Intensification of Continuous Biodiesel Production from Waste Cooking Oils Using Shockwave Power Reactor: Process Evaluation and Optimization through Response Surface Methodology (RSM)

Abstract

:1. Introduction

2. Material and Method

2.1. Materials

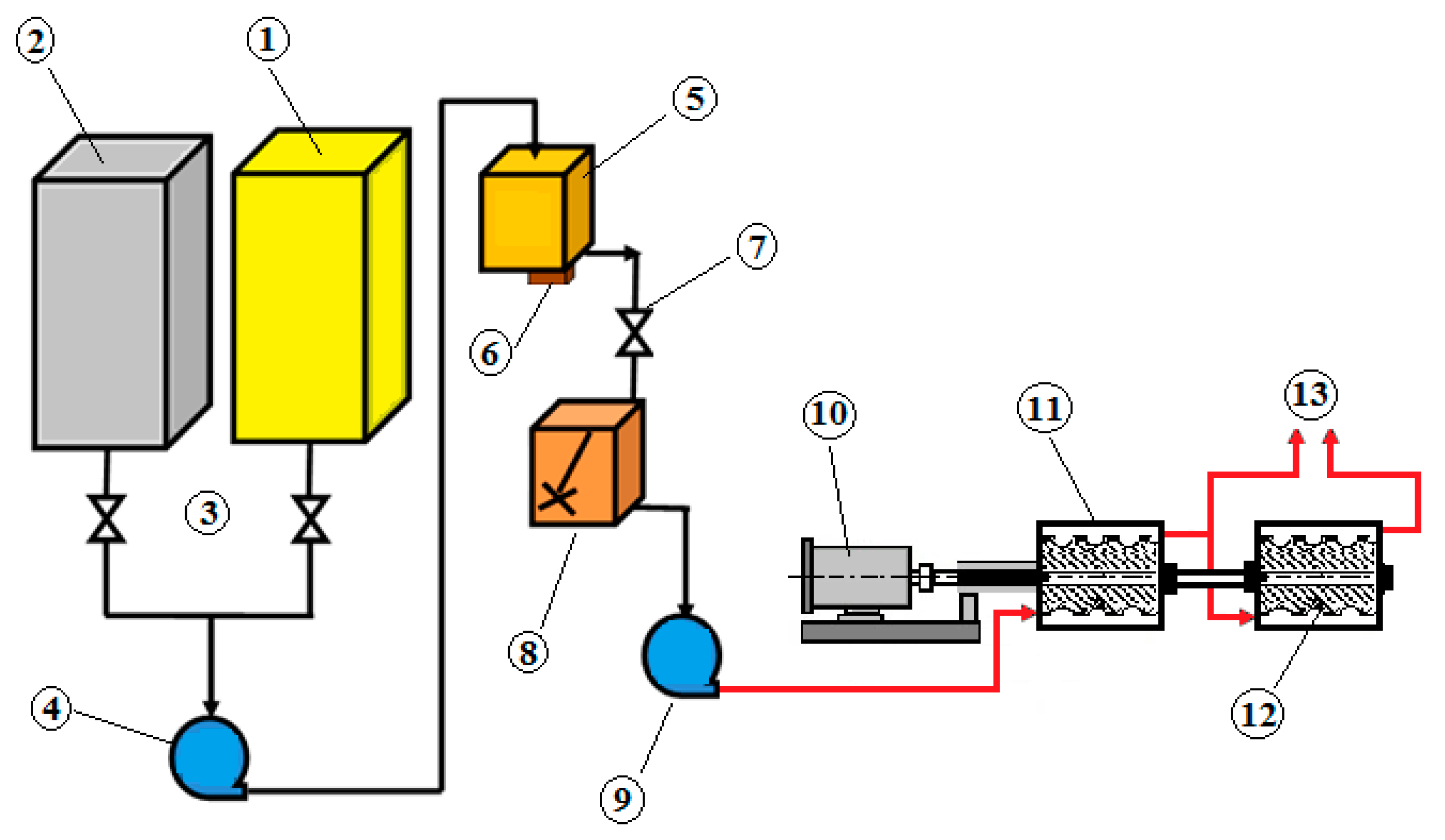

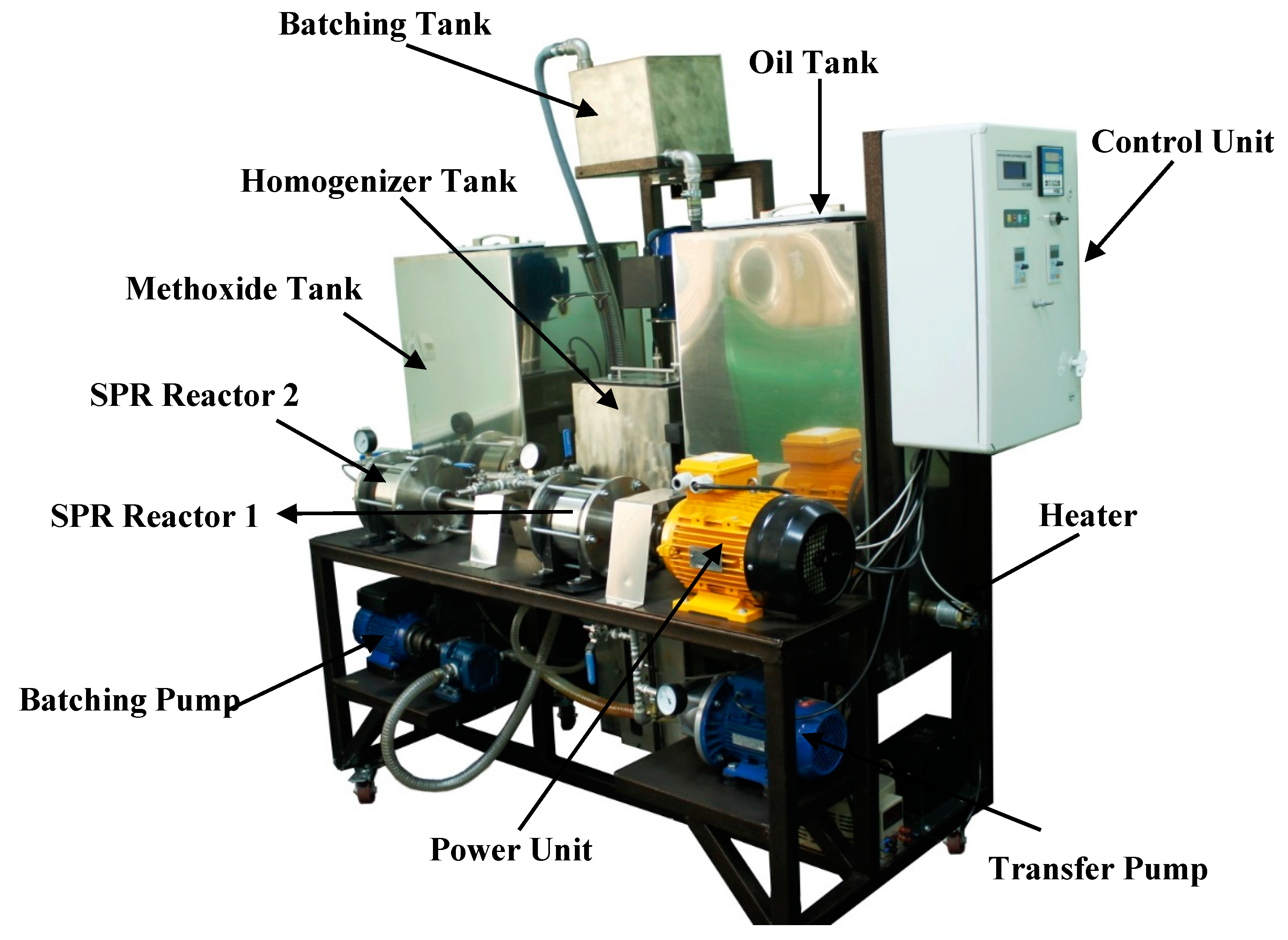

2.2. System Configurations

2.3. Transesterification of Waste Cooking Oil

2.4. Experimental Design and Statistical Analysis

3. Results and Discussion

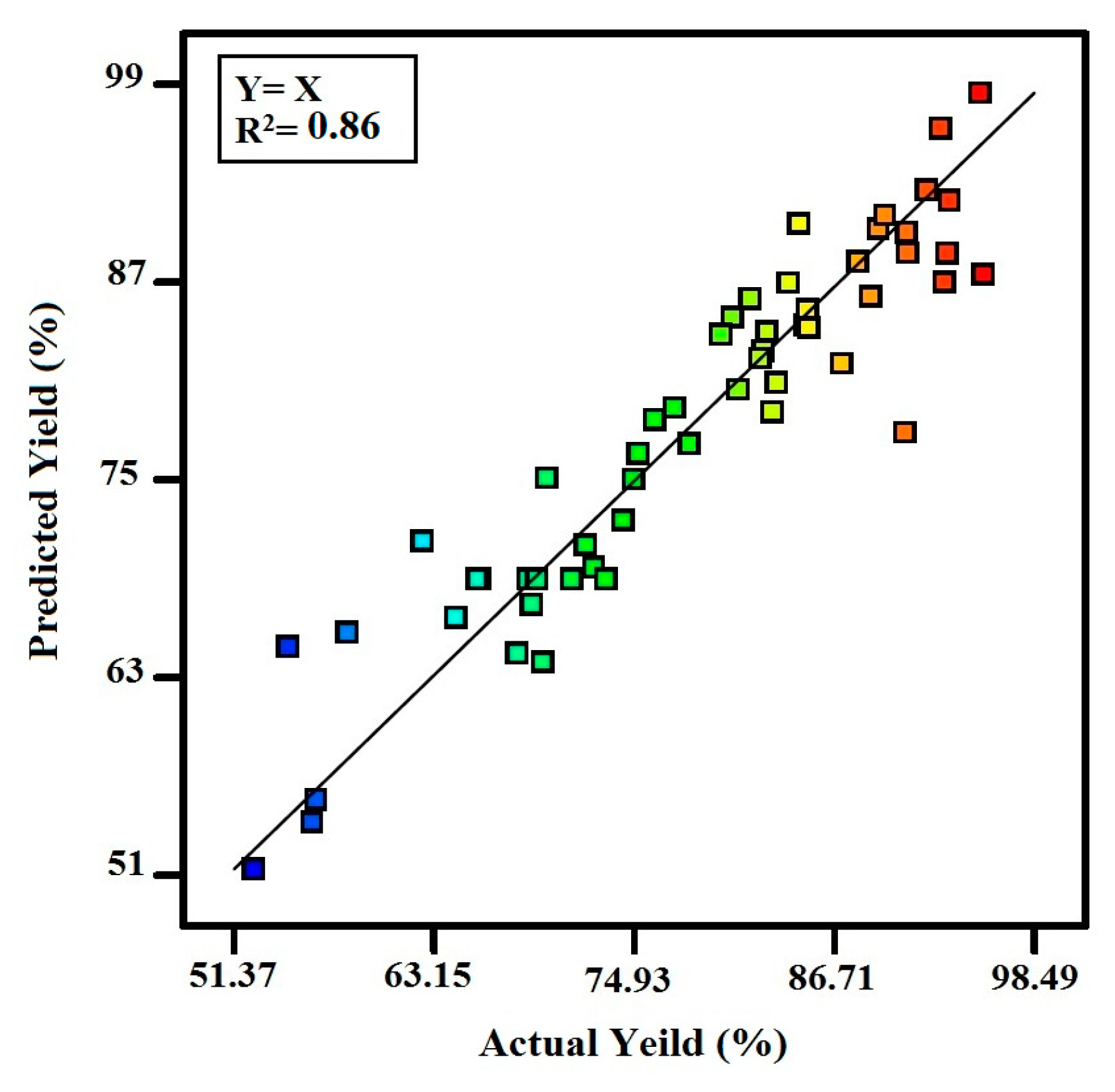

3.1. Statistical Analysis

3.2. Optimization Analysis

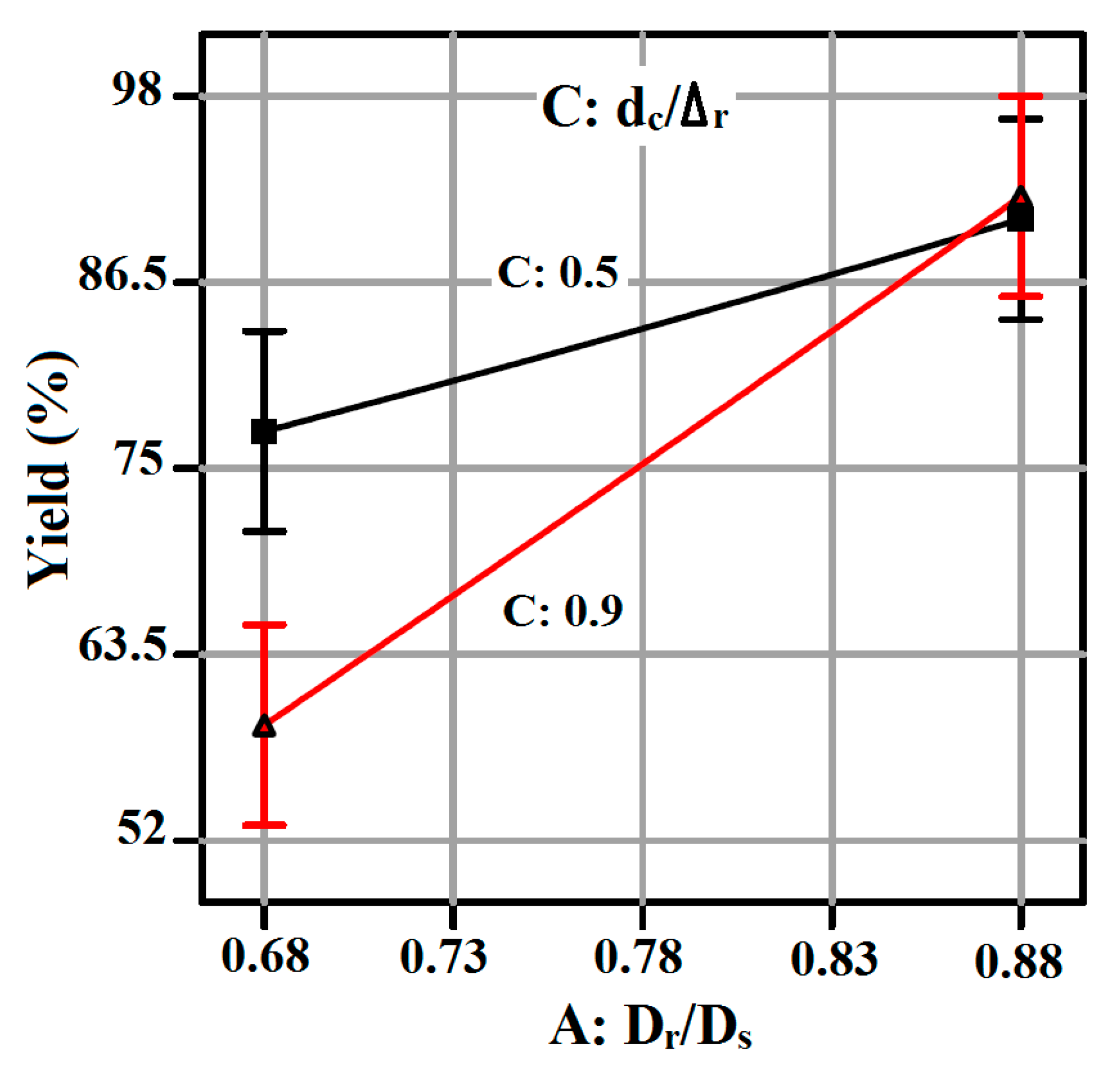

3.3. Effect of Parameters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Renewables 2018 Global Status Report. Available online: http://www.ren21.net/gsr (accessed on 20 August 2018).

- Vonortas, A.; Papayannakos, N. Comparative analysis of biodiesel versus green diesel. Rev. Energy Environ. 2014, 3, 3–23. [Google Scholar] [CrossRef]

- Chongkhong, S.; Tonguara, C.; Chetpattananondh, P.; Bunyaka, C. Biodiesel production by esterification of palm fatty acid distillate. Biomass Bioenergy 2007, 31, 563–568. [Google Scholar] [CrossRef]

- Yuste, A.J.; Dorado, M.P. A neural network approach to simulate biodiesel production from waste olive oil. Energy Fuels 2006, 20, 399–402. [Google Scholar] [CrossRef]

- Hasheminejad, M.; Tabatabaei, M.; Mansourpanah, Y.; Khatamifar, M.; Javani, A. Upstream and downstream strategies to economize biodiesel production. Bioresour. Technol. 2010, 102, 461–468. [Google Scholar] [CrossRef] [PubMed]

- Cintas, P.; Mantegna, S.; Calcio Gaudino, E.; Cravotto, G. A new pilot flow reactor for high-intensity ultrasound irradiation. Application to the synthesis of biodiesel. Ultrason. Sonochem. 2010, 17, 985–989. [Google Scholar] [CrossRef] [PubMed]

- Avinash, A.; Murugesan, A. Economic analysis of biodiesel production from waste cooking oil. Energy Sour. Part B Econ. Plan. Policy 2017, 12, 890–894. [Google Scholar] [CrossRef]

- Zhang, Y.; Dubé, M.A.; McLean, D.D.; Kates, M. Biodiesel production from waste cooking oil: 2. Economic assessment and sensitivity analysis. Bioresour. Technol. 2003, 90, 229–240. [Google Scholar] [CrossRef]

- Banerjee, A.; Chakraborty, R. Parametric sensitivity in transesterification of waste cooking oil for biodiesel production—A review. Resour. Conserv. Recycl. 2009, 53, 490–497. [Google Scholar] [CrossRef]

- Chhetri, A.B.; Watts, K.C.; Islam, M.R. Waste Cooking Oil as an Alternate Feedstock for Biodiesel Production. Energies 2008, 1, 3–18. [Google Scholar] [CrossRef] [Green Version]

- Moecke, E.H.S.; Feller, R.; Santos, H.A.D.; Machado, M.D.M.; Cubas, A.L.V.; Dutra, A.R.D.A.; Santos, L.L.V.; Soares, S.R. Biodiesel production from waste cooking oil for use as fuel in artisanal fishing boats: Integrating environmental, economic. J. Clean. Prod. 2016, 135, 679–688. [Google Scholar] [CrossRef]

- Qiu, Z. Intensification of Liquid-Liquid Contacting Processes. Ph.D Thesis, Department of Chemical and Petroleum Engineering, University of Kansas, Lawrence, KS, USA, 2010. [Google Scholar]

- Abbaszadeh, A.; Ghobadian, B.; Omidkhah, M.R.; Najafi, G. Current biodiesel production technologies: A comparative review. Energy Convers. Manag. 2012, 63, 138–148. [Google Scholar] [CrossRef]

- Sungwornpatansakul, P.; Hiroi, J.; Nigahara, Y.; Jayasinghe, T.K.; Yoshikawa, K. Enhancement of biodiesel production reaction employing the static mixing. Fuel Process. Technol. 2013, 116, 1–8. [Google Scholar] [CrossRef]

- Somnuk, K.; Prasit, T.; Prateepchaikul, G. Effects of mixing technologies on continuous methyl ester production: Comparison of using plug flow, static mixer, and ultrasound clamp. Energy Convers. Manag. 2017, 140, 91–97. [Google Scholar] [CrossRef]

- Suryanto; Utomo, W.B.; Marwan. Novel Oscillatory Flow Reactor to Improve Biodiesel Production Continuous System. Int. J. Sci. Res. 2015, 4, 103–106. [Google Scholar]

- Azam, N.A.M.; Uemura, Y.; Kusakabe, K.; Bustam, M.A. Biodiesel Production from Palm Oil Using Micro Tube Reactors: Effects of Catalyst Concentration and Residence Time. Procedia Eng. 2016, 148, 354–360. [Google Scholar] [CrossRef]

- Cancela, A.; Maceiras, R.; Urrejola, S.; Sanchez, A. Microwave-Assisted Transesterification of Macroalgae. Energies 2012, 5, 862–871. [Google Scholar] [CrossRef] [Green Version]

- Choedkiatsakul, I.; Ngaosuwan, K.; Assabumrungrat, S.; Mantegna, S.; Cravotto, G. Biodiesel production in a novel continuous flow microwave reactor. Renew. Energy 2015, 83, 25–29. [Google Scholar] [CrossRef]

- Lertsathapornsuk, V.; Pairintrab, R.; Aryusukb, K.; Krisnangkurab, K. Microwave assisted in continuous biodiesel production from waste frying palm oil and its performance in a 100 kW diesel generator. Fuel Process. Technol. 2008, 89, 1330–1336. [Google Scholar] [CrossRef]

- Dube, M.A.; Tremblay, A.Y.; Liu, J. Biodiesel production using a membrane reactor. Bioresour. Technol. 2007, 98, 639–647. [Google Scholar] [CrossRef] [PubMed]

- Atadashi, I.M.; Aroua, M.K.; Abdul Aziz, A.R.; Sulaiman, N.M.N. Membrane biodiesel production and refining technology: A critical review. Renew. Sust. Energy Rev 2011, 15, 5051–5062. [Google Scholar] [CrossRef]

- Pradana, Y.S.; Hidayat, A.; Prasetya, A.; Budiman, A. Biodiesel production in a reactive distillation column catalyzed by heterogeneous potassium catalyst. Energy Procedia 2017, 143, 742–747. [Google Scholar] [CrossRef]

- Simasatitkul, L.; Siricharnsakunchai, P.; Patcharavorachot, Y.; Assabumrungrat, S.; Arpornwichanop, S. Reactive distillation for biodiesel production from soybean oil. Korean J. Chem. Eng. 2011, 28, 649–655. [Google Scholar] [CrossRef]

- Ilmi, M.; Kloekhorst, A.; Winkelman, J.G.M.; Euverink, G.J.W.; Hidayat, C.; Heeres, H.J. Process intensification of catalytic liquid-liquid solid processes: Continuous biodiesel production using an immobilized lipase in a centrifugal contactor separator. Chem. Eng. J. 2017, 321, 76–85. [Google Scholar] [CrossRef]

- Silva, N.D.L.D.; Garnica, J.A.G.; Batistella, C.B.; Maciel, M.R.W.; Filho, R.M. Use of experimental design to investigate biodiesel production by multiple-stage Ultra-Shear reactor. Bioresour. Technol. 2011, 102, 2672–2677. [Google Scholar] [CrossRef] [PubMed]

- Mostafaei, M.; Ghobadian, B.; Barzegar, M.; Banakar, A. Optimization of ultrasonic assisted continuous production of biodiesel using response surface methodology. Ultrason. Sonochem. 2015, 27, 54–61. [Google Scholar] [CrossRef] [PubMed]

- Hingu, S.M.; Gogate, R.; Rathod, V.K. Synthesis of biodiesel from waste cooking oil using sonochemical reactors. Ultrason. Sonochem. 2010, 17, 827–832. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.; Teng, S.; Yuan, M.; Ji, D.; Chang, C.; Chen, Y.; Shie, J.; Ho, C.; Tian, S.; Andrade-Tacca, C.A.; et al. Esterification of Jatropha Oil with Isopropanol via Ultrasonic Irradiation. Energies 2018, 11, 1456. [Google Scholar] [CrossRef]

- Ghayal, D.; Pandit, A.B.; Rathod, V.K. Optimization of biodiesel production in a hydrodynamic cavitation reactor using used frying oil. Ultrasonics Sonochem. 2013, 20, 322–328. [Google Scholar] [CrossRef] [PubMed]

- Maddikeri, G.; Gogate, P.R.; Pandit, A. Intensified synthesis of biodiesel using hydrodynamic cavitation reactors based on the interesterification of waste cooking oil. Fuel 2014, 137, 285–292. [Google Scholar] [CrossRef]

- Pal, A.; Verma, A.; Kachhwaha, S.S.; Maji, S. Biodiesel production through hydrodynamic cavitation and performance testing. Renew. Energy 2010, 35, 619–624. [Google Scholar] [CrossRef]

- Gogate, P.R. Cavitational reactors for process intensification of chemical processing applications: A critical review. Chem. Eng. Process. 2008, 47, 515–527. [Google Scholar] [CrossRef]

- Hydro Dynamics, Inc. 2015. Available online: http://hydrodynamics.com (accessed on 14 March 2017).

- Mancosky, D.G.; Armstead, D.A.; McGurk, T.; Hopkins, G.; Hudson, K. The Use of a Controlled Cavitation Reactor for Bio-Diesel Production. In Proceedings of the AIChE Spring Meeting and Global Congress on Process Safety, Houston, TX, USA, 24 April 2007. [Google Scholar]

- Thanh, L.T.; Okitsu, K.; Sadanaga, Y.; Takenaka, N.; Maeda, Y.; Bandow, H. A two-step continuous ultrasound assisted production of biodiesel fuel from waste cooking oils: A practical and economical approach to produce high quality biodiesel fuel. Bioresour. Technol. 2010, 101, 5394–5401. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, A.K.; Kumar, A.; Raheman, H. Biodiesel production from jatropha oil (Jatropha curcas) with high free fatty acids: An optimized process. Biomass Bioenergy 2007, 31, 569–575. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 5th ed.; John Wiley & Sons: New Work, NY, USA, 2000; ISBN 9780471316497. [Google Scholar]

- Ryan, T.P. Modern Experimental Design; John Wiley & Sons: Hoboken, NJ, USA, 2007; ISBN 978-0-471-21077-1. [Google Scholar]

| Fatty Acid | Formula | Structure | wt % |

|---|---|---|---|

| Myristic | C14H28O2 | C14:0 | 4.78 ± 0.17 |

| Palmitic | C16H32O2 | C16:0 | 30.36 ± 0.44 |

| Palmitoleic | C16H30O2 | C16:1 | 6.46 ± 0.22 |

| Stearic | C18H36O2 | C18:0 | 2.77 ± 0.15 |

| Oleic | C18H34O2 | C18:1 | 32.94 ± 0.52 |

| Linoleic | C18H32O2 | C18:2 | 21.00 ± 0.34 |

| Linolenic | C18H30O2 | C18:3 | 0.87 ± 0.07 |

| Others | - | - | 0.72 ± 0.06 |

| Factors | Unit | Levels | |||

|---|---|---|---|---|---|

| Actual | Coded | −1 | 0 | +1 | |

| Dr/Ds | A | - | 0.68 | 0.78 | 0.88 |

| Dc/Dr | B | - | 0.06 | 0.08 | 0.10 |

| dc/∆r | C | - | 0.5 | 0.7 | 0.9 |

| N | D | rpm | 2000 | 2500 | 3000 |

| Tr | E | s | 30 | 45 | 60 |

| Sources | Sum of Squares | DF | Mean Squares | F-Value | p-Value | Remark |

|---|---|---|---|---|---|---|

| Model | 6089.15 | 20 | 304.46 | 9.77 | <0.0001 | significant |

| A | 3479.17 | 1 | 3479.17 | 111.68 | <0.0001 | significant |

| B | 203.17 | 1 | 203.17 | 6.52 | 0.0155 | significant |

| C | 605.01 | 1 | 605.01 | 19.42 | <0.0001 | significant |

| D | 135.57 | 1 | 135.57 | 4.18 | 0.0474 | significant |

| E | 41.64 | 1 | 41.64 | 1.34 | 0.2259 | |

| AB | 0.062 | 1 | 0.062 | 2.00 × 10−3 | 0.9646 | |

| AC | 214.41 | 1 | 214.41 | 6.88 | 0.0131 | significant |

| AD | 22.44 | 1 | 22.44 | 0.72 | 0.4022 | |

| AE | 9.65 | 1 | 9.65 | 0.31 | 0.5816 | |

| BC | 3.70 | 1 | 3.70 | 0.12 | 0.7352 | |

| BD | 0.021 | 1 | 0.021 | 6.736 × 10−4 | 0.9795 | |

| BE | 1.54 | 1 | 1.54 | 0.049 | 0.8254 | |

| CD | 374.71 | 1 | 374.71 | 12.03 | 0.0015 | significant |

| CE | 0.39 | 1 | 0.39 | 0.012 | 0.9118 | |

| DE | 32.71 | 1 | 32.71 | 1.05 | 0.3130 | |

| A2 | 0.27 | 1 | 0.27 | 8.547 × 10−3 | 0.9269 | |

| B2 | 693.20 | 1 | 693.20 | 22.25 | <0.0001 | significant |

| C2 | 174.99 | 1 | 174.99 | 5.62 | 0.0238 | significant |

| D2 | 192.95 | 1 | 192.95 | 6.19 | 0.0180 | significant |

| E2 | 18.91 | 1 | 18.91 | 0.61 | 0.4415 | |

| Residual | 1028.04 | 33 | 31.15 | |||

| Lack of Fit | 618.82 | 16 | 38.67 | 4.16 | 0.0642 | Non-significant |

| Pure Error | 209.22 | 17 | 12.31 |

| Experimental Region | |||||

|---|---|---|---|---|---|

| Variable | Ultimate Goal | Lower Limit | Higher Limit | Weight | Importance |

| Dr/Ds (A) | In range | 0.68 | 0.88 | 1 | +++ |

| Dc/Dr (B) | In range | 0.05 | 0.09 | 1 | +++ |

| dc/∆r (C) | In range | 0.5 | 0.9 | 1 | +++ |

| N (D) | In range | 1000 | 3000 | 1 | +++ |

| Tr (E) | In range | 30 | 90 | 1 | +++ |

| Yield (Y) | Maximized | 52.53 | 96.50 | 1 | +++++ |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbaszadeh-Mayvan, A.; Ghobadian, B.; Najafi, G.; Yusaf, T. Intensification of Continuous Biodiesel Production from Waste Cooking Oils Using Shockwave Power Reactor: Process Evaluation and Optimization through Response Surface Methodology (RSM). Energies 2018, 11, 2845. https://doi.org/10.3390/en11102845

Abbaszadeh-Mayvan A, Ghobadian B, Najafi G, Yusaf T. Intensification of Continuous Biodiesel Production from Waste Cooking Oils Using Shockwave Power Reactor: Process Evaluation and Optimization through Response Surface Methodology (RSM). Energies. 2018; 11(10):2845. https://doi.org/10.3390/en11102845

Chicago/Turabian StyleAbbaszadeh-Mayvan, Ahmad, Barat Ghobadian, Gholamhassan Najafi, and Talal Yusaf. 2018. "Intensification of Continuous Biodiesel Production from Waste Cooking Oils Using Shockwave Power Reactor: Process Evaluation and Optimization through Response Surface Methodology (RSM)" Energies 11, no. 10: 2845. https://doi.org/10.3390/en11102845

APA StyleAbbaszadeh-Mayvan, A., Ghobadian, B., Najafi, G., & Yusaf, T. (2018). Intensification of Continuous Biodiesel Production from Waste Cooking Oils Using Shockwave Power Reactor: Process Evaluation and Optimization through Response Surface Methodology (RSM). Energies, 11(10), 2845. https://doi.org/10.3390/en11102845