Slip Control of a Squirrel Cage Induction Generator Driven by an Electromagnetic Frequency Regulator to Achieve the Maximum Power Point Tracking

Abstract

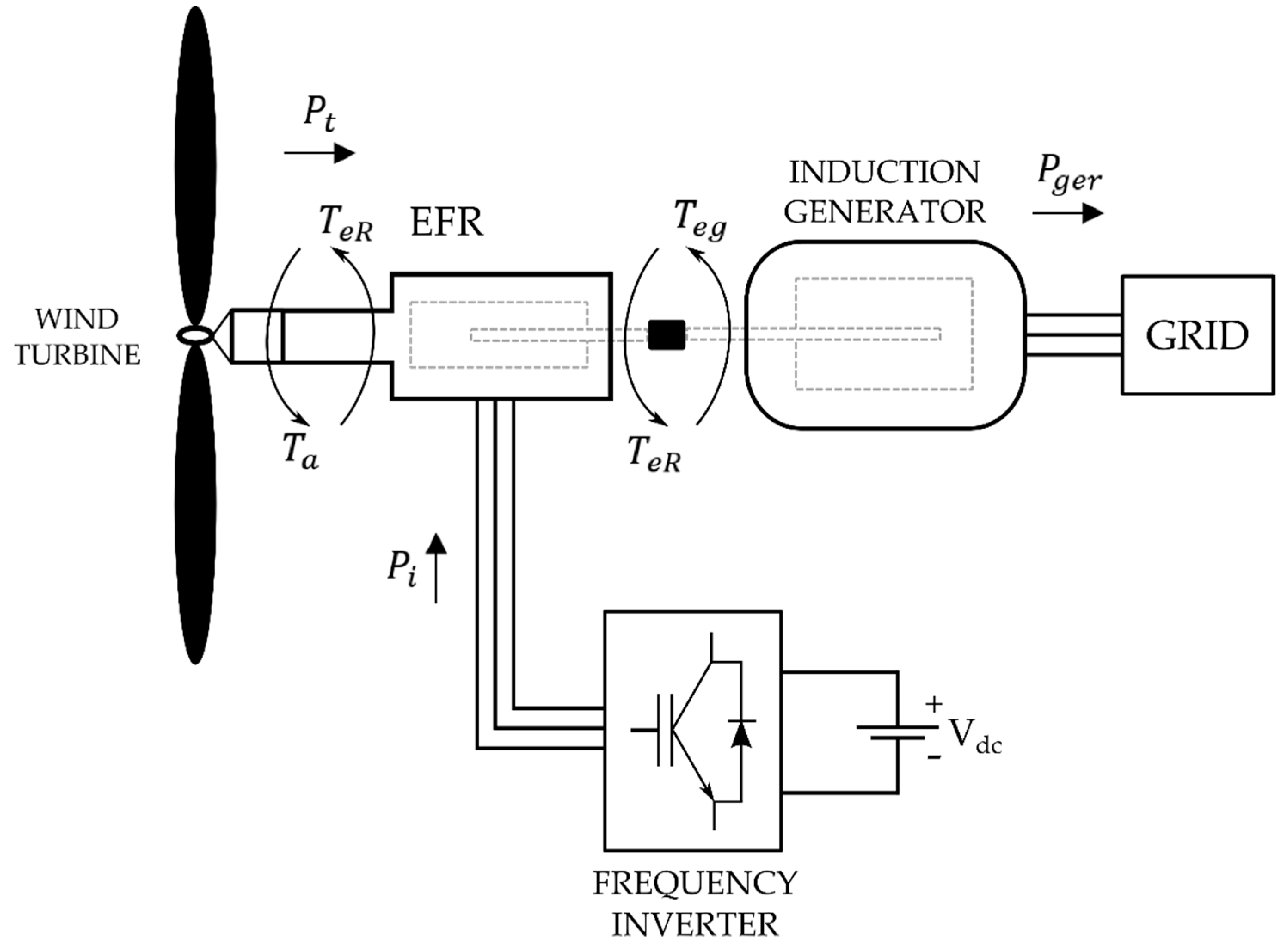

1. Introduction

2. Mathematical Modeling of the System

2.1. Horizontal Axis Wind Turbine

2.2. Induction Generator

2.3. Electromagnetic Frequency Regulator

3. Control Strategy

4. Results

4.1. Steady State Analysis

4.2. Dynamic Analysis

4.2.1. Step Response

4.2.2. Wind Speed Variations

- The initial average value of the wind speed

- A ramp component

- A gust component

- Turbulence

4.2.3. The Fault-Ride-Through Capability

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Turbine mechanical power | |

| Air density | |

| Radius of the blade | |

| Turbine Power Coefficient | |

| Wind speed | |

| Tip-Speed Ratio | |

| Turbine angular speed | |

| Blade pitch angle | |

| Turbine mechanical torque | |

| , | Voltage in d and q axes of the stator |

| Stator resistance | |

| , | Electrical current in the d and q axes of the stator |

| Synchronous angular frequency | |

| , | Flux linkage in the d and q axes of the stator |

| , | Voltage in d and q axes of the rotor |

| Rotor resistance | |

| , | Electrical current in the d and q axes of the rotor |

| Number of poles of the machine | |

| Angular speed of rotor shaft | |

| , | Flux linkage in the d and q axes of the rotor |

| Self-inductance of any stator winding | |

| Self-inductance of any rotor winding | |

| Mutual inductance between any two windings in the stator | |

| Mutual inductance between any two windings in the rotor | |

| Maximum mutual inductance between stator and rotor windings | |

| Inertia of the rotor | |

| Electromagnetic torque | |

| Mechanical torque | |

| Rotor friction constant | |

| Gearbox ratio | |

| Angular speed of the EFR’s armature | |

| Mechanical torque at the EFR’s armature | |

| , | Voltage in d and q axes of the EFR’s armature |

| , | Electrical current in the d and q axes of the EFR’s armature |

| , | Flux linkage in the d and q axes of the EFR’s armature |

| Inverter voltage pulsation | |

| , | Voltage in d and q axes of the EFR’s rotor |

| , | Electrical current in the d and q axes of the EFR’s rotor |

| , | Flux linkage in the d and q axes of the EFR’s rotor |

| Sum of inertia of the EFR’s rotor with the inertia of induction generator rotor | |

| Electromagnetic torque developed in the EFR | |

| Electromagnetic torque in the induction generator | |

| Inertia of the turbine added to the inertia of the rotating armature | |

| Turbine friction constant | |

| Synchronous angular mechanical speed | |

| number of phases of the induction generator | |

| Slip of the induction generator | |

| Reactance of the rotor windings | |

| Grid phase voltage | |

| Magnetizing reactance | |

| Reactance of the stator windings |

References

- Renewable Energy Policy Network for the 21 Century. Global Status Report. 2018. Available online: http://www.ren21.net/gsr-2018 (accessed on 29 June 2018).

- International Renewable Energy Agency. Renewable Capacity Statistics. 2018. Available online: http://www.irena.org/publications/2018/Mar/ Renewable-Capacity-Statistics-2018 (accessed on 29 June 2018).

- Sharkawi, M.A.E. Overview of Wind Turbines. In Wind Energy: An Introduction, 1st ed.; CRC Press: New York, NY, USA, 2016; ISBN 978-1-4822-6400-5. [Google Scholar]

- Vasconcelos, C.H.S.; Ferreira, A.C.; Stephan, R.M. Wind turbine generator system based on Cascaded Doubly Fed Induction Generator. In Proceedings of the 2015 IEEE 13th Brazilian Power Electronics Conference and 1st Southern Power Electronics Conference, Fortaleza, Brazil, 29 November–2 December 2015. [Google Scholar]

- Löhdefink, P.; Dietz, A.; Möckel, A. Modeling and power flow analysis of cascaded doubly-fed induction machines. In Proceedings of the 2015 5th International Electric Drives Production Conference, Nuremberg, Germany, 15–16 September 2015. [Google Scholar]

- Li, J.; Chau, K.T.; Jiang, Z.; Liu, C.; Li, W. A New Efficient Permanent-Magnet Vernier Machine for Wind Power Generation. IEEE Trans. Magn. 2010, 46, 1475–1478. [Google Scholar] [CrossRef]

- Jamil, M.; Gupta, R.; Singh, M. A review of power converter topology used with PMSG based wind power generation. In Proceedings of the 2012 IEEE Fifth Power India Conference, Murthal, India, 19–22 Decmber 2012. [Google Scholar]

- Geliel, M.A.; Zidane, I.F.; Anany, M.; Rezeka, S.F. Modeling and simulation of a hybrid power generation system of wind turbine, micro-turbine and solar heater cells. In Proceedings of the 11th IEEE International Conference on Control & Automation, Taichung, Taiwan, 18–20 June 2014; pp. 1304–1309. [Google Scholar]

- Kalaivani, C.; Divyalakshmi, D.; Subramaniam, N.P. A standalone hybrid power generation system. In Proceedings of the 2017 International Conference on Computation of Power, Energy Information and Communication, Melmaruvathur, India, 22–23 March 2017; pp. 800–806. [Google Scholar]

- Daniel, S.A.; AmmasaiGounden, N. A novel hybrid isolated generating system based on PV fed inverter-assisted wind-driven induction Generators. IEEE Trans. Energy Convers. 2004, 19, 416–422. [Google Scholar] [CrossRef]

- Liu, C.; Chau, K.T.; Zhang, X. An Efficient Wind–Photovoltaic Hybrid Generation System Using Doubly Excited Permanent-Magnet Brushless Machine. IEEE Trans. Ind. Electron. 2010, 57, 831–839. [Google Scholar]

- Verma, A.; Chakraborti, A.; Das, B.; Kasari, P.R.; Mishra, M.; Pal, S. A new topology for hybrid wind-solar generation system for isolated loads. In Proceedings of the 2018 International Conference on Power, Instrumentation, Control and Computing, Thrissur, India, 18–20 January 2018. [Google Scholar]

- Silva, P.V.; Pinheiro, R.F.; Salazar, A.O.; Santos, L.P., Jr.; Azevedo, C.C. A proposal for a New Wind Turbine Topology Using an Electromagnetic Frequency Regulator. IEEE Latin Am. Trans. 2015, 13, 989–997. [Google Scholar] [CrossRef]

- Silva, P.V.; Pinheiro, R.F.; Salazar, A.O.; Fernandes, J.D. Performance analysis of a new system for speed control in wind turbines. Int. Conf. Renew. Energies Power Q. 2015, 13, 445–460. [Google Scholar] [CrossRef]

- You, R.; Barahona, B.; Chai, J.; Cutululis, N.A. A Novel Wind Turbine Concept Based on an Electromagnetic Coupler and the Study of Its Fault Ride-through Capability. Energies 2013, 6, 6120–6136. [Google Scholar] [CrossRef]

- García, H.; Segundo, J.; Rodríguez-Hernández, O.; Campos-Amezcua, R.; Jaramillo, O. Harmonic Modelling of the Wind Turbine Induction Generator for Dynamic Analysis of Power Quality. Energies 2018, 11, 104. [Google Scholar] [CrossRef]

- Kolesnik, S.; Kuperman, A. Analytical Derivation of Electrical-Side Maximum Power Line for Wind Generators. Energies 2017, 10, 1498. [Google Scholar] [CrossRef]

- Chavira, F.; Ortega-Cisneros, S.; Rivera, J. A Novel Sliding Mode Control Scheme for a PMSG-Based Variable Speed Wind Energy Conversion System. Energies 2017, 10, 1476. [Google Scholar] [CrossRef]

- Ackermann, T. Wind Power in Power Systems; John Wiley & Sons Ltd.: Chichester, UK, 2005; ISBN 0-470-85508-8. [Google Scholar]

- Kundur, P. Power System Stability and Control; McGraw-Hill: New York, NY, USA, 1994; ISBN 0-07-035958-X. [Google Scholar]

- Yang, X.; Liu, G.; Li, A.; Le, V.D. A Predictive Power Control Strategy for Ds Based on a Wind Energy Converter System. Energies 2017, 10, 1098. [Google Scholar] [CrossRef]

- Fitzgerald, A.E.; Kingsley, C., Jr.; Umans, S.D. Máquinas Elétricas, 6th ed.; Bookman: Porto Alegre, Brazil, 2006; pp. 310–313. ISBN 85-60031-04-9. [Google Scholar]

- Duong, M.Q.; Leva, S.; Mussetta, M.; Le, K.H. A Comparative Study on Controllers for Improving Transient Stability of DFIG Wind Turbines During Large Disturbances. Energies 2018, 11, 480. [Google Scholar] [CrossRef]

- Slootweg, J.G. Wind Power: Modelling and Impact on Power System Dynamics. Ph.D. Thesis, Technische Universiteit Delft, Delft, The Netherlands, 2003. [Google Scholar]

- Iov, F.; Hansen, A.D.; Sørensen, P.E.; Cutululis, N.A. Mapping of Grid Faults and Grid Codes; Forskningscenter Risoe. Risoe-R, 1617(EN); Risø National Laboratory: Roskilde, Denmark, 2007. [Google Scholar]

| Parameter | Value | Unity |

|---|---|---|

| Number of poles | 4 | - |

| Armature resistance | 0.01 | p.u. |

| Rotor resistance | 0.01 | p.u. |

| Armature leakage inductance | 0.10 | p.u. |

| Rotor leakage inductance | 0.08 | p.u. |

| Mutual inductance | 3.0 | p.u. |

| Inertia constant | 0.5 | s |

| Parameter | Value | Unity |

|---|---|---|

| Diameter | 90 | m |

| Gearbox ratio | 100 | - |

| Nominal turbine speed | 18 | RPM |

| Nominal wind speed | 11 | m/s |

| Inertia constant | 2.5 | s |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos, T.; Medeiros Júnior, M.F.; Pinheiro, R.; Medeiros, A. Slip Control of a Squirrel Cage Induction Generator Driven by an Electromagnetic Frequency Regulator to Achieve the Maximum Power Point Tracking. Energies 2019, 12, 2100. https://doi.org/10.3390/en12112100

Ramos T, Medeiros Júnior MF, Pinheiro R, Medeiros A. Slip Control of a Squirrel Cage Induction Generator Driven by an Electromagnetic Frequency Regulator to Achieve the Maximum Power Point Tracking. Energies. 2019; 12(11):2100. https://doi.org/10.3390/en12112100

Chicago/Turabian StyleRamos, Thales, Manoel F. Medeiros Júnior, Ricardo Pinheiro, and Arthur Medeiros. 2019. "Slip Control of a Squirrel Cage Induction Generator Driven by an Electromagnetic Frequency Regulator to Achieve the Maximum Power Point Tracking" Energies 12, no. 11: 2100. https://doi.org/10.3390/en12112100

APA StyleRamos, T., Medeiros Júnior, M. F., Pinheiro, R., & Medeiros, A. (2019). Slip Control of a Squirrel Cage Induction Generator Driven by an Electromagnetic Frequency Regulator to Achieve the Maximum Power Point Tracking. Energies, 12(11), 2100. https://doi.org/10.3390/en12112100