performances for each feeder under three cases are shown in

Table 7.

It can be seen from the results that the SAIDI of all five feeders ranges from a minimal of 1.6354 to a high of 10.4182 with an average of 5.7714 in case 1. However, if the breakers and fuses operate successfully at a probability of 0.8, the SAIDI of the whole system would jump to 7.3089 in case 2, indicating that breaker/fuse have a large effect on the system reliability performance. The changing trends of other reliability indices also support this conclusion. Therefore, more reliable protective equipments are crucial for minimizing the frequency and duration of interruptions, and so the system reliability performance can be accordingly enhanced. In other words, the system reliability performance for industrial distribution systems would deteriorate hugely if the protective equipment lacked adequate maintenance and inspection.

Moreover, with reference to case 2–3, it can be founded that SAIDI of the system jumps to 11.8669 when the operation time of all tie-switches is set to 1.5 h, which is far beyond 7.3089 in case 2. This indicates that the AS has a significant impact on the improvement of system reliability performance. This is why the modern distribution system is usually upgraded as a hand-in-hand loop structure in which a Tie-Line Switch (Sectionalizer) is located at the end and middle of these feeders.

The calculation events as well as the run time of FMEA, RNEA, ST, SPM and the proposed recursive method are tabulated in

Table 8 and

Table 9. As seen, the calculation events for FA-FE using the proposed method are 7.52%, 7.41%, 7.97%, 3.55%, and 3.68% of that required for FMEA. The run time for FA-FE using the recursive method is 7.18%, 6.75%, 5.34%, 3.81%, and 3.44% of that required for FMEA. The results also demonstrate that the proposed method exhibits the highest efficiency over RNEA, ST and SPM, which is consistent with the conclusions obtained in

Section 5.1.

5.3. Discussions

The proposed recursive algorithm mainly consists of a bottom-up and a top-down recursive process, which have been discussed in

Section 3 and

Section 4. The former quantifies the effect of downstream failures on certain upstream bus. This effect is similar to the effect of an

equivalent lateral section on the bus in Reference [

12]. The latter considers the effect of upstream failures on certain downstream bus, and this effect is similar to the effect of an

equivalent series component on the bus in Reference [

12]. The reliability indices of the

equivalent lateral section and

equivalent series component can be determined by using the recursive algorithm presented in Formulas (8)–(22). To any bus, there is always one

equivalent series component and several

equivalent lateral sections, and the synthesis of reliability indices of those components and sections yields the reliability performance of that bus.

With the above analysis, it is clear that the top-down or bottom-up recursive process is not only applied to the nodes in the lateral network, but also to the nodes in the main network. Also, the reliability indices of any node can be recursively obtained based on those of neighboring nodes only, while reliability information of the rest of network is not required at all. This is because the combined effect of downstream failures on a certain node is considered in analyzing the reliability performance of its connected downstream nodes in the proposed recursive method. Similarly, the combined effect of upstream failures on the node is accounted for in the reliability analysis of its connected upstream nodes. Therefore, the proposed recursive method provides a more generalized element-by-element equivalent principle, with which the network simplification for reliability evaluation can be fully realized. Compared to the sub-feeder-based approach in many existing methods, where network simplification has to be designed according to specific network topology involving excessive computational costs, the proposed recursive method can maximally simplify the network and thus minimize the computation cost accordingly due to its element-by-element recursive principles. Moreover, the computation cost of the proposed recursive method is further minimized using several techniques, as follows,

- (1)

Section of a branch is utilized to reduce the number of equivalent process, and thus the distribution system can be simplified.

- (2)

The upstream recursive process adopts SPM [

13], in which the components in other branches are treated as a lateral equivalent section, and so the computation cost can be further mitigated.

Therefore, theoretically, it can be concluded that the proposed recursive method exhibits higher calculation efficiency than FMEA, RNEA, ST and SPM, which is consistent with the simulation results presented in

Section 5.1 and

Section 5.2.

It should be noted that the proposed recursive method can also be used in bidirectional power flow case and non-radial network’s structures, due to the emergency of sustainable energy and the requirement of high reliability in recent years. First, the distribution system has several typical operation scenarios. Here, operation scenario indicates the operational status of the distribution system at a given moment. Each scenario has a fixed power flow with a unique direction and different scenarios may exhibit different power flow directions. We can use our method to calculate the reliability indices at any operational scenario. Synthesizing these indices at all scenarios generates the final reliability indices of the distribution system. Second, the energy in the distribution system generally flows from the transmission system to load points. Any non-radial structure, such as a circular, can be viewed as a basic component in (1). Its equivalent failure rate and outage duration are calculated in Formulas (2) and (3), As a result, the reliability indices of the not-radial distribution system can be evaluated by taking the non-radial structure as an equivalent component. Therefore, our recursive method has wide application in distribution systems.