Simulation Study of CO2 Huff-n-Puff in Tight Oil Reservoirs Considering Molecular Diffusion and Adsorption

Abstract

:1. Introduction

2. Methodology

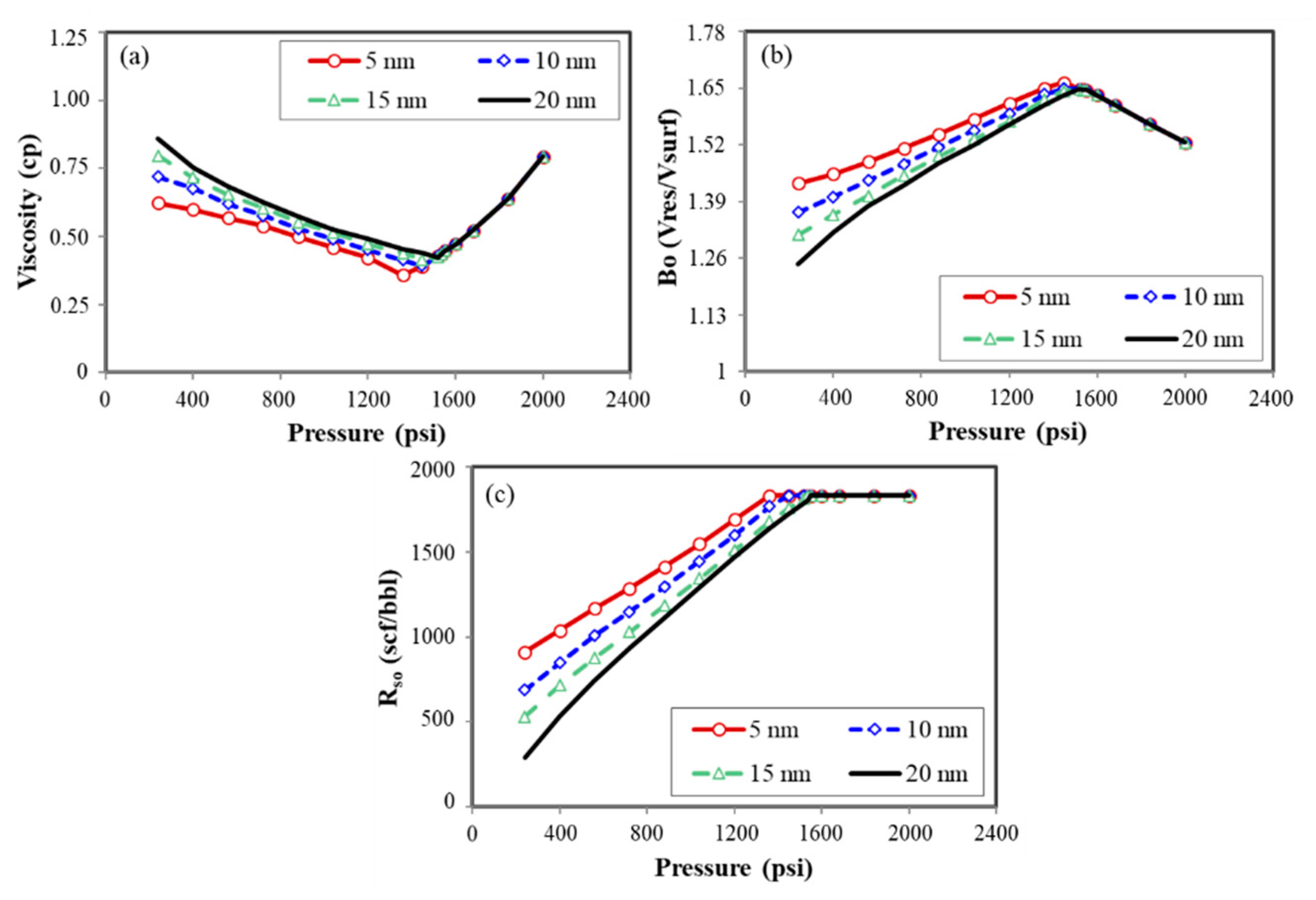

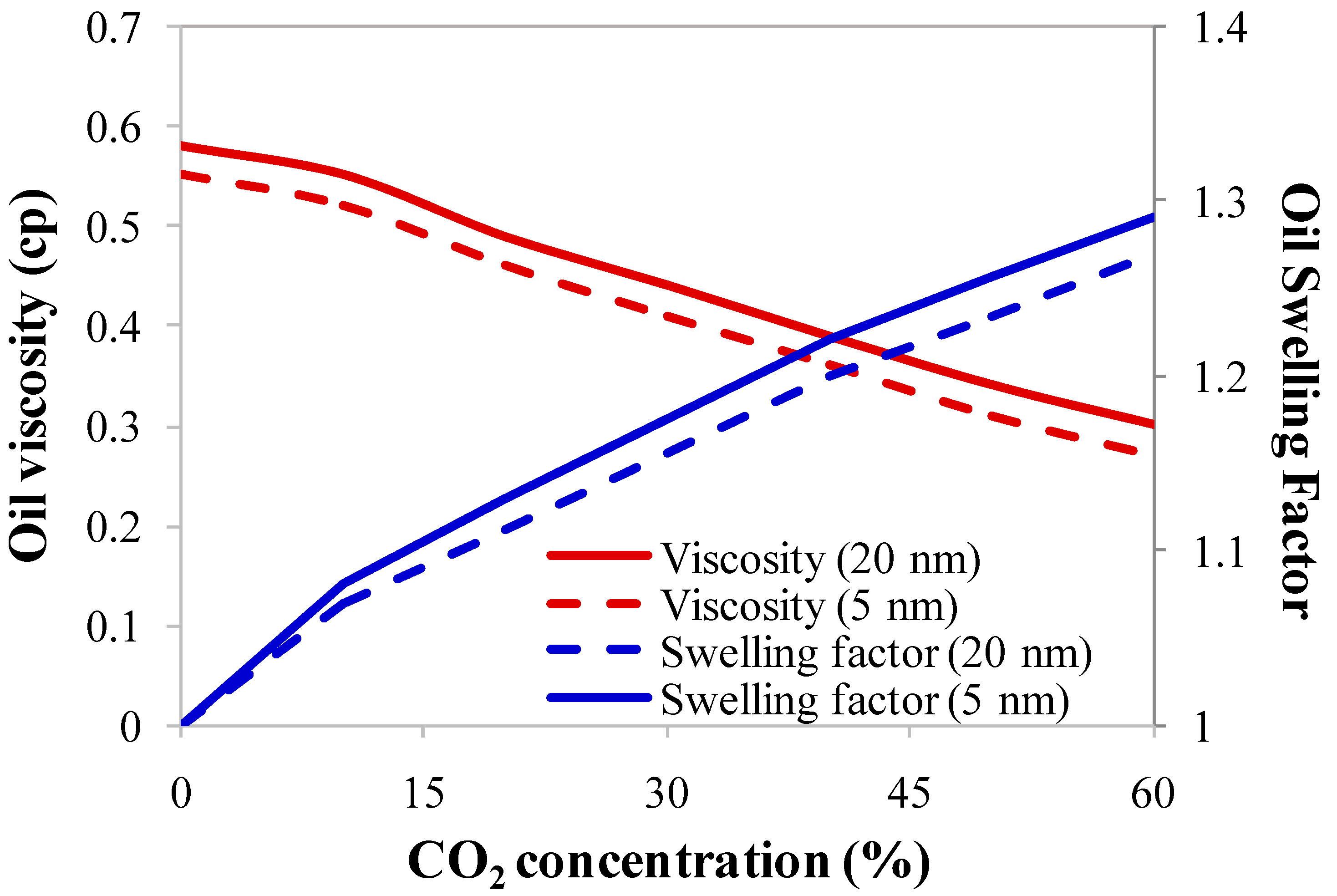

2.1. Critical Property Shifts in Nanopores

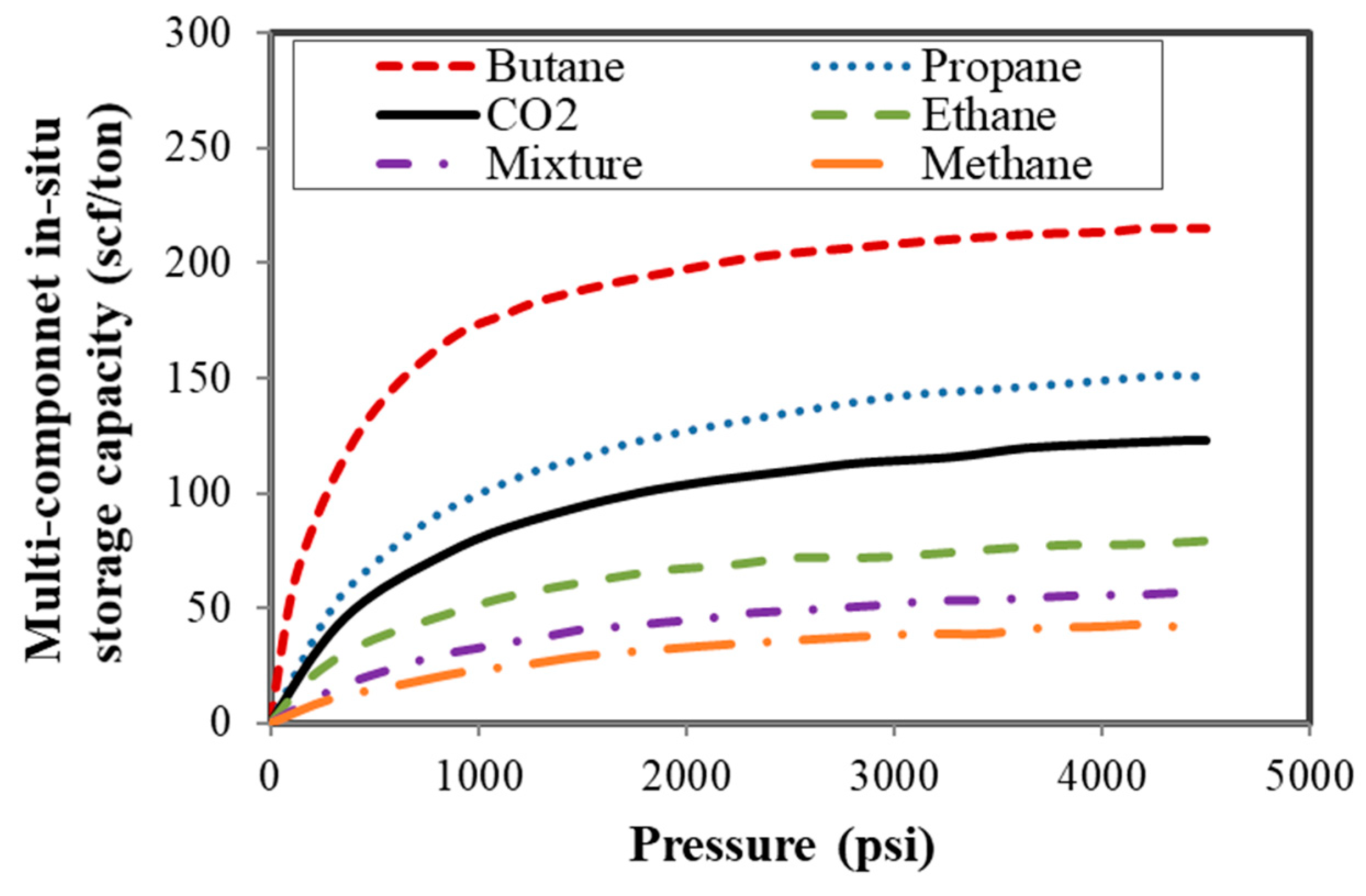

2.2. Flow Governing Equations

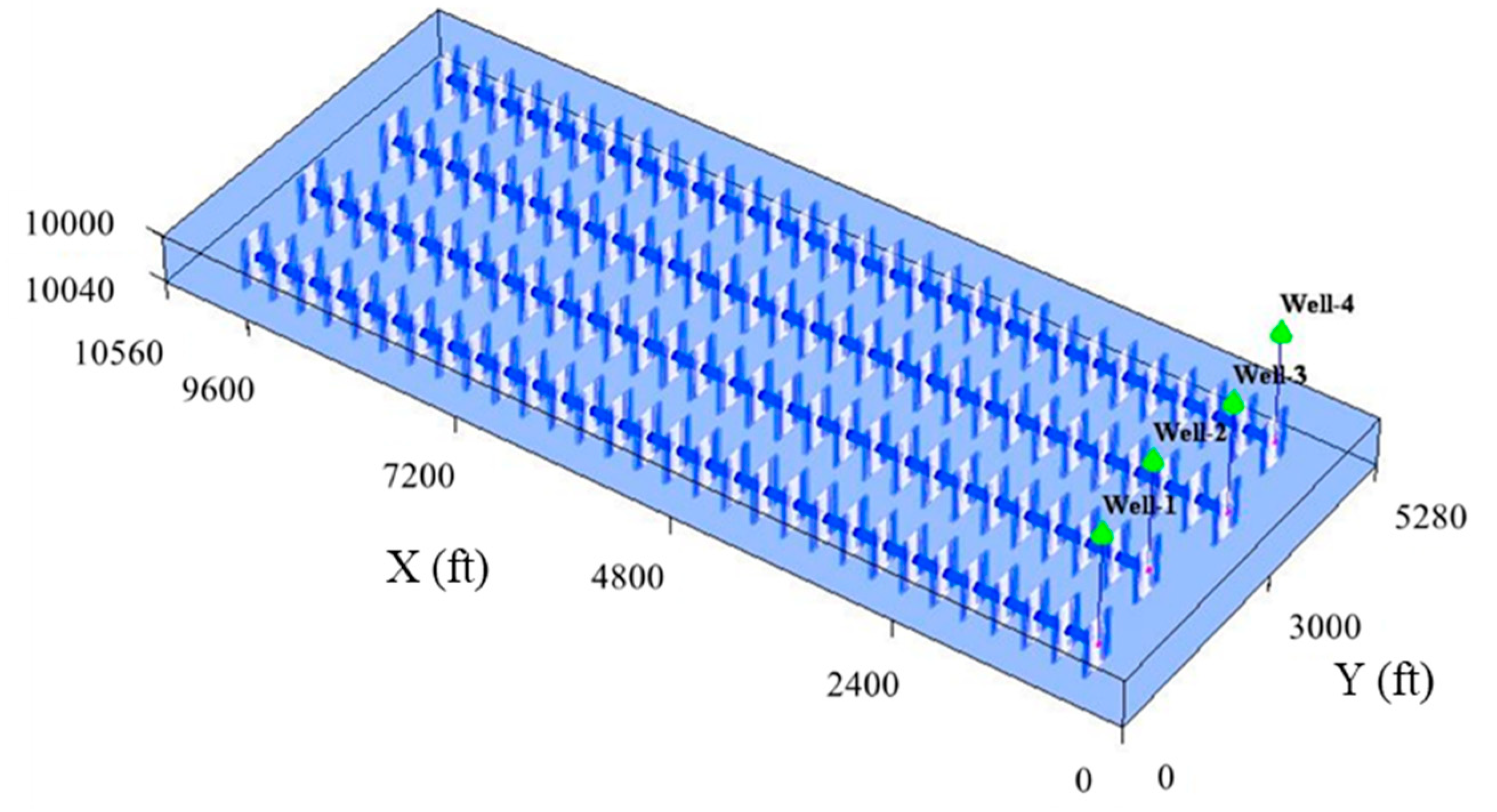

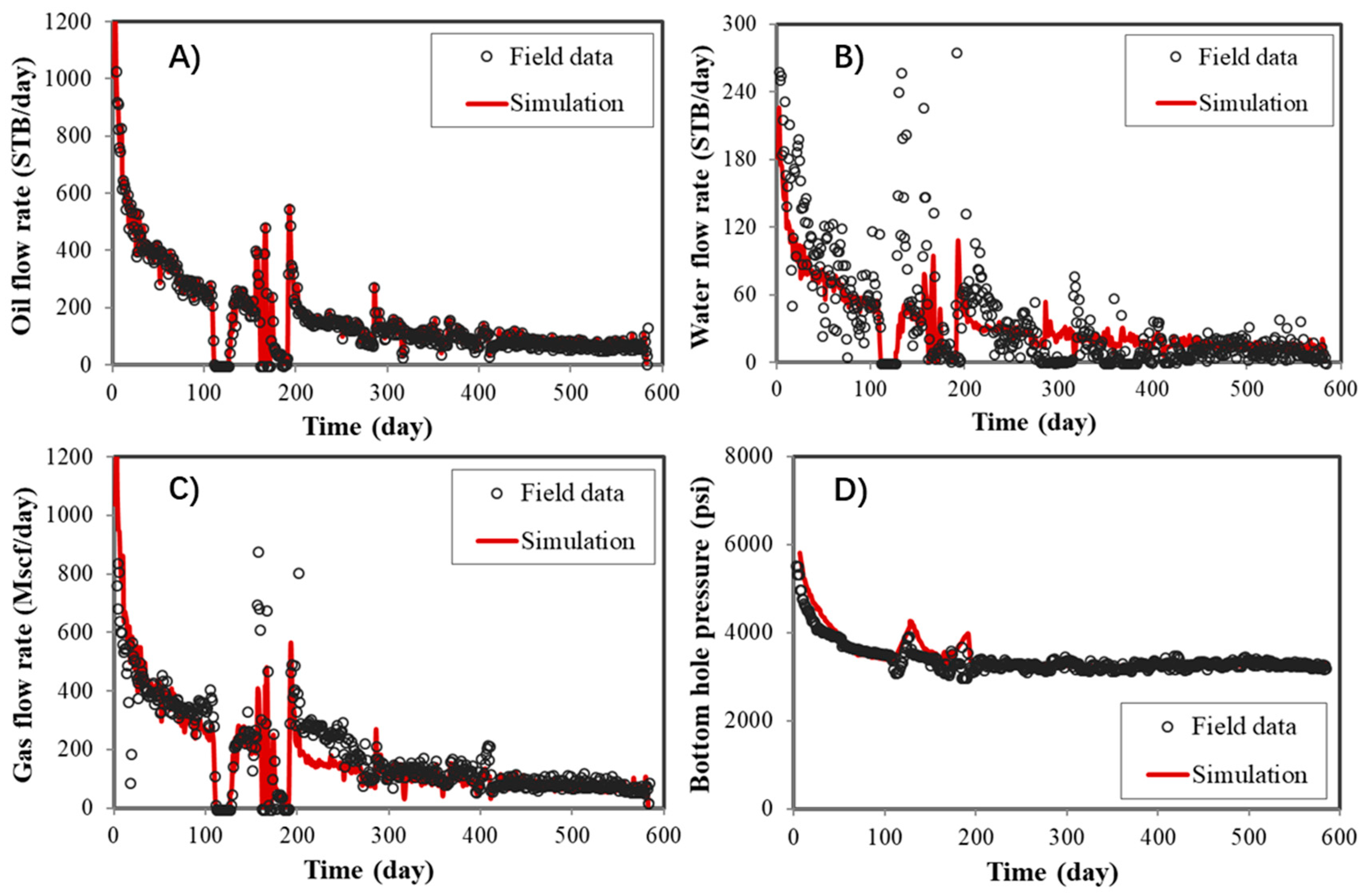

2.3. History Matching with An Actual Well from Eagle Ford Tight Oil Reservoir

3. Results and Discussion

4. Conclusions

- (1)

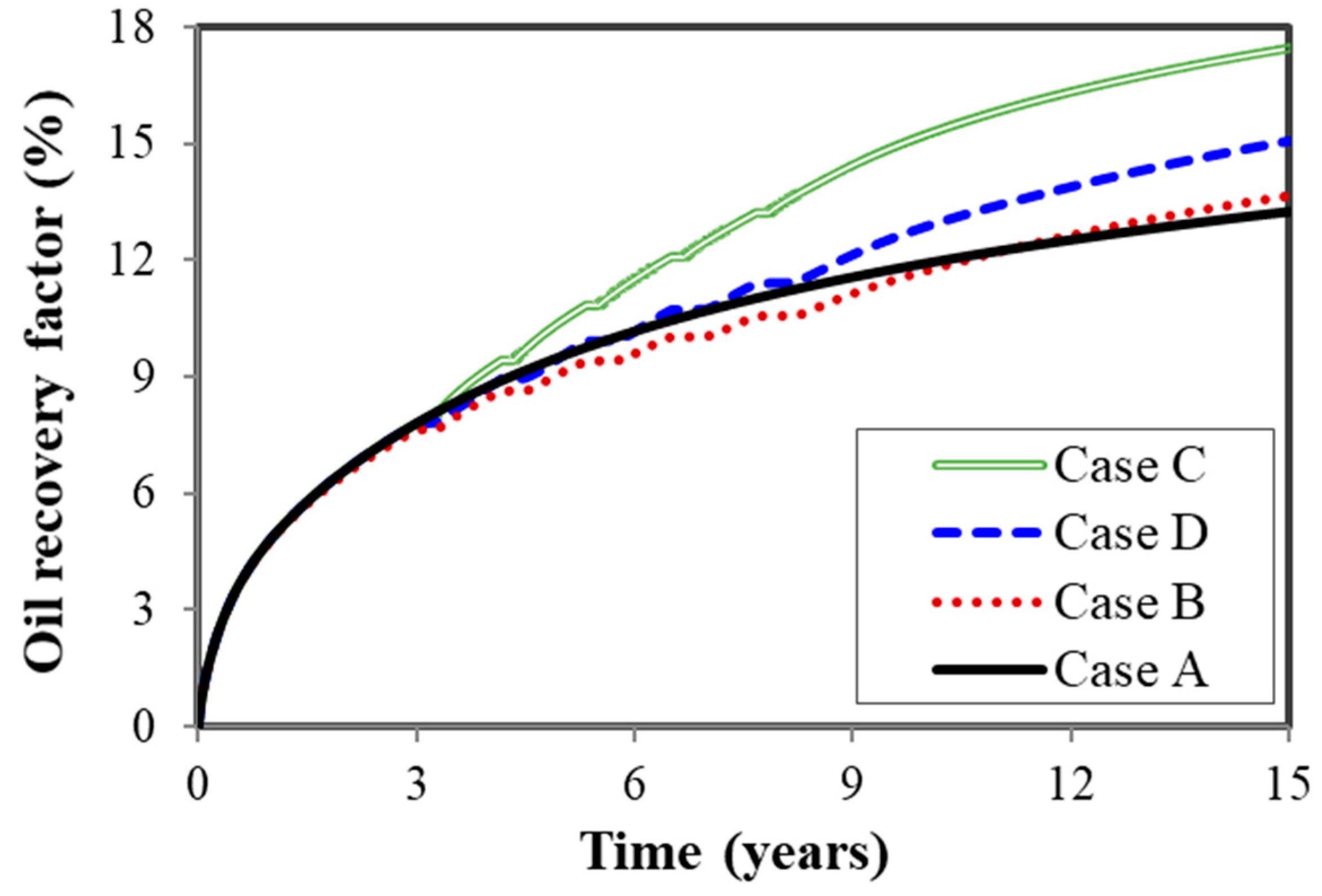

- Simulation results illustrate that CO2 molecules move from fractures to matrix with the mechanism of CO2 molecular diffusion, which can efficiently improve the oil recovery factor in the CO2-EOR process. The oil recovery increases by 4.8% with the diffusion coefficient of 0.001 cm2/s compared to the base case.

- (2)

- Compared to the case with molecular diffusion, the mechanism of adsorption influences CO2 penetration into the matrix, performing a negative influence on the incremental oil recovery of the CO2 Huff-n-Puff process. In this study, the increment of oil recovery is 2.1% considering both molecular diffusion and adsorption, 2.7% lower than the case only including the molecular diffusion.

- (3)

- Results indicate that molecular diffusion and adsorption will decrease the cumulative CO2 backflow in the simulation of CO2-EOR process. For this typical reservoir, the cumulative CO2 backflow decreases to 59%. Hence, these mechanisms should be properly considered in the analysis.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Salahshoor, S.; Fahes, M.; Teodoriu, C. A review on the effect of confinement on phase behavior in tight formations. J. Nat. Gas Sci. Eng. 2018, 51, 89–103. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, X.; Wu, Y.; Li, X. Enhanced oil recovery by air-foam flooding system in tight oil reservoirs: Study on the profile-controlling mechanisms. J. Pet. Sci. Eng. 2017, 150, 208–216. [Google Scholar] [CrossRef]

- Liao, K.; Zhang, S.; Ma, X.; Zou, Y. Numerical investigation of fracture compressibility and uncertainty on water-loss and production performance in tight oil reservoirs. Energies 2019, 12, 1189. [Google Scholar] [CrossRef]

- Bai, J.; Liu, H.; Wang, J.; Qiao, G.; Peng, Y.; Gao, Y.; Yan, L.; Chen, F. CO2, Water and N2 injection for enhanced oil recovery with spatial arrangement of fractures in tight-oil reservoirs using Huff-’n-puff. Energies 2019, 12, 823. [Google Scholar] [CrossRef]

- Sheng, J.J. Critical review of field EOR projects in shale and tight reservoirs. J. Pet. Sci. Eng. 2017, 159, 654–665. [Google Scholar] [CrossRef]

- Hawthorne, S.B.; Gorecki, C.D.; Sorensen, J.A.; Steadman, E.N.; Harju, A.J.; Melzer, S. Hydrocarbon mobilization mechanisms from upper, middle, and lower Bakken reservoir rocks exposed to CO2. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 5–7 November 2013. [Google Scholar]

- Yu, W.; Lashgari, H.R.; Wu, K.; Sepehrnoori, K. CO2 injection for enhanced oil recovery in Bakken tight oil reservoirs. Fuel 2015, 159, 354–363. [Google Scholar] [CrossRef]

- Ren, B.; Ren, S.; Zhang, L.; Chen, G.; Zhang, H. Monitoring on CO2 migration in a tight oil reservoir during CCS-EOR in Jilin Oilfield China. Energy 2016, 98, 108–121. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, W.; Li, Z.; Sepehrnoori, K. Simulation study of factors affecting CO2 Huff-n-Puff process in tight oil reservoirs. J. Pet. Sci. Eng. 2018, 163, 264–269. [Google Scholar] [CrossRef]

- Zuloaga-Molero, P.; Yu, W.; Xu, Y.; Sepehrnoori, K.; Li, B. Simulation Study of CO2-EOR in Tight Oil Reservoirs with Complex Fracture Geometries. Sci. Rep. 2016, 6, 33445. [Google Scholar] [CrossRef] [PubMed]

- Sanchez Rivera, D. Reservoir Simulation and Optimization of CO2 Huff-and-Puff Operations in the Bakken Shale. Master’s Thesis, The University of Texas at Austin, Austin, TX, USA, 2014. [Google Scholar]

- Janiga, D.; Czarnota, R.; Stopa, J.; Wojnarowski, P. Huff and puff process optimization in micro scale by coupling laboratory experiment and numerical simulation. Fuel 2018, 224, 289–301. [Google Scholar] [CrossRef]

- Wan, T.; Zhang, Y.; Wang, W.; Jiang, J. Pore-scale analysis of gas huff-n-puff enhanced oil recovery and waterflooding process. Fuel 2018, 215, 561–571. [Google Scholar] [CrossRef]

- Hoteit, H. Modeling diffusion and gas-oil mass transfer in fractured reservoirs. J. Pet. Sci. Eng. 2013, 105, 1–17. [Google Scholar] [CrossRef]

- Hoteit, H.; Firoozabadi, A. Compositional modeling by the combined discontinuous Galerkin and mixed method. SPE J. 2006, 11, 19–34. [Google Scholar] [CrossRef]

- Nojabaei, B.; Johns, R.T.; Chu, L. Effect of capillary pressure on phase behavior in tight rocks and shales. SPE Res. Eval. Eng. 2013, 16, 281–289. [Google Scholar] [CrossRef]

- Sandoval, D.; Yan, W.; Michelsen, M.L.; Stenby, E.H. Phase envelope calculations for reservoir fluids in the presence of capillary pressure. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar]

- Zhang, Y.; Di, Y.; Yu, W.; Sepehrnoori, K. A comprehensive model for investigation of CO2-EOR with nanopore confinement in the Bakken tight oil reservoir. SPE Res. Eval. Eng. 2019, 22, 122–136. [Google Scholar] [CrossRef]

- Sapmanee, K. Effects of Pore Proximity on Behavior and Production Prediction of Gas/Condensate. Master’s Thesis, University of Oklahoma, Norman, OK, USA, 2011. [Google Scholar]

- Zhang, K.; Jia, N.; Liu, L. CO2 storage in fractured nanopores underground: Phase behaviour study. Appl. Energy 2019, 238, 911–928. [Google Scholar] [CrossRef]

- Zhang, K.; Jia, N.; Li, S. Millimeter to nanometer-scale tight oil–CO2 solubility parameter and minimum miscibility pressure calculations. Fuel 2018, 220, 645–653. [Google Scholar] [CrossRef]

- Kang, S.M.; Fathi, E.; Ambrose, R.J.; Akkutlu, I.Y.; Sigal, R.F. CO2 Storage Capacity of Organic-Rich Shales. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010. [Google Scholar]

- Cipollar, C.L.; Lolon, E.P.; Erdle, J.C.; Rubin, B. Reservoir modeling in shale-gas reservoirs. SPE Res. Eval. Eng. 2010, 12, 638–653. [Google Scholar] [CrossRef]

- Yang, S.; Chen, Z.; Wei, Y.; Wu, K.; Shao, L.; Wu, W. A simulation model for accurate prediction of uneven proppant distribution in the Marcellus Shale coupled with reservoir geomechanics. In Proceedings of the SPE Eastern Regional Meeting, Morgantown, WV, USA, 13–15 October 2015. [Google Scholar]

- Clarkson, C.R.; Haghshenas, B. Modeling of supercritical fluid adsorption on organic-rich shales and coal. In Proceedings of the SPE Unconventional Resources Conference, The Woodlands, TX, USA, 10–12 April 2013. [Google Scholar]

- Haghshenas, B.; Qanbari, F.; Clarkson, C.R. Simulation of enhanced recovery using CO2 in a liquid-rich western Canadian unconventional reservoir: Accounting for reservoir fluid adsorption and compositional heterogeneity. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 15–16 February 2017. [Google Scholar]

- Yang, S.; Wei, Y.; Chen, Z.; Wu, W.; Xu, J. Effects of multicomponent adsorption on enhanced shale reservoir recovery by CO2 injection coupled with reservoir geomechanics. In Proceedings of the SPE Low Perm Symposium, Denver, CO, USA, 5–6 May 2016. [Google Scholar]

- Wan, T.; Mu, Z. The use of numerical simulation to investigate the enhanced Eagle Ford shale gas condensate well recovery using cyclic CO2 injection method with nano-pore effect. Fuel 2018, 233, 123–132. [Google Scholar] [CrossRef]

- Sun, R.; Yu, W.; Xu, F.; Pu, H.; Miao, J. Compositional simulation of CO2 Huff-n-Puff process in Middle Bakken tight oil reservoirs with hydraulic fractures. Fuel 2019, 236, 1446–1457. [Google Scholar] [CrossRef]

- Wang, L.; Yu, W. Mechanistic simulation study of gas Puff and Huff process for Bakken tight oil fractured reservoir. Fuel 2019, 239, 1179–1193. [Google Scholar] [CrossRef]

- Czarnota, R.; Janiga, D.; Stopa, J. Acoustic investigation of CO2 mass transfer into oil phase for vapor extraction process under reservoir conditions. Int. J. Heat Mass Transf. 2018, 127, 430–437. [Google Scholar] [CrossRef]

- Diaz Campos, M.; Akkutlu, I.Y.; Sigal, R.F. A molecular dynamics study on natural gas solubility enhancement in water confined to small pores. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar]

- Devegowda, D.; Sapmanee, K.; Civan, F.; Sigal, R.F. Phase behavior of gas condensates in shales due to pore proximity effects: Implications for transport, reserves and well productivity. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Singh, S.K.; Sinha, A.; Deo, G.; Singh, J.K. Vapor-liquid phase coexistence, critical properties, and surface tension of confined alkanes. J. Phys. Chem. C 2009, 113, 7170–7180. [Google Scholar] [CrossRef]

- Reid, R.C.; Prausnitz, J.M.; Poling, B.E. The Properties of Gases and Liquids; McGraw Hill: New York, NY, USA, 1987. [Google Scholar]

- CMG. GEM-GEM User’s Guide; Computer Modeling Group Ltd.: Calgary, AB, Canada, 2012. [Google Scholar]

- Lashgari, H.R. Development of a Four-Phase Thermal-Chemical Reservoir Simulator for Heavy Oil. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2014. [Google Scholar]

- Sigmund, P.M. Prediction of Molecular Diffusion at Reservoir Conditions. Part II—Estimating the Effects of Molecular Diffusion and Convective Mixing in Multicomponent Systems. J. Can. Pet. Technol. 1976, 15, 53–62. [Google Scholar] [CrossRef]

- Nghiem, L.X.; Kohse, B.F.; Sammon, P.H. Compositional simulation of the vapex process. In Proceedings of the Canadian International Petroleum Conference, Calgary, AS, Canada, 4–8 June 2000. [Google Scholar]

- Yu, W.; Sepehrnoori, K. Optimization of well spacing for Bakken tight oil reservoirs. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 25–27 August 2014. [Google Scholar]

- Luo, S.; Wolff, M.; Ciosek, J.M.; Rasdi, M.F.; Neal, L.; Arulampalam, P.; Willis, S.K. Probabilistic reservoir simulation workflow for unconventional resource play: Bakken case study. In Proceedings of the SPE EUROPEC/EAGE Annual Conference and Exhibition, Vienna, Austria, 23–26 May 2011. [Google Scholar]

- Condon, S.M.; Dyman, T.S. Geologic Assessment of Undiscovered Conventional Oil and Gas Resources in the Upper Cretaceous Navarro and Taylor Groups, Western Gul Province; Texas: USGS Digital Data Series; USGU: Reston, VG, USA, 2006.

- Zhang, Y.; Di, Y.; Shi, Y.; Hu, J. Cyclic CH4 injection for enhanced oil recovery in the Eagle Ford shale reservoirs. Energies 2018, 11, 3094. [Google Scholar] [CrossRef]

- Orangi, A.; Nagarajan, N.R.; Honarpour, M.M.; Rosenzweig, J.J. Unconventional shale oil and gas-condensate reservoir production, impact of rock, fluid, and hydraulic fractures. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 24–26 January 2011. [Google Scholar]

- Peng, D.Y.; Robinson, D.B. A new two-constant equation of state. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Zhang, Y.; Lashgari, H.R.; Di, Y. Capillary pressure effect on phase behavior of CO2/hydrocarbons in unconventional reservoirs. Fuel 2017, 197, 575–582. [Google Scholar] [CrossRef]

- Yu, W.; Zhang, Y.; Varavei, A.; Sepehrnoori, K.; Zhang, T.; Wu, K.; Miao, J. Compositional simulation of CO2 Huff-n-Puff in Eagle Ford tight oil reservoirs with CO2 molecular diffusion, nanopore confinement and complex natural fractures. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Sanaei, A.; Jamili, A.; Callard, J.; Mathur, A. Production modeling in the Eagle Ford gas condensate window: Integrating new relationships between core permeability, pore size, and confined PVT properties. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 16–18 April 2014. [Google Scholar]

- Zhang, Y.; Yu, W.; Di, Y.; Sepehrnoori, K. Investigation of nanopore confinement on fluid flow in tight reservoirs. J. Pet. Sci. Eng. 2017, 150, 265–271. [Google Scholar] [CrossRef]

- Mohebbinia, S.; Wong, T. Molecular diffusion calculations in simulation of gasfloods in fractured reservoirs. In Proceedings of the SPE Reservoir Simulation Conference, Montgomery, AL, USA, 20–22 February 2017. [Google Scholar]

- Renner, T.A. Measurement and correlation of diffusion coefficients for CO2 and rich-gas applications. SPE Res. Eng. 1988, 3, 517–523. [Google Scholar] [CrossRef]

- Kumar, P.; Mittal, K.L. Handbook of Microemulsion Science and Technology, 1st ed.; CRC Press: New York, NY, USA, 1999. [Google Scholar]

- Ambrose, R.J.; Hartman, R.C.; Akkutlu, I.Y. Multi-component sorbed-phase considerations for shale gas-in-place calculations. In Proceedings of the SPE Production and Operations Symposium, Oklahoma City, OK, USA, 27–29 March 2011. [Google Scholar]

- Alfarge, D.; Wei, M.; Bai, B. Mechanistic study for the applicability of CO2-EOR in unconventional liquids rich reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Habibi, A.; Yassin, M.R.; Dehghanpour, H.; Bryan, D. CO2-oil interactions in tight rocks: An experimental study. In Proceedings of the SPE unconventional resources conference, Calgary, AB, Canada, 15–16 February 2017. [Google Scholar]

| Parameters | Value | Unit |

|---|---|---|

| Initial reservoir pressure | 7500 | psi |

| Reservoir temperature | 270 | °F |

| Production time | 15 | years |

| Matrix porosity | 12% | - |

| Total compressibility | 1 × 10−6 | psi−1 |

| Matrix permeability | 0.001 | mD |

| Initial water saturation | 17% | - |

| Fracture height | 40 | ft |

| Fracture spacing | 320 | ft |

| Fracture half-length (HM parameter) | 220 | ft |

| Fracture conductivity (HM parameter) | 48 | mD-ft |

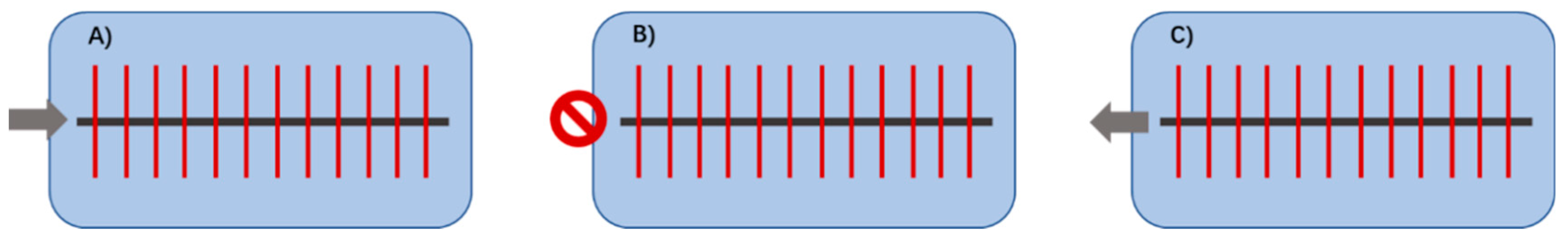

| Case | CO2 Huff-n-Puff | Molecular Diffusion | Adsorption |

|---|---|---|---|

| Case A | N | N | N |

| Case B | Y | N | N |

| Case C | Y | Y | N |

| Case D | Y | Y | Y |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Hu, J.; Zhang, Q. Simulation Study of CO2 Huff-n-Puff in Tight Oil Reservoirs Considering Molecular Diffusion and Adsorption. Energies 2019, 12, 2136. https://doi.org/10.3390/en12112136

Zhang Y, Hu J, Zhang Q. Simulation Study of CO2 Huff-n-Puff in Tight Oil Reservoirs Considering Molecular Diffusion and Adsorption. Energies. 2019; 12(11):2136. https://doi.org/10.3390/en12112136

Chicago/Turabian StyleZhang, Yuan, Jinghong Hu, and Qi Zhang. 2019. "Simulation Study of CO2 Huff-n-Puff in Tight Oil Reservoirs Considering Molecular Diffusion and Adsorption" Energies 12, no. 11: 2136. https://doi.org/10.3390/en12112136

APA StyleZhang, Y., Hu, J., & Zhang, Q. (2019). Simulation Study of CO2 Huff-n-Puff in Tight Oil Reservoirs Considering Molecular Diffusion and Adsorption. Energies, 12(11), 2136. https://doi.org/10.3390/en12112136