1. Introduction

Since the beginning of the industrial revolution, the world’s economic growth and human prosperity has always been dependent on energy supply. Nowadays, global population growth and climate changes are encouraging new interests and investments in renewable sources in order to provide access to reliable and sustainable energy [

1].

Geothermal sources are worldwide available, especially in the USA, in the Philippines, Indonesia, Italy and New Zealand [

2]. Technologies like organic Rankine cycle (ORC) and Kalina cycles allow the exploitation of low and medium enthalpy sources [

3]. Therefore, geothermal energy can also be exploited in countries with a lack of high-enthalpy reservoirs, such as Germany. Geothermal power plants provide sustainable and reliable energy with very high capacity factors, both in power-only and combined heat and power (CHP) configuration [

2]. Nevertheless, ORC geothermal solutions generally have a low thermal efficiency with a worldwide average value equal to 12% [

4]. In fact, auxiliary power consumptions (ORC pumps, reinjection pumps, air-cooled condenser) are not negligible. Even though an air-cooled condenser is a positive solution to the lack of water for the wet condensation process, the ORC unit inevitably becomes ambient temperature dependent, reducing the annual net energy production. In particular, electric power production decreases in summer when the electricity demand increases, creating inconvenient working load conditions [

5]. Consequently, part load working conditions and turbine isentropic efficiency deviations during the year have to be considered [

6].

Technical and economic parameters of geothermal applications can be improved through hybridization, coupling the geothermal source with other renewable sources. Most of the investigated hybrid geothermal case studies are thermal solar based. The Stillwater triple hybrid power plant, built by Enel Green Power, is a geothermal hybrid power plant with additional power provided by a CSP and PV field [

7]. Heberle et al. [

8] investigated the solar thermal retrofit of a binary geothermal application in Turkey. Here, hybridization regards superheating the working fluid before entering the turbine, improving annual power production. Ghasemi et al. [

6] also investigated a hybrid geothermal thermal solar solution, where solar power preheats geothermal water before entering the ORC unit.

Hybridization with biomass also represents a possible solution. Enel Green Power [

9] hybridized the existing geothermal power plant Cornia 2 with a biomass combustor, providing an overall power increase of 5 MW

el, superheating the dry steam before entering the turbine. Thain et al. [

10] investigated three different layouts at the power plant Rotokawa I, New Zealand. The most promising concept concerns a biomass system where the geothermal water preheats the combustion air, enhancing the overall thermal efficiency. Srinivas et al. [

11] investigated several hybrid biomass concepts with an extended focus on economic results.

In Germany, there are nowadays 9 running geothermal power plants with a total installed capacity of 37.13 MW

el, while the installed heat capacity is equal to 374 MW

th [

12]. In fact, the development of the ORC technology makes geothermal for electric power production feasible also in Germany, in spite of the lack of high enthalpy resources in shallow depth [

12].

In 2016, Bioenergy [

13] counted 8500 biogas installations in Germany with 4.5 GW as a total installed capacity. In the same year, the biogas electricity production in Germany was equal to 32,370 GWh, while heat production resulted in 17,437 GWh [

13]. Biogas is versatile, sustainable and can partially replace fossil fuels both in heat and power production, also being integrated in the existing natural gas grid and used as renewable vehicle fuel [

13]. In biogas installations, the generated thermal power is partially used for heating the digester but it can also be used for other agricultural applications such as drying or directly for heat production [

13]. Nevertheless, heating applications may encounter several obstacles, like high costs and a lack of a closely located heat demand. Therefore, producing additional electricity from waste heat is a valuable alternative.

Benato et al. [

14] investigated the use of an ORC unit for a 1 MW

el biogas engine waste heat recovery. According to thermodynamic results, toluene appeared as the most performing working fluid. Nevertheless, due to the very high inlet turbine temperature and to the very low condensing pressure, authors suggested benzene as the most suitable working fluid. Part load conditions, dynamic behavior and complete economic analysis are addressed in future works. David et al. [

15] investigated an ORC biogas waste heat recovery example producing 160 kW

el with a 20% thermal efficiency, using toluene as working fluid. The economic analysis highlights a payback period lower than five years, thanks to a special feed-in tariff available in France for this application.

Heberle et al. [

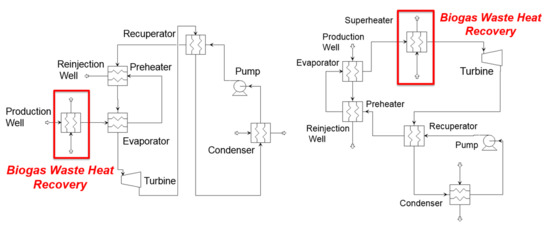

16] performed a techno-economic analysis of a hybrid binary geothermal power plant coupled with a biogas WHR, comparing hybrid and simple solutions in different CHP configuration (parallel and serial). Results demonstrated how hybrid solutions are promising concepts: The most performing case study is a hybrid CHP parallel circuit. Currently, there are no investigations providing results on flexible power generation, hybrid retrofit configurations and hybrid CHP layouts with an integrated real heat demand.

This paper is focused on the case study of a new-build hybrid binary geothermal power plant and biogas WHR is investigated according to boundary conditions available in Bavaria, Southern Germany. Two different hybrid power plant layouts are performed and the working fluid is selected in order to maximize the electric power generation.

The main objectives of this work are:

Techno-economic analysis of the new-build hybrid system in comparison to the geothermal-only one.

Investigation of flexible power generation (MRL).

Next to the new-build system, analysis of a hybrid retrofit one.

Analysis of a CHP configuration, according to the implementation of a real heat demand.

Hybridization is investigated in order to improve technical and economic parameters, comparing results of hybrid models to geothermal-only solutions. The considered models are evaluated also according to the switch-off of the second resource and to ambient temperature fluctuations during the year. Hybrid concept feasibility is analyzed also from the perspective of flexible power generation, considering the current requirements of the Minute reserve (MRL). Hybridization is investigated both as new-build configuration (first approach) and as retrofit solutions. In the end, also a CHP configuration is proposed.

4. Conclusions

In this work a new-build binary hybrid geothermal and biogas waste heat recovery application is investigated, according to boundary conditions related to Southern Germany. Considering on-design working load conditions, biogas WHR represents only 3.28% of the total available thermal power. Consequently, decoupling the second source does not profoundly influence off-design deviations. It is demonstrated that ambient temperature fluctuations deeply affect technical results during the year, as described by Toselli et al. [

25]. Nevertheless, hybridization represents an interesting step to improve the technical and economic performance compared to the geothermal-only case. In this context, the following points for the new-build hybrid system should be pointed out:

Furthermore, hybridization is analyzed from the perspective of flexible power generation:

According to the assumed boundary conditions, the proposed examples are not able to comply with the requirements of the minute reserve.

In order to meet the existing requirements, several solutions are suggested, such as adopting heat from the combustion of solid biomass as secondary source or implementing a thermal storage system. Additional flexible power generation can also be obtained by varying the ORC dynamic behavior.

Toselli et al. [

25] showed better power flexibility results considering the turbine off-design and fixed pinch points temperature in the heat exchangers.

The retrofit case study is mainly linked to the following points:

Finally, regarding the CHP-mode:

The economic analysis is developed without considering the economic impact of the biogas engine, as done by Heberle et al. [

16]. This hypothesis is assumed in order to highlight the direct effect of hybridization.

The LCOE in new-build power-only is 2.05 €ct/kWh lower than in new-build CHP-mode.

The new-build hybrid CHP-mode provides a higher BEP (+0.56 years) than in power-only configuration and comparable total revenues at the end of the investment.

According to a price of heat higher than 7 €ct/kWh, the BEP in geothermal-only example is comparable or even lower than in the new-build hybrid power-only. CHP configuration results reveal moderate improvements in the investment profitability.

In the meantime, the sensitivity on the cost of hybridization highlights no particular variations on the hybrid LCOE.

Hybridization feasibility firstly relies on the availability of both sources in the same location. Regardless, the presence of numerous biogas engines is demonstrated in Southern Germany [

29].

The economic feasibility of hybridization is strictly dependent on the assumed cost of maintenance, which can be reasonably lowered by exploiting possible synergies between the geothermal system and the biogas engine. In literature, there are currently no detailed economic data regarding this type of hybridization and related costs.

In this work, direct heat transfer from exhaust gases to geothermal water is assumed. In practice, the use of an internal loop with pressurized water or silicon oil may be suggested in order to reduce eventual thermal losses and optimize the area of heat exchangers. Dynamic calculations are addressed in future works; both biogas engines and ORC geothermal units are anyway able to provide fast ramps. In future works, the investigation of a real case study, both technically and economically, would represent an important step. Moreover, further calculations can be developed also according to different geothermal sources, such as dry steam reservoirs, increasing power plant thermal efficiency.