Comparison and Evaluation of the Potential Energy, Carbon Emissions, and Financial Impacts from the Incorporation of CHP and CCHP Systems in Existing UK Hotel Buildings

Abstract

:1. Introduction

2. Literature Review

3. Methodology

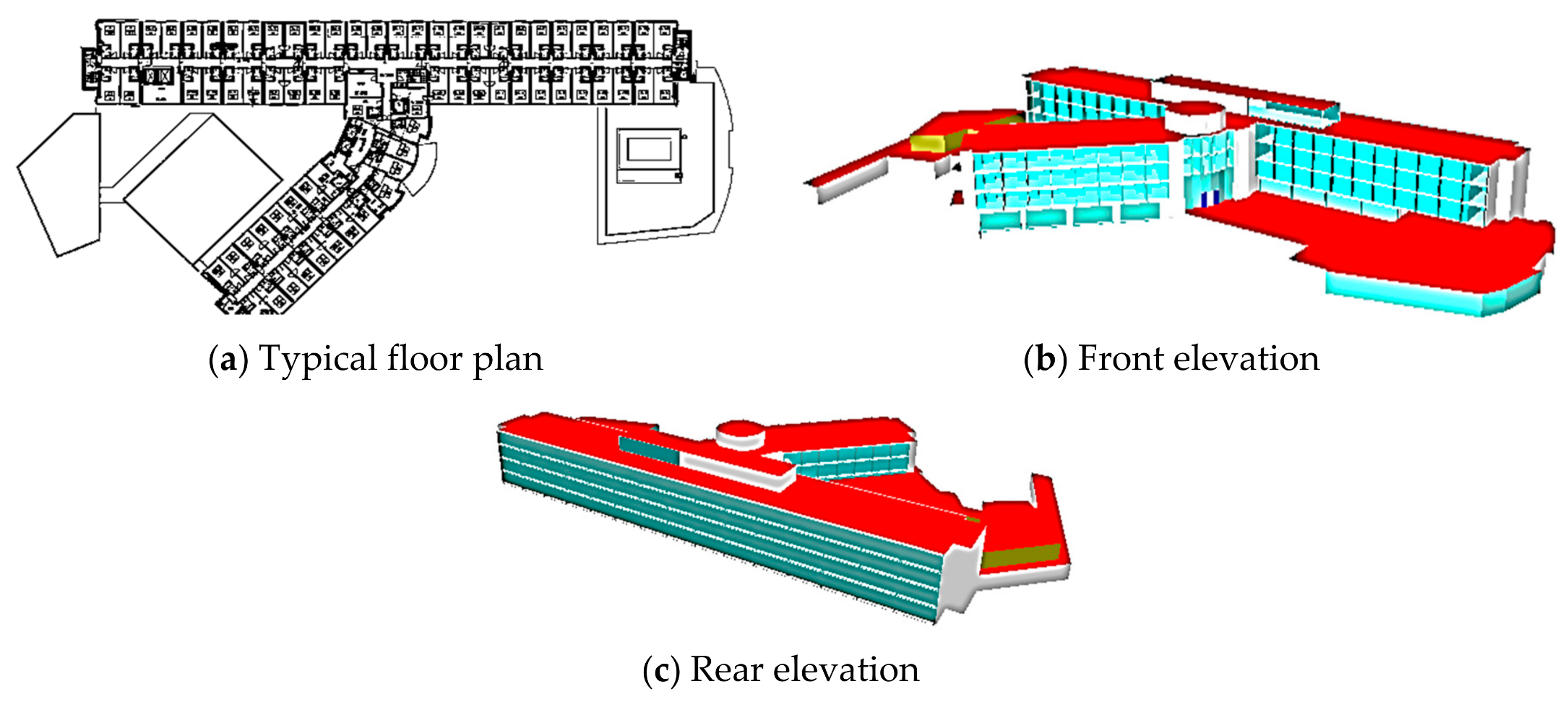

3.1. Building Description and Modelling

3.2. Modelling Assumptions

- It is assumed that the hotel is occupied 24 h, seven days a week. This is selected based on average occupancy patterns in the hotel.

- The National Calculation Method (NCM) database will be used to represent all zones, including circulation, reception, and toilets, as shown in Table 1. It will be assumed that these conditions are the actual current conditions of the hotel.

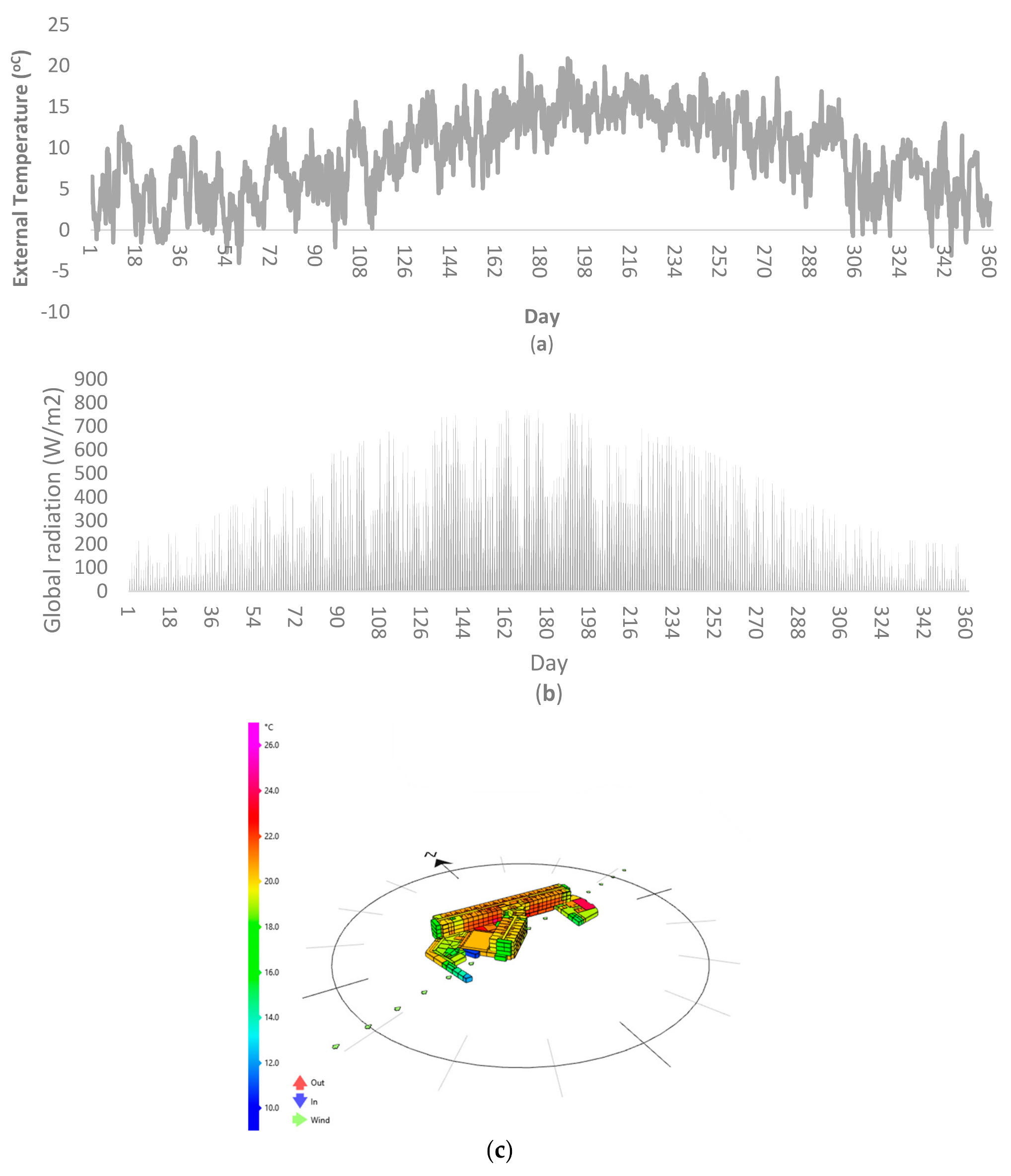

- Fully adopting the CIBSE TRY weather files without any alterations and assuming that they are valid and relevant to the microclimate of Reading.

- Figure 2 shows the external temperature and global solar radiation of the simulation weather data and the 3D visualisation of the resultant temperature on the building case study.

3.3. Financial Analysis

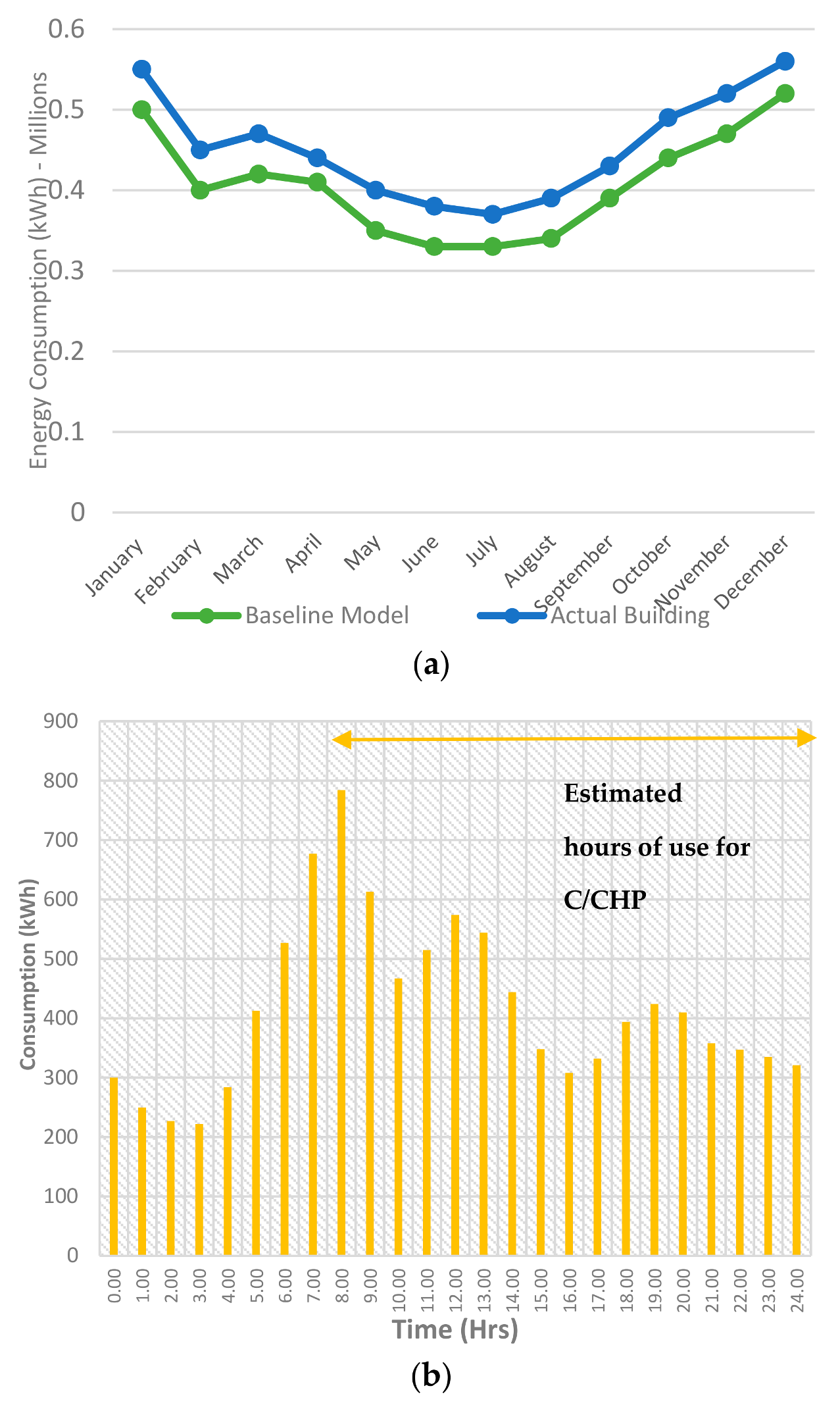

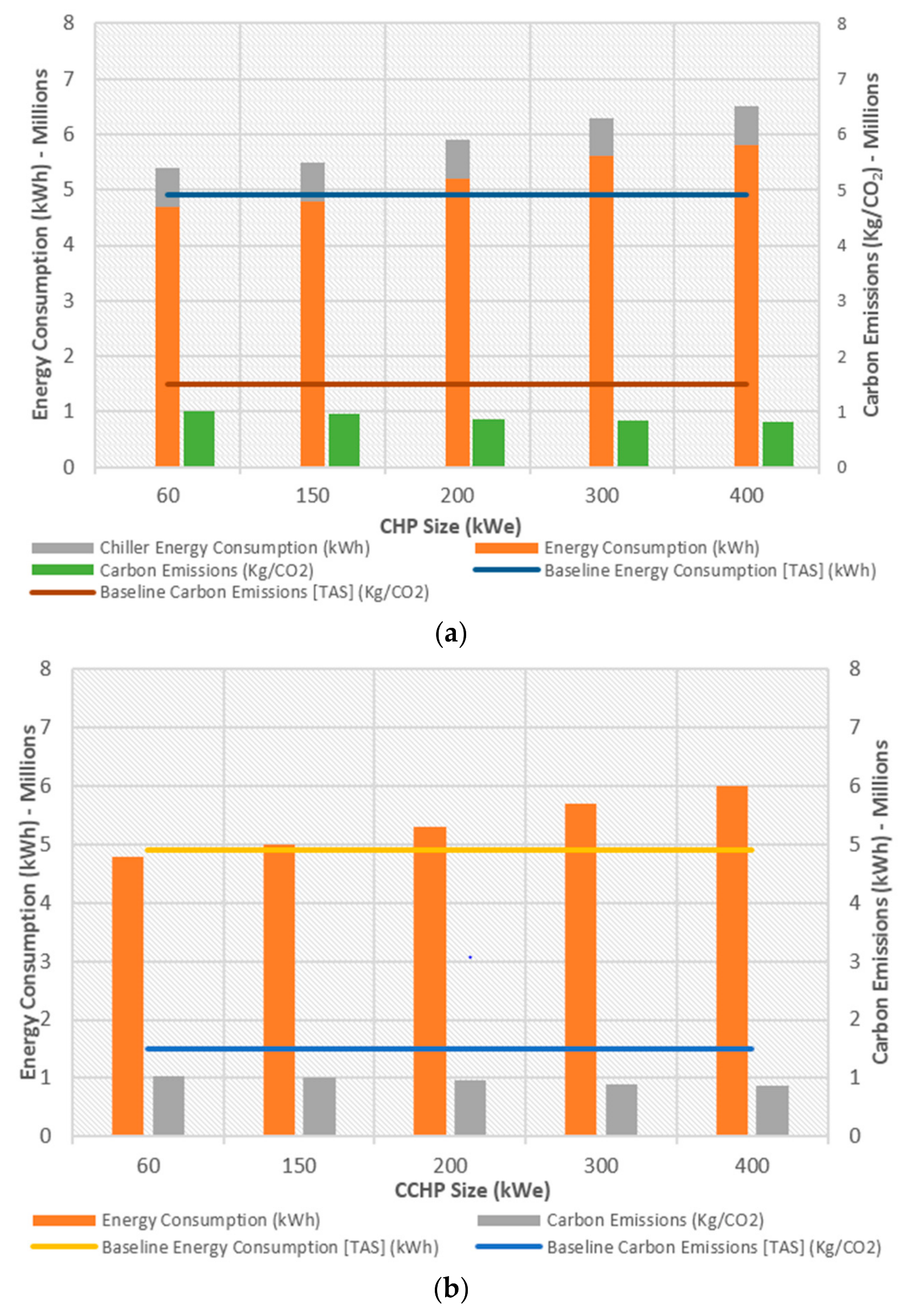

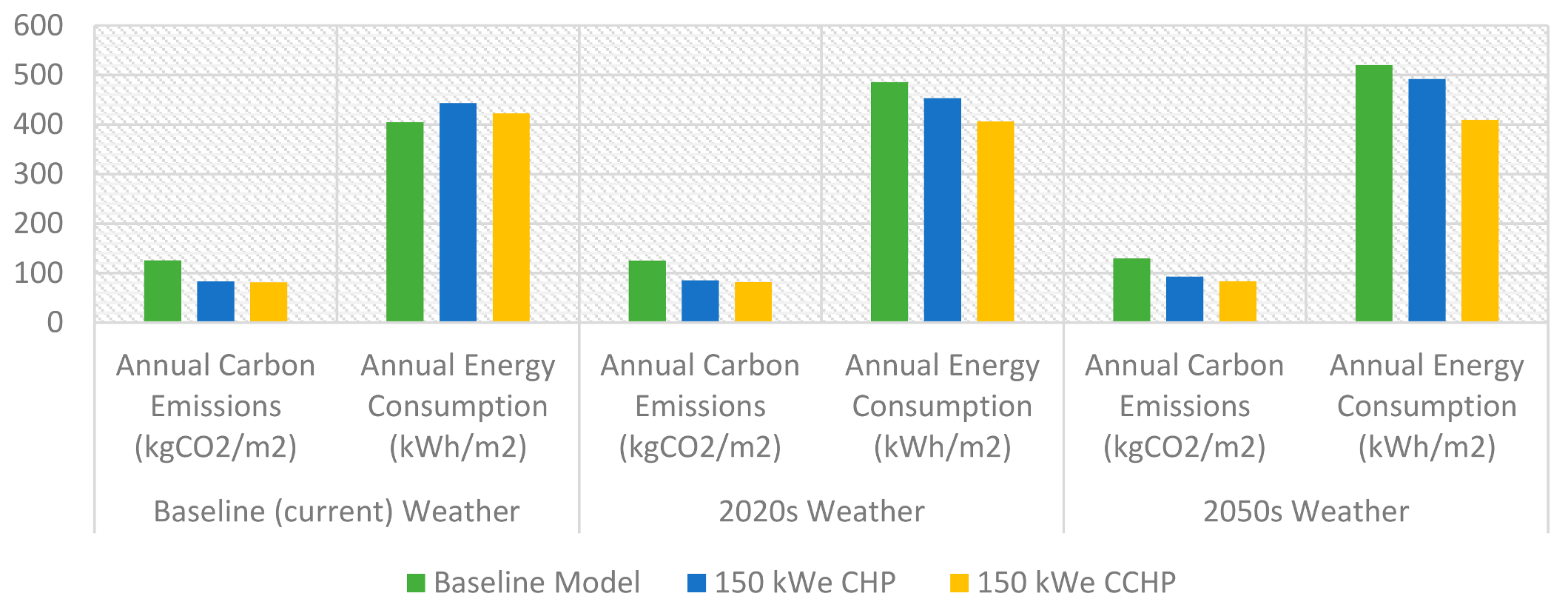

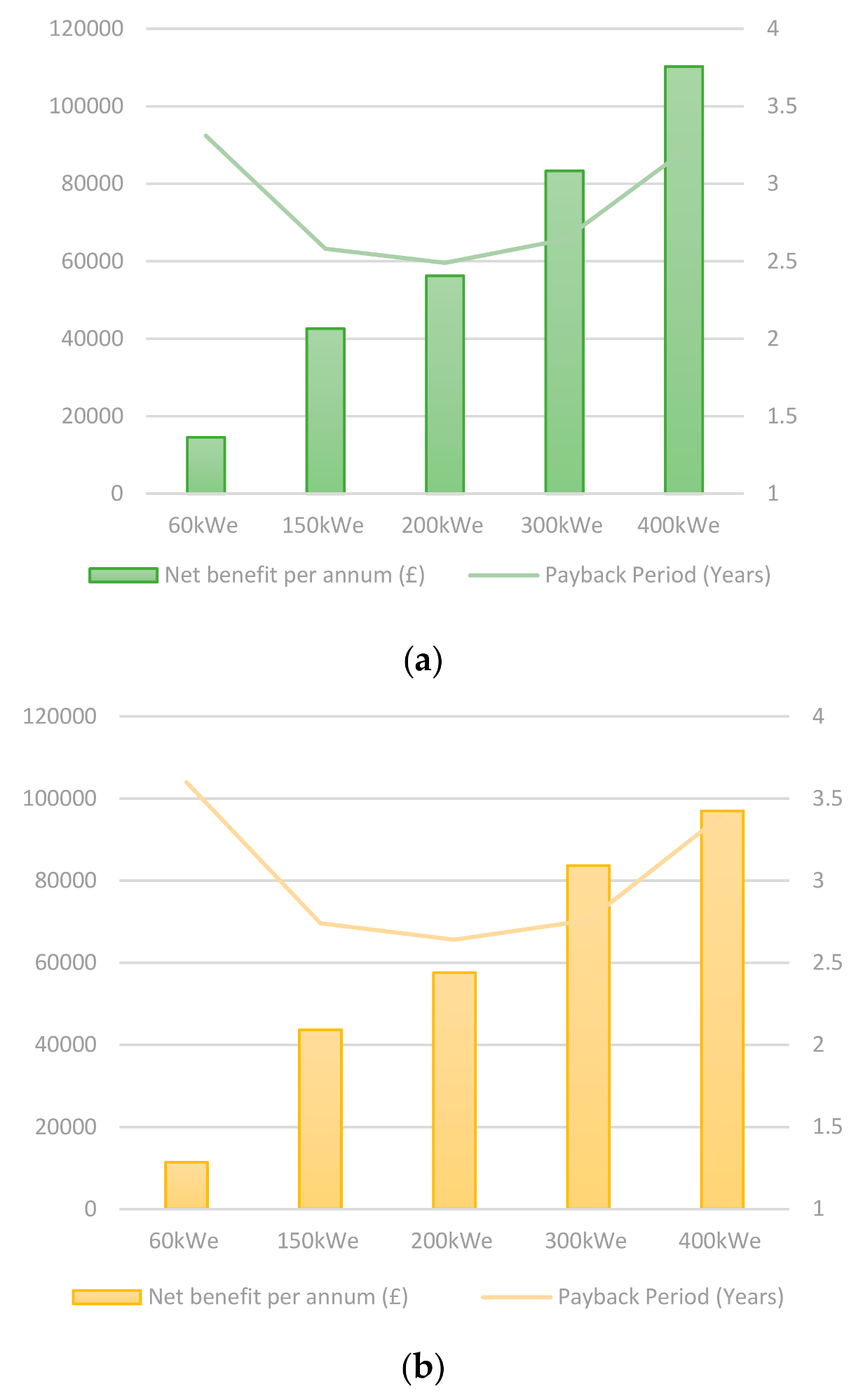

4. Results and Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- American Council for Energy Efficient Economy (ACEEE). Combined Heat and Power (CHP). Available online: https://aceee.org/topics/combined-heat-and-power-chp (accessed on 25 January 2018).

- DFIC. Cogeneration & Trigeneration—How to Produce Energy Efficiently. Available online: https://www.giz.de/expertise/downloads/giz2016-en-energy-cogeneration-trigeneration-guide.pdf (accessed on 28 January 2018).

- Jing, Y.; Bai, H.; Wang, J.; Liu, L. Life cycle assessment of a solar combined cooling heating and power system in different operation strategies. Appl. Energy 2012, 92, 843–853. [Google Scholar] [CrossRef]

- Medved, D. Trigeneration Units. Available online: http://home.zcu.cz/~tesarova/IP/Proceedings/Proc_2011/Files/Medved.pdf (accessed on 10 February 2018).

- Directive 2004/8/EC. Directive 2004/8/EC of the European Parliament and of the Council of 11 February 2004 on the Promotion of Cogeneration Based On a Useful Heat Demand in the Internal Energy Market and Amending Directive 92/42/EEC. Off. J. Eur. 2004, 52, 50–60. [Google Scholar]

- Department of Energy and Climate Change (DECC). Combined Heat and Power. Available online: https://www. gov.uk/guidance/combined-heat-and-power (accessed on 28 January 2018).

- DUKES. UK Energy in Brief 2017. Available online: https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/631146/UK_Energy_in_Brief_2017.pdf (accessed on 3 February 2018).

- Arcuri, P.; Florio, G.; Fragiacomo, P. A mixed integer programming model for optimal design of trigeneration in a hospital complex. Energy 2010, 32, 1430–1447. [Google Scholar] [CrossRef]

- Smith, A.D.; Mago, P.J.; Fumo, N. Benefits of thermal energy storage option combined with CHP system for different commercial building types. Sustain. Energy Technol. Assess. 2013, 35, 32–45. [Google Scholar] [CrossRef]

- Chartered Institute of Building Services Engineers (CIBSE). Absorption Cooling. Available online: https://www.cibse.org/getmedia/5c9a9e15-5103-4b70-8aa1-1b7456fdf9a5/Datasheet-7-Absorption-Cooling.pdf.aspx (accessed on 5 February 2018).

- Desideri, U.; Manfrida, G.; Sciubba, E. Cost optimisation, and simulation of CCHP units. In Proceedings of the 25th International Conference on Efficiency, Cost, Optimization and Simulation of Energy Conversion Systems and Processes, Perugia, Italy, 26–29 June 2012; pp. 131–140. [Google Scholar]

- D’Agostino, D. Assessment of the progress towards the establishment of definitions of Nearly Zero Energy Buildings (nZEBs) in European Member States. J. Build. Eng. 2015, 1, 20–32. [Google Scholar] [CrossRef]

- Barbolini, F.; Cappellacci, P.; Guadigli, L. A design strategy to reach nZEB standards integrating energy efficiency measures and passive energy use. In Proceedings of the 8th International Conference on Sustainability in Energy and Buildings, Turin, Italy, 11–13 September 2016; pp. 205–214. [Google Scholar]

- Carbon Trust. Energy Efficiency in Non-Domestic Buildings. Available online: www.carbontrust/new/2016/08/energy-efficiency-in-non-domestic-buildings/ (accessed on 22 February 2018).

- Paepe, M.; D’Herdt, P.; Mertens, D. Micro-CHP systems for residential applications. Energy Convers. Manag. 2006, 47, 3435–3446. [Google Scholar] [CrossRef]

- Rosato, A.; Sibilio, S. Calibration and validation of a model for simulating thermal and electric performance of an internal combustion engine-based micro-cogeneration device. Appl. Therm. Energy 2012, 45, 79–98. [Google Scholar] [CrossRef]

- Cardona, E.; Piacentino, A.; Cardona, F. Matching Economical, Energetic and Environmental Benefits: An Analysis for Hybrid CHCP-Heat Pump Systems. Energy Convers. Manag. 2006, 47, 3530–3542. [Google Scholar] [CrossRef]

- Mago, P.J.; Smith, A.D. Evaluation of the potential emissions reductions from the use of CHP systems in different commercial buildings. Build. Environ. 2012, 53, 74–82. [Google Scholar] [CrossRef]

- Maria, U.; Jose, I.L.; Eva, A. Feasibility assessment of an Organic Rankine Cycle (ORC) cogeneration plant (CHP/CCHP) fuelled by biomass for a district network in mainland Spain. Energy 2017, 133, 969–985. [Google Scholar]

- Mago, P.J.; Fumo, N.; Chamra, L.M. Performance analysis of CCHP and CHP systems operating following the thermal and electric load. Int. J. Energy Res. 2009, 33, 852–864. [Google Scholar] [CrossRef]

- Wang, H.; Yin, W.; Abdollahi, E.; Lahdelma, R.; Jiao, W. Modelling and optimization of CHP based district heating system with renewable energy production and energy storage. Appl. Energy 2015, 159, 401–421. [Google Scholar] [CrossRef]

- Magnani, S.; Pezzola, L.; Danti, P. Design Optimization of a Heat Thermal Storage Coupled with a Micro-CHP for a Residential Case Study. Energy Procedia 2016, 101, 830–837. [Google Scholar] [CrossRef]

- Santini, E.; Romito, D.Z. Sizing and economic analysis of a trigeneration and CHP system in a commercial site. In Proceedings of the IEEE International Energy Conference, Dubrovnik, Croatia, 13–16 May 2014; pp. 1156–1161. [Google Scholar]

- Pedram, H.; Eshraghi, J.; Ahmadi, P.; Sattari, A. Evaluation and sizing of a CCHP system for a commercial and office buildings. J. Build. Eng. 2016, 5, 67–78. [Google Scholar]

- Gu, Q.; Ren, H.; Gao, W.; Ren, J. Integrated assessment of combined cooling heating and power systems under different design and management options for residential buildings in Shanghai. Energy Build. 2012, 51, 143–152. [Google Scholar] [CrossRef]

- Kazempoor, P.; Dorer, V.; Weber, A. Modelling and evaluation of building integrated SOFC systems. Int. J. Hydrog. Energy 2011, 36, 13241–13249. [Google Scholar] [CrossRef]

- Harrod, J.; Mago, P.J.; Luck, R. Sizing analysis of a combined cooling, heating, and power system for a small office building using a wood waste biomass-fired Stirling engine. Int. J. Energy Res. 2012, 36, 64–74. [Google Scholar] [CrossRef]

- Cuviella-Suárez, C.; Colmenar-Santos, A.; Castro-Gil, M. Tri-generation system to couple production to demand in a combined cycle. Energy 2012, 40, 271–290. [Google Scholar] [CrossRef]

- Wei, L.; Tian, W.; Zuo, J.; Yang, Z.; Liu, Y.; Yang, S. Effects of Building Form on Energy Use for Buildings in Cold Climate Regions. Procedia Eng. 2016, 146, 182–189. [Google Scholar] [CrossRef]

- Zhang, A.; Bokel, R.; van den Dobbelsteen, A.; Sun, Y.; Huang, Q.; Zhang, Q. The Effect of Geometry Parameters on Energy and Thermal Performance of School Buildings in Cold Climates of China. Sustainability 2017, 9, 1708. [Google Scholar] [CrossRef]

- EDSL (Environmental Design Solutions Limited). Available online: http://www.edsl.net/ (accessed on 10 February 2018).

- Amoako-Attah, J.; B-Jahromi, A. Impact of standard construction specification on thermal comfort in UK dwellings. Adv. Environ. Res. 2014, 3, 253–281. [Google Scholar] [CrossRef]

- Eames, M.E.; Ramallo-Gonzalez, A.P.; Wood, M.J. An update of the UK’s test reference year: The implications of a revised climate on building design. Build. Serv. Eng. Res. Technol. 2016, 37, 316–333. [Google Scholar] [CrossRef] [Green Version]

- Hacker, J.; Capon, R.; Mylona, A. TM48: Use of Climate Change Scenarios for Building Simulation: The CIBSE Future Weather Years; Cibse: London, UK, 2009; ISBN 978-19-068-46015. [Google Scholar]

- Marsland, C. The Role of Small Scale CHP in Energy-Efficient Buildings. Available online: http://www.modbs.co.uk/news/archivestory.php/aid/15648/The_role_of_small_scale_CHP__in_energy-efficient_buildings.html (accessed on 6 February 2018).

- CIBSE. CIBSE Weather Data Sets; CIBSE: London, UK, 2016. Available online: http://www.cibse.org.uk/knowledge/cibse-weather-data-sets (accessed on 9 February 2018).

- Gu, W.; Wu, Z.; Bo, R.; Liu, W.; Zhou, G.; Chen, W.; Wu, Z. Modelling, planning and optimal energy management of combined cooling, heating and power microgrid: A review. Int. J. Electr. Power Energy Syst. 2014, 54, 26–37. [Google Scholar] [CrossRef]

- Maraver, D.; Sin, A.; Sebastian, F.; Royo, J. Environmental assessment of CCHP (combined cooling heating and power) systems based on biomass combustion in comparison to conventional generation. Energy 2013, 57, 17–23. [Google Scholar] [CrossRef]

- CIBSE Good Practice Guide 388 (GPG). CHP for Buildings. Available online: http://www.cwp-ltd.com/wp-content/uploads/2012/03/UKGoodPracticeGuide.pdf (accessed on 9 February 2018).

- UK GOV. Climate Change Levy Rates. Available online: https://www.gov.uk/government/publications/rates-and-allowances-climate-change-levy/climate-change-levy-rates (accessed on 11 February 2018).

- Carbon Trust. Cogeneration & Trigeneration. Available online: https://www.carbontrust.com/media/19529/ctv044/ (accessed on 3 February 2018).

- Burns, C. CHP QA—How to Achieve ‘Good Quality CHP’ and Gain Access to Fiscal Incentives. Available online: http://chpblog.energ-group.com/managing-cogeneration-emissions-and-compliancem/ (accessed on 4 February 2018).

- HES. Analysis on Energy Use by European Hotels. Available online: http://hes.unwto.org/sites/all/files/docpdf/analysisonenergyusebyeuropeanhotelsonlinesurveyanddeskresearch2382011-1.pdf (accessed on 6 February 2018).

- Rotimi, A.; Bahadori-Jahromi, A.; Mylona, A.; Godfrey, P.; Cook, D. Estimation and Validation of Energy Consumption in UK Existing Hotel Building Using Dynamic Simulation Software. Sustainability 2017, 9, 1391. [Google Scholar] [CrossRef]

- Chartered Institute of Building Services Engineers (CIBSE). Energy Efficiency in Commercial Kitchens; CIBSE TM50; Chartered Institute of Building Services Engineers: London, UK, 2009. [Google Scholar]

- International Tourism Partnership (ITP). ITP Global Hotel Decarbonisation Report. Available online: https://www.tourismpartnership.org/blog/itp-carbon-report-provides-hotel-sectors-goal-mitigate-climate-change/ (accessed on 17 February 2018).

- Department for Business, Energy and Industrial Strategy (BEIS). Energy and Emissions Projections. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/671187/Updated_energy_and_emissions_projections_2017.pdf (accessed on 20 February 2018).

- DEFRA, Government GHG Conversion Factors for Company Reporting. Methodology Paper for Emission Factors. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/553488/2016_methodology_paper_Final_V01-00.pdf (accessed on 18 February 2018).

- Hawkes, A.D. Estimating marginal CO2 emissions rates for national electricity systems. Energy Policy 2010, 38, 5977–5987. [Google Scholar] [CrossRef]

- Harrison, J. The Role of Micro CHP within a Decarbonizing Energy System. Available online: http://www.decentralized-energy.com/articles/print/volume-12/issue-4/features/the-role-of-micro-chp-within-a-decarbonizing-energy-system.html (accessed on 24 February 2018).

- Staffell, I. Measuring the progress and impacts of decarbonising British electricity. Energy Policy 2017, 102, 463–475. [Google Scholar] [CrossRef]

| 1a. Building Fabric & Fuel Source Data | |

| Element | Ua-calc (W/m2K) |

| Wall | 0.35 |

| Floor | 0.25 |

| Roof | 0.25 |

| Windows | 2.67 |

| Doors | 1.30 |

| Air permeability rate (m3/h/m2 @50 Pa) | 5.0 |

| Ua-calc = Calculated area-weighted average U-values (W/m2K) | |

| - Fuel Source: Natural gas—CO2 factor, 0.216 Kg/kWh - Grid Supplied electricity—CO2 factor, 0.519 Kg/kWh | |

| 1b. NCM Internal Conditions Database | |

| Zone | Occupancy Levels, People Density, Lux Level |

| Car Park | 0.0059 person/m2, 100 lux |

| Bedroom | 0.094 person/m2, 100 lux |

| Toilet | 0.1188 person/m2, 200 lux |

| Plant Room | 0.11 person/m2, 50 lux |

| Changing room | 0.112 person/m2, 100 lux |

| Reception | 0.105 person/m2, 200 lux |

| Hall | 0.183 person/m2, 300 lux |

| Food prep/kitchen | 0.108 person/m2, 500 lux |

| Eat/Drink area | 0.2 person/m2, 150 lux |

| Office | 0.106 person/m2, 400 lux |

| Meeting room | 0.094 person/m2, 100 lux |

| Swimming pool | 0.14 person/m2, 300 lux |

| Gym | 0.14 person/m2, 150 lux |

| Circulation | 0.115 person/m2, 100 lux |

| Store | 0.11 person/m2, 50 lux |

| Laundry | 0.12 person/m2, 300 lux |

| Gas Cost (Pence/kWh) | 3.50 |

|---|---|

| Electricity Cost (pence/kWh) | 10.30 |

| Maintenance Cost (pence/kWh) [39,41] | 0.90 |

| Climate Change Levy (CCL) rate for gas (pence/kWh) [40] | 0.203 |

| CCL rate for Electricity (pence/kWh) [40] | 0.583 |

| C/CHP installation cost (£/kWe) [39,41] | 500–1200 |

| Anticipated running hours | 17 h per day |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salem, R.; Bahadori-Jahromi, A.; Mylona, A.; Godfrey, P.; Cook, D. Comparison and Evaluation of the Potential Energy, Carbon Emissions, and Financial Impacts from the Incorporation of CHP and CCHP Systems in Existing UK Hotel Buildings. Energies 2018, 11, 1219. https://doi.org/10.3390/en11051219

Salem R, Bahadori-Jahromi A, Mylona A, Godfrey P, Cook D. Comparison and Evaluation of the Potential Energy, Carbon Emissions, and Financial Impacts from the Incorporation of CHP and CCHP Systems in Existing UK Hotel Buildings. Energies. 2018; 11(5):1219. https://doi.org/10.3390/en11051219

Chicago/Turabian StyleSalem, Radwa, Ali Bahadori-Jahromi, Anastasia Mylona, Paulina Godfrey, and Darren Cook. 2018. "Comparison and Evaluation of the Potential Energy, Carbon Emissions, and Financial Impacts from the Incorporation of CHP and CCHP Systems in Existing UK Hotel Buildings" Energies 11, no. 5: 1219. https://doi.org/10.3390/en11051219