Evaluation on Tensile Behavior Characteristics of Undisturbed Loess

Abstract

:1. Introduction

- Designing a stress-controlled uniaxial test apparatus for measuring the stress-strain curve of testing materials. The accuracy and reliability of the apparatus has been improved from three shortages influencing the accuracy of the test.

- Performing a series of experiments on undisturbed loess with different water content and dry densities and analyzing two factors that affect tensile strength, including anisotropy and loading interval.

- Analyzing deformation characteristics and fracture patterns and discussing the existing strength prediction models. Further, based on the dynamic constitutive model of loess presented by Lanmin Wang et al. [36], establishing the constitutive relations to describe the tensile stress–strain behavior of undisturbed loess under different water contents.

2. Testing Apparatus

3. Materials and Methods

3.1. Materials

3.2. Methods

- (1)

- Sample preparation: to study the anisotropy effect, soils were taken from 8 m below the ground. The original soils were cut in different directions to get a rectangular specimen (Figure 6), and the average dry density of these samples was 1.48 g/cm3. Similarly, different dry density samples of 1.37 g/cm3, and 1.46 g/cm3 to study the loading interval effect and stress-strain relationship. In all tests, the water film transfer method was adopted in the allocation of different water content (Figure 7), and soil samples were sealed in a moisturizing dish for two days to homogenize the water content.

- (2)

- Sample installation and instrument debugging: the specimen was placed on the apparatus and then glued to the front and rear clamps using epoxy adhesive. The levelling bubble was situated in the center by minor adjustments of the height of four bolts. The dial gauge was installed and settled to zero. Before the test, 2 min was allowed to let the adhesive solidify. The whole course was carried out in an 18 °C constant temperature room, and thin vaseline was daubed on the specimen surface to prevent evaporation.

- (3)

- Tensile test: there were five weights used—20, 30, 50, 100, and 300 g. The tensile stress was computed by dividing the tensile force by the cross-sectional area (3.0 × 3.0 cm) of the specimen. Weights can be combined when loaded. It is possible to obtain a more accurate tensile strength value by applying the lower weights in the later stage of the test. What needs to be emphasized is that, in the time effect test, when the water content is lower than the plastic limit, each time the applied mass is 150 g and the water content is higher than the plastic limit, it is 50 g each time. The displacement value was recorded for each loading stage. Except for loading interval test, the other displacement values were recorded every 2 min. If the specimen broke at the edge of one of the clamps, the tensile strength was considered to be invalid and the test was carried out again until the specimen broke along the middle cross section. The reliability of the test apparatus was verified by most samples’ fracture at the middle part.

4. Experimental Results and Analysis

4.1. Anisotropy Effect

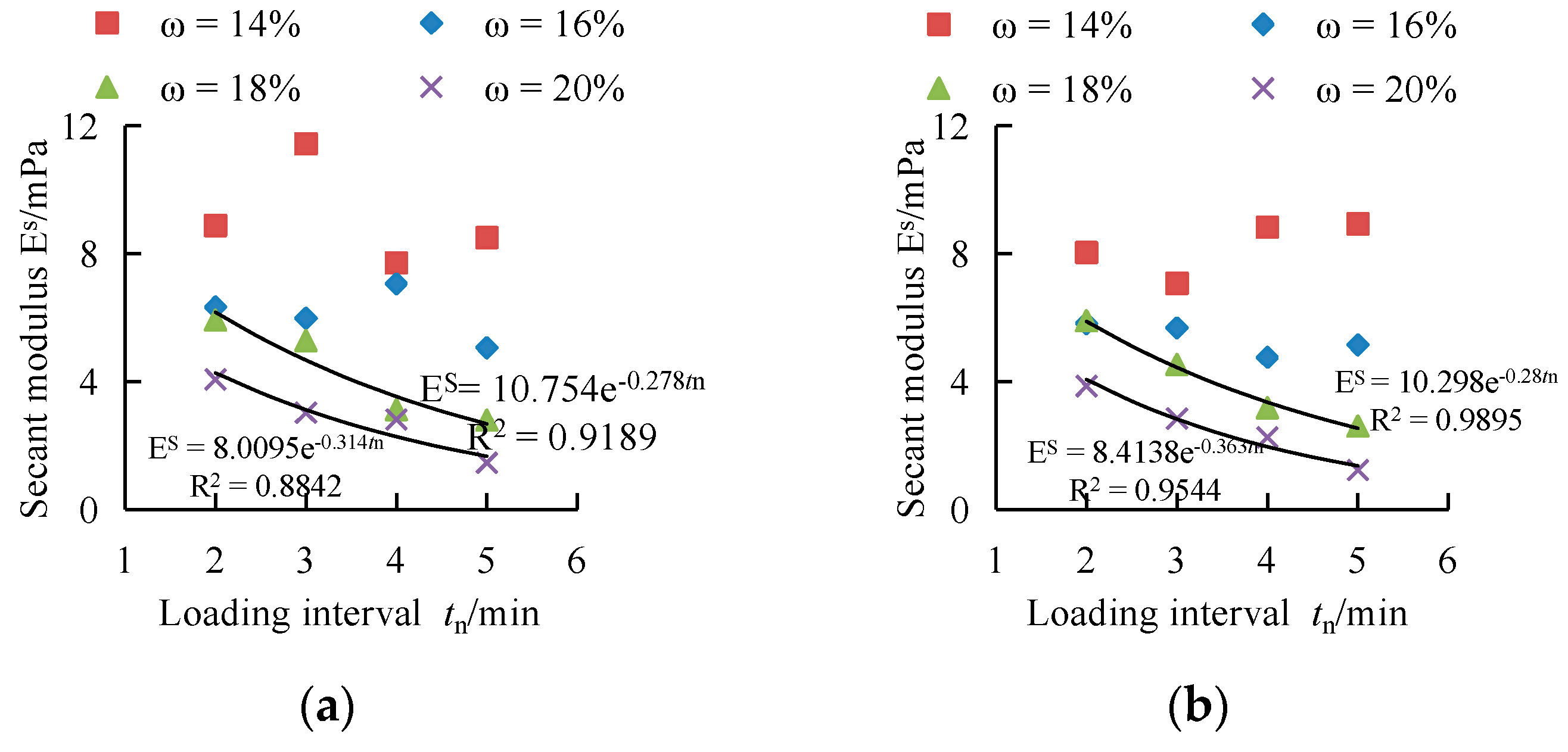

4.2. Loading Interval Effect

5. Two Fracture Patterns of Undisturbed Loess

5.1. Deformation Behavior in Tensile Test

5.2. Tensile Strength Prediction

6. Constitutive Relation for Undisturbed Soils under Uniaxial Tension

6.1. Hyperbolic Equation for the Stress-Strain Curve

6.2. Mechanical Meaning of Constants a and b

6.3. The Tangent Modulus Et and Specific Strain Energy u

7. Conclusions

- The developed uniaxial direct-tension test apparatus can acquire the accurate value of tensile strength and the stress-strain curve of soils through a series of improvements by reducing friction, decreasing eccentricity, and developing new clamps.

- The effects of anisotropy on the tensile strength of undisturbed loess are significant. The tensile strength generally decreases with increasing direction inclination θ and eventually reaches a minimum value in the range of 30° < θ < 60°, and then it increases until the maximal value of θ = 90°. The loading interval has a negligible influence on the tensile behavior when ω < PL. However, it does have an impact on the tensile strength, limit displacement, and stiffness response of the undisturbed loess when ω > PL.

- Regarding the tensile deformation of the specimen, there were two crack patterns of transverse failure and serrated failure. For the transverse failure, a brittle fracture could be observed when ω < PL, but plastoelastic failure became the main form when ω > PL. For the serrated failure, it was not found that this pattern is related to factors such as the cut orientation, water content, and dry density of the sample.

- Regarding the tensile strength prediction, the strength expression was proposed by the total stress in the serrated failure. Since models by Lu et al. and Maryam Varsei were all based on the M-C failure criterion, an idea was put forward for expressing tensile strength by isotropic stress (bonding stress) in the transverse failure. However, the models need further experimental verification.

- Based on the concept of a fracture process zone, a method was proposed to calculate the apparent tensile strain, and an empirical constitutive relation was established to describe the stress-strain relationship of undisturbed loess. Reasonable agreement between the model predictions and experimental results was obtained. Further, the expressions of the tangent modulus and the specific strain energy could be derived.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Peng, D.; Xu, Q.; Qi, X.; Ju, Y. Study on early recognition of loess landslides based on field investigation. Int. J. Geohazards Environ. 2016, 2, 32–52. [Google Scholar] [CrossRef]

- Li, Y. A review of shear and tensile strengths of the Malan Loess in China. Eng. Geol. 2017, 236, 4–10. [Google Scholar] [CrossRef]

- Trabelsi, H.; Jamei, M.; Zenzri, H.; Olivella, S. Crack patterns in clayey soils: Experiments and modeling. Int. J. Numer. Anal. Methods Geomech. 2012, 36, 1410–1433. [Google Scholar] [CrossRef]

- Spencer, E. Effect of tension of stability of embankment. J. Soil Mech. Found. Div. 1968, 94, 1159–1173. [Google Scholar]

- Suklje, L. Rheological Aspects of Soil Mechanics; Wiley-Interscience: London, UK, 1969; pp. 456–473. [Google Scholar]

- Leonards, G.A.; Narain, J. Flexibility of clay and cracking of earth dams. J. Soil Mech. Found. Div. 1963, 89, 47–98. [Google Scholar]

- Ajaz, A.; Parry, R.H.G. Stress-strain behaviour of two compacted claysin tension and compression. Géotechnique 1975, 25, 495–512. [Google Scholar] [CrossRef]

- Thusyanthan, N.I.; Take, W.A.; Madabhushi, S.P.G.; Bolton, M.D. Crack initiation in clay observed in beam bending. Géotechnique 2007, 57, 581–594. [Google Scholar] [CrossRef]

- Viswanadham, B.V.S.; Jha, B.K.; Pawar, S.N. Experimental study on flexural testing of compacted soil beams. J. Mater. Civ. Eng. 2010, 10, 460–468. [Google Scholar] [CrossRef]

- Narain, J.; Rawat, P.C. Tensile strength of compacted soils. J. Soil Mech. Found. Div. 1970, 96, 2185–2190. [Google Scholar]

- Mellor, M.; Hawkes, I. Measurement of tensile strength by diametral compression of discs and annuli. Eng. Geol. 1971, 5, 73–225. [Google Scholar] [CrossRef]

- Krishnayya, A.V.G.; Eisenstein, Z.; Morgenstern, N.R. Behavior of compacted soil in tension. J. Geotech. Eng. Div. 1974, 100, 1051–1061. [Google Scholar]

- Ghosh, A.; Subbarao, C. Tensile strength bearing ratio and slake durability of class fly ash stabilized with lime and gypsum. J. Mater. Civ. Eng. 2006, 10, 18–27. [Google Scholar] [CrossRef]

- De Souza Villar, L.F.; De Campos, T.M.P.; Azevedo, R.F.; Zornberg, J.G. Tensile strength changes under drying and its correlations with total and matric suctions. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009; Volume 1, pp. 793–796. [Google Scholar]

- Consoli, N.C.; Cruz, R.C.; Consoli, B.S.; Maghous, S. Failure envelope of artificially cemented sand. Géotechnique 2012, 62, 543–547. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Smith, J.C.; Ciancio, D.; Augarde, C.E. Tensile strengths of flocculated compacted unsaturated soils. Géotech. Lett. 2015, 5, 254–260. [Google Scholar] [CrossRef] [Green Version]

- Fang, H.Y.; Chen, W.F. Further study of double-punch test for tensile strength of soils. In Proceedings of the 3rd Southeast Asian Conference on Soil Engineering, Southeast Asian Geotechnical Society, Pathumthani, Thailand, 6–10 November 1972; pp. 211–215. [Google Scholar]

- Favaretti, M. Tensile strength of compacted clays. In Proceedings of the 1st International Conference on Unsaturated Soils, Balkema, Rotterdam, The Netherlands, 6–8 September 1995; pp. 51–56. [Google Scholar]

- Kim, T.H.; Kim, C.K.; Jung, S.J.; Lee, J.H. Tensile strength characteristics of contaminated and compacted sand-bentonite mixtures. Environ. Geol. 2007, 52, 653–661. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, T.-H.; Kang, G.-C.; Ge, L. Factors influencing crack-induced tensile strength of compacted soil. J. Mater. Civ. Eng. 2012, 24, 315–320. [Google Scholar] [CrossRef]

- Lutenegger, A.J.; Rubin, A. Tensile strength of some compacted fine-grained soils. In Unsaturated Soils: Advances in Geo-Engineering; Toll, D.G., Augarde, C.E., Gallipoli, D., Wheeler, S.J., Eds.; Taylor & Francis: London, UK, 2008; pp. 411–415. [Google Scholar]

- Li, X.; Liu, Y.; Jiang, L.; Tang, Y. Determination of tensile strength of compacted loess by double punch test. Adv. Mater. Res. 2011, 15, 194–196. [Google Scholar] [CrossRef]

- Tschebotarioff, G.P.; Ward, E.R.; Dephillippe, A.A. The tensile strength of disturbed and recompacted soils. In Proceedings of the Third International Conference on Soil Mechanics and Foundation Engineering, Zurich, Switzerland, 16–27 August 1953; ISSMFE: Zurich, Switzerland, 1953; pp. 207–210. [Google Scholar]

- Tang, G.X.; Graham, J. A method for testing tensile strength in unsaturated soils. Geotech. Test. J. 2000, 23, 377–382. [Google Scholar]

- Nahlawi, H.; Chakrabarti, S.; Kodikara, J. A direct tensile strength testing method for unsaturated geomaterials. J. Geotech. Test. 2004, 27, 356–361. [Google Scholar]

- Zhang, B.-Y.; Li, Q.-M.; Yuan, H.-N.; Sun, X. Tensile Fracture Characteristics of Compacted Soils under Uniaxial Tension. J. Mater. Civ. Eng. 2015, 27, 04014274. [Google Scholar] [CrossRef]

- Tollenaar, L.A.; van Paassen, C. Experimental evaluation of the effects of pull rate on the tensile behavior of a clay. Appl. Clay Sci. 2017, 144, 131–140. [Google Scholar] [CrossRef]

- Ibarra, S.Y.; Mc Kyes, E.; Broughton, R.S. Measurement of tensile strength of unsaturated sandy loam soil. Soil Tillage Res. 2005, 81, 15–23. [Google Scholar] [CrossRef]

- Lakshmikantha, M.R.; Prat, P.C.; Ledesma, A. Image analysis for the quantification of a developing crack network on a drying soil. ASTM Geotech. Test. J. 2009, 32, 505–515. [Google Scholar]

- Tang, C.-S.; Pei, X.-J.; Wang, D.-Y.; Shi, B.; Li, J. Tensile Strength of Compacted Clayey Soil. J. Geotech. Geoenviron. Eng. 2015, 141, 04014122. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhu, J.G.; Chiu, C.F.; Zhang, H. Experimental study on fracture toughness and tensile strength of a clay. Eng. Geol. 2007, 94, 65–75. [Google Scholar] [CrossRef]

- Morris, P.H.; Graham, J.; Williams, D.J. Cracking in drying soils. Can. Geotech. J. 1992, 29, 263–272. [Google Scholar] [CrossRef]

- Blazejczak, D.; Horn, R.; Pytka, J. Soil tensile strength as affected by time, water content and bulk density. Int. Agrophys. 1995, 9, 179–188. [Google Scholar]

- Sun, P.; Peng, J.; Chen, L.; Yin, Y.; Wu, S. Weak tensile characteristics of loess in China-an important reason for ground fissures. Eng. Geol. 2009, 108, 153–159. [Google Scholar] [CrossRef]

- Lu, N.; Kim, T.; Sture, S.; Likos, W. Tensile strength of unsaturated sand. J. Eng. Mech. 2009, 12, 1410–1419. [Google Scholar] [CrossRef]

- Wang, L. The dynamic constitutive model of loess under irregular seismic loading. Northwest. J. Seismol. 1992, 4, 61–68. [Google Scholar]

- Burland, J.B. On the compressibility and shear strength of natural clays. Géotechnique 1990, 40, 29–78. [Google Scholar] [CrossRef]

- Maryam, V.; Gerald, A.; Miller, P.E.; Hassanikhah, A. Novel Approach to Measuring Tensile Strength of Compacted Clayey Soil during Desiccation. Int. J. Geomech. 2016, 16, D4016011. [Google Scholar]

- Alonso, O.S.; Vaunat, J.; Pereira, J.M. A microstructurally based effective stress for unsaturated soils. Géotechnique 2010, 60, 913–925. [Google Scholar] [CrossRef]

- Lu, N.; Likos, W.J. Suction stress characteristic curve for unsaturated soil. J. Geotech. Geoenviron. Eng. 2006, 132, 131–142. [Google Scholar] [CrossRef]

- Lechman, J.; Lu, N.; Wu, D. Hysteresis of matric suction and capillary stress in monodisperse disk-shaped particles. J. Eng. Mech. 2006, 5, 565–577. [Google Scholar] [CrossRef]

- Hillerborg, A. The theoretical basis of a method to determine fracture energy GF of concrete. Mater. Struct. 1985, 18, 291–296. [Google Scholar] [CrossRef]

- Labuz, J.F.; Shah, S.P.; Dowding, C.H. The fracture processzone in granite: Evidence and effect. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1987, 24, 235–246. [Google Scholar] [CrossRef]

- Duncan, J.M.; Chang, C.-Y. Nonlinear analysis of stress and strain in soils. J. Soil Mech. Found. Div. 1970, 96, 1629–1653. [Google Scholar]

| Specific Gravity Gs | Liquid Limit LL (%) | Plastic Limit PL (%) | Plasticity Index PI (%) | Optimum Water Content ωopt (%) | Maximum Dry Density ρd max (g/cm−3) |

|---|---|---|---|---|---|

| 2.67 | 27.2 | 17.6 | 9.6 | 14.8 | 1.82 |

| Groups | Dry Density ρd (g/cm−3) | Water Content ω (%) | Dip Angle θ (°) | Interval Time tn (min) |

|---|---|---|---|---|

| Anisotropy effect | 1.48 | 14.0, 16.0, 18.0, 20.0 | 0, 30, 60, 90 | _ |

| Loading interval effect | 1.37, 1.46 | 14.0, 16.0, 18.0, 20.0 | _ | 2, 3, 4, 5 |

| ω (%) ρd (g/cm3) | a | b | a | b | a | b | a | b |

|---|---|---|---|---|---|---|---|---|

| 1.28 | 1.37 | 1.46 | 1.53 | |||||

| 14 | 0.0178 | 0.0322 | 0.0142 | 0.0267 | 0.0141 | 0.0233 | 0.0091 | 0.0192 |

| 16 | 0.0284 | 0.0386 | 0.0253 | 0.0311 | 0.03 | 0.0259 | 0.0153 | 0.0243 |

| 18 | 0.0542 | 0.0478 | 0.0433 | 0.0362 | 0.0313 | 0.0389 | 0.0227 | 0.0313 |

| 20 | 0.1137 | 0.0599 | 0.0541 | 0.0443 | 0.0429 | 0.0432 | 0.0332 | 0.0352 |

| Dry Density ρd (g/cm3) | Fitting Formula | |

|---|---|---|

| 1.28 | R2 = 0.977 | R2 = 0.989 |

| 1.37 | R2 = 0.982 | R2 = 0.985 |

| 1.36 | R2 = 0.881 | R2 = 0.929 |

| 1.45 | R2 = 0.999 | R2 = 0.989 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Bai, H.; Xu, Z. Evaluation on Tensile Behavior Characteristics of Undisturbed Loess. Energies 2018, 11, 1974. https://doi.org/10.3390/en11081974

He S, Bai H, Xu Z. Evaluation on Tensile Behavior Characteristics of Undisturbed Loess. Energies. 2018; 11(8):1974. https://doi.org/10.3390/en11081974

Chicago/Turabian StyleHe, Shixin, Haibo Bai, and Zhiwei Xu. 2018. "Evaluation on Tensile Behavior Characteristics of Undisturbed Loess" Energies 11, no. 8: 1974. https://doi.org/10.3390/en11081974