1. Introduction

The global energy demand is continuously rising due to an increase in population and economic development [

1]. Although enough energy sources (like hydro, wind, solar, geothermal) are available in the world to meet the constantly increasing demand, the depletion of fossil fuels and stochastic nature of intermittent renewable energy (IRE) sources pose challenges to the future acquisition of a sustainable system. Therefore, a hybrid energy system (HES) which involves the integration of multiple energy carriers (like electricity and heat) is becoming increasingly significant because it can counter-balance the drawbacks of these carriers [

2,

3]. Electricity and district heating contribute to the highest share of world’s energy demand, which is mostly used in household activities, industrial works and other purposes. Specifically, heat is the largest consumed energy carrier and 46% of heat is utilized in the residential sector, e.g., space and water heating. Heating in the residential sector in the UK accounts for 11% of greenhouse gas (GHG) emissions in the UK [

4]. It is estimated that individual heating in dwellings produces around 19% of global emissions [

5]. Consequently, other than electricity and district heating, individual heating is gaining attention in the context of a HES in order to protect the environment.

China is the world’s largest energy consumer and CO

2 emitter. The country has the second largest district heating grid and is shifting its focus towards a HES as well [

6,

7]. The Chinese government initiated the ‘Internet+smart energy’ project in 2015 that facilitates the integration of electricity, thermal energy and natural gas (Ngas) [

8]. Several pilot projects have already been completed in Jiaxing city (Zhejiang province), Qilian city (Qinghai province) and Shanghai (municipality). China’s residential energy demand has rapidly increased over the past two decades due to industrialization and an increase in income levels [

9]. Especially in the northern cities of China like Harbin, individual heating accounts for more than 30% of total heating demand in the residential sector [

10].

A hybrid energy system also plays a key role in increasing system efficiency and decreasing GHG emissions by reducing the dependency on widely used fossil fuel sources and easing out IRE integration [

11]. Technologies like the combined heat and power (CHP), energy storage (ES), electrolyser and heat pumps facilitate the integration of different energy carriers. These technologies not only increase the flexibility of the overall energy system but also help in balancing the fluctuations of IRE sources such as wind and solar photovoltaic (PV). The energy hub approach proposed by [

12] has become successful for the integration of HES. Moreover, energy storage has been extensively used to improve system resilience by mitigating the uncertainties and variability of IRE. Many storage technologies in HES have been used to cope with the stochastic nature of IRE and pumped hydro storage (PHS) is the most mature and well-established technology [

13]. Thermal storage like rockbed storage is becoming a viable choice to integrate IRE due to its fast transfer rate, higher thermal conductivity and low initial costs [

14].

Shafiqur R. et al. [

15] elaborated the technological review of PHS while Bjarne S. [

16] illustrates the development of PHS in Germany. The feasibility analysis of PHS for integrating renewable energy is proposed by [

17]. Rockbed heat transfer analysis is discussed in [

18] while the comprehensive review of such thermal storages and its role in integrating IRE is analyzed in [

19]. Individual and district heating comparisons are undertaken in [

20]. A new strategy for the European Union for Individual heat pumps and district heating is proposed by Connolly et al. [

21]. The role of micro-CHP (M-CHP) in increasing the utilization of available energy is proposed in [

22] while the role of an electrolyser in a HES for greenhouse heating is presented in [

23].

However, comprehensive individual heating planning by evaluating heat pumps, micro CHP and electrolyzers on a massive scale of the yearly hybrid energy system model are mostly neglected, especially in Asia. Thus far, around 90% of heat is produced by coal and Ngas boilers which are the main source of carbon emissions. Therefore, in order to fill the gap, this research aims to be the first study to investigate alternative individual heating scenarios of China in a HES to replace predominant fossil fuel boilers. Moreover, most of the PHS analysis studies for integrating IRE are limited to single penstock PHS that does not allow charging and discharging simultaneously. However, the simultaneous operation of turbine and pump is possible with double penstock which improves the performance of storage and allows more penetration of IRE.

This work conducts the technical analysis of both single and double penstock PHS using EnergyPLAN tool. Besides PHS, rockbed storage is also exploited to find the most economical and fossil-free alternative for integrating maximum renewable energy in HES. In this paper, electricity and heat energy data are collected to model HES of China for the year 2030 by using the smart energy hub approach in EnergyPLAN. A technical analysis of M-CHP, electrolysers and heat pumps in individual heating infrastructure is carried out to replace coal and Ngas boilers, which would help in achieving cleaner and cost-effective solutions. Simulation strategy 1 (balancing heat demand) is employed to find out prominent factors like annual costs, primary energy supply (PES) or fuel consumption and CO2 emissions. Moreover, energy storages such as rockbed storage, single and double penstock PHS are introduced in a HES to integrate the maximum amount of IRE by using simulation strategy 1 (balancing heat demand) and 2 (balancing both heat and electricity demand). These storage additions help in decarbonizing the atmosphere by reducing the dependency on fossil fuel sources. Besides the aforementioned factors (annual costs, PES, CO2 emissions) renewable energy share, critical excess and exportable excess are also determined for every storage.

The rest of the paper is organized as follows.

Section 2 elaborates methodology while

Section 3 describes data simulation required for HES modelling of China by 2030.

Section 4 and

Section 5 demonstrate different cases for individual heating and energy storages modelling.

Section 6 represents the results of the simulation and

Section 7 concludes the paper.

2. Methodology

The HES of China by the year 2030, that includes the electricity network, district heating network and individual heating network, has been analyzed using the EnergyPLAN software. EnergyPLAN was developed in 1999 by Henrik Lund and uses hourly steps to model regional or national energy systems; to date, 14 versions have been released [

24]. The deterministic nature of this tool always results in the same outputs against the same inputs. General inputs for this freeware energy analysis tool are demands (electricity, heating, cooling and so on), production component capacities (fossil fuels plants, renewable energy sources and so on), conversion unit capacities (electrolysers, CHP and so on), costs (investment costs, lifetime and percentage of investment) and different simulation strategies (technical simulation and market economic simulation). Annual production, energy balance, fuel consumption, emissions and import/export are the outputs of this model. The combination of object-oriented programming and integrated development environment known as Delphi Pascal programming is used to calculate the above outputs. EnergyPLAN is already a developed tool that has been used in modelling 100% renewable energy in countries like Ireland, Denmark, Croatia, Latvia, Netherland, Portugal, Macedonia and Finland [

25,

26,

27,

28,

29,

30,

31,

32]. This energy system analysis tool has already been used in Hong Kong energy modelling and several case studies of China including, Chongming, Beijing and Jiangsu province [

33,

34,

35,

36]. Further, EnergyPLAN has also exploited the role of district heating [

37,

38,

39,

40], CHP [

41,

42,

43] and vehicle to grid [

44,

45,

46,

47] in sustainable energy supply.

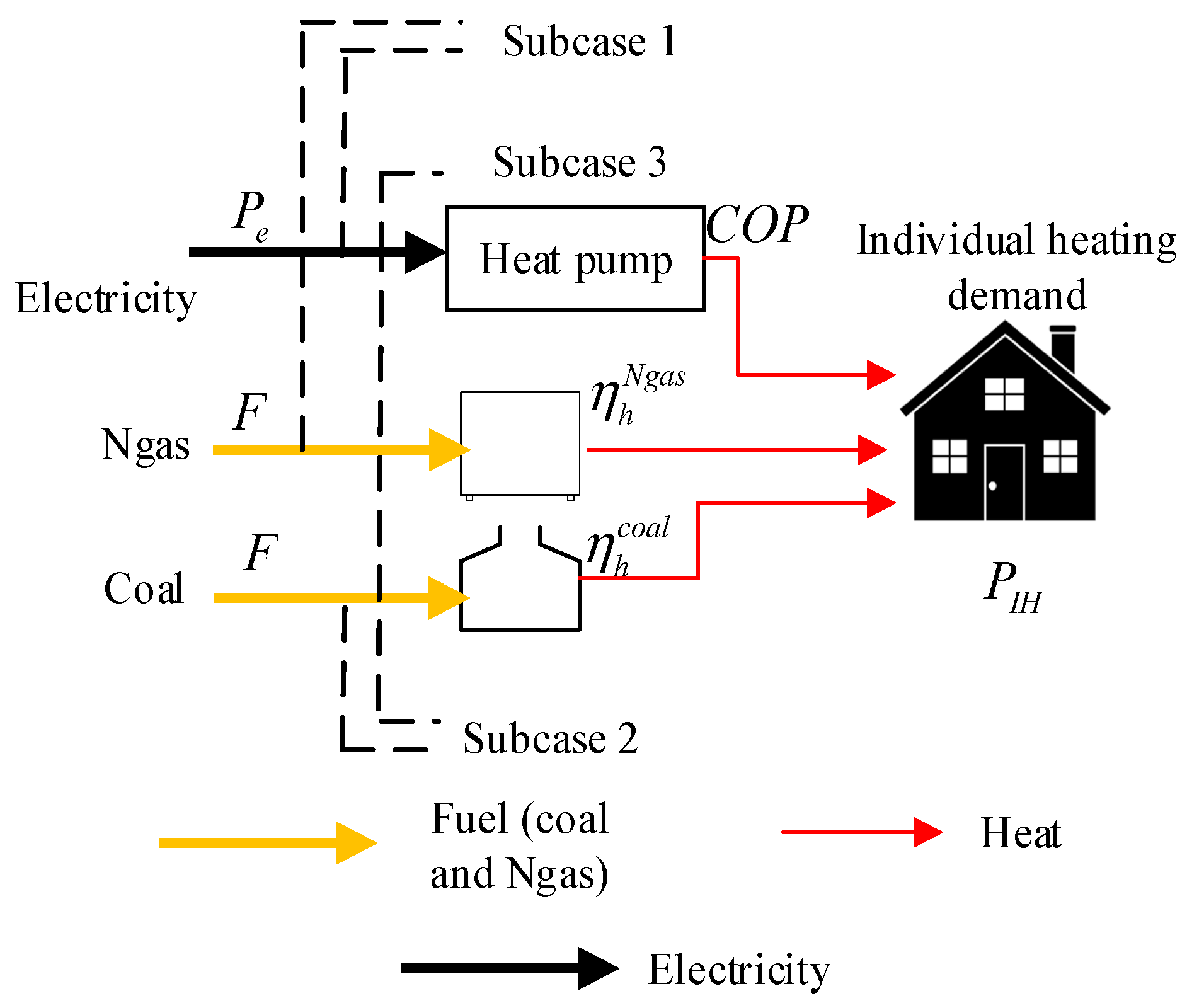

The utilization of various components, conversions from one form to another and the coordination of smart grids within the EnergyPLAN model makes this system a smart energy system that achieves higher efficiency with reduced costs and emissions. The proposed smart energy hub including inputs, outputs, converters and storages is illustrated in

Figure 1.

The above smart energy hub modelling of the electricity network, district heating network and energy constraints have already been proposed in our previous article [

48]. However, this work analyzes different cases of the individual heating scenario indicated with dashed lines in

Figure 1. Further, various energy storages like pumped hydro storage with single penstock, pumped hydro storage with double penstock and rock bed storages are also investigated to integrate the maximum share of renewable energy while making the system cost-effective as well. The technical simulation strategy is employed to find out the optimal combination of different storages. The operation of each component in the hub is defined to determine the least consuming option. Two different simulation strategies that are discussed below determines the following prominent factors like annual costs, fuel consumption, total emissions, renewable energy share, critical and exportable excess electricity.

(1) Technical simulation strategy 1

In this strategy, all units produce energy according to heat demands and condensing unit CHP do not operate according to variations of renewable energy sources. In this strategy, the units are given priority according to the following sequence: industrial CHP (CSHP), CHP units, heat pumps and peak load boilers.

(2) Technical simulation strategy 2

In this strategy, all units including CHP produce energy according to electricity and heat demands. The export of electricity is minimized using heat pumps at CHP plants which will increase electricity consumption and decrease the electricity production. Therefore, CHP units have to decrease heat production in order to fulfill the electricity demand.

In the aforementioned strategies, the proposed model also takes into account the following constraints:

- (i)

Conventionally, the system stability is maintained by large CHP and thermal power plants, unless one specifies that little percentage of renewable energy can also provide stabilization but only after eliminating the uncertainties associated with these sources by the help of energy storages. Therefore, during any hour the specified share of thermal power plants and CHP to keep the system stable falls below the prescribed percentage, EnergyPLAN shows the warning ‘grid stab. problem’ and if this warning is not addressed the system may lead to cascaded failure [

49,

50].

- (ii)

EnergyPLAN shows the ‘PP/import’ warning if during any hour there is not enough capacity to fulfill electricity demand.

- (iii)

It always makes sure during the modelling that the generated electricity does not increase beyond the transmission line capacity and this surplus electricity is represented by critical excess electricity production in EnegyPLAN.

3. Data for the Simulation Hybrid Energy System of China for 2030

The composite HES analysis is investigated in hourly steps resolution for the year 2030 by using the latest version (14) of EnergyPLAN [

24]. A lot of assumptions have been made by different researchers and organizations in order to predict future energy demands [

51,

52]. Nevertheless, the electricity demand for the year 2030 is estimated by taking a 1.5% annual increase rate, as this rate was suggested by the International Energy Agency from 2014–2030 for China’s national energy demand [

53]. Further, many state-owned websites [

54,

55], the China energy yearbook [

56], State Grid Corporation of China and China power industry statistics [

57] are used to collect initial data.

Based on [

53,

54,

55,

56,

57], electricity demand including losses and electric heating for the year 2030 is estimated to be 11,047 and 153 TWh/year respectively. Therefore, the total electricity demand of 11,200 TWh/year is fulfilled by renewable energy sources like wind and PV, geothermal, hydropower, CHP (which is represented by PP1 in EnergyPLAN), CSHP and thermal power plants (which is represented by PP2 in EnergyPLAN).

Figure 2 and

Figure 3 demonstrate the monthly electricity consumption for the specified year (2030) and production by the aforementioned sources.

District heating demand for 2030 which is met by boilers and CHP found out to be 1216 TWh/year [

52,

53,

56,

57]. Besides the district heating demand, individual heating also contributes to a considerable proportion of the total heating demand. The individual heating demand which is met by Ngas and coal boilers is 390 TWh/year that makes the total heating demand 1607 TWh/year. The monthly distribution of district and individual heating consumption and production by CHP and boilers are shown in

Figure 4.

Demand per building, which is used to calculate the number of households with individual heating, is assumed as 15,000 kWh/year and total Individual heating (390 TWh/year) also includes electric heating (153 TWh/year). The heat demand in individual houses is met by the following heat producing technologies:

Boilers than can be fired by Coal, oil and Ngas.

Micro CHP is fired by hydrogen or Ngas.

Heat pumps use electricity to generate heat.

District heating modelling and the analysis of alternate scenarios for reducing CO

2 emissions by taking into account cost analysis were addressed in our previous article [

48]. However, this work focuses on finding the optimal scenarios for individual heating infrastructure and observing the roles of different storages on the electricity network for integrating maximum renewable energy. All of the aforementioned heat producing components (1, 2 and 3) were analyzed by employing the technical simulation strategy 1 of EnergyPLAN.

The individual heating for 2030 using coal and Ngas boilers to meet heat demand is considered as the base case and the inputs of these boilers are shown in

Table 1.

Other than specifying demands, EnergyPLAN also requires a costs analysis of all the production components in order to perform technical simulation. These costs analyses include total investment costs, a lifetime of the respective production unit and the percentage of investment, which are shown in

Figure 5 and

Figure 6.

6. Results and Discussion

Energy planning is a critical area in order to analyze a future energy system by determining sustainable and flexible alternatives. This section demonstrates the quantitative comparisons of cleaner heating solutions in individual heating infrastructure. Moreover, it also finds the technically viable storage to integrate maximum variable renewable energy. Therefore, multiple individual heating cases and different storages technical analysis are carried out to attain a sustainable, economically viable and decarbonized solution.

6.1. Coal and Ngas Boilers in Individual Heating Infrastructure (Base Case)

Thermal efficiency and fuel inputs of coal and Ngas boilers are required to meet individual heat demand and all these specifications are listed in

Table 1.

Quantitative results of performance indicators such as total costs, PES and CO2 emissions calculated against the base case is calculated as 3246 GRMB, 47,324 TWh/year and 12,227 Mt respectively. The minimum condensing PP2 capacity requires the fulfillment of stabilizing units at 490,000 MWe. The maximum intermittent renewable electricity including wind and PV capacity is recorded as 407,616 and 38,899 MW.

6.2. Hydrogen Operated Micro CHP in Individual Heating Infrastructure (Case 1)

Micro CHP fired by hydrogen is a carbon-free alternative to coal and Ngas and it is becoming popular in Europe especially in the UK and Germany to provide space and water heating [

62,

63]. Therefore, this work explores the role of M-CHP in devising a non-fossil and low carbon heat policy for China.

The electrolyser minimum capacity when replacing with coal boilers and Ngas boilers are found out to be 94,616 and 77,810 MWe respectively which were calculated from Equations (6)–(11). The inclusion of H2 M-CHP, apart from producing individual heating, generates electricity as well that is mentioned in the previous section. As more electricity is generated, PP2 also has to increase its capacity in order to maintain the 30% stabilizing unit ratio. Therefore, PP2 is increased up to 541,777 and 531,971 MWe in Subcases 1 and 2. However, hydrogen-based M-CHP addition allows to penetrate more renewable energy that increases wind share up to 456,078 and 454,612 MW in both subcases. Subcase 3 is also considered but is not included in the research as it is not a feasible option because the size of electrolyzer required will be quite large when M-CHP replaces both coal and Ngas boilers. It will enormously increase the annual costs. The impact of including M-CHP on total costs, PES and CO

2-concentration for Subcases 1 and 2 are presented in

Table 5.

Coal boilers are the main source of emitting emissions and thereby replacing coal boilers with H2 M-CHP results in the least fuel consumption and case (47,230.73 TWh/year, 12,149.51 Mt) than base scenario (47,324.9 TWh/year, 12,227.47 Mt) and subcase 2 (47,406.26 TWh/year, 12,228.73 Mt). Micro CHP, in this case, is operated by hydrogen which is produced by electrolysers. These phenomena of producing hydrogen by electrolysis are more expensive than Ngas and cheap coal reservoirs; therefore, the total costs increases in both subcases of case 1 in comparison to the base case.

6.3. Natural Gas Operated Micro-CHP in Individual Heating Infrastructure (Case 2)

As it has been observed in the above case that M-CHP is technically feasible for energy savings and reducing emission intensity. Further, if M-CHP fuel is replaced with Ngas, it becomes economically optimal because of the higher efficiency and low investment costs [

18]. In this case, only the source of M-CHP from hydrogen is changed to Ngas as electrolysis phenomena are quite expensive so this case certainly helps more in reducing the total costs than case 1. Moreover,

Table 6 depicts a comparison of all three subcases of case 2 in order to find out the most cost-effective and most decarbonized subcase.

The addition of Ngas M-CHP decreases all three performance indicators more than the base case and case 1. The most economically feasible and less CO2 intensive emitter is Subcase 3 (when both coal and Ngas boilers are replaced with Ngas M-CHP) as it saves up to 57,056 million renminbi (MRMB) and decreases fuel consumption and CO2 emissions up to 225.17 TWh/year and 144.78 Mt of CO2 when compared with the base case. Further, Subcase 3 saves more than 129,136 MRMB in comparison to most economical subcase of case 1 (Ngas boilers are replaced with H2 M-CHP), and reduces fuel consumption and CO2 emissions up to 131 TWh/year and 66 Mt more than the most decarbonized subcase of case 1 (wherein coal boilers are replaced with H2 M-CHP).

6.4. Heat Pumps in Individual Heating Infrastructure (Case 3)

Besides using M-CHP for individual heating, electrification of heat by deploying heat pumps is also a good strategy to reduce reliance on fossil fuels and improve energy efficiency [

64]. It uses less energy than conventional heating systems and many European countries have set ambitious targets to develop a low carbon society by exploiting heat pumps [

65]. The comparison of all three subcases of case 3 is shown in

Table 7. The inclusion of heat pumps in this work increases annual costs due to the high capital costs associated with them. Nevertheless, with a higher efficiency than boilers, using electricity to produce heating decreases fuel consumption and CO

2 emissions not only in comparison to the base case, but also in comparison to all the subcases of cases 1 and 2.

Similar to case 2, subcase 3 proves out to be optimal as it reduces cost and emissions to minimum than Subcases 1 and 2.

A comparison of all the best cases (Subcase 2 of case 1, Subcase 3 of case 2 and Subcase 3 of case 3) is elaborated in the figure below (

Figure 12). Only case 1 not economical because the annual costs are increased more than the base case total costs, which are shown as negative, while in the remaining best cases all the eminent factors decrease.

The least-cost strategy is the inclusion of M-CHP (case 2) when replaced by both coal and Ngas boilers (Subcase 3) as it saves up to 57,056 MRMB. However, if the green atmosphere and reducing pollution is a priority, then the heat pump (case 3) replacement for both coal and Ngas boilers (subcase 3) is the best alternative solution, reducing fuel consumption up to 495 TWh/year and CO2 emissions up to 152.47 Mt.

6.5. Single Penstock Pumped Hydro Storage

The most mature and well-established technology to match the fluctuations of renewable energy storage is PHS [

13]. PHS usually has a single penstock that does not allow charging and discharging simultaneously. It charges during the night (when electricity prices are low) and discharges during high electricity demand in the day (when electricity prices are high). Although it facilitates renewable energy integration up to a certain limit, RES cannot provide grid stabilization.

Maximum RES generation in case of single PHS is 3157 TWh/year while total costs, PES and CO2 emissions are 3265 GRMB, 47,329 TWh/year and 12,229 Mt, respectively. Although there is not much difference in quantitative results for two different simulation strategies as strategy 2 slightly decreases objective functions in comparison to strategy 1. However, simulation strategy 1 in comparison to strategy 2 increases both CEEP and exportable excess electricity from 0 TWh/year to 1.07 and 1.2 TWh/year, respectively. Further, the maximum wind and PV penetration is reached up to 407,616 and 388,999 MW, respectively.

6.6. Double Penstock Pumped Hydro Storage

The implementation of double penstock PHS not only decreases the investment costs but also provides greater flexibility to integrate renewable energy [

66]. Therefore, renewable energy sources can replace conventional fossil fuel sources in order to offer grid stabilization if there is a possibility of charging and discharging PHS at the same time. Thus, PHS with the double penstock system provides this option, which not only facilitates RES integration, but also provides ancillary services that play an active role in grid stabilization. EnergyPLAN gives the option of PHS with double penstock by enabling the simultaneous operation of a turbine and pump in the energy storage tab. Therefore, by enabling this feature, it not only increases the flexibility by storing excess wind and balancing the electricity system, but also decreases all the prominent factors like annual costs, fuel consumption and CO

2 emissions. During this double penstock PHS operation (when the simultaneous operation of turbine and storage is allowed), the maximum wind that can integrate into the system is increased up to 442,115 MW and the maximum condensing PP2 share is decreased to 457,142 MW. Maximum RES generation in comparison to single penstock increases from 3157 to 3457 TWh/year and the quantitative results for other performance indicators (total costs, PES and CO

2 emissions) are 2866 GRMB, 44,328 TWh/year and 10,732 Mt.

In comparison to PHS with single penstock, RES generation is increased, therefore, it results in decreasing PES and CO2 emissions from 47,324 to 44,324 TWh/year and 12,277 to 10,727.47 Mt. Further, it also proves to be cost-effective as it saves up to 400 billion RMB (GRMB).

6.7. Rockbed Storage

In this work, high-temperature thermal rock bed storage uses electricity to generate steam for condensing PP2 and CHP that results in reducing fuel demands. Further, low investment costs also decrease the total annual costs [

19]. This storage is charged during excess electricity production and is therefore used to reduce critical excess and exportable excess electricity. Thus, this storage enables the accommodation of excess electricity in the form of steam and is fed to the condensing units (PP2 and CHP/PP1) which is represented by SHARERockbed in EnegyPLAN. It results in replacing the fuel consumption which is represented by

in

Table 4.

By replacing the PHS storage with rockbed storage and assuming the same capacity of PHS storage, all the prominent factors are calculated as 3095 GRMB annual costs, 47,329 TWh/year PES and Mt of 12,228 emissions.

As the capacity of rockbed storage is considered equal to PHS, so the maximum wind integration (407,616 MW) and RES generation (3157.61 TWh/year) remain the same. Likewise, the emission and total fuel consumption of PHS (single penstock) and rockbed storage are almost same, however, it decreases annual costs up to 3095 GRMB due to low investment cost.

To find out the most optimal storage: cost, emissions and fuel consumptions are evaluated for all three above mentioned cases. The comparisons between the above mentioned factors are illustrated in

Figure 13.

As can be seen in

Figure 13, PHS during the simultaneous operation of the turbine and pump reduces all the objective functions more than rockbed storage and PHS with a single penstock. However, PHS with double penstock integrates maximum amount of wind integration and also reduces PP2 share that’s why it results in least emission and cost. Nevertheless, considering the same storage capacity that integrates the same amount of RES, rockbed is considered more cost-effective than PHS (single penstock and double penstock) due to its cheaper initial investment cost than PHS.

7. Conclusions

This study applied the EnergyPLAN tool for the HES modelling of China for year 2030. Multiple storage options and different individual heating alternatives are investigated in order to integrate the maximum IRE share and to attain cleaner heating solutions. Two different simulation strategies are employed for the technical analysis of single penstock PHS, double penstock PHS and rockbed storages. The simultaneous activation of turbine and pump adds 34,499 MW more IRE share to the system while decreasing 3000 TWh/year fuel consumption and 1500 Mt emissions in comparison to rockbed and single penstock PHS. Rockbed storage decreases annual costs up to 3095 GRMB due to the low investment costs required whereas double penstock reduces annual costs up to 2865 GRMB because its simultaneous activation feature helps in integrating the maximum IRE as well as reducing condensing units share.

In addition, coal and Ngas boilers in heating infrastructure are used to meet individual heating demand which is considered as a base case for this work. To investigate the economic performance and low carbon alternatives, hydrogen-based M-CHP (case 1), Ngas M-CHP (case 2) and heat pumps (case 3) are included. Each of these three cases are further divided into three subcases that have been elaborated in

Section 4. Ngas M-CHP when replaced by both the coal and Ngas boilers (subcase 3 of case 2) of the base case is more cost-effective than the rest of the cases as it saves up to 57,056 MRMB. Nonetheless, the most decarbonized alternative method involves the addition of a heat pump because it decreases fuel consumption and emission up to 495 TWh/year and 152 Mt of CO

2 due to its higher efficiency than the boiler and M-CHP. These additions achieve substantial benefits in the electricity and heat network that not only improve energy security but also make the hybrid energy system fuel efficient and economically optimal.