A Review of the Energy Performance and Life-Cycle Assessment of Building-Integrated Photovoltaic (BIPV) Systems

Abstract

:1. Introduction

2. BIPV Definition and BIPV Advantages

3. PV Materials and PV Cells

4. PV Modules Suitable for Building Integration

5. Classifications of the BIPV Systems

6. Performances of BIPV Systems

6.1. Power Performance of BIPV Systems

6.1.1. Electricity Generation Capacity of BIPV Systems in Buildings

6.1.2. BIPV Electricity Generation Potential of a City or a Country

6.2. The Thermal Performance of BIPV Systems

6.3. The Optical Performance of Semi-Transparent BIPV Systems

6.4. The Overall Energy Performance and Energy-Saving Potential of Semi-Transparent BIPV Systems

7. Life-Cycle Assessment (LCA) of PV Systems

7.1. The LCA of BIPV Systems

7.2. The LCA of Different Types of PV Modules

8. Barriers and Strategies for BIPV Development

- Policy barriers: lack of government support;

- Perception barriers: poor public understanding;

- Economic barriers: the high cost of BIPV modules, the high cost of design and construction;

- Technical barrier: lack of standards, low power efficiency, poor power reliability.

9. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Peng, C.; Huang, Y.; Wu, Z. Building-integrated photovoltaics (BIPV) in architectural design in china. Energy Build. 2011, 43, 3592–3598. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A review of solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Temby, O.; Kapsis, K.; Berton, H.; Rosenbloom, D.; Gibson, G.; Athienitis, A.; Meadowcroft, J. Building-integrated photovoltaics: Distributed energy development for urban sustainability. Environ. Sci. Policy Sustain. Dev. 2014, 56, 4–16. [Google Scholar] [CrossRef]

- Transparency Market Research. Building Integrated Photovoltaics Market: Global Industry Analysis, Size, Share, Growth, Trends and Forecast, 2013–2019; Transparency Market Research: Albany, NY, USA, 2015. [Google Scholar]

- Nanomarkets. BIPV Technologies and Market, 2015–2022; Nano-839; N-Tech Research: Glen Allen, VA, USA, 2015. [Google Scholar]

- Tabakovic, M.; Fechner, H.; Sark, W.V.; Louwen, A.; Georghiou, G.; Makrides, G.; Loucaidou, E.; Ioannidou, M.; Weiss, I.; Arancon, S.; et al. Status and outlook for building integrated photovoltaics (BIPV) in relation to educational needs in the BIPV sector. Energy Procedia 2017, 111, 993–999. [Google Scholar] [CrossRef]

- Sharma, S.; Jain, K.K.; Sharma, A. Solar cells: In research and applications—A review. Mater. Sci. Appl. 2015, 6, 1145–1155. [Google Scholar] [CrossRef]

- Gul, M.; Kotak, Y.; Muneer, T. Review on recent trend of solar photovoltaic technology. Energy Explor. Exploit. 2016, 34, 485–526. [Google Scholar] [CrossRef] [Green Version]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. A comprehensive review on design of building integrated photovoltaic system. Energy Build. 2016, 128, 99–110. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Greea, M.A. High-efficiency PERL and PERT silicon solar cells on FZ and MCZ substrates. Sol. Energy Mater. Sol. Cells 2011, 65, 429–435. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory (NREL). Best Research-Cell Efficiencies. Available online: https://www.nrel.gov/pv/assets/images/efficiency-chart.png (accessed on 13 November 2018).

- Song, J.-H.; An, Y.-S.; Kim, S.-G.; Lee, S.-J.; Yoon, J.-H.; Choung, Y.-K. Power output analysis of transparent thin-film module in building integrated photovoltaic system (BIPV). Energy Build. 2008, 40, 2067–2075. [Google Scholar] [CrossRef]

- Yoon, J.-H.; Song, J.; Lee, S.-J. Practical application of building integrated photovoltaic (BIPV) system using transparent amorphous silicon thin-film PV module. Sol. Energy 2011, 85, 723–733. [Google Scholar] [CrossRef]

- Ng, P.K.; Mithraratne, N.; Kua, H.W. Energy analysis of semi-transparent BIPV in Singapore buildings. Energy Build. 2013, 66, 274–281. [Google Scholar] [CrossRef]

- Park, K.E.; Kang, G.H.; Kim, H.I.; Yu, G.J.; Kim, J.T. Analysis of thermal and electrical performance of semi-transparent photovoltaic (PV) module. Energy 2010, 35, 2681–2687. [Google Scholar] [CrossRef]

- Yoon, J.-H.; Shim, S.-R.; An, Y.S.; Lee, K.H. An experimental study on the annual surface temperature characteristics of amorphous silicon BIPV window. Energy Build. 2013, 62, 166–175. [Google Scholar] [CrossRef]

- Fossa, M.; Ménézo, C.; Leonardi, E. Experimental natural convection on vertical surfaces for building integrated photovoltaic (BIPV) applications. Exp. Therm. Fluid Sci. 2008, 32, 980–990. [Google Scholar] [CrossRef]

- Gan, G. Numerical determination of adequate air gaps for building-integrated photovoltaics. Sol. Energy 2009, 83, 1273–1353. [Google Scholar] [CrossRef]

- Ritzen, M.J.; Vroon, Z.A.E.P.; Rovers, R.; Lupíšek, A.; Geurts, C.P.W. Environmental impact comparison of a ventilated and a non-ventilated building-integrated photovoltaic rooftop design in the Netherlands: Electricity output, energy payback time, and land claim. Sol. Energy 2017, 155, 304–313. [Google Scholar] [CrossRef]

- Charron, R.; Athienitis, A.K. Optimization of the performance of double facades with integrated photovoltaic panel and motorized blinds. Sol. Energy 2006, 80, 482–491. [Google Scholar] [CrossRef]

- Tian, H.; Yu, X.; Zhang, J.; Duan, W.; Tian, F.; Yu, T. The Influence of environmental factors on DSSCs for BIPV. Int. J. Electrochem. Sci. 2012, 7, 4686–4691. [Google Scholar]

- Ordenes, M.; Marinoski, D.L.; Braun, P.; Rüther, R. The impact of building integrated photovoltaics on the energy demand of multi-family dwellings in Brazil. Energy Build. 2007, 39, 629–642. [Google Scholar] [CrossRef]

- BIPV China. Available online: http://www.bipvcn.org/project/case/domestic (accessed on 13 November 2018).

- You, S.; Yang, H. The potential electricity generating capacity of BIPV in Hong Kong. In Proceedings of the Conference Record of the Twenty-Sixth IEEE Photovoltaic Specialists Conference, Anaheim, CA, USA, 29 September–3 October 1997; pp. 1345–1348. [Google Scholar]

- International Energy Agency. Potential for Building Integrated Photovoltaics. Report IEA-PVPST7-4:2002. Available online: www.iea-pvps.org/index.php?id=9&eID=dam_frontend_push&docID=394 (accessed on 13 November 2018).

- Peng, J.; Lu, L. Investigation on the development potential of rooftop PV system in Hong Kong and its environmental benefits. Renew. Sustain. Energy Rev. 2013, 27, 149–162. [Google Scholar] [CrossRef]

- Defaix, P.R.; van Sark, W.G.J.H.M.; Worrell, E.; Visser, E.D. Technical potential for photovoltaics on buildings in the eu-27. Sol. Energy 2012, 86, 2644–2653. [Google Scholar] [CrossRef]

- Peng, J.; Lin, L.; Yang, H. An experimental study of the thermal performance of a novel photovoltaic double-skin facade in Hong Kong. Sol. Energy 2013, 97, 293–304. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Han, J. Investigation on the annual thermal performance of a photovoltaic wall mounted on a multi-layer façade. Appl. Energy 2013, 112, 646–656. [Google Scholar] [CrossRef]

- Yang, H.; Burnett, J.; Ji, J. Simple approach to cooling load component calculation through PV walls. Energy Build. 2000, 31, 285–290. [Google Scholar] [CrossRef]

- Ji, J.; Chow, T.; He, W. Dynamic performance of hybrid photovoltaic/thermal collector wall in Hong Kong. Build. Environ. 2003, 38, 1327–1334. [Google Scholar] [CrossRef]

- Chow, T.T.; Pei, G.; Chan, L.S.; Lin, Z.; Fong, K.F. A comparative study of PV glazing performance in warm climate. Indoor Built Environ. 2009, 18, 32–40. [Google Scholar] [CrossRef]

- Chow, T.T.; Qiu, Z.; Li, C. Potential application of “see-through” solar cells in ventilated glazing in Hong Kong. Sol. Energy Mater. Sol. Cells 2009, 93, 230–238. [Google Scholar] [CrossRef]

- He, W.; Zhang, Y.X.; Sun, W.; Hou, J.X.; Jiang, Q.Y.; Ji, J. Experimental and numerical investigation on the performance of amorphous silicon photovoltaics window in east china. Build. Environ. 2011, 46, 363–369. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, W.; Ren, J.; Ren, J.; Zhu, L.; Wang, Q. Influence of a building’s integrated-photovoltaics on heating and cooling loads. Appl. Energy 2006, 83, 989–1003. [Google Scholar] [CrossRef]

- Fung, T.Y.Y.; Yang, H. Study on thermal performance of semi-transparent building-integrated photovoltaic glazings. Energy Build. 2008, 40, 341–350. [Google Scholar] [CrossRef]

- Wong, P.W.; Shimoda, Y.; Nonaka, M.; Inoue, M.; Mizuno, M. Semi-transparent PV: Thermal performance, power generation, daylight modelling and energy saving potential in a residential application. Renew. Energy 2008, 33, 1024–1036. [Google Scholar] [CrossRef]

- Han, J.; Lu, L.; Yang, H. Numerical evaluation of the mixed convective heat transfer in a double-pane window integrated with see-through a-Si PV cells with low-e coatings. Appl. Energy 2010, 87, 3431–3437. [Google Scholar] [CrossRef]

- Han, J.; Lu, L.; Yang, H. Thermal behavior of a novel type see-through glazing system with integrated PV cells. Build. Environ. 2009, 44, 2129–2136. [Google Scholar] [CrossRef]

- Norton, B.; Eames, P.C.; Mallick, T.K.; Huang, M.J.; McCormack, S.J.; Mondol, J.D.; Yohanis, Y.G. Enhancing the performance of building integrated photovoltaics. Sol. Energy 2011, 85, 1629–1664. [Google Scholar] [CrossRef] [Green Version]

- Chow, T.-T.; Li, C.; Lin, Z. Innovative solar windows for cooling-demand climate. Sol. Energy Mater. Sol. Cells 2010, 94, 212–220. [Google Scholar] [CrossRef]

- Skandalos, N.; Karamanis, D. Investigation of thermal performance of semi-transparent PV technologies. Energy Build. 2016, 124, 19–34. [Google Scholar] [CrossRef]

- Tuchinda, C.; Srivannaboon, S.; Lim, H.W. Photoprotection by window glass, automobile glass, and sunglasses. J. Am. Acad. Dermatol. 2006, 54, 845–854. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, T.; Akisawa, A.; Kashiwagi, T. Energy savings of office buildings by the use of semi-transparent solar cells for windows. Renew. Energy 2005, 30, 281–304. [Google Scholar] [CrossRef]

- Chae, Y.T.; Kim, J.; Park, H.; Shin, B. Building energy performance evaluation of building integrated photovoltaic (BIPV) window with semi-transparent solar cells. Appl. Energy 2014, 129, 217–227. [Google Scholar] [CrossRef]

- Kroon, J.M.; Bakker, N.J.; Smit, H.J.P.; Liska, P.; Thampi, K.R.; Wang, P.; Grätzel, M.; Hinsch, A.; Hore, S.; Würfel, U.; et al. Nanocrystalline dye-sensitized solar cells having maximum performance. Prog. Photovolt. Res. Appl. 2007, 15, 1–18. [Google Scholar] [CrossRef]

- Ito, S.; Zakeeruddin, S.M.; Humphry-Baker, R.; Liska, P.; Charvet, R.; Comte, P.; Nazeeruddin, M.K.; Péchy, P.; Takata, M.; Miura, H.; et al. High-efficiency organic-dye-sensitized solar cells controlled by nanocrystalline-TiO2 electrode thickness. Adv. Mater. 2006, 18, 1202–1205. [Google Scholar] [CrossRef]

- Nazeeruddin, M.K.; De Angelis, F.; Fantacci, S.; Selloni, A.; Viscardi, G.; Liska, P.; Ito, S.; Takeru, B.; Grätzel, M. Combined experimental and DFT-TDDFT computational study of photoelectrochemical cell ruthenium sensitizers. J. Am. Chem. Soc. 2005, 127, 16835–16847. [Google Scholar] [CrossRef] [PubMed]

- Dennler, G.; Sariciftci, N.S. Flexible conjugated polymer-based plastic solar cells: From basics to applications. Proc. IEEE 2005, 93, 1429–1439. [Google Scholar] [CrossRef]

- Jørgensen, M.; Norrman, K.; Krebs, F.C. Stability/degradation of polymer solar cells. Sol. Energy Mater. Sol. Cells 2008, 92, 686–714. [Google Scholar] [CrossRef]

- Kim, H.; Kushto, G.P.; Arnold, C.B.; Kafafi, Z.H.; Piqué, A. Laser processing of nanocrystalline TiO2 films for dye-sensitized solar cells. Appl. Phys. Lett. 2004, 85, 464–466. [Google Scholar] [CrossRef]

- Schmidt-Mende, L.; Zakeeruddin, S.M.; Grätzel, M. Efficiency improvement in solid-state-dye-sensitized photovoltaics with an amphiphilic Rutheniumdye. Appl. Phys. Lett. 2005, 86, 013504. [Google Scholar] [CrossRef]

- Jiang, B.; Ji, J.; Yi, H. The influence of PV coverage ratio on thermal and electrical performance of photovoltaic-Trombe wall. Energy Conserv. 2007, 33, 2491–2498. [Google Scholar] [CrossRef]

- Yun, G.Y.; Mcevoy, M.; Steemers, K. Design and overall energy performance of a ventilated photovoltaic façade. Sol. Energy 2007, 81, 383–394. [Google Scholar] [CrossRef]

- Xu, S.; Liao, W.; Huang, J.; Kang, J. Optimal PV cell coverage ratio for semi-transparent photovoltaics on office building façades in central China. Energy Build. 2014, 77, 130–138. [Google Scholar] [CrossRef] [Green Version]

- Yoon, S.; Tak, S.; Kim, J.; Jun, Y.; Kang, K.; Park, J. Application of transparent dyesensitized solar cells to building integrated photovoltaic systems. Build. Environ. 2011, 46, 1899–1904. [Google Scholar] [CrossRef]

- Kang, J.-G.; Kim, J.-H.; Kim, J.-T. Performance evaluation of DSC windows for buildings. Int. J. Photoenergy 2013, 2013, 472086. [Google Scholar] [CrossRef]

- López, C.S.P.; Sangiorgi, M. Comparison assessment of BIPV façade semitransparent modules: Further insights on human comfort conditions. Energy Procedia 2014, 48, 1419–1428. [Google Scholar] [CrossRef]

- Olivieri, L.; Caamaño-Martin, E.; Olivieri, F.; Neila, J. Integral energy performance characterization of semi-transparent photovoltaic elements for building integration under real operation conditions. Energy Build. 2014, 68, 280–291. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Law, K.M. Overall energy performance of semi-transparent single-glazed photovoltaic (PV) window for a typical office in Hong Kong. Renew. Energy 2013, 49, 250–254. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, L.; Peng, J.; Song, A. Comparison of the overall energy performance of semi-transparent photovoltaic windows and common energy-efficient windows in Hong Kong. Energy Build. 2016, 128, 511–518. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Zhang, W. Numerical investigation of the energy saving potential of a semi-transparent photovoltaic double-skin facade in a cool-summer Mediterranean climate. Appl. Energy 2016, 165, 345–356. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Lu, L.; Ma, T.; Yang, H. Assessment of energy performance of semi-transparent PV insulating glass units using a validated simulation model. Energy 2016, 112, 538–548. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Yang, H.; Wang, C.; Li, X.; Lu, T. Comparison of energy performance between PV double skin facades and PV insulating glass units. Appl. Energy 2017, 194, 148–160. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Ma, T. Comparative study of the thermal and power performances of a semi-transparent photovoltaic façade under different ventilation modes. Appl. Energy 2015, 138, 572–583. [Google Scholar] [CrossRef]

- Bahaj, A.S.; James, P.A.B.; Jentsch, M.F. Potential of emerging glazing technologies for highly glazed buildings in hot arid climates. Energy Build. 2008, 40, 720–731. [Google Scholar] [CrossRef]

- Radhi, H. Energy analysis of facade-integrated photovoltaic systems applied to UAE commercial buildings. Sol. Energy 2010, 84, 2009–2021. [Google Scholar] [CrossRef]

- Leite Didoné, E.; Wagner, A. Semi-transparent PV windows: A study for office buildings in Brazil. Energy Build. 2013, 67, 136–142. [Google Scholar] [CrossRef]

- Li, D.H.W.; Lam, T.N.T.; Chan, W.W.H.; Mak, A.H.L. Energy and cost analysis of semitransparent photovoltaic in office buildings. Appl. Energy 2009, 86, 722–729. [Google Scholar] [CrossRef]

- Chow, T.T.; Fong, K.F.; He, W.; Lin, Z.; Chan, A.L.S. Performance evaluation of a PV ventilated window applying to office building of Hong Kong. Energy Build. 2007, 39, 643–650. [Google Scholar] [CrossRef]

- Olivieri, L.; Caamaño-Martín, E.; Moralejo-Vázquez, F.J.; Martín-Chivelet, N.; Olivieri, F.; Neila-Gonzalez, F.J. Energy saving potential of semi-transparent photovoltaic elements for building integration. Energy 2014, 76, 572–583. [Google Scholar] [CrossRef] [Green Version]

- Wei, L.; Xu, S. Energy performance comparison among see-through amorphous-silicon PV (photovoltaic) glazings and traditional glazings under different architectural conditions in China. Energy 2015, 83, 267–275. [Google Scholar]

- Fthenakis, V.M.; Kim, H.C. Photovoltaics: Life-cycle analyses. Sol. Energy 2009, 85, 1609–1628. [Google Scholar] [CrossRef]

- Fthenakis, V.; Frischknecht, R.; Raugei, M.; Kim, H.C.; Alsema, E.; Held, M.; de Wild-Scholten, M. Methodology Guidelines on Life Cycle Assessment of Photovoltaic Electricity, 3rd ed.; IEA PVPS Task 12; International Energy Agency Photovoltaic Power systems Programme: Ursen, Switzerland, 2016; Available online: http://www.iea-pvps.org/fileadmin/dam/public/report/technical/Task_12_-_Methodology_Guidelines_on_Life_Cycle_Assessment_of_Photovoltaic_Electricity_3rd_Edition.pdf (accessed on 13 November 2018).

- Lamnatou, C.; Baig, H.; Chemisana, D.; Mallick, T.K. Environmental assessment of a building-integrated linear dielectric-based concentrating photovoltaic according to multiple life-cycle indicators. J. Clean. Prod. 2016, 131, 773–784. [Google Scholar] [CrossRef]

- Menoufi, K.; Chemisana, D.; Rosell, J.I. Life Cycle Assessment of a Building Integrated Concentrated Photovoltaic scheme. Appl. Energy 2013, 111, 505–514. [Google Scholar] [CrossRef]

- Ng, P.K.; Mithraratne, N. Lifetime performance of semi-transparent building-integrated photovoltaic (BIPV) glazing systems in the tropics. Renew. Sustain. Energy Rev. 2014, 31, 736–745. [Google Scholar] [CrossRef]

- Li, G.; Xuan, Q.; Pei, G.; Su, Y.; Lu, Y.; Ji, J. Life-cycle assessment of a low-concentration PV module for building south wall integration in China. Appl. Energy 2018, 215, 174–185. [Google Scholar] [CrossRef]

- Bizzarri, G.; Morini, G.L. A Life Cycle Analysis of roof integrated photovoltaic systems. Int. J. Environ. Technol. Manag. 2007, 7. [Google Scholar] [CrossRef]

- Lu, L.; Yang, H.X. Environmental payback time analysis of a roof-mounted building-integrated photovoltaic (BIPV) system in Hong Kong. Appl. Energy 2010, 87, 3625–3631. [Google Scholar] [CrossRef]

- Perez, M.J.R.; Fthenakis, V. A lifecycle assessment of façade BIPV in New York. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 003271–003276. [Google Scholar]

- Belussi, L.; Mariotto, M.; Meroni, I.; Zevi, C.; Dei Svaldi, S. LCA study and testing of a photovoltaic ceramic tile prototype. Renew. Energy 2015, 74, 263–270. [Google Scholar] [CrossRef]

- Baumann, A.E.; Hill, R.; Hynes, K.M. Environmental impacts of PV systems-ground-based vs. BIPV. In Proceedings of the Conference Record of the Twenty Sixth IEEE Photovoltaic Specialists Conference, Anaheim, CA, USA, 29 September–3 October 1997; pp. 1361–1364. [Google Scholar]

- Hammond, G.P.; Harajli, H.A.; Jones, C.I.; Winnett, A.B. Integrated appraisal of a building integrated photovoltaic (BIPV) system. In Proceedings of the 2009 International Conference on Sustainable Power Generation and Supply, Nanjing, China, 6–7 April 2009; pp. 1–9. [Google Scholar]

- Wu, Y.W.; Wen, M.H.D.; Young, L.M.; Hsu, I.T. LCA-Based Economic Benefit Analysis for Building Integrated Photovoltaic (BIPV) Façades: A Case Study in Taiwan. Int. J. Green Energy 2017, 15. [Google Scholar] [CrossRef]

- Jayathissa, P.; Jansen, M.; Heeren, N.; Nagy, Z.; Schlueter, A. Life cycle assessment of dynamic building integrated photovoltaics. Sol. Energy Mater. Sol. Cells 2016, 156, 75–82. [Google Scholar] [CrossRef]

- Agrawal, B.; Tiwari, G.N. Life cycle cost assessment of building integrated photovoltaic thermal (bipvt) systems. Energy Build. 2010, 42, 1472–1481. [Google Scholar] [CrossRef]

- Tripathy, M.; Joshi, H.; Panda, S.K. Energy payback time and life-cycle cost analysis of building integrated photovoltaic thermal system influenced by adverse effect of shadow. Appl. Energy 2017, 208, 376–389. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H. Review on life cycle assessment of energy payback and greenhouse gas emission of solar photovoltaic systems. Renew. Sustain. Energy Rev. 2013, 19, 255–274. [Google Scholar] [CrossRef]

- Hammond, G.P.; Harajli, H.A.; Jones, C.I.; Winnett, A.B. Whole systems appraisal of a UK building integrated photovoltaic (BIPV) system: Energy, environmental, and economic evaluations. Energy Policy 2012, 40, 219–230. [Google Scholar] [CrossRef]

- Ito, M.; Kato, K.; Komoto, K.; Kichimi, T.; Kurokava, K. A comparative study on cost and life-cycle analysis for 100 MW very large-scale (VLS-PV) systems in deserts using m-Si, a-Si CdTe and CIS modules. Prog. Photovolt. Res. Appl. 2008, 16, 17–30. [Google Scholar] [CrossRef]

- Raugei, M.; Bargigli, S.; Ulgiati, S. Life cycle assessment and energy pay-back time of advanced photovoltaic modules: CdTe and CIS compared to poly-Si. Energy 2007, 32, 1310–1318. [Google Scholar] [CrossRef]

- Pacca, S.; Sivaraman, D.; Keoleian, G.A. Parameters affecting the life cycle performance of PV technologies and systems. Energy Policy 2007, 35, 3316–3326. [Google Scholar] [CrossRef]

- Battisti, R.; Corrado, R. Evaluation of technical improvements of photovoltaic systems through life cycle assessment methodology. Energy 2005, 30, 952–967. [Google Scholar] [CrossRef]

- Held, M.; Ilg, R. Update of environmental indicators and energy payback time of CdTe PV systems in Europe. Prog. Photovolt. Res. Appl. 2011, 19, 614–626. [Google Scholar] [CrossRef]

- Wilson, R.; Young, A. The embodied energy payback period of photovoltaic installations applied to buildings in the UK. Build. Environ. 1996, 31, 299–305. [Google Scholar] [CrossRef]

- Kato, K.; Murata, A.; Sakuta, K. Energy pay-back time and life-cycle CO2 emission of residential PV power system with silicon PV module. Prog. Photovolt. Res. Appl. 1998, 6, 105–115. [Google Scholar] [CrossRef]

- Alsema, E.A.; Wild-Scholten, M.J. The real environmental impacts of crystalline silicon PV modules: An analysis based on up-to-date manufacture data. In Proceedings of the 20th European Photovoltaic Solar Energy Conference, Barcelona, Spain, 6–10 June 2005. [Google Scholar]

- Alsema, E.A.; Wild-Scholten, M.J.; Fthenakis, V.M. Environmental impacts of PV electricity generation—A critical comparison of energy supply options. In Proceedings of the 21th European Photovoltaic Solar Energy Conference, Dresden, Germany, 4–8 September 2006. [Google Scholar]

- Jungbluth, N.; Dones, R.; Frischknecht, R. Life cycle assessment of photovoltaics: Update of the ecoinvent database. In Proceedings of the 14th SETAC LCA Case Studies Symposium, Giteborg, Sweden, 3–4 December 2007. [Google Scholar]

- Wild-Scholten, M.J. Energy payback times of PV modules and systems. In Proceedings of the Workshop Photovoltaik-Modultechnik, Koln, Germany, 26–27 November 2009. [Google Scholar]

- Ito, M.; Komoto, K.; Kurokawa, K. Life-cycle analyses of very-large scale PV systems using six types of PV modules. Curr. Appl. Phys. 2010, 10, S271–S273. [Google Scholar] [CrossRef]

- Seng, L.Y.; Lalchand, G.; Lin, G.M.S. Economical, environmental and technical analysis of building integrated photovoltaic systems in Malaysia. Energy Policy 2008, 36, 2130–2142. [Google Scholar] [CrossRef]

- Phylipsen, G.J.M.; Alsema, E.A. Environmental Life-Cycle Assessment of Multicrystalline Silicon Solar Cell Modules; Report No. 95057; Department of Science, Technology and Society, Utrecht University: Utrecht, The Netherlands, 1995. [Google Scholar]

- Alsema, E.A. Energy pay-back time and CO2 emissions of PV systems. Prog. Photovolt. Res. Appl. 2000, 8, 17–25. [Google Scholar] [CrossRef]

- Ito, M.; Kato, K.; Sugihara, H.; Kichimi, T.; Song, J.; Kurokava, K. A preliminary study on potential for very large-scale photovoltaic power generation (VLS-PV) system in the Gobi desert from economic and environmental viewpoints. Sol. Energy Mater. Sol. Cells 2003, 75, 507–517. [Google Scholar] [CrossRef]

- Jungbluth, N. Life cycle assessment of crystalline photovoltaics in the Swiss ecoinvent database. Prog. Photovolt. Res. Appl. 2005, 13, 429–446. [Google Scholar] [CrossRef] [Green Version]

- Lewis, G.; Keoleian, G. Life Cycle Design of Amorphous Silicon Photovoltaics Modules; APE/600/SR-97/081; Environmental Protection Agency Center for Environmental Research Information: Cincinnati, OH, USA, 1997. Available online: http://www.umich.edu/~nppcpub/research/pv.pdf). (accessed on 13 November 2018).

- Alsema, E.A. Energy requirements of thin film solar cell modules—A review. Renew. Sustain. Energy Rev. 1998, 2, 387–415. [Google Scholar] [CrossRef]

- Kato, K.; Hibino, T.; Komoto, K.; Ihara, S.; Yamamoto, S.; Fujihara, H. A life-cycle analysis on thin-film CdS/CdTe PV modules. Sol. Energy Mater. Sol. Cells 2001, 67, 279–287. [Google Scholar] [CrossRef]

- Fthenakis, V.M.; Kim, H.C. Energy use and greenhouse gas emissions in the life cycle of thin film CdTe photovoltaics. In Proceedings of the Symposium G-Life Cycle Analysis, Materials Research Society Fall Meeting, Boston, MA, USA, 29 November–2 December 2005. [Google Scholar]

- Fthenakis, V.; Kim, H.C.; Held, M.; Raugei, M.; Krones, J. Update of PV energy payback times and life-cycle greenhouse gas emissions. In Proceedings of the 24th European Photovoltaic Solar Energy Conference, Hamburg, Germany, 21–25 September 2009. [Google Scholar]

- Keoleian, G.A.; Lewis, G.M. Modeling the life cycle energy and environmental performance of amorphous silicon BIPV roofing in the US. Renew. Energy 2003, 28, 271–293. [Google Scholar] [CrossRef]

- Yang, R.J.; Zou, P.X.W. Building integrated photovoltaics (BIPV): Costs, benefits, risks, barriers and improvement strategy. Int. J. Constr. Manag. 2016, 16, 39–53. [Google Scholar] [CrossRef]

- Moosavian, S.M.; Rahim, N.A.; Selvaraj, J.; Selvaraj, J.; Solangi, K.H. Energy policy to promote photovoltaic generation. Renew. Sustain. Energy Rev. 2013, 25, 44–58. [Google Scholar] [CrossRef]

- Azadian, F.; Radzi, M.A.M. A general approach toward building integrated photovoltaic systems and its implementation barriers: A review. Renew. Sustain. Energy Rev. 2013, 22, 527–538. [Google Scholar] [CrossRef] [Green Version]

- Abdullah, A.S.; Abdullah, M.P.; Hassan, M.Y.; Hussin, F. Renewable energy cost-benefit analysis under Malaysian feed-in-tariff. In Proceedings of the 2012 IEEE Student Conference on Research and Development (SCOReD), Pulau Pinang, Malaysia, 5–6 December 2012; pp. 160–165. [Google Scholar]

| Region/Country | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | CAGR (%) |

|---|---|---|---|---|---|---|---|---|

| Asia/Pacific | 300 | 492 | 772 | 1159 | 1672 | 2329 | 3.134 | 47.8 |

| Europe | 650 | 967 | 1441 | 2103 | 2929 | 3807 | 4838 | 39.7 |

| USA | 319 | 476 | 675 | 917 | 1200 | 1491 | 1766 | 33.0 |

| Canada | 42 | 61 | 86 | 119 | 157 | 190 | 228 | 32.6 |

| Japan | 143 | 201 | 268 | 349 | 434 | 520 | 612 | 27.5 |

| Rest of world | 81 | 125 | 184 | 263 | 355 | 451 | 561 | 37.9 |

| Total (GW) | 1.5 | 2.3 | 3.4 | 4.9 | 6.7 | 8.8 | 11.1 |

| Authors | Module Type | Region | Objectives | Outcomes |

|---|---|---|---|---|

| Song [12] | a-Si | Korea | Studied the influential factors of PV electricity performance | South-facing PV module with a slope of 30° achieved the highest annual power performance |

| Yoon [13] | a-Si | Korea | Evaluated the long-term performance of a thin-film a-Si BIPV window | The optimized design can improve electricity production by 47% |

| Ng [1,4] | c-Si, a-Si | Singapore | Examined the overall performance of a semi-transparent BIPV system | The proposed system can be used in building components of all orientations |

| Park [15] | mc-Si | Korea | Investigated the electrical and thermal performance of a semi-transparent PV module | A 1 °C increase in the operating temperature of a c-Si PV module may result in power decreases of 0.48% and 0.52% |

| Yoon [16] | c-Si | Korea | Investigated the long-term surface temperature characteristics of a PV window | Inner surface temperature of PV window differs from that of normal windows |

| Fossa [17] | a-Si | - | Studied the influence of the cavity thickness on the performance | The thickness has a significant effect on the operating temperature and the efficiency |

| Gan [18] | - | - | Investigated the effect of an air gap on a PV module’s electrical performance | A 12–16 cm air gap could greatly reduce the overheating problem and increase the electricity generation. |

| Ritzen, M.J. [19] | mc-Si | Netherlands | Investigated the performances of ventilated and non-ventilated BIPV rooftops | The electricity production of a ventilated IPV rooftop was 2.6% higher than that of a non-ventilated rooftop |

| Charron, R. [20] | c-Si | Montreal | Found the optimized design to maximize the conversion efficiency | An optimized design can increase the efficiency by 80% |

| Tian, H. [21] | DSSC | - | Examined the influence factors of the I–V curve | Temperature and irradiance greatly impact the DSSC’s performance |

| Ordenes [22] | mc-Si, pc-Si, a-Si, CdTe, CIS | Brazil | Investigated the potential of BIPV potential in Brazil | For 30% of the running time, the electricity generation exceeds building’s demand |

| Project Name | Brief Introduction | |||||

|---|---|---|---|---|---|---|

| Site | Integration Mode | Panel Type | Active Area (m2) | PV Power (kWp) | Power Yield (MWh/year) | |

Shandong Museum | Jinan, Shandong, China | Roof integrated | Poly-Si | 9500 | 450 | 560 |

Capital Museum (China) | Beijing, China | Roof integrated | a-Si | 5000 | 300 | - |

Qinghai science and Technology Museum | Xilin, Qinghai, China | Roof and façade integrated | Mono-Si | 1600 | 186.6 | 220 |

Zhongnan international building materials market | Hangzhou, Zhejiang, China | Roof and façade integrated | Mono-Si | 1210 | 400 | 290 |

China National Gymnasium | Beijing, China | Roof integrated and shadings | Mono-Si | 1000 | 102.5 | 97 |

Suntech Eco Building | Wuxi, Jiangsu, China | Roof and façade integrated | Poly-Si | 6900 | 1010 | 1020 |

Canton Tower | Guangzhou, Guangdong, China | Façade integrated | Thin-film | 1120 | 20 | 12.66 |

Power Valley Plaza Business Conference Center | Baoding, Hebei, China | Roof and façade integrated | Poly-Si | - | 500 | 420 |

Astronergy Manufacture Factory | Hangzhou, Zhejiang, China | Roof and façade integrated | Mono-Si, thin-film | - | 510 | 558.8 |

Hangzhou East Railway Station | Hangzhou, Zhejiang, China | Roof integrated | Poly-Si | 79,000 | 10,000 | 10,000 |

Weihai Public Cultural Center | Weihai, Shandong, China | Roof integrated | Thin-film | 7800 | 480 | 330 |

Tianjin West Railway Station | Tianjin, China | Roof integrated | a-Si | 36,000 | 1884 | 2000 |

Changsha cSCEc Building | Changsha, Hunan, China | Roof and façade integrated | Mono-Si, Poly-Si | - | 96.82 | 37.5 |

Guangzhou South Railway Station | Guangzhou, Guangdong, China | Roof integrated | Mono-Si | 5016 | 253 | 260 |

Beijing South Railway Station | Beijing, China | Roof integrated | CIGS | 7000 | 240 | 223.6 |

Wuhan Railway Station | Wuhan, Hubei, China | Roof integrated | Mono-Si | 15,200 | 2200 | 2000 |

Shenzhen International Landscape Flowers Exposition Park | Shenzhen, Guangdong, China | Roof integrated | Mono-Si, Poly-Si | 7660 | 1000 | 1000 |

Nanjing South Railway Station | Nanjing, Jiangsu, China | Roof integrated | c-Si | 82,000 | 10,670 | 9230 |

Shanghai Hongqiao Railway Station | Shanghai, China | Roof integrated | Poly-Si | 61,000 | 6688 | 6300 |

Shenzhen North Railway Station | Shenzhen, Guangdong, China | Roof integrated | Mono-Si | 7896 | 501.4 | 537 |

| Country | Potential Area of Roofs (km2) | Potential Area of Façades (km2) | Potential of Roofs (TWh/year) | Potential of Façades (TWh/year) | Total Potential (TWh/year) | Actual Consumption (TWh) | Potential-Demand Ratio (%) |

|---|---|---|---|---|---|---|---|

| Australia | 422.5 | 158.34 | 68.176 | 15.881 | 84.057 | 182.24 | 46.1 |

| Austria | 139.62 | 52.36 | 15.197 | 3.528 | 18.725 | 53.93 | 34.7 |

| Canada | 963.54 | 361.33 | 118.708 | 33.054 | 151.762 | 495.31 | 30.6 |

| Denmark | 87.98 | 32.99 | 8.710 | 2.155 | 10.865 | 34.43 | 31.6 |

| Finland | 127.31 | 32.99 | 11.763 | 3.063 | 14.827 | 76.51 | 19.4 |

| Germany | 1295.92 | 485.97 | 128.296 | 31.745 | 160.040 | 531.64 | 30.1 |

| Italy | 763.53 | 286.32 | 103.077 | 23.827 | 126.904 | 282.01 | 45.0 |

| Japan | 966.38 | 362.39 | 117.416 | 29.456 | 146.872 | 1012.94 | 14.5 |

| Netherlands | 259.36 | 97.26 | 25.677 | 6.210 | 31.887 | 99.06 | 32.2 |

| Spain | 448.82 | 168.31 | 70.689 | 15.784 | 86.473 | 180.17 | 48.0 |

| Sweden | 218.77 | 82.04 | 21.177 | 5.515 | 26.692 | 137.12 | 19.5 |

| Switzerland | 138.22 | 51.83 | 15.044 | 3.367 | 18.410 | 53.17 | 34.6 |

| United Kingdom | 914.67 | 343.00 | 83.235 | 22.160 | 105.395 | 343.58 | 30.7 |

| United States | 10,096.26 | 3876.10 | 1662.349 | 418.312 | 2080.661 | 3602.63 | 57.8 |

| Authors | Module Type | Region | Objectives | Outcomes |

|---|---|---|---|---|

| Peng [28] | a-Si | Hong Kong | Evaluate the thermal property of a newly designed PV-DSF | The ventilated mode could minimize the solar heat gain among all the operation modes |

| Peng [29] | m-Si | Hong Kong | Investigate the thermal performance of a multi-layer PV façade | The PV façade performed the best in reducing the thermal loss |

| Yang [30] | c-Si | China | PV wall thermal performance in typical cities of China | The cooling load can be reduced by 33–50% with a PV wall |

| Ji [31] | a-Si, m-Si | Hong Kong | Test the transient thermal property of a PV wall system | The PV wall reduced the total heat gain by 53–59.2% during the summer period |

| Chow [32] | a-Si | Hong Kong | Investigate the performances of different PV glazed windows. | The air-conditioning load could be significantly reduced by PV windows |

| Chow [33] | a-Si | Hong Kong | Evaluate the cooling load reduction effect of ventilated PV windows | The PV window reduced the heat gain of an office by 28% |

| He [34] | a-Si | Hefei, China | Evaluate the benefits of a double-glazed PV window | The window system cut down the thermal load and had a lower inner surface temperature |

| Wang [35] | c-Si | Tianjin, China | Investigate the effects of PV roofs on a building’s heating and cooling loads | The PV roof with air-gap provides a higher power efficiency and lower cooling load |

| Fung [36] | mc-Si | Hong Kong | Investigate the thermal performance of semitransparent PV modules | The area and orientation of the solar cell greatly influenced the heat gain |

| Wong [37] | a-Si | Japan | Investigate the performance of semi-transparent PV roofs | A net energy savings of 3.0–8.7% were produced by the PV roof with a transparency of 50% |

| Han [38] | a-Si | Hong Kong | Find the thermal performance influential factors of a double-pane PV window | Radiative heat transfer can be reduced in the air cavity by a PV window with Low-E coating |

| Han [39] | a-Si | Hong Kong | Find the optimal thickness of the air cavity in a double glazed PV window | The air gap with a thickness between 6 and 8 cm achieves the best thermal performance |

| Authors | Module Type | Region | Objectives | Outcomes |

|---|---|---|---|---|

| Jiang [53] | c-Si | Hefei, China | Investigated the effect of PV cell coverage ratio on the performances of PV Trombe walls | A higher coverage ratio leads to a higher generation of electrical and a higher overall efficiency, but a lower indoor temperature and thermal efficiency |

| Miyazaki [44] | a-Si | Tokyo | Studied the performance influential factors of PV windows | PV windows with a transmittance of 40% and a window-to-wall ratio of 50% achieved the best overall performance |

| Yun [54] | c-Si | Stockholm, London, Madrid | Determined the optimal transparency by considering the room and depth-window-wall ratio | The optimal PV cell coverage ratio must be determined together with the window-to-wall ratio and room depth |

| Xu [55] | c-Si | Wuhan, China | Evaluated the optimal PV cell coverage ratio of BIPV façades | The PV cell coverage ratio greatly affects the performance. An optimal PV ratio reduces energy use by 13% |

| Yoon [56] | DSSC | - | Studied the effect of transmittance on the performance of DSSC | A higher module efficiency does not always bring a higher overall efficiency for the window |

| Kang [57] | DSSC | - | Investigate the optical performance of DSSC windows | TiO2 thickness greatly influences the transmittance and absorption, but the reflectance is not affected |

| López [58] | mc-Si a-Si CIS | Milan | Evaluated the daylighting and shading performance of PV windows | PV module integration reduces the daylighting perception, but the shading effect offers great potential in mitigating the overheating problem |

| Olivieri [59] | a-Si | Madrid | Evaluated the transparency of a PV module under different outdoor conditions | SHGC diversities occurred when the PV was located in different environmental conditions |

| Authors | Module Type | Region | Objectives | Outcomes |

|---|---|---|---|---|

| Lu [60] | a-Si | Hong Kong | Investigated the overall energy performance of a PV window | The proposed window was able to reduce the heat gain by 65% |

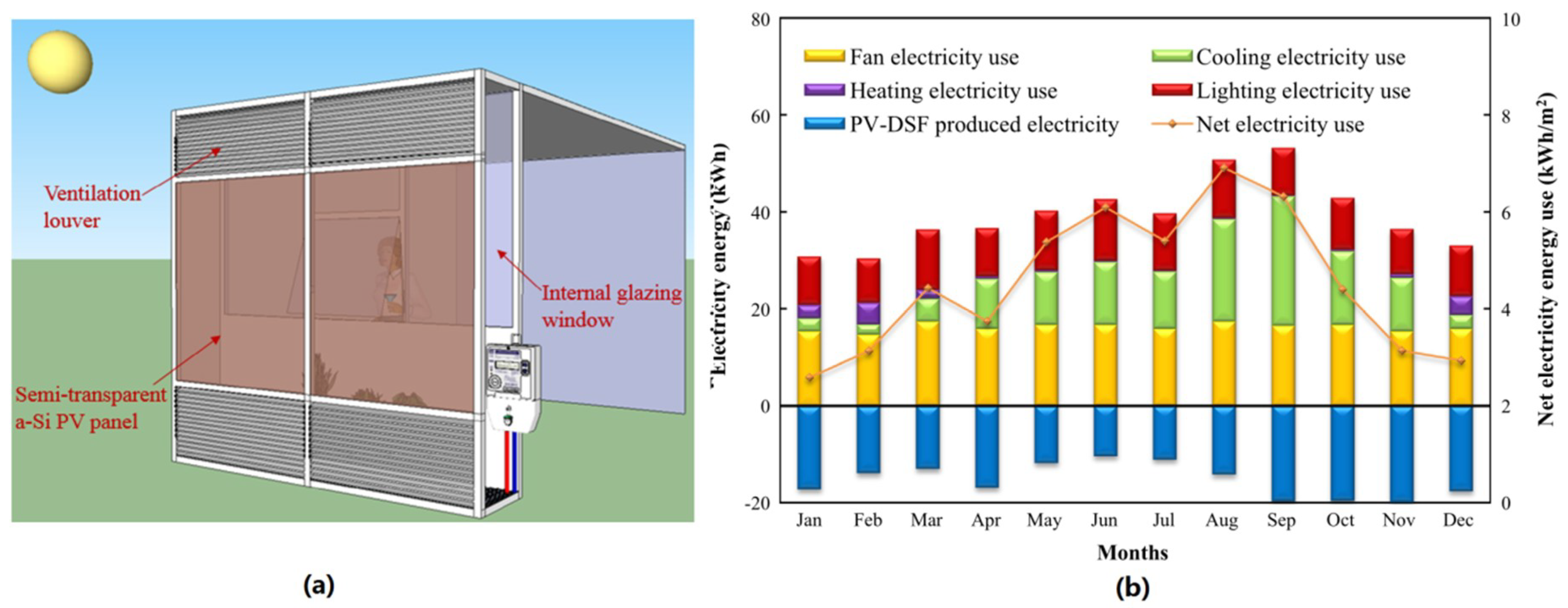

| Peng [65] | a-Si | Hong Kong | Examined the performances of a semi-transparent PV double-skin façade | Ventilated mode provides a higher electricity output and a lower solar heat gain, the non-ventilated mode provides a better thermal insulation performance |

| Peng [62] | a-Si | Berkeley | Investigated the overall energy performance of a PV-DSF | The proposed system was able to save the net electricity use by 50% |

| Wang [63] | a-Si | Hong Kong | Examined the overall performance of a new PV insulating glass unit | The energy-saving potentials of the new unit were 25.3% and 10.7% compared to a single clear glass window and a Low-E glass window |

| Wang [64] | a-Si | Hong Kong | Comparatively studied a PV-DSF and a PV insulating glass unit | The overall energy-saving potentials were 28.4% and 30% for the two PV systems |

| Zhang [61] | a-Si | Hong Kong | Compared the overall energy performance of an STPV window and energy-efficient window | An STPV window can save 18% and 16% of the electricity consumption per year |

| Bahaj [66] | a-Si | The Middle East | Evaluated the energy-saving potential of semitransparent BIPV systems | The system reduced the cooling load by 31% during a one-year operation |

| Radhi [67] | a-Si | United Arab Emirates | Investigated the energy performance of façade-integrated PV systems | Operational energy consumption was reduced by 1.1–2.2%. Energy payback time was able to be reduced by 10 years |

| Didone [68] | a-Si | Brazil | Investigated the daylighting and overall energy performance of different window systems | The PV window saves up to 43% of the energy use, providing the best overall energy performance among all the window systems |

| Miyazaki [44] | a-Si | Tokyo | Studied the key factors of a PV window’s performance | The optimal performance was obtained when the transmittance was 40% and the window-to-wall ratio was 50% |

| Ng [14] | c-Si, a-Si | Singapore | Studied the energy-saving potential of BIPV | An energy-saving potential of 16.7–41.3% was achieved with different BIPV technologies |

| Wong [37] | a-Si | Japan | Evaluated the overall performance of PV roofs | PV roofs produced net energy savings of 3.0–8.7% |

| Li [69] | a-Si | Hong Kong | Studied the influential parameters of PV systems | Thermal and optical performances of the PV systems contribute a major part to the overall energy performance |

| Chow [33] | a-Si | Hong Kong | Employed ESP-r to study the energy performance of different window systems | Proposed PV windows can reduce the annual cooling electricity consumption by 23% and 28% |

| Chow [32] | a-Si | Hong Kong | Investigated the energy-saving potential of ventilated PV glazing | Proposed PV windows were able to cut down the cooling load by 26% and 61% |

| Chow [70] | a-Si | Hong Kong | Studied the performances of different PV windows | Ventilated PV window with a transmittance of 0.45–0.55 saves the annual energy use by up to 55% |

| Olivieri [71] | a-Si | Madrid, Spain | Evaluated the performance of five semitransparent PV elements | Semitransparent solutions with a window-to-wall ratio larger than 33% saves the energy requirement by 18–59% |

| Liao [72] | a-Si | Wuhan, China | Compared the performances of PV glazing with three traditional glazings | See-through a-Si PV glazing showed a better energy performance than single and double glazing |

| Authors | Module Type | Region | Objectives | Outcomes |

|---|---|---|---|---|

| Lamnatou [75] | m-Si | Barcelona, Exeter, Dublin | Investigated the life-cycle property of a BICPV | The PBTs of the BICPV of different cities ranged between 3.6 to 7.8 years |

| Menoufi [76] | m-Si | Lleida, Spain | LCA study of a BICPV scheme at the University of Lleida | The environmental impact of a PV system is about 2.35 times the impact of the BICPV scheme |

| Ng [77] | -- | Singapore | Examined the environmental performance of semi-transparent BIPV modules | The EPBT and EROEI for the modules ranged from 0.68 to 1.98 and 11.72 to 34.49 |

| Li [78] | c-Si | 5 cities in China | Performed an LCA study for a novel aCPC-PV in China | The EPBTs of the aCPC-PV module are 2.82–4.74 years in the five cities in China |

| Bizzarri [79] | c-Si, thin-film | Ferrara, Italy | Investigated the energetic and environmental impact of a BIPV roof | The roof-integrated PV systems can bring both energy and environmental benefits |

| Lu [80] | m-Si | Hong Kong | Investigated the EPBT and GPBT of a rooftop BIPV system | The EPBT is 7.3 years and the GPBT is 5.2 years |

| Perez [81] | m-Si | New York | LCA for façade-integrated BIPV systems | The façade-integrated BIPV system has an EPBT of 3.8 years |

| Belussi [82] | a-Si | Bologna, Italy | Quantified the environmental impact of a ceramic BIPV module | The impact of the module takes on values comparable to conventional PV systems |

| Baumann [83] | m-Si | Toledo, Newcastle | Compared the impacts of a ground-based system and a BIPV system | The CO2 emissions were 88 t/GWh and 143 t/GWh, respectively |

| Hammond [84] | -- | Bath, UK | Studied the performance of a domestic BIPV system | The impacts from the production were offset by the electricity generation |

| Wu [85] | -- | Taiwan | Investigated the economic benefits of BIPV facilities | The BIPV façade reaches its breakeven point within 10 years of the payback period and 16 years |

| Jayathissa [86] | CIGS | ETH Honggerberg | Accessed the environmental impact of a dynamic and adaptive BIPV system | The environmental impact of the dynamic BIPV system is 50% higher than a static system |

| Agrawal [87] | m-Si, a-Si | New Delhi | Determined the energy, exergy, and life-cycle cost of a BIPV system | Energy and exergy efficiencies are found to be 33.54% and 7.13% |

| Tripathy [88] | m-Si | Cities in India | Performed the LCCA and EPBT of BIPV systems in India | The EPBT of the system was found to range between 7.30 years and 16.9 years |

| Investigator | Module Type | EPBT (year) | GHGE Rate (g CO2-eq./kWh) |

|---|---|---|---|

| Wilson and Young [96] | mono-Si | 7.4–12.1 | - |

| Peng et al. [89] | mono-Si | 1.7–2.7 | 29.0–45.0 |

| Kato and Murata [97] | mono-Si | 8.9 | 61 |

| Alsema and Wild-Scholten [98] | mono-Si | 2.6 | 41 |

| Alsema and Wild-Scholten [99] | mono-Si | 2.1 | 35 |

| Jungbluth and Dones [100] | mono-Si | 3.3 | - |

| Hammond et al. [90] | mono-Si | 4.5 | - |

| Wild-Scholten [101] | mono-Si | 1.75 | 30 |

| Ito and Komoto [102] | mono-Si | 2.5 | 50 |

| Lu and Yang [80] | mono-Si | 7.3 | - |

| Ito et al. [91] | mono-Si | 2.0–2.5 | 43.0–55.0 |

| Seng et al. [103] | mono-Si | 3.2–4.4 | - |

| Phylipsen and Alsema [104] | multi-Si | 2.7 | - |

| Kato and Murata [97] | multi-Si | 2.4 | 20 |

| Alsema [105] | multi-Si | 3.2 | 60 |

| Ito and Kato [106] | multi-Si | 1.7 | 12 |

| Battisti and Corrado [94] | multi-Si | 3.3 | - |

| Alsema and Wild- Scholten [99] | multi-Si | 1.9 | 32 |

| Pacca and Sivaraman [93] | multi-Si | 2.1 | 54.6 |

| Jungbluth and Dones [100] | multi-Si | 2.9 | - |

| Raugei and Bargigli [92] | multi-Si | 2.4 | 72 |

| Wild-Scholten [101] | multi-Si | 1.75 | 29 |

| Ito and Komoto [102] | multi-Si | 2.0 | 43 |

| Seng et al. [103] | multi-Si | 2.2–3.0 | - |

| Pacca et al. [93] | multi-Si | 7.5 | 72.4 |

| Jungbluth [107] | multi-Si | 3.0–6.0 | 39.0–110.0 |

| Lewis and Keoleian [108] | a-Si | 3.0 | - |

| Alsema [109] | a-Si | 3.2 | - |

| Alsema [105] | a-Si | 2.7 | 50 |

| Jungbluth and Dones [100] | a-Si | 3.1 | - |

| Pacca and Sivaraman [93] | a-Si | 3.2 | 34.3. |

| Ito and Kato [91] | a-Si | 2.5 | 15.6 |

| Wild-Scholten [100] | a-Si | 1.4 | 24 |

| Alsema [109] | CdTe | 3.2 | - |

| Kato [110] | CdTe | 1.7 | 14 |

| Fthenakis and Kim [111] | CdTe | 1.2 | 23.6 |

| Held and Ilg [95] | CdTe | 0.7–1.1 | 19.0–30.0 |

| Alsema and Wild-Scholten [99] | CdTe | 1.1 | 25 |

| Jungbluth and Dones [100] | CdTe | 2.5 | - |

| Raugei and Bargigli [92] | CdTe | 1.5 | 48 |

| Wild-Scholten [101] | CdTe | 0.84 | 16 |

| Fthenakis [112] | CdTe | 0.79 | 18 |

| Ito and Komoto [102] | CdTe | 2.1 | 50 |

| Alsema [105] | CdTe | 1.7 | 14.0 |

| Held [95] | CdTe | 0.7–1.1 | 19–30 |

| Jungbluth and Dones [100] | CIS | 2.9 | - |

| Raugei and Bargigli [92] | CIS | 2.8 | 95 |

| Ito and Kato [91] | CIS | 1.6 | 10.5 |

| Ito et al. [106] | CIS | 1.8 | 45.0 |

| Wild-Scholten [101] | CIS | 1.45 | 21 |

| Ito and Komoto [102] | CIS | 1.8 | 46 |

| Peng et al. [89] | Thin film | 0.75–3.5 | 10.5–50.0 |

| Seng et al. [103] | Thin film | 1.9–2.6 | - |

| Pacca et al. [93] | Thin film | 3.2 | 34.3 |

| Keoleian and Lewis [113] | Thin film | 3.39–5.52 | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Wang, M.; Yang, H. A Review of the Energy Performance and Life-Cycle Assessment of Building-Integrated Photovoltaic (BIPV) Systems. Energies 2018, 11, 3157. https://doi.org/10.3390/en11113157

Zhang T, Wang M, Yang H. A Review of the Energy Performance and Life-Cycle Assessment of Building-Integrated Photovoltaic (BIPV) Systems. Energies. 2018; 11(11):3157. https://doi.org/10.3390/en11113157

Chicago/Turabian StyleZhang, Tiantian, Meng Wang, and Hongxing Yang. 2018. "A Review of the Energy Performance and Life-Cycle Assessment of Building-Integrated Photovoltaic (BIPV) Systems" Energies 11, no. 11: 3157. https://doi.org/10.3390/en11113157