An Investigation on Flame Shape and Size for a High-Pressure Turbulent Non-Premixed Swirl Combustion

Abstract

:1. Introduction

2. Experimental Setup

2.1. Experimental Apparatus

- (1)

- The supply section, where fuel (methane) is supplied with a gasholder. The fuel is controlled and measured with a mass flow controller VF-100-SONARtrac, with a maximum fuel mass flow rate of 36 g/min. Air is provided by an air compressor, which has a maximum total air mass flow rate of 2.5 kg/min. The air mass flow rate is regulated using an electric control valve EV-25PCUN40RPF and measured with an air flow meter LUGB-2405-P4.

- (2)

- The combustion chamber, which is an axisymmetric cylindrical chamber, has a diameter of 0.3 m and height of 1.35 m, as displayed in Figure 3. This combustion chamber is primarily composed of four components: swirl injector, wind distributing plate, annular cooling slot close to the inner wall, and combustor. The swirl injector is employed for improving mixing quality, as shown in Figure 4. A portion of air flows tangentially through a radical swirler to carry fuel supplied by a central fuel nozzle into the combustor where combustion occurs. This portion of air is called primary air. The methane and primary air mix with each other partially in the injector sector; this mixing degree is not complete as the distance where mixing can occur is relatively short. The rest of the air flows through small holes in the air distributing plate and annular slot close to the inner wall. This air cools the metal material, thus, avoiding heat damage and then blends with the combustion gas. There is an optically accessible window mounted on the combustor wall, which is employed to record the flame zone.

- (3)

- The exhaust section consists of two components: a pressure regulating valve and an induced draught system. The pressure regulating valve controls the combustor operating pressure. The induced draught system is applied to induce exhaust gas to the atmospheric environment.

2.2. Measurement Methods

2.3. Experimental Conditions

3. CFD Simulation Setup

4. Results and Discussion

4.1. Theoretical Results of Flame Length

4.2. Effects of Fuel Mass Flow Rate

4.3. Effects of Combustor Pressure

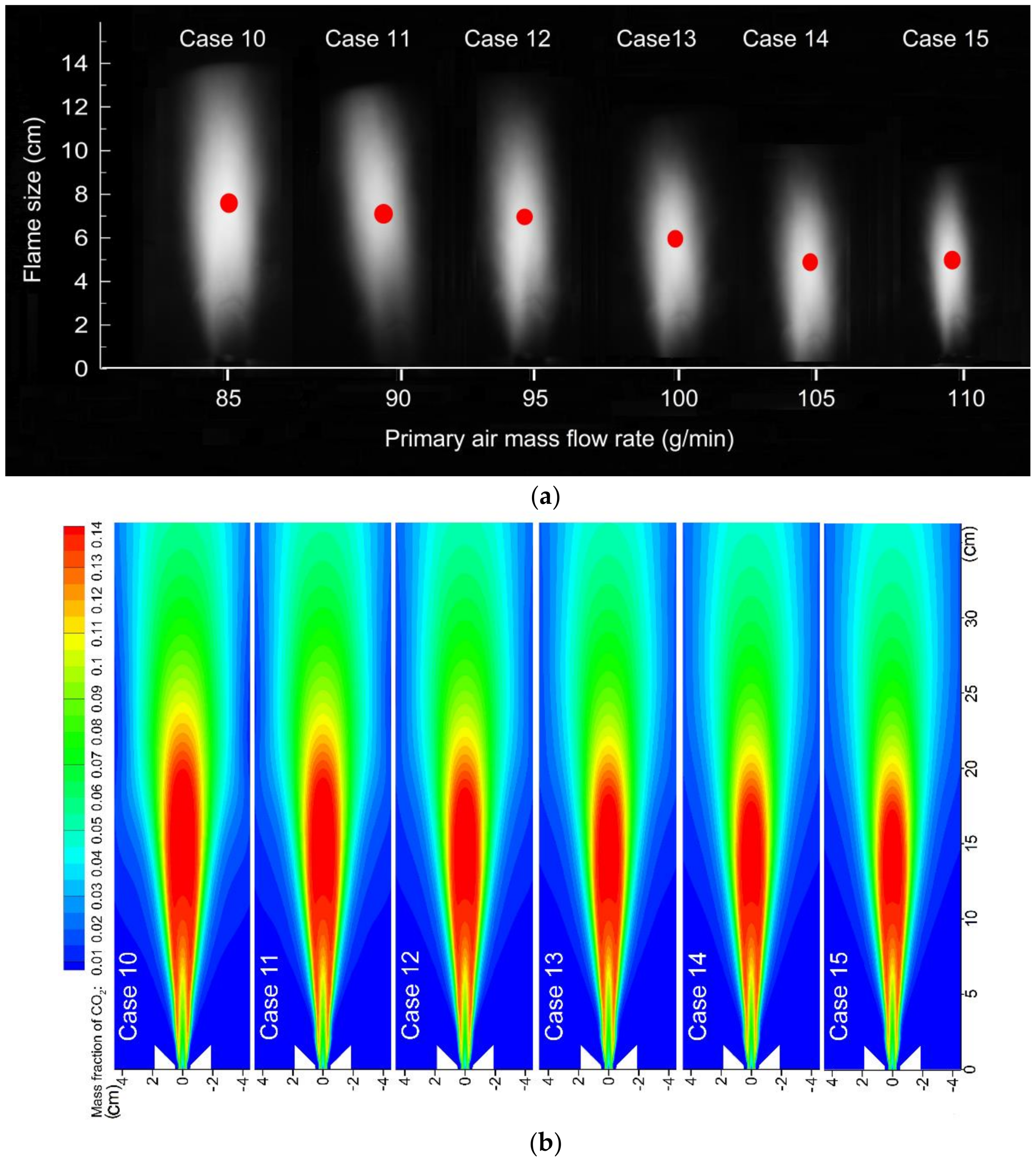

4.4. Effects of Primary Air Mass Flow Rate

4.5. Effects of Nozzle Exit Velocity

4.6. Flame Size for Primary Air to Fuel Ratio

5. Conclusions

- (1)

- As fuel mass flow rate ṁF increased, the flame shape became longer and wider, flame length increased and had a linear relation with ṁF. This is attributed to the enhancement in the axial diffusion of fuel and the increase in requirement of ambient air entrainment for diluting the fuel to stoichiometric proportions.

- (2)

- As combustor pressure P increased, the flame shape shortened and widened; flame length decreased and had a power relation with P. This probably resulted from declined axial diffusion and enhanced radial diffusion of the fuel at higher P.

- (3)

- As primary air mass flow rate ṁpri increased, the flame shape became shorter and narrower. The phenomenon is mainly caused by reduced air entrainment required to achieve stoichiometric proportions.

- (4)

- As the nozzle exit velocity ve increased, flame length and width remained unchanged basically. This is mainly due to the concurrently increasing ṁF and ṁpri, with ṁpri/ṁF nearly being constant, the two effects are opposite and seem to cancel each other out.

- (5)

- In order to consider the effects of different operating conditions at the same combustor pressure collectively, the influences of ṁF, ṁpri and ve were plotted together versus ṁpri/ṁF. As ṁpri/ṁF increased, flame length and width generally diminished, which is attributed to the reduction of air entrainment.

- (6)

- CFD provided decent prediction of the varying trends of flame shape and size, although some deviations were observed, which indicates that the present simulation is a reliable prediction tool for calculating the approximate flame shape and size.

- (7)

- The theoretical flame length also showed correct estimation of the varying trends. The difference between theoretical and experimental flame length is due to the influence of swirl; to consider swirl effects, a swirl factor is proposed to be added to the original equation.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Turns, S.R. Laminar diffusion flames. In An Introduction to Combustion: Concepts and Applications; McGraw-Hill: New York, NY, USA, 2000; p. 315. ISBN 0677026900. [Google Scholar]

- Sunderland, P.B.; Mendelson, B.J.; Yuan, Z.G.; Urban, D.L. Shapes of buoyant and nonbuoyant laminar jet diffusion flames. Combust. Flame 1999, 116, 376–386. [Google Scholar] [CrossRef]

- Lin, K.C.; Faeth, G.M.; Sunderland, P.B.; Urban, D.L.; Yuan, Z.G. Shapes of nonbuoyant round luminous hydrocarbon/air laminar jet diffusion flames. Combust. Flame 1999, 116, 415–431. [Google Scholar] [CrossRef]

- Joo, S.; Yoon, J.; Kim, J.; Lee, M.; Yoon, Y. NOx emissions characteristics of the partially premixed combustion of H2/CO/CH4 syngas using artificial neural networks. Appl. Therm. Eng. 2015, 80, 436–444. [Google Scholar] [CrossRef]

- Yoon, J.; Kim, M.K.; Hwang, J.; Lee, J.; Yoon, Y. Effect of fuel-air mixture velocity on combustion instability of a model gas turbine combustor. Appl. Therm. Eng. 2013, 54, 92–101. [Google Scholar] [CrossRef]

- Figura, L.; Lee, J.G.; Quay, B.D.; Santavicca, D.A. The Effects of Fuel Composition on Flame Structure and Combustion Dynamics in a Lean Premixed Combustor. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; pp. 181–187. [Google Scholar] [CrossRef]

- Hottel, H.C. Burning in laminar and turbulent fuel jets. Symp. Combust. 1953, 4, 97–113. [Google Scholar] [CrossRef]

- Hawthorne, W.R.; Weddell, D.S.; Hottel, H.C. Mixing and combustion in turbulent gas jets. In Symposium on Combustion and Flame and Explosion Phenomena; Elsevier: New York, NY, USA, 1949; Volume 3, pp. 266–288. [Google Scholar]

- Wohl, K.; Gazley, C.; Kapp, N. Diffusion flames. In Symposium on Combustion and Flame and Explosion Phenomena; Elsevier: New York, NY, USA, 1949; Volume 3, pp. 288–300. [Google Scholar]

- Becker, H.A.; Liang, D. Visible length of vertical free turbulent diffusion flames. Combust. Flame 1978, 32, 115–137. [Google Scholar] [CrossRef]

- Delichatsios, M.A. Transition from momentum to buoyancy-controlled turbulent jet diffusion flames and flame height relationships. Combust. Flame 1993, 92, 349–364. [Google Scholar] [CrossRef]

- Blake, T.R.; McDonald, M. An examination of flame length data from vertical turbulent diffusion flames. Combust. Flame 1993, 94, 426–432. [Google Scholar] [CrossRef]

- Chen, R.H.; Driscoll, J.F. The role of the recirculation vortex in improving fuel-air mixing within swirling flames. Symp. Combust. 1989, 22, 531–540. [Google Scholar] [CrossRef]

- Peters, N.; Göttgens, J. Scaling of buoyant turbulent jet diffusion flames. Combust. Flame 1991, 85, 206–214. [Google Scholar] [CrossRef]

- Røkke, N.A.; Hustad, J.E.; Sønju, O.K. A study of partially premixed unconfined propane flames. Combust. Flame 1994, 97, 88–106. [Google Scholar] [CrossRef]

- Mei, Z.; Mi, J.; Wang, F.; Zheng, C. Dimensions of CH4-Jet Flame in Hot O2/CO2 Coflow. Energy Fuel. 2012, 26, 3257–3266. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Sciolti, A.; Campilongo, S.; Ficarella, A. Flame structure and chemiluminescence emissions of inverse diffusion flames under sinusoidally driven plasma discharges. Energies 2017, 10, 334. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, F.; Liu, H.; Zhou, Z.; Palacios, A. Experimental investigation on the effect of reduced pressure on the combustion characteristics and flame height of gaseous fuel jets in parallel sidewalls. Energy Fuel. 2017. [Google Scholar] [CrossRef]

- Bahadori, M.Y.; Stocker, D.P.; Vaughan, D.F.; Zhou, L.; Edelman, R.B. Effects of Buoyancy on Laminar, Transitional, and Turbulent Gas Jet Diffusion Flames. In Modern Developments in Energy Combustion & Spectroscopy; Pergamon Press: New York, NY, USA, 1993; pp. 49–66. [Google Scholar]

- Choudhuri, A.R.; Gollahalli, S.R. Characteristics of hydrogen-hydrocarbon composite fuel turbulent jet flames. Int. J. Hydrogen Energy 2003, 28, 445–454. [Google Scholar] [CrossRef]

- Yang, W.; Blasiak, W. Chemical flame length and volume in liquified propane gas combustion using high-temperature and low-oxygen-concentration oxidizer. Energy Fuel. 2004, 18, 1329–1335. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, Y.; Lee, S.M.; Ahn, K.Y. Studies on combustion characteristics and flame length of turbulent oxy-fuel flames. Energy Fuel. 2007, 21, 1459–1467. [Google Scholar] [CrossRef]

- Hu, L.; Wang, Q.; Delichatsios, M.; Tang, F.; Zhang, X.; Lu, S. Flame height and lift-off of turbulent buoyant jet diffusion flames in a reduced pressure atmosphere. Fuel 2013, 109, 234–240. [Google Scholar] [CrossRef]

- Samaniego, J.-M.; Egolfopoulos, F.N.; Bowman, C.T. CO2* Chemiluminescence in Premixed Flames. Combust. Sci. Technol. 1995, 109, 183–203. [Google Scholar] [CrossRef]

- Lee, J.G.; Santavicca, D.A. Experimental Diagnostics for the Study of Combustion Instabilities in Lean Premixed Combustors. J. Propuls. Power 2003, 19, 735–750. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.; Santavicca, D. A Study of the Role of Equivalence Ratio Fluctuations During Unstable Combustion in a Lean Premixed Combustor. In Proceedings of the 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Indianapolis, IN, USA, 7–10 July 2002. [Google Scholar]

- Fluent Inc. FLUENT 6.3 Theory Guide; Fluent Inc.: Lebanon, NH, USA, 2006. [Google Scholar]

- Magnussen, B.F.; Hjertager, B.H. On mathematical modeling of turbulent combustion with special emphasis on soot formation and combustion. Symp. Combust. 1977, 16, 719–729. [Google Scholar] [CrossRef]

- Most, J.M.; Mandin, P.; Chen, J.; Joulain, P.; Durox, D.; Carlos Fernande-Pello, A. Influence of gravity and pressure on pool fire-type diffusion flames. Symp. Combust. 1996, 26, 1311–1317. [Google Scholar] [CrossRef]

- Turns, S.R.; Myhr, F.H.; Bandaru, R.V.; Maund, E.R. Oxides of nitrogen emissions from turbulent jet flames: Part II-Fuel dilution and partial premixing effects. Combust. Flame 1993, 93, 255–269. [Google Scholar] [CrossRef]

| Case | Combustor Pressure, P (bar) | Fuel Mass Flow Rate, ṁF (g/min) | Air Mass Flow Rate, ṁA (kg/min) | Primary Air, ṁpri (g/min) | ṁpri/ṁF | Nozzle Exit Velocity, ve (m/s) | |

|---|---|---|---|---|---|---|---|

| I | 1 | 4 | 8 | 1.7 | 85 | 10.6 | 3.73 |

| 2 | 4 | 10 | 1.7 | 85 | 8.5 | 3.73 | |

| 3 | 4 | 12 | 1.7 | 85 | 7.1 | 3.73 | |

| 4 | 5 | 8 | 1.7 | 85 | 10.6 | 2.98 | |

| 5 | 5 | 10 | 1.7 | 85 | 8.5 | 2.98 | |

| 6 | 5 | 12 | 1.7 | 85 | 7.1 | 2.98 | |

| 7 | 6 | 8 | 1.7 | 85 | 10.6 | 2.49 | |

| 8 | 6 | 10 | 1.7 | 85 | 8.5 | 2.49 | |

| 9 | 6 | 12 | 1.7 | 85 | 7.1 | 2.49 | |

| II | 10 | 5 | 16 | 1.7 | 85 | 5.3 | 2.98 |

| 11 | 5 | 16 | 1.8 | 90 | 5.6 | 3.16 | |

| 12 | 5 | 16 | 1.9 | 95 | 5.9 | 3.33 | |

| 13 | 5 | 16 | 2.0 | 100 | 6.3 | 3.51 | |

| 14 | 5 | 16 | 2.1 | 105 | 6.6 | 3.69 | |

| 15 | 5 | 16 | 2.2 | 110 | 6.9 | 3.86 | |

| III | 16 | 5 | 8 | 1.3 | 65 | 8.1 | 2.28 |

| 17 | 5 | 10 | 1.6 | 80 | 8.0 | 2.81 | |

| 18 | 5 | 12 | 1.9 | 95 | 7.9 | 3.33 | |

| 19 | 5 | 14 | 2.2 | 110 | 7.9 | 3.86 | |

| 20 | 5 | 16 | 2.5 | 125 | 7.8 | 4.39 | |

| Case | P (bar) | ṁF (g/min) | ṁA (kg/min) | ṁpri (g/min) | ṁpri/ṁF | ve (m/s) | ρA (kg/m3) | fs | Frf | Lf (cm) |

| 1 | 4 | 8 | 1.7 | 85 | 10.6 | 3.73 | 4.84 | 0.639 | 2.303 | 18.4 |

| 2 | 4 | 10 | 1.7 | 85 | 8.5 | 3.73 | 4.84 | 0.522 | 1.702 | 24.3 |

| 3 | 4 | 12 | 1.7 | 85 | 7.1 | 3.73 | 4.84 | 0.444 | 1.336 | 28.6 |

| 4 | 5 | 8 | 1.7 | 85 | 10.6 | 2.98 | 6.05 | 0.639 | 1.843 | 19.6 |

| 5 | 5 | 10 | 1.7 | 85 | 8.5 | 2.98 | 6.05 | 0.522 | 1.361 | 24.4 |

| 6 | 5 | 12 | 1.7 | 85 | 7.1 | 2.98 | 6.05 | 0.444 | 1.068 | 27.8 |

| 7 | 6 | 8 | 1.7 | 85 | 10.6 | 2.49 | 7.26 | 0.639 | 1.536 | 20.0 |

| 8 | 6 | 10 | 1.7 | 85 | 8.5 | 2.49 | 7.26 | 0.522 | 1.134 | 23.9 |

| 9 | 6 | 12 | 1.7 | 85 | 7.1 | 2.49 | 7.26 | 0.444 | 0.890 | 26.8 |

| 10 | 5 | 16 | 1.7 | 85 | 5.3 | 2.98 | 6.05 | 0.347 | 0.737 | 32.6 |

| 11 | 5 | 16 | 1.8 | 90 | 5.6 | 3.16 | 6.05 | 0.364 | 0.839 | 32.2 |

| 12 | 5 | 16 | 1.9 | 95 | 5.9 | 3.33 | 6.05 | 0.381 | 0.949 | 31.6 |

| 13 | 5 | 16 | 2 | 100 | 6.3 | 3.51 | 6.05 | 0.398 | 1.068 | 31.0 |

| 14 | 5 | 16 | 2.1 | 105 | 6.6 | 3.69 | 6.05 | 0.416 | 1.194 | 30.2 |

| 15 | 5 | 16 | 2.2 | 110 | 6.9 | 3.86 | 6.05 | 0.433 | 1.330 | 29.4 |

| 16 | 5 | 8 | 1.3 | 65 | 8.1 | 2.28 | 6.05 | 0.501 | 0.980 | 24.2 |

| 17 | 5 | 10 | 1.6 | 80 | 8.0 | 2.81 | 6.05 | 0.495 | 1.181 | 25.4 |

| 18 | 5 | 12 | 1.9 | 95 | 7.9 | 3.33 | 6.05 | 0.490 | 1.384 | 26.0 |

| 19 | 5 | 14 | 2.2 | 110 | 7.9 | 3.86 | 6.05 | 0.487 | 1.586 | 26.2 |

| 20 | 5 | 16 | 2.5 | 125 | 7.8 | 4.39 | 6.05 | 0.484 | 1.789 | 26.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, Z.; Fu, Z.; Hu, X.; Sabir, S.W.; Jiang, Y. An Investigation on Flame Shape and Size for a High-Pressure Turbulent Non-Premixed Swirl Combustion. Energies 2018, 11, 930. https://doi.org/10.3390/en11040930

Xi Z, Fu Z, Hu X, Sabir SW, Jiang Y. An Investigation on Flame Shape and Size for a High-Pressure Turbulent Non-Premixed Swirl Combustion. Energies. 2018; 11(4):930. https://doi.org/10.3390/en11040930

Chicago/Turabian StyleXi, Zhongya, Zhongguang Fu, Xiaotian Hu, Syed Waqas Sabir, and Yibo Jiang. 2018. "An Investigation on Flame Shape and Size for a High-Pressure Turbulent Non-Premixed Swirl Combustion" Energies 11, no. 4: 930. https://doi.org/10.3390/en11040930

APA StyleXi, Z., Fu, Z., Hu, X., Sabir, S. W., & Jiang, Y. (2018). An Investigation on Flame Shape and Size for a High-Pressure Turbulent Non-Premixed Swirl Combustion. Energies, 11(4), 930. https://doi.org/10.3390/en11040930