Multiple Phase Change Material (PCM) Configuration for PCM-Based Heat Sinks—An Experimental Study

Abstract

:1. Introduction

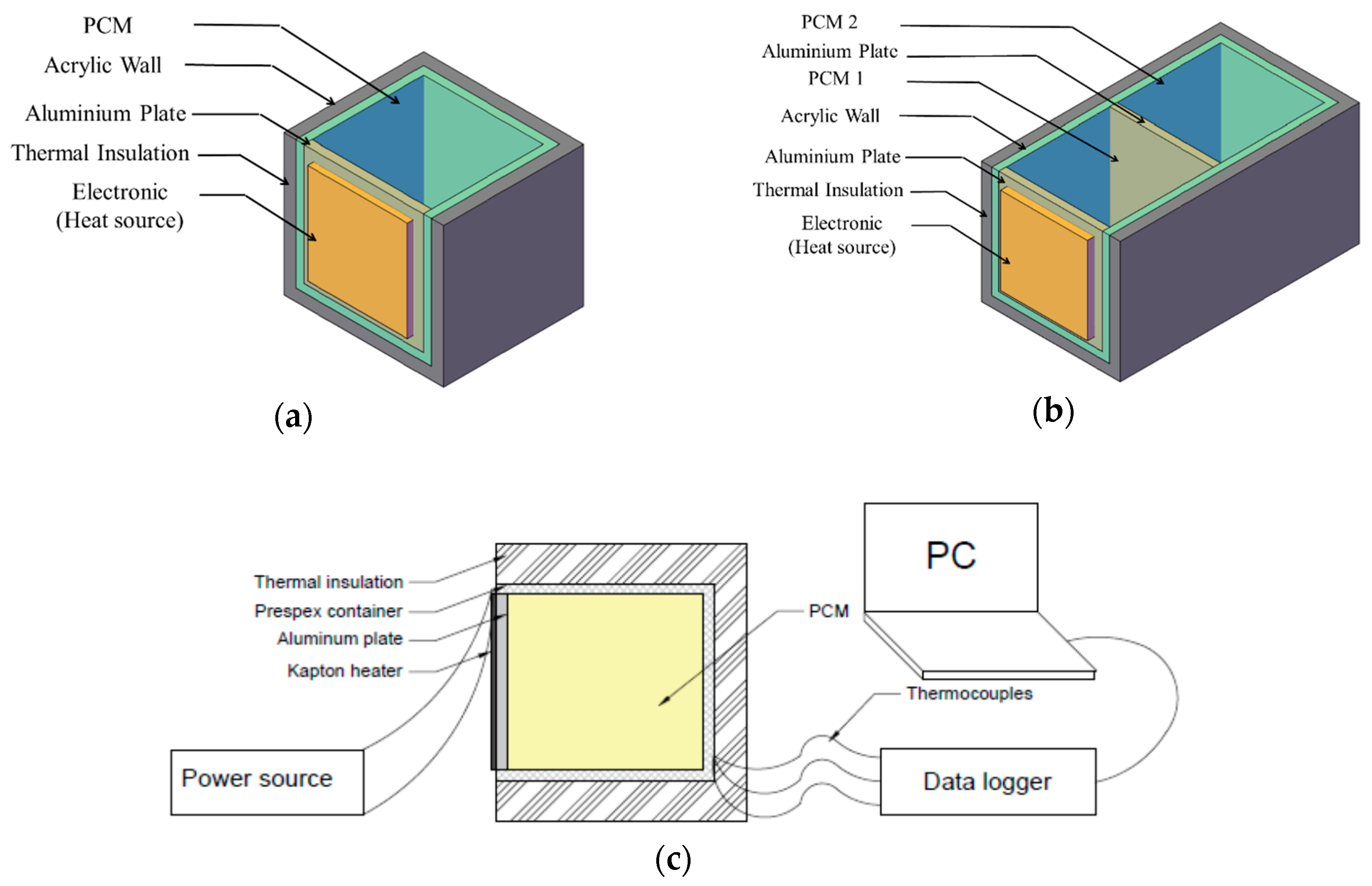

2. Experimental Setup and Procedure

3. Results and Discussion

3.1. Comparison of Heat Sink with and without PCM

3.2. Effect of Heater Power Rating

3.3. Effect of PCM Melting Temperature

3.4. Effect of PCM Thickness on Heat Sink Temperature

3.5. Effect of Using Two PCMs on Heat Sink Temperature

4. Conclusions

- Two PCM techniques with arrangement of RT50–RT55 increases the thermal regulation period by 110 min and 130 min as compared to RT50 and RT55, respectively. Using RT50–RT55, the heat sink temperature at the end of the operation is reduced by 10.3 °C and 6.1 °C as compared to RT50 and RT55, respectively, for 2.0 W.

- Two PCMs with the arrangement of RT58-RT47 reduces slightly the maximum temperature as compared to RT47–RT58.

- As PCM thickness increases from 30 to 60 mm, the thermal regulation period increases by 50 min and 35 min for 1.5 W and 2.0 W power ratings, respectively. As the PCM melting temperature increases from 47 (RT47) to 58 °C (RT58), the thermal regulation period increases from 30 to 70 min for 2.0 W. However, the heat sink temperature also increases from 63 to 74 °C.

- The thermal regulation period significantly decreases as power rating increases from 1 to 2 W. Also, the heat sink temperature increases by 29.5 °C with an increase in power rating.

Author Contributions

Funding

Conflicts of Interest

References

- Etemoglu, A.B. A brief survey and economical analysis of air cooling for electronic equipments. Int. Commun. Heat Mass Transf. 2007, 34, 103–113. [Google Scholar] [CrossRef]

- Yeh, L.T. Review of heat transfer technologies in electronic equipment. J. Electron. Packag. 1995, 117, 333–339. [Google Scholar] [CrossRef]

- Alawadhi, E.M.; Amon, C.H. PCM thermal control unit for portable electronic devices: Experimental and numerical studies. IEEE Trans. Compon. Packag. Technol. 2003, 26, 116–125. [Google Scholar] [CrossRef]

- Faraji, M.; El Qarnia, H. Passive Cooling of Protruding Electronic Components by Latent Heat of Fusion Storage. ASME J. Electron. Packag. 2009, 131, 021011. [Google Scholar] [CrossRef]

- Jaworski, M. Thermal performance of heat spreader for electronics cooling with incorporated phase change material. Appl. Therm. Eng. 2012, 35, 212–219. [Google Scholar] [CrossRef]

- Kandlikar, S.G.; Ii, C.N.H. Liquid Cooled Cold Plates for Industrial High- Power Electronic Devices—Thermal Design and Manufacturing Considerations Liquid Cooled Cold Plates for Industrial High-Power Electronic Devices—Thermal Design and Manufacturing Considerations. Heat Transf. Energy 2011, 30, 918–930. [Google Scholar] [CrossRef]

- Zhu, L.; Boehm, R.F.; Wang, Y.; Halford, C.; Sun, Y. Water immersion cooling of PV cells in a high concentration system. Sol. Energy Mater. Sol. Cells 2011, 95, 538–545. [Google Scholar] [CrossRef]

- Tardy, F.; Sami, S.M. Thermal analysis of heat pipes during thermal storage. Appl. Therm. Eng. 2009, 29, 329–333. [Google Scholar] [CrossRef]

- Vandersande, J.W.; Fleurial, J.-P. Thermal Management of Power Electronics using Thermoelectric Coolers. In Proceedings of the Fifteenth International Conference on Thermoelectrics, Pasadena, CA, USA, 26–39 March 1996; pp. 252–255. [Google Scholar]

- Ohadi, M.; Choo, K.; Dessiatoun, S.; Cetegen, E. Next Generation Microchannel Heat Exchangers; Springer: Berlin, Germany, 2013; ISBN 978-1-4614-0778-2. [Google Scholar]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Ge, Z.; Li, Y.; Li, D.; Sun, Z.; Jin, Y.; Liu, C.; Li, C.; Leng, G.; Ding, Y. Thermal energy storage: Challenges and the role of particle technology. Particuology 2014, 15, 2–8. [Google Scholar] [CrossRef]

- Ma, T.; Yang, H.; Zhang, Y.; Lu, L.; Wang, X. Using phase change materials in photovoltaic systems for thermal regulation and electrical efficiency improvement: A review and outlook. Renew. Sustain. Energy Rev. 2015, 43, 1273–1284. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Humphries, W.; Griggs, E. A Design Handbook for Phase Change Thermal Control and Energy Storage Devices; NASA Technical Paper; NASA: Buffalo, NY, USA, 1977.

- Hasan, A.; Alnoman, H.; Shah, A. Energy Efficiency Enhancement of Photovoltaics by Phase Change Materials through Thermal Energy Recovery. Energies 2016, 9, 782. [Google Scholar] [CrossRef]

- Hasan, A.; McCormack, S.J.; Huang, M.J.; Norton, B. Energy and cost saving of a photovoltaic-phase change materials (PV-PCM) System through temperature regulation and performance enhancement of photovoltaics. Energies 2014, 7, 1318–1331. [Google Scholar] [CrossRef]

- Krishnan, S.; Garimella, S.V. Thermal Management of Transient Power Spikes in Electronics—Phase Change Energy Storage or Copper Heat Sinks? J. Electron. Packag. 2004, 126, 308. [Google Scholar] [CrossRef]

- Tan, F.L.; Tso, C.P. Cooling of mobile electronic devices using phase change materials. Appl. Therm. Eng. 2004, 24, 159–169. [Google Scholar] [CrossRef]

- Hodes, M.; Weinstein, R.D.; Pence, S.J.; Piccini, J.M.; Manzione, L.; Chen, C. Transient Thermal Management of a Handset Using Phase Change Material (PCM). J. Electron. Packag. 2002, 124, 419. [Google Scholar] [CrossRef]

- Lafdi, K.; Mesalhy, O.; Elgafy, A. Merits of Employing Foam Encapsulated Phase Change Materials for Pulsed Power Electronics Cooling Applications. J. Electron. Packag. 2008, 130, 021004. [Google Scholar] [CrossRef]

- Saha, S.K. Cooling of Electronics with Phase Change Materials under Constant Power and Cyclic Heat Loads. AIP Conf. Proc. 2009, 31. [Google Scholar] [CrossRef]

- Kandasamy, R.; Wang, X.-Q.; Mujumdar, A.S. Application of phase change materials in thermal management of electronics. Appl. Therm. Eng. 2007, 27, 2822–2832. [Google Scholar] [CrossRef]

- Weinstein, R.D.; Kopec, T.C.; Fleischer, A.S.; D’Addio, E.; Bessel, C.A. The Experimental Exploration of Embedding Phase Change Materials With Graphite Nanofibers for the Thermal Management of Electronics. J. Heat Transf. 2008, 130, 042405. [Google Scholar] [CrossRef]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Climatic behaviour of solar photovoltaic integrated with phase change material. Energy Convers. Manag. 2018, 166, 590–601. [Google Scholar] [CrossRef]

- Fan, L.W.; Xiao, Y.Q.; Zeng, Y.; Fang, X.; Wang, X.; Xu, X.; Yu, Z.T.; Hong, R.H.; Hu, Y.C.; Cen, K.F. Effects of melting temperature and the presence of internal fins on the performance of a phase change material (PCM)-based heat sink. Int. J. Therm. Sci. 2013, 70, 114–126. [Google Scholar] [CrossRef]

- Thapa, S.; Chukwu, S.; Khaliq, A.; Weiss, L. Fabrication and analysis of small-scale thermal energy storage with conductivity enhancement. Energy Convers. Manag. 2014, 79, 161–170. [Google Scholar] [CrossRef]

- Baby, R.; Balaji, C. Experimental investigations on thermal performance enhancement and effect of orientation on porous matrix filled PCM based heat sink. Int. Commun. Heat Mass Transf. 2013, 46, 27–30. [Google Scholar] [CrossRef]

- Huang, M.J. The effect of using two PCMs on the thermal regulation performance of BIPV systems. Sol. Energy Mater. Sol. Cells 2011, 95, 957–963. [Google Scholar] [CrossRef]

- Jegadheeswaran, S.; Pohekar, S.D. Performance enhancement in latent heat thermal storage system: A review. Renew. Sustain. Energy Rev. 2009, 13, 2225–2244. [Google Scholar] [CrossRef]

- Wang, X.Q.; Mujumdar, A.S.; Yap, C. Effect of orientation for phase change material (PCM)-based heat sinks for transient thermal management of electric components. Int. Commun. Heat Mass Transf. 2007, 34, 801–808. [Google Scholar] [CrossRef]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Performance analysis of tilted photovoltaic system integrated with phase change material under varying operating conditions. Energy 2017, 133, 887–899. [Google Scholar] [CrossRef] [Green Version]

- Avci, M.; Yazici, M.Y. An experimental study on effect of inclination angle on the performance of a PCM-based flat-type heat sink. Appl. Therm. Eng. 2018, 131, 806–814. [Google Scholar] [CrossRef]

- Poran, S.; Ahmed, D.H. Effect of cavity shape and heat source/sink orientation on PCM melting. J. Therm. Energy Syst. 2018, 3, 1–22. [Google Scholar]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Optimization of solar photovoltaic system integrated with phase change material. Sol. Energy 2018, 163, 591–599. [Google Scholar] [CrossRef]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Optimization of finned solar photovoltaic phase change material (finned pv pcm) system. Int. J. Therm. Sci. 2018, 130, 313–322. [Google Scholar] [CrossRef]

- Kandasamy, R.; Wang, X.Q.; Mujumdar, A.S. Transient cooling of electronics using phase change material (PCM)-based heat sinks. Appl. Therm. Eng. 2008, 28, 1047–1057. [Google Scholar] [CrossRef]

- Fok, S.C.; Shen, W.; Tan, F.L. Cooling of portable hand-held electronic devices using phase change materials in finned heat sinks. Int. J. Therm. Sci. 2010, 49, 109–117. [Google Scholar] [CrossRef]

- Mahmoud, S.; Tang, A.; Toh, C.; AL-Dadah, R.; Soo, S.L. Experimental investigation of inserts configurations and PCM type on the thermal performance of PCM based heat sinks. Appl. Energy 2013, 112, 1349–1356. [Google Scholar] [CrossRef]

- Huang, M.J.; Eames, P.C.; Norton, B. Phase change materials for limiting temperature rise in building integrated photovoltaics. Sol. Energy 2006, 80, 1121–1130. [Google Scholar] [CrossRef]

- Wang, X.Q.; Yap, C.; Mujumdar, A.S. A parametric study of phase change material (PCM)-based heat sinks. Int. J. Therm. Sci. 2008, 47, 1055–1068. [Google Scholar] [CrossRef]

- Arshad, A.; Ali, H.M.; Ali, M.; Manzoor, S. Thermal performance of phase change material (PCM) based pin-finned heat sinks for electronics devices: Effect of pin thickness and PCM volume fraction. Appl. Therm. Eng. 2017, 112, 143–155. [Google Scholar] [CrossRef]

- Saha, S.K.; Srinivasan, K.; Dutta, P. Studies on optimum distribution of fins in heat sinks filled with phase change materials. J. Heat Transf. 2008, 130, 034505. [Google Scholar] [CrossRef]

- Tomizawa, Y.; Sasaki, K.; Kuroda, A.; Takeda, R.; Kaito, Y. Experimental and numerical study on phase change material (PCM) for thermal management of mobile devices. Appl. Therm. Eng. 2016, 98, 320–329. [Google Scholar] [CrossRef] [Green Version]

- Emam, M.; Ahmed, M. Cooling concentrator photovoltaic systems using various configurations of phase-change material heat sinks. Energy Convers. Manag. 2018, 158, 298–314. [Google Scholar] [CrossRef]

- Shaikh, S.; Lafdi, K. Effect of multiple phase change materials (PCMs) slab configurations on thermal energy storage. Energy Convers. Manag. 2006, 47, 2103–2117. [Google Scholar] [CrossRef]

- Soares, N.; Gaspar, A.R.; Santos, P.; Costa, J.J. Experimental study of the heat transfer through a vertical stack of rectangular cavities filled with phase change materials. Appl. Energy 2015, 142, 192–205. [Google Scholar] [CrossRef]

| PCM Type | Heat Sink Temperature at the Phase Change (°C) | Heat Sink Temperature at the End of Charging (210 min) °C | ||||

|---|---|---|---|---|---|---|

| Power Rating | Power Rating | |||||

| 1.0 W | 1.5 W | 2.0 W | 1.0 W | 1.5 W | 2.0 W | |

| RT47 | 55.2 | 59.0 | 63.0 | 56.8 | 72.3 | 86.3 |

| RT50 | 60.1 | 62.3 | 64.9 | 60.3 | 75.0 | 86.0 |

| RT52 | 59.3 | 63.6 | 67.3 | 59.3 | 74.4 | 87.0 |

| RT55 | 62.0 | 65.0 | 67.4 | 62.0 | 72.3 | 85.3 |

| RT58 | 64.4 | 69.0 | 73.6 | 64.4 | 69.0 | 84.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Siyabi, I.; Khanna, S.; Mallick, T.; Sundaram, S. Multiple Phase Change Material (PCM) Configuration for PCM-Based Heat Sinks—An Experimental Study. Energies 2018, 11, 1629. https://doi.org/10.3390/en11071629

Al Siyabi I, Khanna S, Mallick T, Sundaram S. Multiple Phase Change Material (PCM) Configuration for PCM-Based Heat Sinks—An Experimental Study. Energies. 2018; 11(7):1629. https://doi.org/10.3390/en11071629

Chicago/Turabian StyleAl Siyabi, Idris, Sourav Khanna, Tapas Mallick, and Senthilarasu Sundaram. 2018. "Multiple Phase Change Material (PCM) Configuration for PCM-Based Heat Sinks—An Experimental Study" Energies 11, no. 7: 1629. https://doi.org/10.3390/en11071629

APA StyleAl Siyabi, I., Khanna, S., Mallick, T., & Sundaram, S. (2018). Multiple Phase Change Material (PCM) Configuration for PCM-Based Heat Sinks—An Experimental Study. Energies, 11(7), 1629. https://doi.org/10.3390/en11071629