Experimental Study on Temperature Change and Crack Expansion of High Temperature Granite under Different Cooling Shock Treatments

Abstract

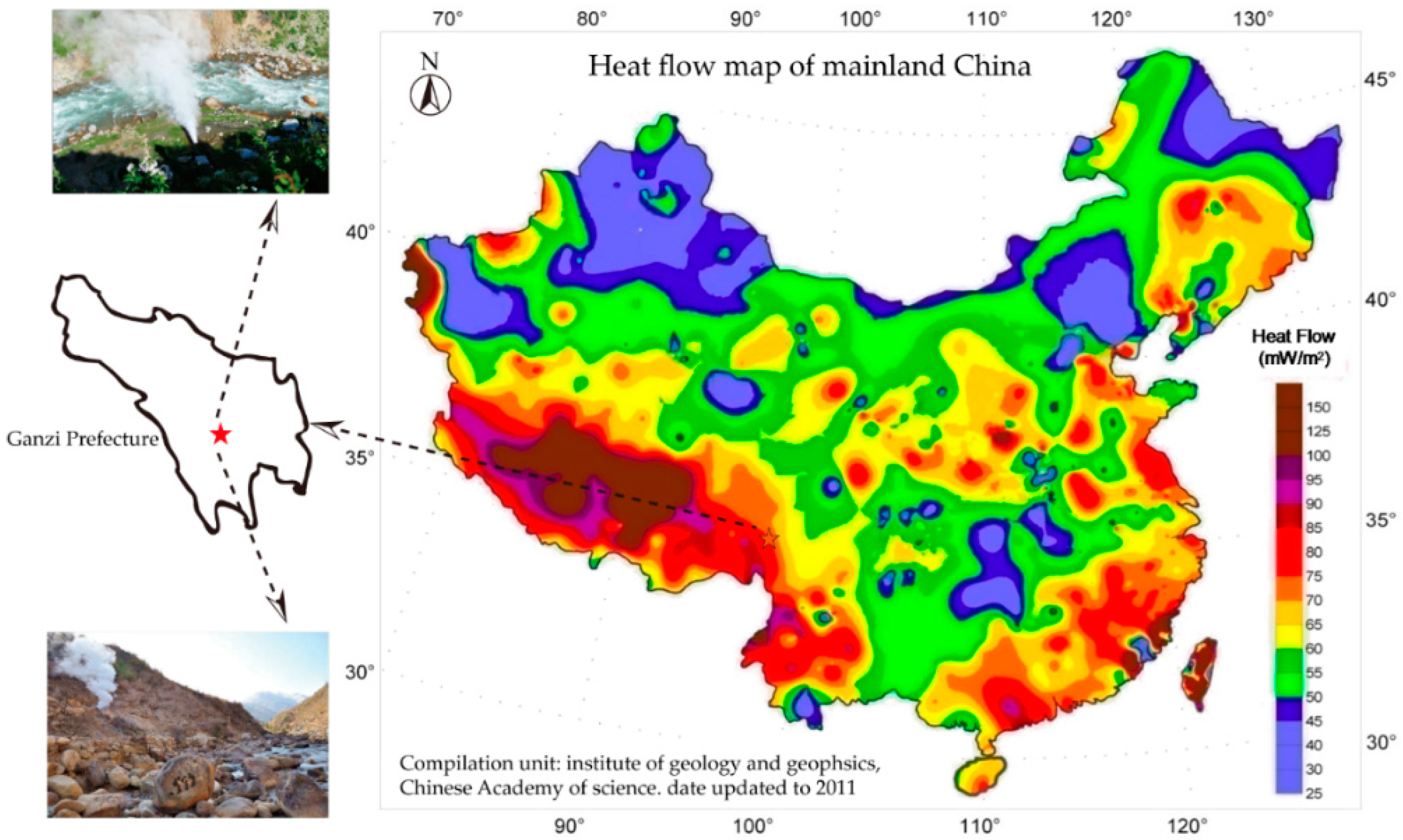

:1. Introduction

2. Materials and Methods

2.1. Rock Sample Preparation

2.2. Refrigerant Preparation

2.3. Test Equipment

3. Test Process

4. Test Results and Analysis

4.1. Comparisons of Temperature Change of High Temperature Granite under Different Cooling Shocks

4.2. Crack Expansion of High Temperature Granite under Different Cooling Shocks

4.2.1. Comparison of Cracking under Different Cooling Shocks at the Same Rock Temperature

4.2.2. Comparisons of Cracking of Different Rock Temperatures under the Same Cooling Shocks

5. Discussion

5.1. Analysis of the Effect of Cold Impact on High Temperature Granite

5.2. Application of Cold Shock Cracking in EGS

6. Conclusions

- (1)

- In the experiment regarding comparative analysis of the temperature-dependent evolution law of high-temperature granite under different cold impacts, it was seen that the dramatic changes cooling effect caused by the strong cooling shock on the high temperature granite usually occurred within the first 5 min of the rapid cooling phase, and when the temperature of the rock increased, the change was more significant and the occurrence time was shorter. Different cooling shocks occurred for approximately 120 min, and the trend of temperature changes and the trend of slow cooling were similar. From the temperature curves of the four groups of granites heated to different temperatures, the cold impact effects of the 550 °C and 750 °C granites were visibly greater than those of the 150 °C and 350 °C groups. Therefore, the temperature threshold for the cooling shock to have a significant cooling effect should be between 350 °C and 550 °C.

- (2)

- By studying the cracking conditions of high-temperature granite under a cooling shock, it can be seen that the effect of rapid cooling under cold impact on the cracking effect of high-temperature granite was much greater than that caused by slow cooling. In this study, granites with temperatures of 550 °C and 750 °C showed large through-cracks under the action of cooling shock at −30 °C, which indicated that the greater the temperature gradient generated, the more intense the damage was to the rock mass. The increase of cold impact resulted in internal shrinkage of the rock mass, external stretching, wider cracks, and denser mesh formed by microcracks. In the area affected by cooling shock, the closer the crack was to the cold impact source, the wider the crack width is, and the crack width gradually narrowed further away from the cold source. In the dynamic heat balance region, there was no large temperature gradient, and the development of cracks was generally relatively stable.

- (3)

- This study provides a new method of using cooling shock to crack rock masses in the establishment of dry heat rock reservoir area. It can be observed that crack expansion after cooling shock was much better. Therefore, to achieve significant cracks, we can consider replacing normal temperature fluid with a lower temperature fluid. In addition, cooling shock would cause wider cracks and denser microcracks, with the refrigerant liquid continuously flowing into these microcracks, such that these microcracks are further enlarged, the effect of cracking will be greatly improved, and the permeability will be increased, thereby extracting more heat. In addition, it can be seen from the test that microcracks caused by the slow cooling of rock were not as serious as those caused by rapid cooling; however, in the design and exploitation of deep thermal reservoirs, such as for geothermal energy, the effects of slow cooling on the rock mass near the thermal reservoir cannot be ignored.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rohde, R.; Muller, R.A.; Jacobsen, R.; Muller, E.; Wickham, C. A new estimate of the average earth surface land temperature spanning 1753 to 2011. Geoinfor. Geostat. Overv. 2013, 1. [Google Scholar] [CrossRef]

- Solomon, S.; Qin, D.; Manning, M.; Chen, Z.; Margiquis, M.; Averyt, K.B.; Tignor, M.; Miller, H.L. Climate Change 2007: The Physical Science Basis, Contribution of Working Group to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change (IPCC); Cambridge University Press: Cambridge, UK, 2007; pp. 434–497. [Google Scholar]

- Clauser, C.; Ewert, M. The renewables cost challenge: Levelized cost of geothermal electric energy compared to other sources of primary energy—Review and case study. Renew. Sustain. Energy Rev. 2018, 82, 3683–3693. [Google Scholar] [CrossRef]

- Speight, J. Geothermal energy: Renewable energy and the environment, second edition, by William E. Glassley. Energy Sources 2015, 37, 2039. [Google Scholar] [CrossRef]

- Shen, Y.J.; Wang, Y.Z.; Yang, Y.; Sun, Q.; Luo, T.; Zhang, H. Influence of surface roughness and hydrophilicity on bonding strength of concrete-rock interface. Constr. Build. Mater. 2019, 213, 156–166. [Google Scholar] [CrossRef]

- Oganov, A.R. Thermodynamics, phase transitions, equations of state, and elasticity of minerals at high pressures and temperatures. Treatise Geophys. 2015, 2, 179–202. [Google Scholar] [CrossRef]

- Yang, S.Q.; Ranjith, P.G.; Jing, H.-W.; Tian, W.-L.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Yin, T.B.; Shu, R.H.; Li, X.B.; Wang, P.; Liu, X.L. Comparison of mechanical properties in high temperature and thermal treatment granite. Trans. Nonferrous Metals Soc. China 2016, 26, 1926–1937. [Google Scholar] [CrossRef]

- Guo, L.-L.; Zhang, Y.-B.; Zhang, Y.-J.; Yu, Z.-W.; Zhang, J.-N. Experimental investigation of granite properties under different temperatures and pressures and numerical analysis of damage effect in enhanced geothermal system. Renew. Energy 2018, 126, 107–125. [Google Scholar] [CrossRef]

- Araújo, R.G.S.; Sousa, J.L.A.O.; Bloch, M. Experimental investigation on the influence of temperature on the mechanical properties of reservoir rocks. Int. J. Rock Mech. Min. 1997, 34, 2980.e1–2980.e16. [Google Scholar] [CrossRef]

- Huang, Y.H.; Yang, S.Q.; Hall, M.R.; Tian, W.L.; Yin, P.F. Experimental study on uniaxial mechanical properties and crack propagation in sandstone containing a single oval cavity. Arch. Civ. Mech. Eng. 2018, 18, 1359–1373. [Google Scholar] [CrossRef]

- Zhang, P.; Mishra, B.; Heasley, K.A. Experimental investigation on the influence of high pressure and high temperature on the mechanical properties of deep deservoir rocks. Rock Mech. Rock Eng. 2015, 48, 2197–2211. [Google Scholar] [CrossRef]

- Freire-Lista, D.M.; Fort, R.; Varas-Muriel, M.J. Thermal stress-induced microcracking in building granite. Eng. Geol. 2016, 206, 83–93. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.F.; Bonner, B.P.; Carlson, S.R.; Kowallis, B.J.; Heard, H.C. Thermal stress cracking in granite. J. Geophys. Res. 1989, 94, 1745. [Google Scholar] [CrossRef]

- Zhao, Z. Thermal influence on mechanical properties of granite: A microcracking perspective. Rock Mech. Rock Eng. 2015, 49, 747–762. [Google Scholar] [CrossRef]

- Hosseini, M. Effect of temperature as well as heating and cooling cycles on rock properties. J. Min. Environ. 2017, 8, 631–644. [Google Scholar] [CrossRef]

- Thirumalai, K.; Demou, S.G. Thermal expansion behavior of intact and thermally fractured mine rocks. Evolution 1974, 53, 147–156. [Google Scholar] [CrossRef]

- Griffiths, L.; Lengliné, O.; Heap, M.J.; Baud, P.; Schmittbuhl, J. Thermal cracking in westerly granite monitored using direct wave velocity, coda wave interferometry, and acoustic emissions. J. Geophys. Res. Solid Earth 2018. [Google Scholar] [CrossRef]

- Todd, T.P. Effect of Cracks on Elastic Properties of Low Porosity Rocks; Massachusetts Institute of Technology: Cambridge, MA, USA, 1973. [Google Scholar]

- Isaka, B.; Gamage, R.; Rathnaweera, T.; Perera, M.; Chandrasekharam, D.; Kumari, W. An influence of thermally-induced micro-cracking under cooling treatments: Mechanical characteristics of Australian granite. Energies 2018, 11, 1338. [Google Scholar] [CrossRef]

- Kim, K.; Kemeny, J.; Nickerson, M. Effect of rapid thermal cooling on mechanical rock properties. Rock Mech. Rock Eng. 2013, 47, 2005–2019. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K.; Abdulagatov, I.M. Temperature-dependent mechanical behaviour of Australian Strathbogie granite with different cooling treatments. Eng. Geol. 2017, 229, 31–44. [Google Scholar] [CrossRef]

- Shao, S.; Wasantha, P.L.P.; Ranjith, P.G.; Chen, B.K. Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int. J. Rock Mech. Min. 2014, 70, 381–387. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K. Experimental investigation of quenching effect on mechanical, microstructural and flow characteristics of reservoir rocks: Thermal stimulation method for geothermal energy extraction. J. Petrol. Sci. Eng. 2018, 162, 419–433. [Google Scholar] [CrossRef]

- Siratovich, P.A.; Villeneuve, M.C.; Cole, J.W.; Kennedy, B.M.; Bégué, F. Saturated heating and quenching of three crustal rocks and implications for thermal stimulation of permeability in geothermal reservoirs. Int. J. Rock Mech. Min. 2015, 80, 265–280. [Google Scholar] [CrossRef]

- Cai, C.; Li, G.; Huang, Z.; Tian, S.; Shen, Z.; Fu, X. Experiment of coal damage due to super-cooling with liquid nitrogen. J. Nat. Gas Sci. Eng. 2015, 22, 42–48. [Google Scholar] [CrossRef]

- Li, R.; Huang, Z.; Wu, X.; Yan, P.; Dai, X. Cryogenic quenching of rock using liquid nitrogen as a coolant: Investigation of surface effects. Int. J. Heat Mass Transf. 2018, 119, 446–459. [Google Scholar] [CrossRef]

- Wu, X.G.; Huang, Z.W.; Li, R.; Zhang, S.K.; Wen, H.T.; Huang, P.P.; Dai, X.; Zhang, C. Investigation on the damage of high-temperature shale subjected to liquid nitrogen cooling. J. Nat. Gas Sci. Eng. 2018, 57, 284–294. [Google Scholar] [CrossRef]

- Hou, J.; Cao, M.; Liu, P. Development and utilization of geothermal energy in China: Current practices and future strategies. Renew. Energy 2018, 125, 401–412. [Google Scholar] [CrossRef]

- Zuo, J.P.; Xie, H.P.; Zhou, H.W.; Peng, S.P. Experimental research on thermal cracking of sandstone under different temperature. Chin. J. Geophys. 2007, 50, 1150–1155. [Google Scholar] [CrossRef]

- Abdallah, G.; Thoraval, A.; Sfeir, A.; Piguet, J.P. Thermal convection of fluid in fractured media. Int. J. Rock Mech. Min. 1995, 32, 481–490. [Google Scholar] [CrossRef]

- Tang, S.B.; Zhang, H.; Tang, C.A.; Liu, H.Y. Numerical model for the cracking behavior of heterogeneous brittle solids subjected to thermal shock. Int. J. Solids Struct. 2016, 80, 520–531. [Google Scholar] [CrossRef]

- Vosteen, H.D.; Schellschmidt, R. Influence of temperature on thermal conductivity, thermal capacity and thermal diffusivity for different types of rock. Phys. Chem. Earth Parts A/B/C 2003, 28, 499–509. [Google Scholar] [CrossRef]

- Kitao, K.; Ariki, K.; Hatakeyama, K.; Wakita, K. Well stimulation using cold-water injection experiments in the Sumikawa geothermal field, Akita prefecture, Japan Transactions. In Proceedings of the Geothermal Resources Council 1990 Annual Meeting, Kailua-Kona, HI, USA, 20–24 August 1990; Volume 14, pp. 1219–1224. [Google Scholar]

- Olsson, R.; Barton, N. An improved model for hydromechanical coupling during shearing of rock joints. Int. J. Rock Mech. Min. 2001, 38, 317–329. [Google Scholar] [CrossRef]

- Freire-Lista, D.M.; Fort, R. Exfoliation microcracks in building granite. Implications for anisotropy. Eng. Geol. 2017, 220, 85–93. [Google Scholar] [CrossRef] [Green Version]

- Chaki, S.; Takarli, M.; Agbodjan, W.P. Influence of thermal damage on physical properties of a granite rock: Porosity, permeability and ultrasonic wave evolutions. Constr. Build. Mater. 2008, 22, 1456–1461. [Google Scholar] [CrossRef]

- Zhang, B.T.; Ling, G.F.; Wu, J.Q. New thinking, method and calculated examples of high temperature thermochronology of granite plutons. J. Geo. Chin. Univ. 2013, 19, 385–402. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, Z.; Xi, B.; Wan, Z.; Yang, D.; Liang, W. Deformation and instability failure of borehole at high temperature and high pressure in hot dry rock exploitation. Renew. Energy 2015, 77, 159–165. [Google Scholar] [CrossRef]

- Shen, Y.J.; Zhang, Y.L.; Gao, F.; Yang, G.S.; Lai, X.P. Influence of temperature on the microstructure deterioration of sandstone. Energies 2018, 11, 1753. [Google Scholar] [CrossRef]

- Shen, Y.J.; Yang, Y.; Yang, G.S.; Hou, X.; Ye, W.J.; You, Z.M.; Xi, J.M. Damage characteristics and thermo-physical properties changes of limestone and sandstone during thermal treatment from −30 °C to 1000 °C. Heat Mass Transf. 2018, 54, 3389–3407. [Google Scholar] [CrossRef]

- Zhao, Z. On the heat transfer coefficient between rock fracture walls and flowing fluid. Comput. Geotech. 2014, 59, 105–111. [Google Scholar] [CrossRef]

- Al-Rbeawi, S. How much stimulated reservoir volume and induced matrix permeability could enhance unconventional reservoir performance. J. Nat. Gas. Sci. Eng. 2017, 46, 764–781. [Google Scholar] [CrossRef]

- O’Sullivan, M.J.; Pruess, K.; Lippmann, M.J. State of the art of geothermal reservoir simulation. Geothermics 2001, 30, 395–429. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Li, X.; Li, L.H.; Chen, B.K.; Avanthi Isaka, B.L.; de Silva, V.R.S. Hydraulic fracturing under high temperature and pressure conditions with micro CT applications: Geothermal energy from hot dry rocks. Fuel 2018, 230, 138–154. [Google Scholar] [CrossRef]

| Test Material | Sample Size (L × H × T) (mm) | Hole Size (Φ × H) (mm) | Temperature Gradient (°C) |

|---|---|---|---|

| Granite | 100 × 100 × 100 | 30 × 80 | 150, 350, 550, 750 |

| Refrigerant | - | - | 20, 0, −30 |

| Granite Temperature (°C) | Refrigerant Temperature (°C) | Initial Temperature (°C) | Minimum Temperature (°C) | Cooling Ratio (%) | Maximum Temperature (°C) | Heating Ratio (%) |

|---|---|---|---|---|---|---|

| 150 | 20 | 148 | 92.3 | 37.6 ↓ | 103.5 | 12.1 ↑ |

| 0 | 148 | 81.2 | 45.1 ↓ | 93.5 | 15.1 ↑ | |

| −30 | 148 | 73.3 | 50.5 ↓ | 85 | 16.0 ↑ | |

| 350 | 20 | 345 | 101.4 | 70.6 ↓ | 198.8 | 96.1 ↑ |

| 0 | 346 | 93.1 | 73.1 ↓ | 188.9 | 102.9 ↑ | |

| −30 | 344 | 83.5 | 75.7 ↓ | 181 | 116.8 ↑ | |

| 550 | 20 | 543 | 142.3 | 73.8 ↓ | 401 | 181.8 ↑ |

| 0 | 540 | 128.7 | 76.2 ↓ | 389 | 202.3 ↑ | |

| −30 | 541 | 113.4 | 79.0 ↓ | 369 | 225.4 ↑ | |

| 750 | 20 | 742 | 162 | 78.2 ↓ | 524 | 223.5 ↑ |

| 0 | 741 | 142.2 | 80.8 ↓ | 511 | 259.4 ↑ | |

| −30 | 740 | 130.4 | 82.4 ↓ | 492 | 277.3 ↑ |

| Temperature | Natural Cooling | Refrigerant (20 °C) | Refrigerant (0 °C) | Refrigerant (−30 °C) |

|---|---|---|---|---|

| Granite (150 °C) |  |  |  |  |

| Granite (350 °C) |  |  |  |  |

| Granite (550 °C) |  |  |  |  |

| Granite (750 °C) |  |  |  |  |

| Granite Temperature | Refrigerant Temperature | Cracking Condition |

|---|---|---|

| 150 °C | 20 °C | No crack |

| 0 °C | No crack | |

| −30 °C | No crack | |

| 350 °C | 20 °C | No crack |

| 0 °C | A few small cracks | |

| −30 °C | A few small cracks | |

| 550 °C | 20 °C | Small cracks |

| 0 °C | Small cracks and a large through-going fracture | |

| −30 °C | Many large through-going fractures | |

| 750 °C | 20 °C | Many small cracks |

| 0 °C | Many small cracks and a large through-going fracture | |

| −30 °C | Many small cracks and many large through-going fractures |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.-J.; Hou, X.; Yuan, J.-Q.; Zhao, C.-H. Experimental Study on Temperature Change and Crack Expansion of High Temperature Granite under Different Cooling Shock Treatments. Energies 2019, 12, 2097. https://doi.org/10.3390/en12112097

Shen Y-J, Hou X, Yuan J-Q, Zhao C-H. Experimental Study on Temperature Change and Crack Expansion of High Temperature Granite under Different Cooling Shock Treatments. Energies. 2019; 12(11):2097. https://doi.org/10.3390/en12112097

Chicago/Turabian StyleShen, Yan-Jun, Xin Hou, Jiang-Qiang Yuan, and Chun-Hu Zhao. 2019. "Experimental Study on Temperature Change and Crack Expansion of High Temperature Granite under Different Cooling Shock Treatments" Energies 12, no. 11: 2097. https://doi.org/10.3390/en12112097