Hydrothermal Carbonization of Biosolids from Waste Water Treatment Plant

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material (Feedstock)

2.2. Method

3. Results and Discussion

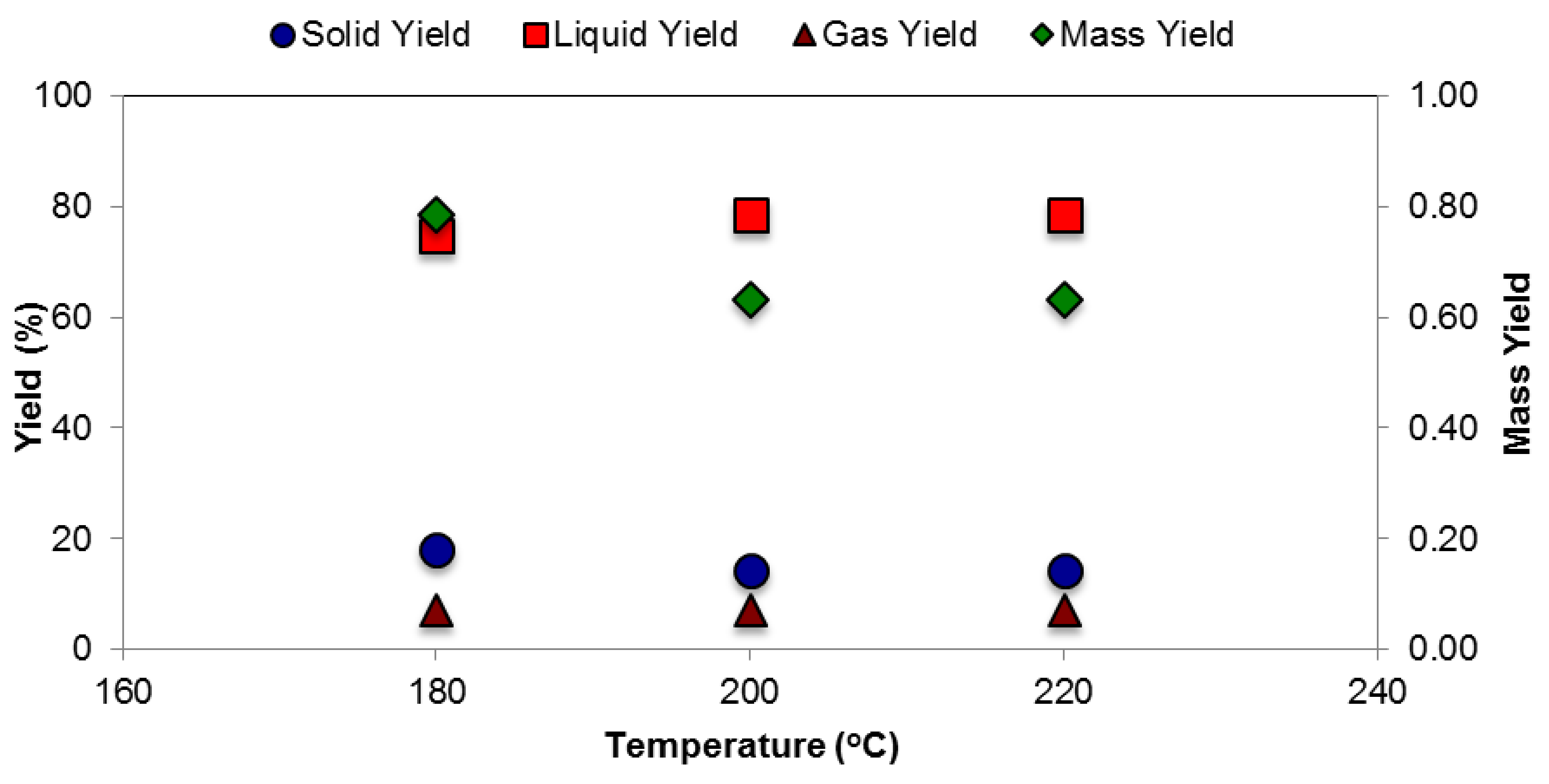

3.1. Product Distribution

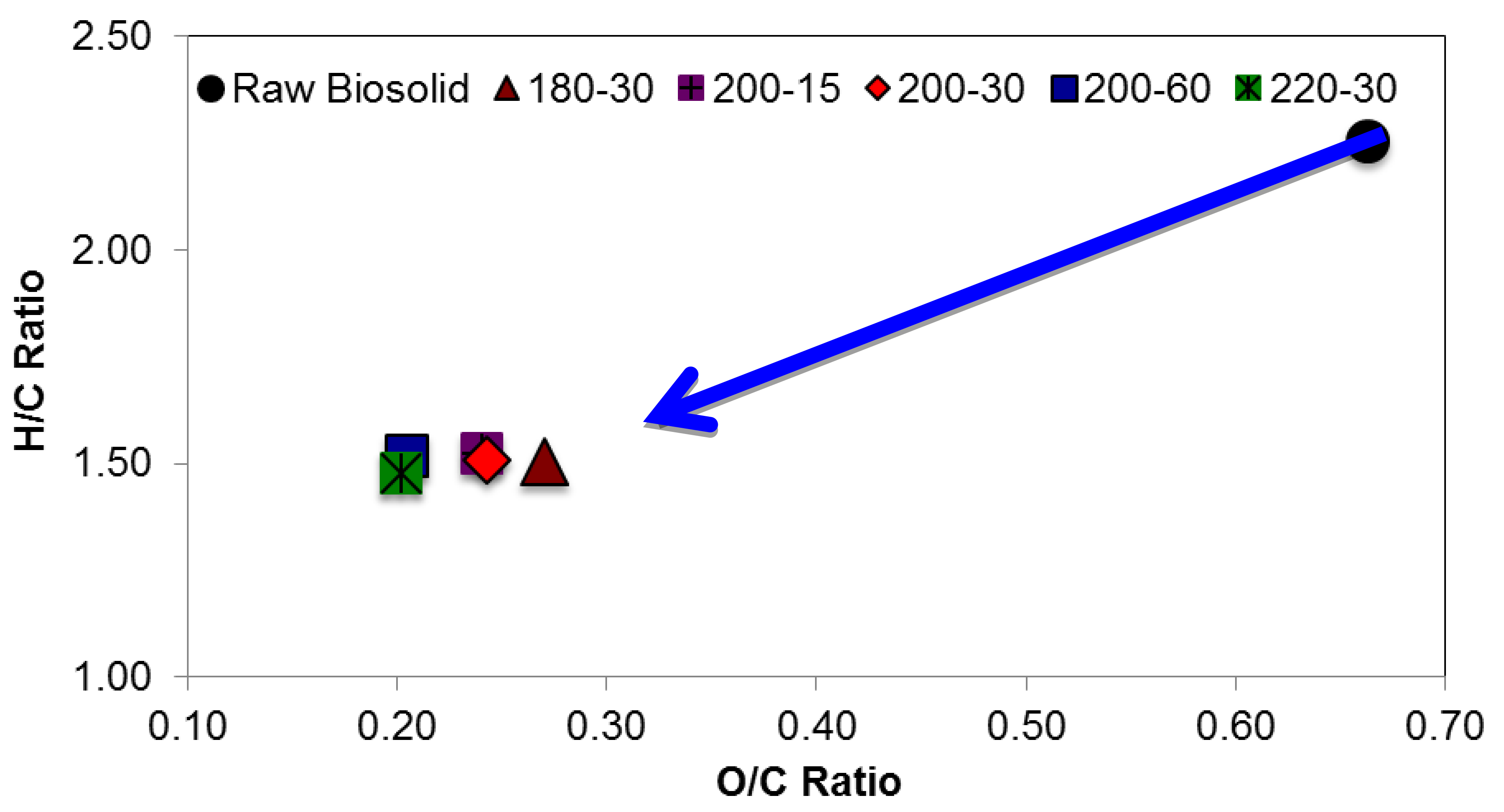

3.2. Physiochemical Properties of Hydrochar

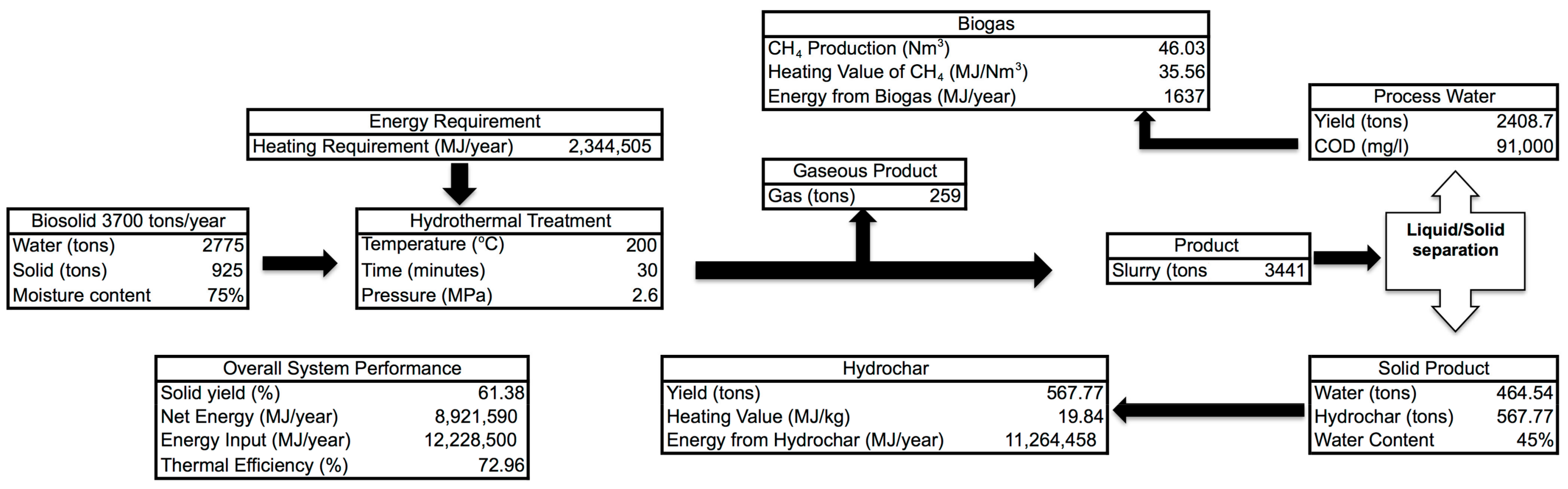

3.3. Mass and Energy Balance

3.4. Mineral Analysis of Solid Hydrochar

3.5. Process Water

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- North East Biosolids and Residuals Association (NEBRA), 2007. A National Biosolids Regulation, Quality, End Use and Disposal Survey. Available online: https://static1.squarespace.com/static/54806478e4b0dc44e1698e88/t/5488541fe4b03c0a9b8ee09b/1418220575693/NtlBiosolidsReport-20July07.pdf (accessed on 12 March 2018).

- Canadian Council of Ministers of the Environment (CCME), Canada-wide Approach for the Management of Wastewater Biosolids. Available online: https://www.ccme.ca/files/Resources/waste/biosolids/pn_1477_biosolids_cw_approach_e.pdf (accessed on 15 May 2018).

- Risks Associated with Application of Municipal Biosolids to Agricultural Lands in a Canadian Context. Available online: http://www.cwn-rce.ca/assets/resources/pdf/McCarthy-Risks-Biosolids-2015.pdf (accessed on 15 April 2018).

- Capareda, S.C. Introduction to Biomass Energy Conversion, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Kambo, H.S.; Dutta, A. Strength, storage, and combustion characteristics of densified lignocellulosic biomass produced via torrefaction and hydrothermal carbonization. Appl. Energy 2014, 135, 182–191. [Google Scholar] [CrossRef]

- Escala, M.; Zumbühl, T.; Koller, C.; Junge, R.; Krebs, R. Hydrothermal carbonization as an energy-efficient alternative to established drying technologies for sewage sludge: A feasibility study on a laboratory scale. Energy Fuels 2013, 27, 454–460. [Google Scholar] [CrossRef]

- Xue, X.; Chen, D.; Song, X.; Dai, X. Hydrothermal and pyrolysis treatment for sewage sludge: Choice from product and from energy benefit1. Energy Procedia 2015, 66, 301–304. [Google Scholar] [CrossRef]

- Lucian, M.; Fiori, L. Hydrothermal carbonization of waste biomass: Process design, modeling, energy efficiency and cost analysis. Energies 2017, 10, 211. [Google Scholar] [CrossRef]

- Sun, X.; Sumida, H.; Yoshikawa, K. Effects of liquid fertilizer produced from sewage sludge by the hydrothermal process on the growth of komatsuna. Br. J. Environ. Clim. Chang. 2014, 4, 261–278. [Google Scholar] [CrossRef]

- Saetae, P.; Tippayawong, N. Recovery of Value-Added Products from Hydrothermal Carbonization of Sewage Sludge. ISRN Chem. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Wilk, M. A novel method of sewage sludge pre-treatment-HTC. In E3S Web of Conferences; EDP Sciences Reyulis: Paris, France, 2016; Volume 10. [Google Scholar] [CrossRef]

- Parshetti, G.K.; Liu, Z.; Jain, A.; Srinivasan, M.P.; Balasubramanian, R. Hydrothermal carbonization of sewage sludge for energy production with coal. Fuel 2013, 111, 201–210. [Google Scholar] [CrossRef]

- Zhai, Y.; Peng, C.; Xu, B.; Wang, T.; Li, C.; Zeng, G.; Zhu, Y. Hydrothermal carbonization of sewage sludge for char production with different waste biomass: Effects of reaction temperature and energy recycling. Energy 2017, 127, 167–174. [Google Scholar] [CrossRef]

- Pruksakit, W.; Patumsawad, S. Hydrothermal carbonization (htc) of sugarcane stranded: Effect of operation condition to hydrochar production. Energy Procedia 2016, 100, 223–226. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Baloch, H.A.; Griffin, G.J.; Mubarak, N.M.; Bhutto, A.W.; Abro, R.; Mazari, S.A.; Ali, B.S. An overview of effect of process parameters on hydrothermal carbonization of biomass. Renew. Sustain. Energy Rev. 2017, 73, 1289–1299. [Google Scholar] [CrossRef]

- Román, S.; Libra, J.; Berge, N.; Sabio, E.; Ro, K.; Li, L.; Ledesma, B.; Álvarez, A.; Bae, S. Hydrothermal Carbonization: Modeling, Final Properties Design and Applications: A Review. Energies 2018, 11, 216. [Google Scholar] [CrossRef]

- Li, H.; Wang, S.; Yuan, X.; Xi, Y.; Huang, Z.; Tan, M.; Li, C. The effects of temperature and color value on hydrochars’ properties in hydrothermal carbonization. Bioresour. Technol. 2018, 249, 574–581. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Quek, A.; Kent Hoekman, S.; Balasubramanian, R. Production of solid biochar fuel from waste biomass by hydrothermal carbonization. Fuel 2013, 103, 943–949. [Google Scholar] [CrossRef]

- Hustad, J.; Barrio, M. Biomass. IFRF Online Combustion Handbook. 2000. Available online: http://www.handbook.ifrf.net/handbook/cf.html?id=23 (accessed on 20 April 2018).

- Reza, M.T.; Lynam, J.; Uddin, M.H.; Coronella, C. Hydrothermal carbonization: Fate of inorganics. Biomass Bioenergy 2013, 49, 86–94. [Google Scholar] [CrossRef]

- Pala, M.; Kantarli, I.C.; Buyukisik, H.B.; Yanik, J. Hydrothermal carbonization and torrefaction of grape pomace: A comparative evaluation. Bioresour. Technol. 2014, 161, 255–262. [Google Scholar] [CrossRef] [PubMed]

- Jan, R.P.; Lucas, P.J.B.; Mark, N.W.N.; Marcel, H.Z.; Mariusz, K.C. Conversion of water plant to biomass fuel using TORRWASH. In Proceedings of the 22nd European Biomass Conference and Exhibition, Hamburg, Germany, 23–26 June 2014. [Google Scholar]

- Volpe, M.; Goldfarb, J.L.; Fiori, L. Hydrothermal carbonization of Opuntia ficus-indica cladodes: Role of process parameters on hydrochar properties. Bioresour. Technol. 2018, 247, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Zhai, Y.; Zhu, Y.; Peng, C.; Wang, T.; Xu, B.; Li, C.; Zeng, G. Feedwater pH affects phosphorus transformation during hydrothermal carbonization of sewage sludge. Bioresour. Technol. 2017, 245, 182–187. [Google Scholar] [CrossRef] [PubMed]

- Gamgoum, R.; Dutta, A.; Santos, R.; Chiang, Y. Hydrothermal conversion of neutral sulfite semi-chemical red liquor into hydrochar. Energies 2016, 9, 435. [Google Scholar] [CrossRef]

- Galdames, A.; Mendoza, A.; Orueta, M.; García, I.S.d.S.; Sánchez, M.; Virto, I.; Vilas, J.L. Development of new remediation technologies for contaminated soils based on the application of zero-valent iron nanoparticles and bioremediation with compost. Resour.-Effic. Technol. 2017, 3, 166–176. [Google Scholar] [CrossRef]

- Fang, J.; Zhan, L.; Ok, Y.S.; Gao, B. Minireview of potential applications of hydrochar derived from hydrothermal carbonization of biomass. J. Ind. Eng. Chem. 2018, 57, 15–21. [Google Scholar] [CrossRef]

- Henze, M.; Loosdrecht, M.C.M.; Ekama, G.A.; Brdjanovic, D. Biological Wastewater Treatment: Principles, Modelling and Design; IWA Publishing: London, UK, 2008; ISBN 9781843391883. [Google Scholar]

- Prabhudessai, V.; Ganguly, A.; Mutnuri, S. Biochemical Methane Potential of Agro Wastes. J. Energy 2013, 2013. [Google Scholar] [CrossRef]

| Proximate Analysis (%) | Ultimate Analysis (%) | Higher Heating Value | ||||||

|---|---|---|---|---|---|---|---|---|

| Fixed Carbon | Ash Content | Volatile Matter | C | H | O | N | S | MJ/kg |

| 6.88 | 24.20 | 68.92 | 34.23 | 6.42 | 30.28 | 4.16 | 0.71 | 13.3 |

| Analysis | Raw | 180-30 | 200-15 | 200-30 | 200-60 | 220-30 |

|---|---|---|---|---|---|---|

| Proximate analysis (%) | ||||||

| Moisture | 77.16 | 42.19 | 47.44 | 46.97 | 53.63 | 47.44 |

| Ash | 24.20 | 32.06 | 32.81 | 33.86 | 33.12 | 33.9 |

| Volatile Matter | 68.92 | 54.22 | 54.49 | 53.56 | 53.37 | 52.67 |

| Fixed Carbon | 6.88 | 13.72 | 12.71 | 12.58 | 13.51 | 13.43 |

| Ultimate analysis (%) | ||||||

| Carbon | 34.23 | 42.27 | 43.11 | 42.15 | 43.98 | 43.94 |

| Hydrogen | 6.42 | 5.3 | 5.47 | 5.3 | 5.55 | 5.41 |

| Nitrogen | 4.16 | 4.1 | 3.74 | 3.98 | 4.22 | 3.79 |

| Oxygen | 30.28 | 15.22 | 13.83 | 13.65 | 12.04 | 11.83 |

| Sulphur | 0.71 | 1.05 | 1.04 | 1.06 | 1.09 | 1.13 |

| HHV (MJ/kg) | 13.23 | 19.94 | 19.90 | 19.85 | 20.12 | 20.16 |

| Energy Densification | - | 1.51 | 1.50 | 1.50 | 1.52 | 1.52 |

| Analysis | 180-30 | 200-15 | 200-30 | 200-60 | 220-30 |

|---|---|---|---|---|---|

| Phosphorus (ppm) | 207.3 | 192 | 154.4 | 136.3 | 86.16 |

| COD (mg/L) | 83,000 | 91,000 | 91,000 | 96,000 | 91,000 |

| pH | 6.56 | 7.57 | 6.11 | 6.04 | 6.49 |

| Methane Production (Nm3/L) | 0.029 | 0.0318 | 0.0318 | 0.0336 | 0.0318 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhatt, D.; Shrestha, A.; Dahal, R.K.; Acharya, B.; Basu, P.; MacEwen, R. Hydrothermal Carbonization of Biosolids from Waste Water Treatment Plant. Energies 2018, 11, 2286. https://doi.org/10.3390/en11092286

Bhatt D, Shrestha A, Dahal RK, Acharya B, Basu P, MacEwen R. Hydrothermal Carbonization of Biosolids from Waste Water Treatment Plant. Energies. 2018; 11(9):2286. https://doi.org/10.3390/en11092286

Chicago/Turabian StyleBhatt, Dhananjay, Ankita Shrestha, Raj Kumar Dahal, Bishnu Acharya, Prabir Basu, and Richard MacEwen. 2018. "Hydrothermal Carbonization of Biosolids from Waste Water Treatment Plant" Energies 11, no. 9: 2286. https://doi.org/10.3390/en11092286

APA StyleBhatt, D., Shrestha, A., Dahal, R. K., Acharya, B., Basu, P., & MacEwen, R. (2018). Hydrothermal Carbonization of Biosolids from Waste Water Treatment Plant. Energies, 11(9), 2286. https://doi.org/10.3390/en11092286