Integrating Two-Stage Phase Change Material Thermal Storage for Cascaded Waste Heat Recovery of Diesel-Engine-Powered Distributed Generation Systems: A Case Study

Abstract

:1. Introduction

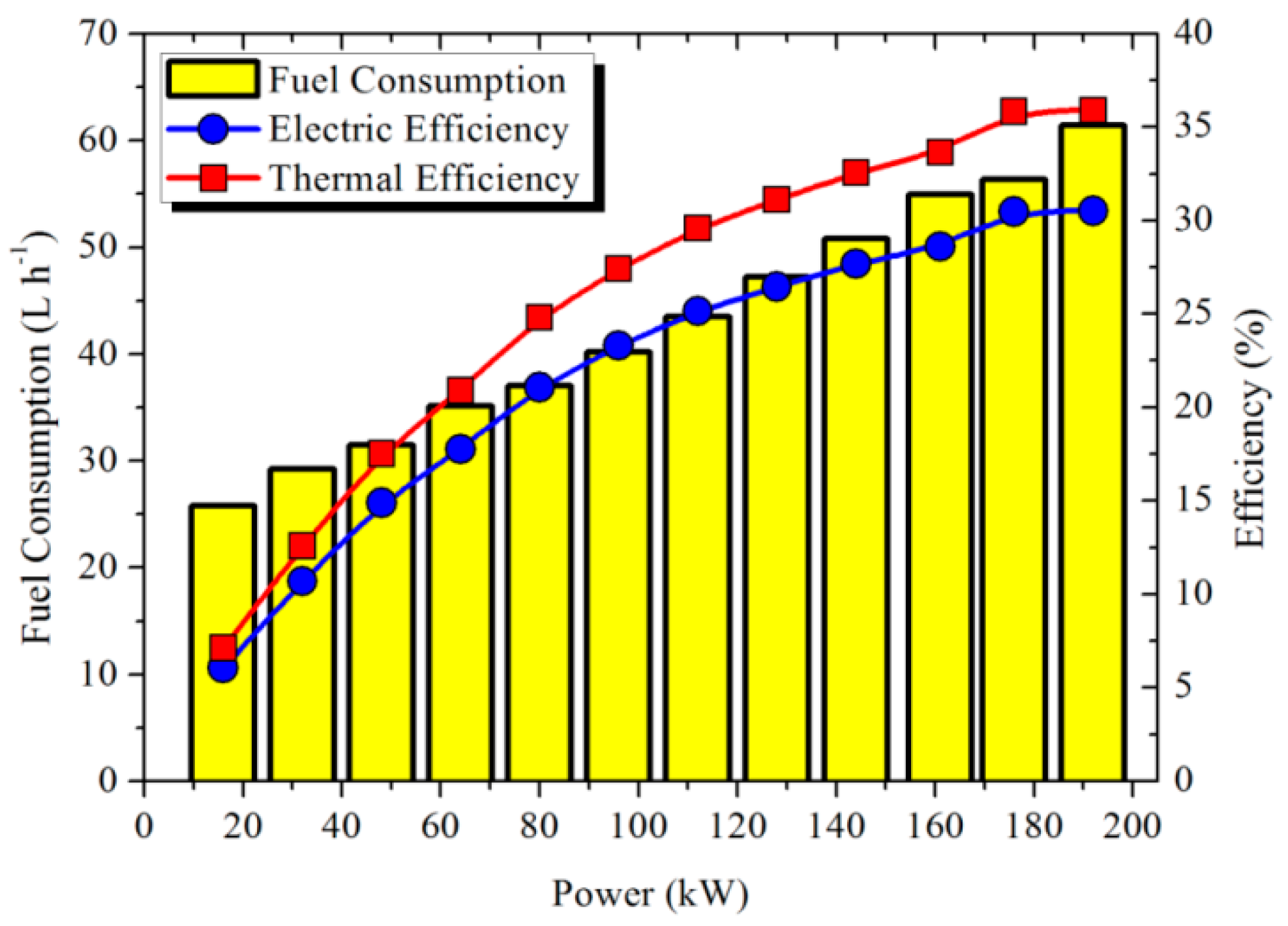

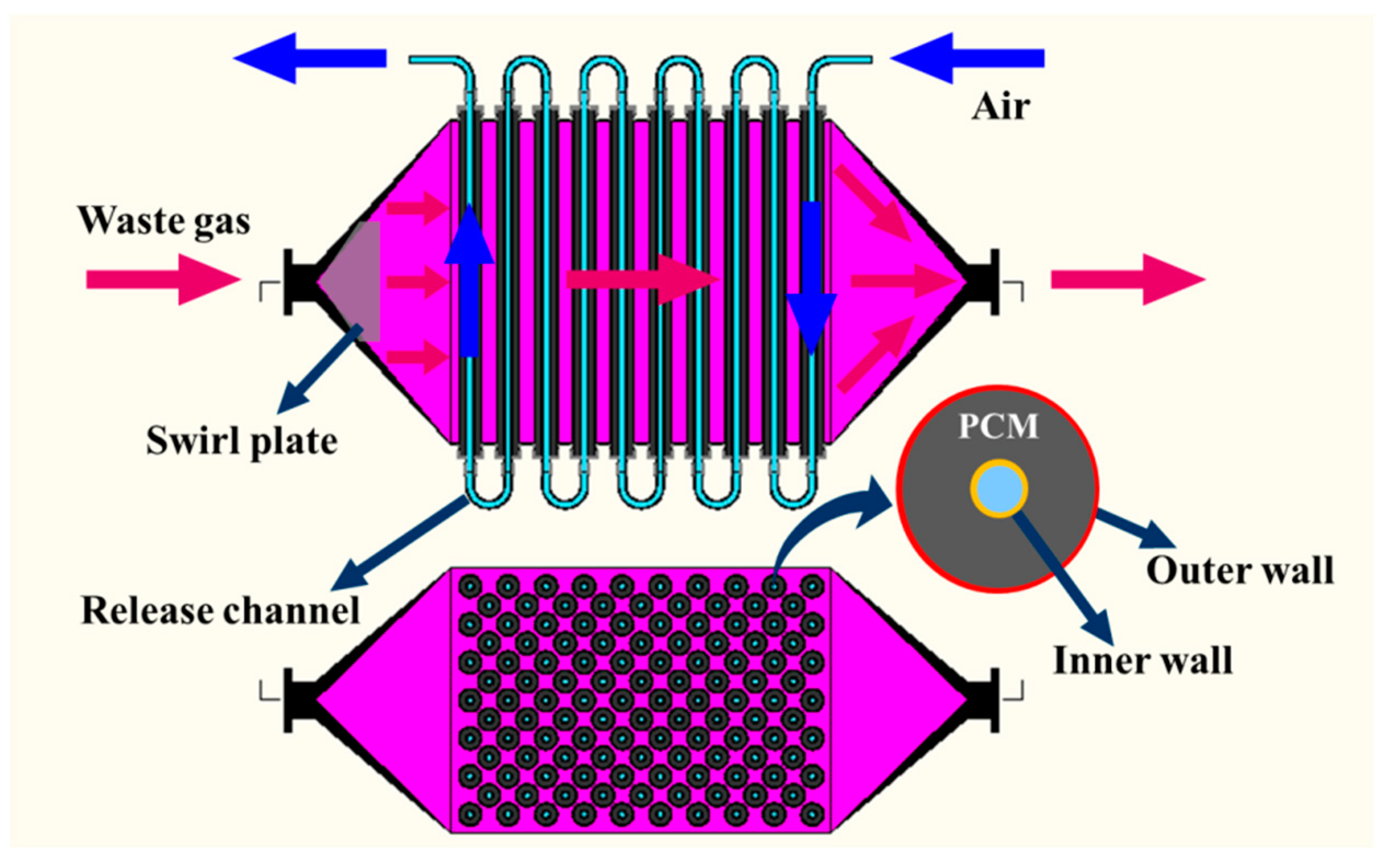

2. Demonstration Study

2.1. System Components

2.2. Methodology

2.2.1. Charging Process

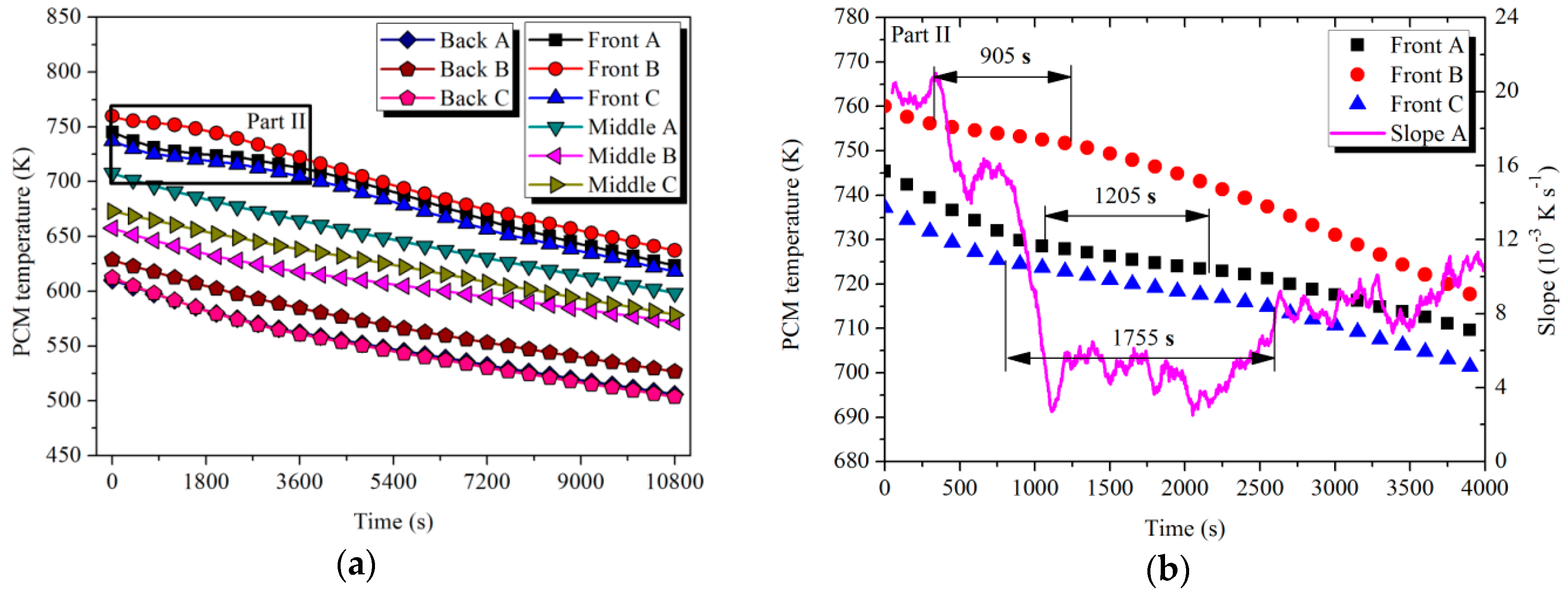

- Part of the input heat will be transferred to the internal gas in the module because of the relatively small thermal resistance compared with the convective resistance between the HTF and tubes.

- Due to the temperature gradient of the inlet gas in the axial direction, there are differences in the thermal energy flow passing through the radial planes (i.e., Planes A and B).

- The resistance of heat conduction inside the tube exists and the temperature uniformity of the tube takes time to reach.

2.2.2. Discharging Process

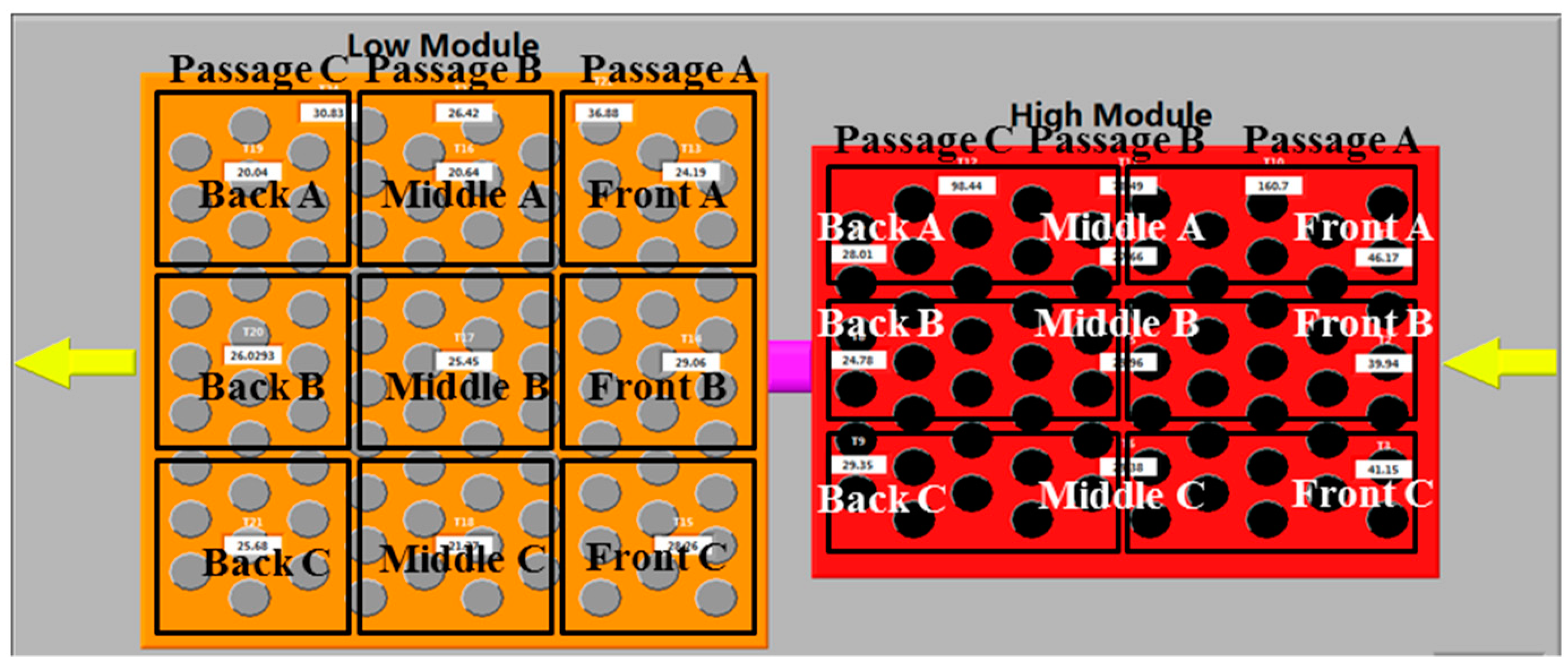

3. Results and Discussion

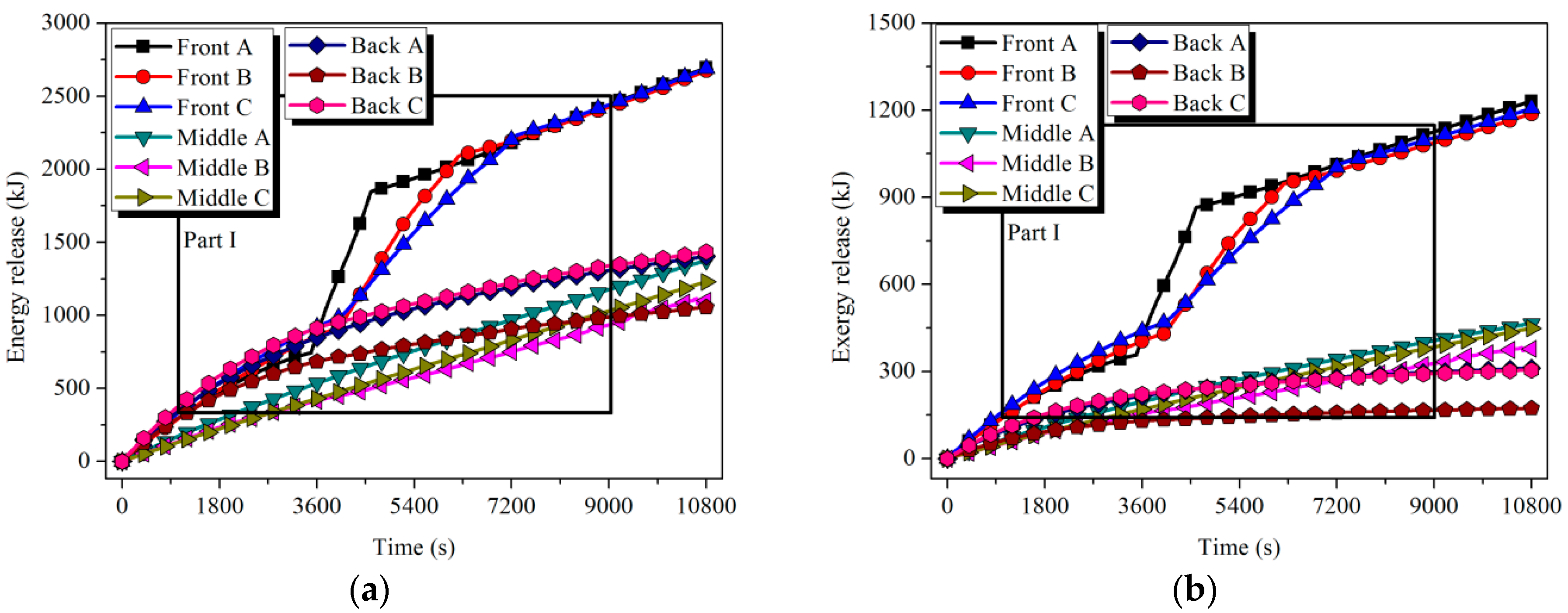

3.1. Charging Process

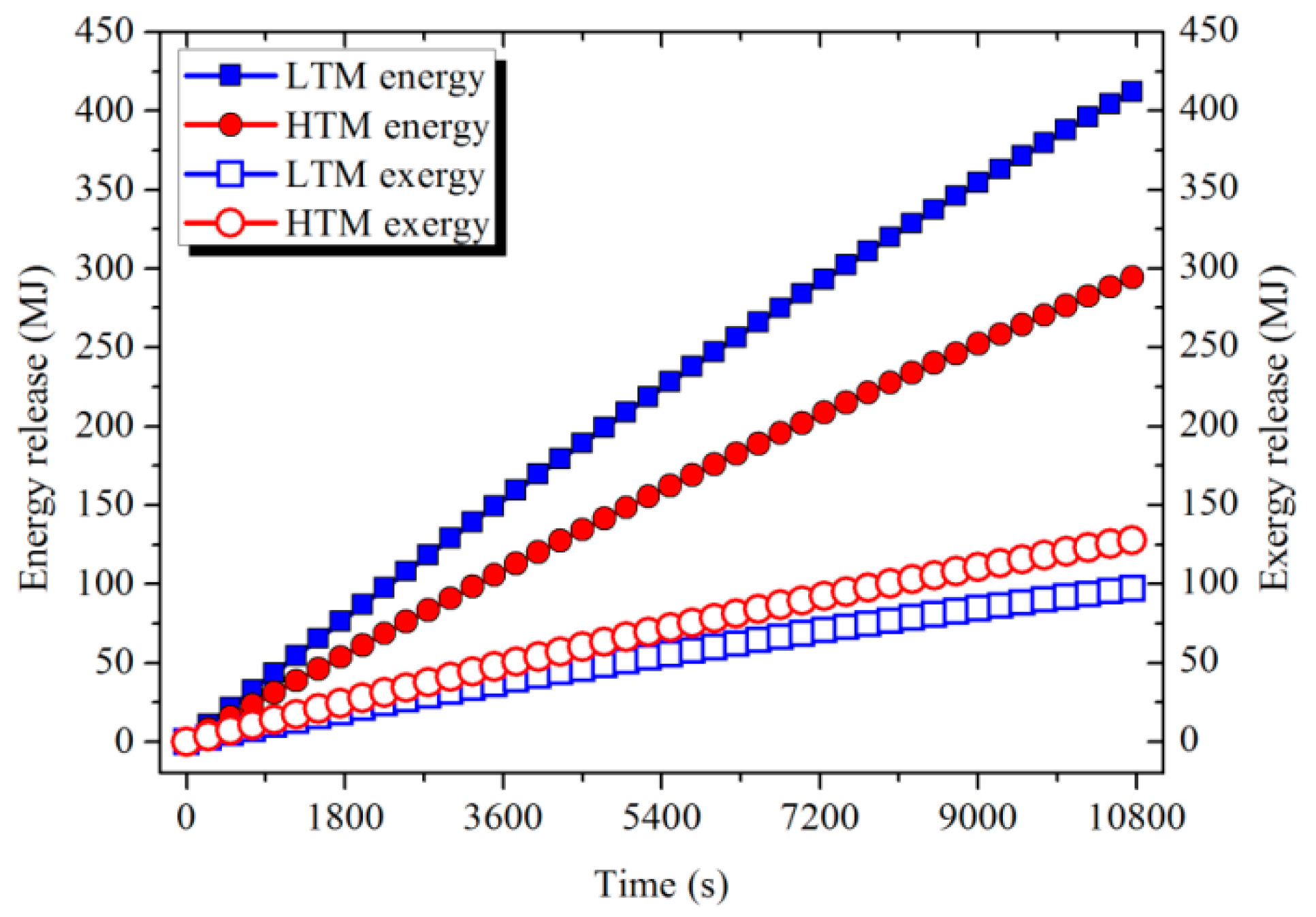

3.2. Discharging Process

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| c | specific heat capacity (kJ kg−1 K−1) |

| d | inner diameter (m) |

| D | outer diameter (m) |

| Ex | exergy |

| H | height (m) |

| H | phase change enthalpy (kJ kg−1) |

| j | jth measurement period during charging |

| k | kth measurement period during discharging |

| L | length (m) |

| LHV | lower heating value (kJ kg−1) |

| m | mass (kg) |

| N | number of tubes |

| Nr | redundant factor |

| P | power (kW) |

| Q | heat (KJ) |

| s | second |

| slp | slope (K s−1) |

| ST | center distance between the adjacent tubes in the vertical gas flow direction (m) |

| SL | center distance between the adjacent tubes in the parallel gas flow direction (m) |

| t | time (s) |

| T | temperature (K) |

| T0 | ambient temperature (K) |

| U | uncertainty (°C, %) |

| V | flow rate (Nm3 h−1) |

| W | width (m) |

| X | total number of measurement periods during charging |

| Y | total number of measurement periods during discharging |

| Greek symbols | |

| γ | heat transfer efficiency (%) |

| Δt | time length of the latent process (s) |

| ΔT | temperature difference (K) |

| η | efficiency (%) |

| θ | slope calculation period (s) |

| λ | thermal conductivity (w m−1 K−1) |

| ρ | density (kg m−3) |

| φ | generator efficiency (%) |

| ψ | usage rate of the latent heat (%) |

| Superscripts | |

| elec | electricity |

| end | end |

| exergy | exergy |

| i | ith tube |

| in | in |

| l | liquid |

| max | maximum |

| rel | release |

| s | solid |

| start | start |

| sto | storage |

| ther | thermal |

| out | out |

| Subscripts | |

| air | air |

| diesel | diesel |

| fuel | fuel |

| gas | gas |

| lpc | liquid–solid phase change |

| loss | loss |

| mod | module |

| pc | phase change |

| pcm | phase change material |

| spc | solid–liquid phase change |

| tube | tube |

| user | user |

| water | water |

| Abbreviations | |

| DGS | distributed generation system |

| HTF | heat transfer fluid |

| HTM | high-temperature module |

| LTM | low-temperature module |

| PCM | phase change material |

References

- Abusoglu, A.; Kanoglu, M. First and second law analysis of diesel engine powered cogeneration systems. Energy Convers. Manag. 2008, 49, 2026–2031. [Google Scholar] [CrossRef]

- Xuan, W.; Ming, J.; Wei, F.; Gequn, S.; Hua, T.; Youcai, L. Cascade energy optimization for waste heat recovery in distributed energy systems. Appl. Energy 2018, 230, 679–695. [Google Scholar]

- Wenzhi, G.; Junmeng, Z.; Guanghua, L.; Qiang, B.; Liming, F. Performance evaluation and experiment system for waste heat recovery of diesel engine. Energy 2013, 55, 226–235. [Google Scholar] [CrossRef]

- Yu, G.; Shu, G.; Tian, H.; Huo, Y.; Zhu, W. Experimental investigations on a cascaded steam-/organic-Rankinecycle (RC/ORC) system for waste heat recovery (WHR) from diesel engine. Energy Convers. Manag. 2016, 129, 43–51. [Google Scholar] [CrossRef]

- Mito, M.T.; Teamah, M.A.; El-Maghlany, W.M.; Shehata, A.I. Utilizing the scavenge air cooling in improving the performance of marine diesel engine waste heat recovery systems. Energy 2018, 142, 264–276. [Google Scholar] [CrossRef]

- Hatami, M.; Ganji, D.D.; Gorji-Bandpy, M. A review of different heat exchangers designs for increasing the diesel exhaust waste heat recovery. Renew. Sustain. Energy Rev. 2014, 37, 168–181. [Google Scholar] [CrossRef]

- José Manuel, L.; Héctor, C.; Dolz, V.; Moratal, A.; José, B.-A.; Soukeur, Z. Potential of exhaust heat recovery for intake charge heating in a diesel engine transient operation at cold conditions. Appl. Therm. Eng. 2016, 105, 501–508. [Google Scholar] [Green Version]

- Thakar, R.; Bhosle, S.; Lahane, S. Design of heat exchanger for waste heat recovery from exhaust gas of diesel engine. Procedia Manuf. 2018, 20, 372–376. [Google Scholar] [CrossRef]

- Riffat, S.B.; Ma, X. Thermoelectrics: A review of present and potential applications. Appl. Therm. Eng. 2003, 23, 913–935. [Google Scholar] [CrossRef]

- Champier, D. Thermoelectric generators: A review of applications. Renew. Sustain. Energy Rev. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Pandiyarajan, V.; Chinna Pandian, M.; Malan, E.; Velraj, R.; Seeniraj, R.V. Experimental investigation on heat recovery from diesel engine exhaust using finned shell and tube heat exchanger and thermal storage system. Appl. Energy 2011, 88, 77–87. [Google Scholar] [CrossRef]

- Mohamed, S.A.; Al-Sulaiman, F.A.; Ibrahim, N.I.; Zahir, M.H.; Al-Ahmed, A.; Saidura, R.; Yılbaş, B.S.; Sahin, A.Z. A review on current status and challenges of inorganic phase change materials for thermal energy storage systems. Renew. Sustain. Energy Rev. 2017, 70, 1027–1089. [Google Scholar] [CrossRef]

- Stathopoulos, N.; El Mankibi, M.; Issoglio, R.; Michel, P.; Haghighat, F. Air–PCM heat exchanger for peak load management: Experimental and simulation. Sol. Energy 2016, 132, 453–466. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Pandey, A.K.; Buddhi, D.; Kothari, R. Thermal performance assessment of encapsulated PCM based thermal management system to reduce peak energy demand in buildings. Energy Build. 2016, 117, 44–52. [Google Scholar] [CrossRef]

- Alva, G.; Liu, L.; Huang, X.; Fang, G. Thermal energy storage materials and systems for solar energy applications. Renew. Sustain. Energy Rev. 2017, 68, 693–706. [Google Scholar] [CrossRef]

- Li, D.; Zheng, Y.; Liu, C.; Wu, G. Numerical analysis on thermal performance of roof contained PCM of a single residential building. Energy Convers. Manag. 2015, 100, 147–156. [Google Scholar] [CrossRef]

- Yan, J.; Wang, Q.; Li, K.; Sun, J. Numerical study on the thermal performance of a composite board in battery thermal management system. Appl. Therm. Eng. 2016, 106, 131–140. [Google Scholar] [CrossRef]

- Alshaer, W.G.; Nada, S.A.; Rady, M.A.; Barrio, E.P.D.; Sommier, A. Thermal management of electronic devices using carbon foam and PCM/nano-composite. Int. J. Therm. Sci. 2015, 89, 79–86. [Google Scholar] [CrossRef]

- Elfeky, K.E.; Ahmed, N.; Wang, Q. Numerical comparison between single PCM and multi-stage PCM based high temperature thermal energy storage for CSP tower plants. Appl. Therm. Eng. 2018, 139, 609–622. [Google Scholar] [CrossRef]

- Peiró, G.; Gasia, J.; Miró, L.; Prieto, C.; Cabeza, L.F. Experimental evaluation at pilot plant scale of multiple PCMs (cascaded) vs. single PCM configuration for thermal energy storage. Renew. Energy 2015, 83, 729–736. [Google Scholar] [CrossRef] [Green Version]

- Solomon, L.; Oztekin, A. Exergy analysis of cascaded encapsulated phase change material—High-temperature thermal energy storage systems. J. Energy Storage 2016, 8, 12–26. [Google Scholar] [CrossRef]

- Shamsi, H.; Boroushaki, M.; Geraei, H. Performance evaluation and optimization of encapsulated cascade PCM thermal storage. J. Energy Storage 2017, 11, 64–75. [Google Scholar] [CrossRef]

- Yuan, F.; Li, M.J.; Ma, Z.; Jin, B.; Liu, Z. Experimental study on thermal performance of high-temperature molten salt cascaded latent heat thermal energy storage system. Int. J. Heat Mass Transf. 2018, 118, 997–1011. [Google Scholar] [CrossRef]

- Aldoss, T.K.; Rahman, M.M. Comparison between the single-PCM and multi-PCM thermal energy storage design. Energy Convers. Manag. 2014, 83, 79–87. [Google Scholar] [CrossRef]

- Xu, Y.; He, Y.L.; Li, Y.Q.; Song, H.J. Exergy analysis and optimization of charging–discharging processes of latent heat thermal energy storage system with three phase change materials. Sol. Energy 2016, 123, 206–216. [Google Scholar] [CrossRef]

- Xu, H.J.; Zhao, C.Y. Thermal performance of cascaded thermal storage with phase-change materials (PCMs). Part I: Steady cases. Int. J. Heat Mass Transf. 2017, 106, 932–944. [Google Scholar] [CrossRef]

- Meng, Z.; Zhang, P. Experimental and numerical investigation of a tube-in-tank latent thermal energy storage unit using composite PCM. Appl. Energy 2017, 190, 524–539. [Google Scholar] [CrossRef]

- Atal, A.; Wang, Y.; Harsha, M.; Sengupta, S. Effect of porosity of conducting matrix on a phase change energy storage device. Int. J. Heat Mass Transf. 2016, 93, 9–16. [Google Scholar] [CrossRef]

- Primus, R.J.; Flynn, P.F. The Assessment of Losses in Diesel Engines Using Second Law Analysis; COMODIA, JSME: Tokyo, Japan, 1985. [Google Scholar]

- Al-Najem, N.M.; Diab, J.M. Energy-exergy analysis of a diesel engine. Heat Recovery Syst. CHP 1992, 12, 525–529. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, F.; Xiao, X. Thermal energy storage and retrieval characteristics of a molten-salt latent heat thermal energy storage system. Appl. Energy 2016, 173, 255–271. [Google Scholar] [CrossRef]

- Almsater, S.; Alemu, A.; Saman, W.; Bruno, F. Development and experimental validation of a CFD model for PCM in a vertical triplex tube heat exchanger. Appl. Therm. Eng. 2017, 116, 344–354. [Google Scholar] [CrossRef]

- Youssef, W.; Ge, Y.T.; Tassou, S.A. CFD modelling development and experimental validation of a phase change material (PCM) heat exchanger with spiral-wired tubes. Energy Convers. Manag. 2018, 157, 498–510. [Google Scholar] [CrossRef]

- Jegadheeswaran, S.; Pohekar, S.D.; Kousksou, T. Exergy based performance evaluation of latent heat thermal storage system: A review. Renew. Sustain. Energy Rev. 2010, 14, 2580–2595. [Google Scholar] [CrossRef]

- Macphee, D.; Dincer, I. Thermodynamic analysis of freezing and melting processes in a bed of spherical PCM capsules. J. Sol. Energy Eng. 2009, 131, 031017-11. [Google Scholar] [CrossRef]

- Song, Z.; Deng, Y.; Li, J.; Nian, H. Expanded graphite for thermal conductivity and reliability enhancement and supercooling decrease of MgCl2⋅6H2O phase change material. Mater. Res. Bull. 2018, 102, 203–208. [Google Scholar] [CrossRef]

- Safari, A.; Saidur, R.; Sulaiman, F.A.; Xu, Y.; Dong, J. A review on supercooling of Phase Change Materials in thermal energy storage systems. Renew. Sustain. Energy Rev. 2017, 70, 905–919. [Google Scholar] [CrossRef]

- Zondag, H.A.; de Boer, R.; Smeding, S.F.; van der Kamp, J. Performance analysis of industrial PCM heat storage lab prototype. J. Energy Storage 2018, 18, 402–413. [Google Scholar] [CrossRef]

| Electric Load (kW) | Gas Temperature (K) | Gas Flow Rate (Nm3 h−1) | Fuel Consumption (10−3 Nm3 h−1) |

|---|---|---|---|

| 192 | 925 | 582 | 61.40 |

| 176 | 883 | 580 | 56.39 |

| 160 | 841 | 562 | 54.94 |

| 144 | 796 | 552 | 50.78 |

| 128 | 761 | 524 | 47.23 |

| 112 | 725 | 503 | 37.02 |

| 96 | 681 | 480 | 40.19 |

| 80 | 640 | 474 | 37.02 |

| 64 | 593 | 452 | 35.15 |

| 48 | 558 | 441 | 31.46 |

| 32 | 517 | 429 | 29.21 |

| 16 | 475 | 412 | 25.78 |

| Parameters | Carbonate PCMs | Nitrate PCMs |

|---|---|---|

| Tpc (K) | 760 | 560 |

| λ (W m−1 K−1) | 4 | 2.5 |

| (kJ kg−1 K−1) | 1.1 | 1.0 |

| (kJ kg−1 K−1) | 1.2 | 1.1 |

| Hpcm (kJ kg−1) | 190 | 103 |

| (a) High-temperature module (HTM: Carbonate PCMs) | |||

| Parameters | Value | Parameters | Value |

| (K) | 870 | (K) | 930 |

| (kg) | 7.46 | (kg) | 12.34 |

| ctube (kJ kg−1 K−1) | 0.5 | Dtube (×10−3 m) | Φ88 × 4 |

| dtube (×10−3 m) | Φ30 × 3 | Ltube (×10−3 m) | 1200 |

| ST (×10−3 m) | 140 | SL (×10−3 m) | 70 |

| L × W × H (×10−3 m) | 1400 × 980 × 1200 | N | 124 |

| (b) Low-temperature module (LTM: Nitrate PCMs) | |||

| Parameters | Value | Parameters | Value |

| (K) | 660 | (K) | 660 |

| (kg) | 10.37 | (kg) | 15.43 |

| ctube (kJ kg−1 K−1) | 0.5 | Dtube (×10−3 m) | Φ88 × 4 |

| dtube (×10−3 m) | Φ30 × 3 | Ltube (×10−3 m) | 1500 |

| ST (×10−3 m) | 140 | SL (×10−3 m) | 70 |

| L × W × H (×10−3 m) | 1680 × 1400 × 1500 | N | 219 |

| U1 (°C) | U2 (°C) | U3 (%) | U4 (%) | U5 (%) |

|---|---|---|---|---|

| 0.5 | 1 | 0.5 | 0.8 | 0.9 |

| LTM | HTM | System |

|---|---|---|

| = 49.2% | = 36.8% | = 43.2% |

| = 41.8% | = 39.4% | = 40.4% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Ding, Y.; Wang, P.; Wang, S.; Yao, H.; Wang, J.; Huang, Y. Integrating Two-Stage Phase Change Material Thermal Storage for Cascaded Waste Heat Recovery of Diesel-Engine-Powered Distributed Generation Systems: A Case Study. Energies 2019, 12, 2121. https://doi.org/10.3390/en12112121

Li D, Ding Y, Wang P, Wang S, Yao H, Wang J, Huang Y. Integrating Two-Stage Phase Change Material Thermal Storage for Cascaded Waste Heat Recovery of Diesel-Engine-Powered Distributed Generation Systems: A Case Study. Energies. 2019; 12(11):2121. https://doi.org/10.3390/en12112121

Chicago/Turabian StyleLi, Dacheng, Yulong Ding, Peilun Wang, Shuhao Wang, Hua Yao, Jihong Wang, and Yun Huang. 2019. "Integrating Two-Stage Phase Change Material Thermal Storage for Cascaded Waste Heat Recovery of Diesel-Engine-Powered Distributed Generation Systems: A Case Study" Energies 12, no. 11: 2121. https://doi.org/10.3390/en12112121

APA StyleLi, D., Ding, Y., Wang, P., Wang, S., Yao, H., Wang, J., & Huang, Y. (2019). Integrating Two-Stage Phase Change Material Thermal Storage for Cascaded Waste Heat Recovery of Diesel-Engine-Powered Distributed Generation Systems: A Case Study. Energies, 12(11), 2121. https://doi.org/10.3390/en12112121