Abstract

The electric arc furnace operation at the Štore Steel company, one of the largest flat spring steel producers in Europe, consists of charging, melting, refining the chemical composition, adjusting the temperature, and tapping. Knowledge of the consumed energy within the individual electric arc operation steps is essential. The electric energy consumption during melting and refining was analyzed including the maintenance and technological delays. In modeling the electric energy consumption, 25 parameters were considered during melting (e.g., coke, dolomite, quantity), refining and tapping (e.g., injected oxygen, carbon, and limestone quantity) that were selected from 3248 consecutively produced batches in 2018. Two approaches were employed for the data analysis: linear regression and genetic programming model. The linear regression model was used in the first randomly generated generations of each of the 100 independent developed civilizations. More accurate models were subsequently obtained during the simulated evolution. The average relative deviation of the linear regression and the genetic programming model predictions from the experimental data were 3.60% and 3.31%, respectively. Both models were subsequently validated by using data from 278 batches produced in 2019, where the maintenance and the technological delays were below 20 minutes per batch. It was possible, based on the linear regression and the genetically developed model, to calculate that the average electric energy consumption could be reduced by up to 1.04% and 1.16%, respectively, in the case of maintenance and other technological delays.

1. Introduction

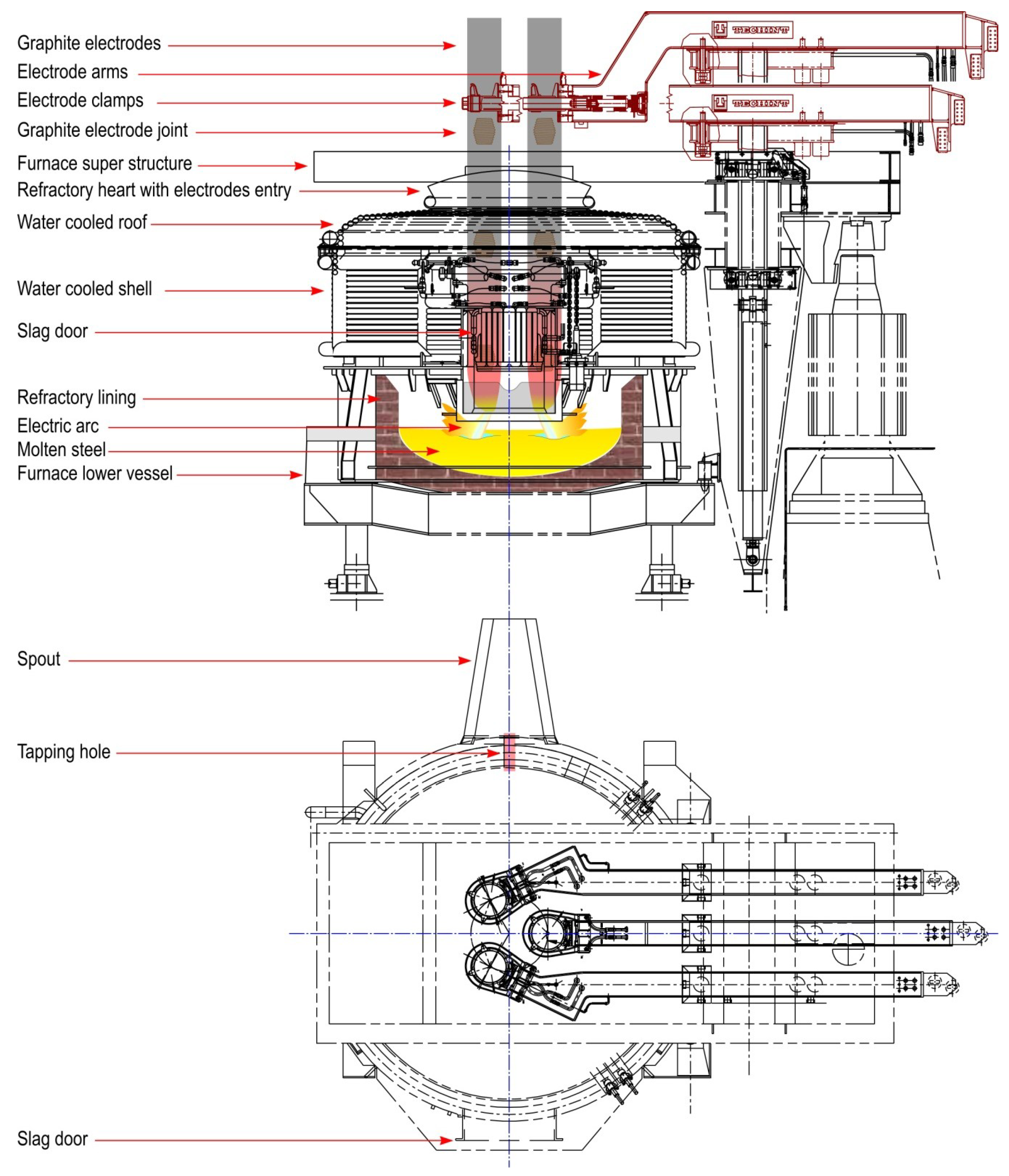

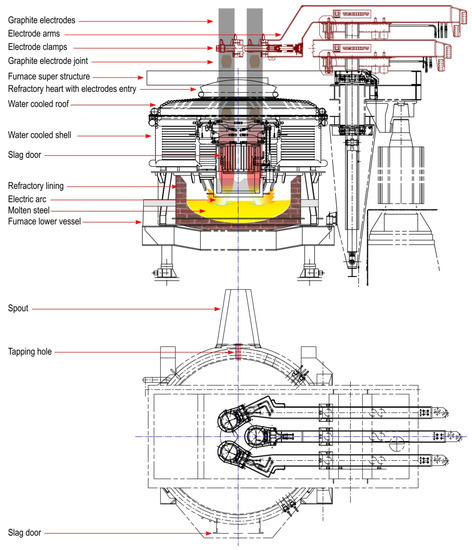

The electric arc furnace (EAF) is a central element and the highest energy consumer in the recycled steel processing industry. The EAF contains electric energy, with a moderate addition of chemical energy, that is used for generating the required heat for the melting of recyclable scrap. The heat energy is primarily generated by the burning arc between the electrodes and the scrap, or its melt. The EAF consists of a shell (walls with water cooled panels and lower vessel), a heart (refractory material that covers lower vessel), and a roof with the electrodes. A scheme of the EAF is presented in Figure 1 [1,2,3].

Figure 1.

Scheme of the electric arc furnace.

The main EAF operation steps are as follows [1,2,3]: charging and melting, refining (oxidizing of the melt), chemical composition and temperature adjusting, and tapping (discharging of the furnace).

With respect to energy consumption, the contemporary research has mainly focused on the total (electric and chemical) consumed energy [2,4,5,6] and individual (electric or chemical) consumed energy [7,8] including other aspects of EAF operation such as transformer optimization [1,9,10,11], molten steel residue [12,13], scrap type [14,15], scrap management [14,16,17], electrode regulation [18,19,20], oxygen injectors [13,21,22,23], and slag cover [24].

The influences of maintenance on the power, steel, and cement industries were analyzed in [25]. The authors found that maintenance and rehabilitation were the key factors only when producing steel using the blast furnace. However, the influence of maintenance on producing steel from scrap through an EAF was not deduced due to insufficient data.

The concept of an adaptive hydraulic control system of the electrode positions was proposed in [26]. The underlying concept for adaptive control represents a simplified model of an EAF. The model also takes into account the influences of process disturbances such as scrap manipulation and its morphology. Several control algorithms are presented and critically assessed.

The dynamic control of an EAF is given in [27]. The electric arc model was divided into four parts by also considering the gas burners (natural gas, oxygen), slag, molten steel, and solid scrap. The developed model was used for predicting the chemical and electrical energy consumption while changing the scrap quantities during the gradual charging of the EAF. The research showed that a proper scrap charging strategy could reduce the energy consumption.

The decision support for the EAF operation was developed in [6] by using open source tools and took into account different EAF operator strategies. The designed decision support system could be integrated with complex EAF models.

The computationally reduced model of the EAF operation during only the refining stage was elaborated in [28]. The typical mass-energy influential parameters were employed including the equipment failures. The MATLAB software was used in the simulations. The authors stated that the model could be significantly improved with additional parameters (e.g., carbon concentration, temperature).

The energy consumption during the refining stage was modeled in [21] by using a comprehensive parameter analysis. The scrap melting evolution (i.e., quantities, timing) was also taken into account. The model was validated in practice on a 40 t EAF.

The paper in [29] focused on modeling the tapping temperature. The energy consumption could be optimized based on the consideration of the influential parameters. For modeling, an artificial neural network was used that combined the final fuzzy interference function. In addition, the operator strategies and experiences were taken into account.

A comprehensive approach toward the electric energy consumption of the EAF, used at the Štore Steel steelmaking company, is elaborated in this work. The entire set of influential parameters during all operation steps including maintenance and other technological delays in 2018 (3248 consecutively produced batches) were taken into account. To predict the electric energy consumption during the EAF operation, both linear regression and the genetic programming were used.

The rest of this paper is organized as follows. Typical processes related to the EAF used at the Štore Steel company including data collection are presented first. Afterward, the related process data from 3248 consecutive batches collected in 2018 were used to model the electric energy consumption with linear regression and genetic programming. The validation of the modeling results was conducted by using data from 278 batches (when the maintenance and other technological delays were below 20 minutes per batch), collected in 2019. The importance of the represented developments for the steel industry is given in the conclusions.

2. Materials and Methods

The Štore Steel company is one of the major flat spring steel producers in Europe. The company produces more than 1000 steel grades with different chemical compositions. The scrap is melted, ladle treated, and continuously cast in billets. The cooled-down billets are reheated and rolled in the continuous rolling plant. The rolled bars can be additionally straightened, examined, cut, sawn, chamfered, drilled, and peeled in the cold finishing plant. The Štore Steel company is known for its application of advanced artificial intelligence modeling tools [30] for better understanding and optimization of the processes.

The production process at the Štore Steel company starts with a 60 t EAF. The scrap is delivered in baskets by train from a scrapyard, located 300 m from the steel plant. The following types of scrap steel are used for melting: E1 (old thick steel scrap); E2 (old thin steel scrap); E3 (thick new production steel scrap); E8 (thin new production steel scrap); E40 (shredded steel scrap); scrapped non-alloyed steel; low-alloyed steel (moderate content of Cr); and pig iron.

The electric arc furnace is typically charged with three baskets. The first, second, and third baskets have the capacity of 22–30 t, 15–20 t, and 6–15 t, respectively. Each individual charging lasts approximately three minutes. The melting of the scrap after charging with the first, second, and third baskets lasts approximately 20 min, 15 min, and 10 min, respectively.

The following activities are conducted before charging with the first basket: examination, cleaning and reparation of the slag door and tapping spout with its refractory material; examination of the EAF refractory linings and reparation of the linings with the dolomite or magnesite; examination of the water-cooled panels; examination of the mast arm (which holds the electrodes); and the changing and settings of the electrodes.

For the slag formation, coke, lime, and dolomite are also used, which are deposited before melting the first basket. The slag insulation and protective ability expands the lifespan of the refractory material, preventing the EAF roof from exposure, and shielding the cooling panels from the intensive heat radiation.

Melting is conducted after swinging back the furnace roof. After lowering the electrodes, the burning arc between the graphite electrodes and the scrap or the molten steel is established. After the last basket has been melted, the EAF roof is swung off, and the remaining non-melted scrap is pushed into the melt bath.

In order to speed up the melting process, oxygen and natural gas from wall-mounted combined burners (natural gas) and injectors (oxygen, coke) are also used, in addition to the electric arc, to generate the complementary chemical heat. After melting the last basket during the refining process, the oxygen jets from the lances penetrate the slag and react with the liquid bath. In particular, the oxidation with the carbon, phosphorous, and sulfur is important. The oxidized products are trapped by the slag, which is removed through the slag doors by tilting the EAF backward. Afterward, the chemical composition analysis is conducted. After the chemical composition changes, the tapping (i.e., tilting the EAF forward) is conducted. The molten steel is charged into the ladle and consequently, the ladle treatment is conducted (e.g., slag formation, chemical composition adjustments, melt stirring). Typical delays during the refining process are connected with the chemical and temperature analysis, oxygen blowing, changing of the steel grade (especially Ca-treated steels for its improved machinability), and waiting for the lower electricity tariff.

In the present research, 26 process parameters including the electric energy consumption were considered. The data were taken from 3248 consecutively produced batches at the Štore Steel company during 2018. The dataset was composed of:

- -

- Melting:

- ○

- the considered process parameters were:

- ▪

- coke (kg): used for protective slag formation,

- ▪

- lime (kg): used for protective slag formation,

- ▪

- dolomite [kg]: used for protective slag formation,

- ▪

- E-type scrap (kg),

- ▪

- low-alloyed steel (moderate content of Cr) (kg),

- ▪

- packets of scrap (kg),

- ▪

- oxygen consumption (Nm3) used for cutting the scrap and its combustion and forming the slag (important component of slag is FeO), and

- ▪

- natural gas consumption (Nm3) used for heating the scrap.

- ○

- The considered maintenance and other technological delays are:

- ▪

- lime addition (min): the additional time needed for lime addition,

- ▪

- scrap charging (min): the additional time needed for charging of the electric arc furnace with scrap,

- ▪

- reparation of the linings with the dolomite or magnesite (min): the additional time needed for reparation of the refractory linings of the heart of the electric arc furnace,

- ▪

- electrode settings (min): the additional time needed for electrode settings and replacing,

- ▪

- other technological delays (min): the additional delays due to, for example, the maintenance of a dust collector, water cooling system, or overhead cranes,

- -

- Refining and tapping:

- ○

- the considered process parameters are:

- ▪

- oxygen consumption (Nm3),which is used for uniform melt temperature distribution for removing the unwanted chemical elements such as sulfur or phosphorus,

- ▪

- limestone (kg), which is used for slag creation,

- ▪

- carbon content obtained by the first chemical composition analysis (%),

- ▪

- nominal final carbon content (%) where the melt can be used for producing several different grades of steel in further processing steps; the possibilities are determined from the first chemical composition analysis, and

- ▪

- carbon powder (kg), which is used for carbonizing and additional slag formation,

- ○

- the considered maintenance and other technological delays:

- ▪

- chemical analysis delay (min): there can be problems with the sampling or the chemical analysis has to be repeated,

- ▪

- temperature and oxygen analysis delay (min): there can be problems with the sampling or the automatic lance used for the analysis,

- ▪

- extended refining (min): due to the chemical analysis and the temperature adjustments, the refining process needs to be extended in order to achieve a proper chemical composition and a proper temperature before tapping,

- ▪

- delay due to Ca-treated steel production (min): to produce Ca-treated steel, proper oxygen content is needed before tapping; in addition, the spout wear and geometry are important,

- ▪

- delay due to waiting for a lower electricity tariff (min): during the higher electricity tariff period (from 6:00 to 8:00 a.m.), the production in the steel plant stops,

- ▪

- delay due to steel grade changing (min): based on the first chemical analysis, the steel grade can be changed according to the foreseen planned production,

- ▪

- delay during tapping (min): delays can occur due to spout maintenance or spout blocking, ladle treatment and casting coordination and management, and, last but not least,

- -

- Electric energy consumption (MWh).

The average values and the standard deviation of the individual parameters are presented in Table 1.

Table 1.

The average values and the standard deviation of the individual parameters from 3248 consecutively produced batches at the Štore Steel company in 2018.

3. EAF Electric Energy Consumption Modeling

Based on the collected data (Table 1), the prediction of the EAF electric energy consumption was conducted by using linear regression and genetic programming. For the fitness function, the average relative deviation between the predicted and the experimental data was selected. The fitness function is defined as:

where n is the size of the collected data and Qi and Q′i stand for the actual and the predicted electric energy consumption, respectively.

3.1. Linear Regression Modeling

The linear regression analysis results demonstrated that the model significantly predicted the electric energy consumption (p < 0.05, ANOVA) and that 63.60% of the total variances could be explained by independent variables variances (R-square). Out of the 25 independent parameters considered, only the following were not significantly influential (p > 0.05): lime, dolomite, scrap charging, chemical analysis delay, temperature and oxygen analysis delay, and delay during tapping.

The deduced linear regression model is:

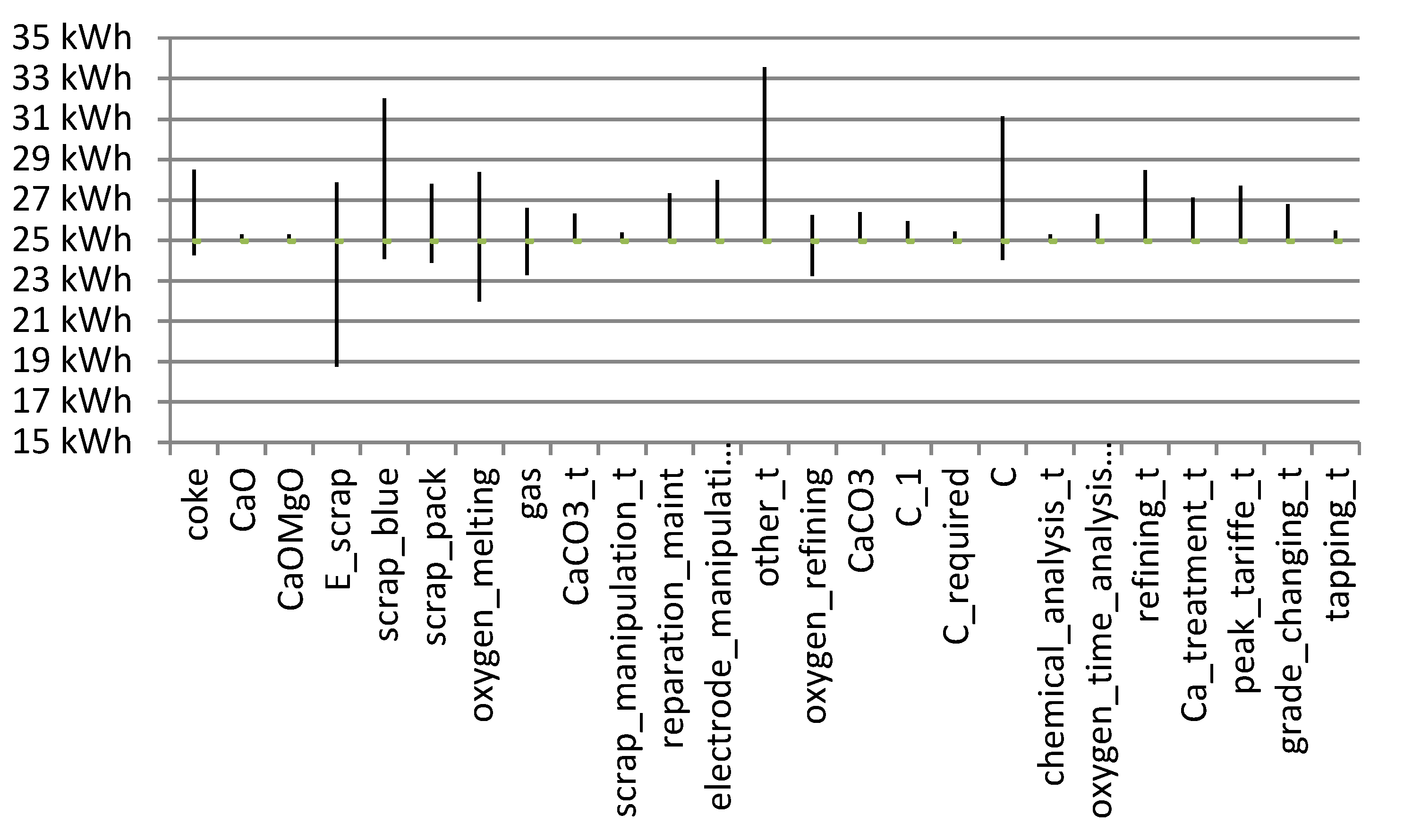

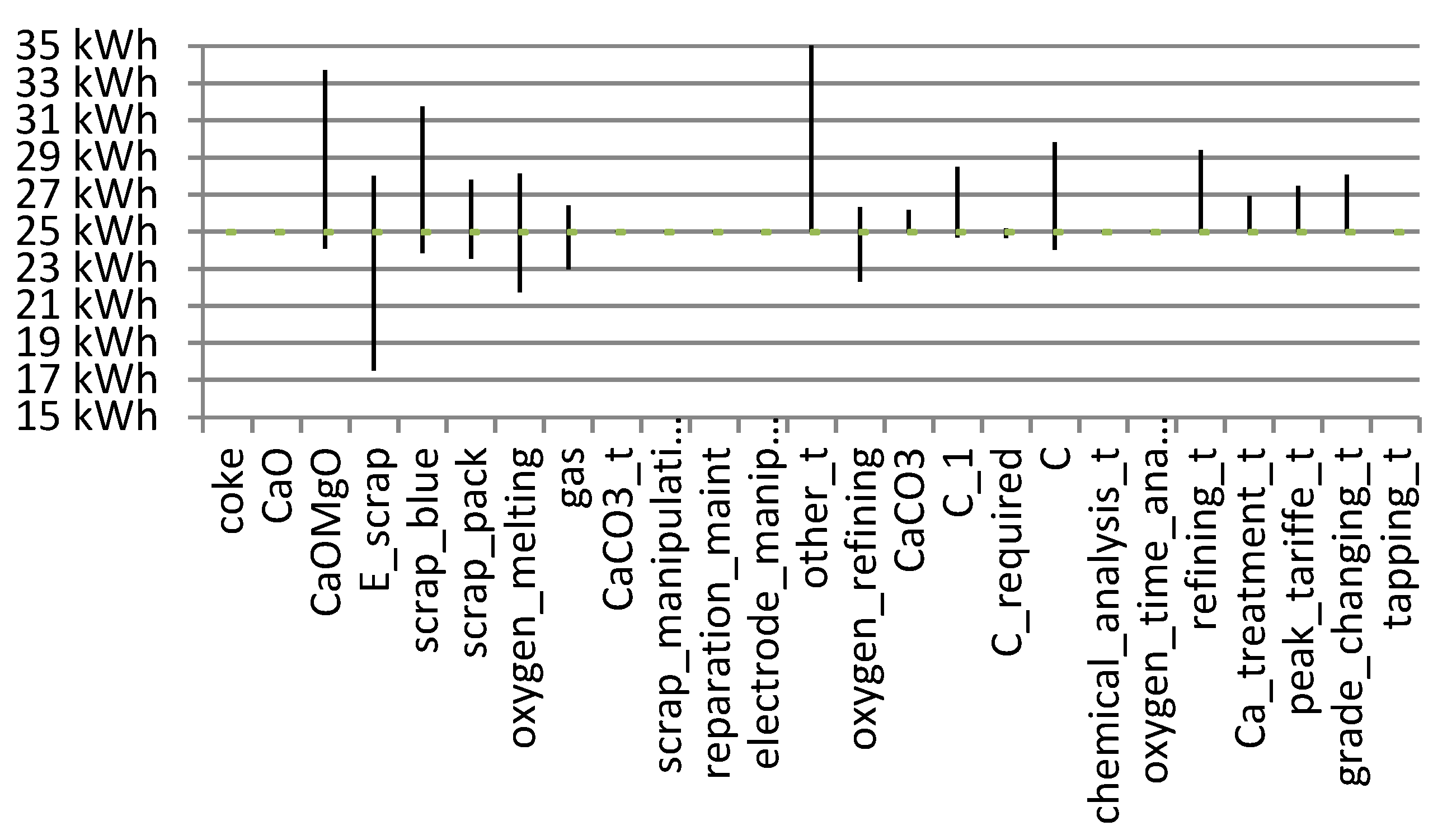

The average and maximal relative deviation from the experimental data was 3.60% and 36.75%, respectively. The calculated influences of the individual parameters (individual variables) on the electric energy consumption are presented in Figure 2. It is possible to conclude that E-type scrap, low-alloyed steel (moderate content of Cr), packets of scrap, oxygen consumption during melting, natural gas consumption, limestone, other technological delays, and coke injection during refining were the most influential factors. Based on the linear regression model, it was possible to calculate that the average electric energy consumption could be reduced by up to 1.04% in the case of the maintenance and other technological delays that we wanted to avoid. On the other hand, the time savings represented 24.89% of the average tapping time. As above-mentioned, during the higher electricity tariff period from 6:00 to 8:00 a.m., the production in the steel plant stopped.

Figure 2.

The calculated influences of the individual parameters on the electric energy consumption using the linear regression model.

3.2. Genetic Programing Modeling

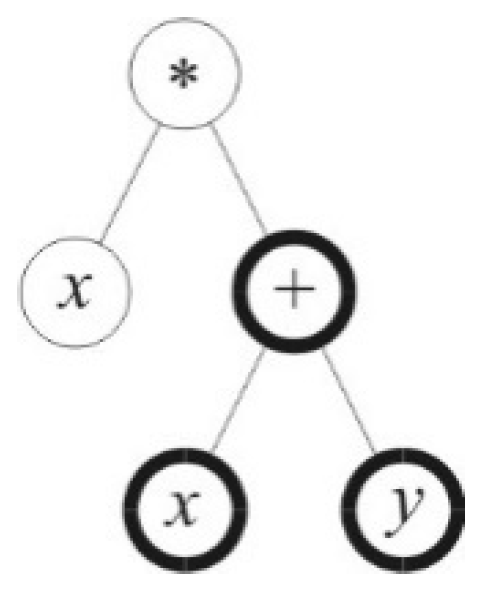

Genetic programming is probably the most general evolutionary optimization method [31,32]. The organisms that undergo adaptation are in fact the mathematical expressions (models) for predicting the ratio between the material with the surface defects and the examined material. The models, i.e., the computer programs, consist of the selected function (i.e., basic arithmetical functions) and terminal genes (i.e., independent input parameters and random floating-point constants). Typical function genes are: addition (+), subtraction (−), multiplication (*), and division (/), and terminal genes (e.g., x, y, z). Random computer programs (Figure 3) for calculating various forms and lengths are generated by means of the selected genes at the beginning of the simulated evolution.

Figure 3.

Random computer program as mathematical expression .

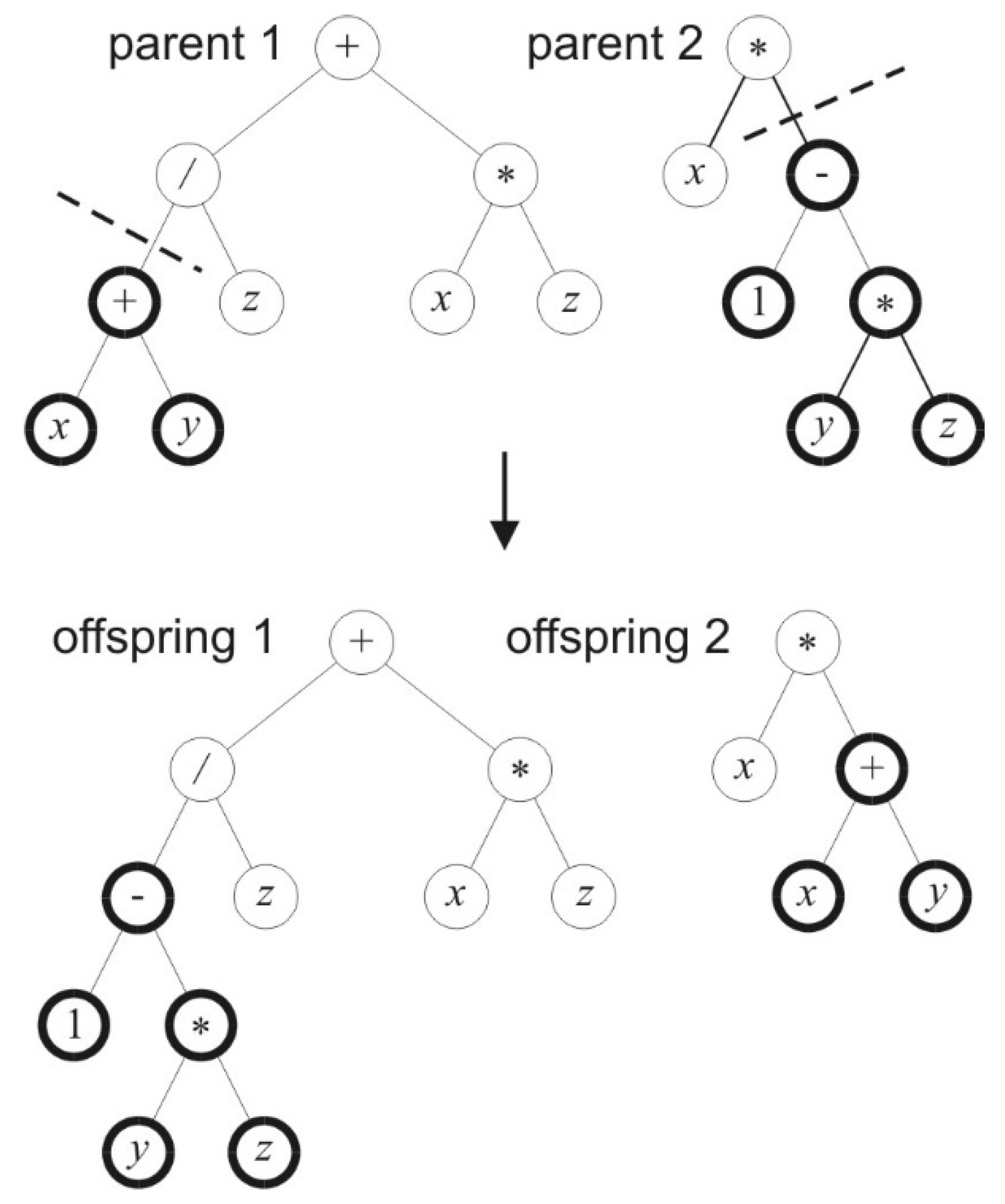

The varying of the computer programs is carried out by means of genetic operations (e.g., crossover, mutation) during several iterations, called generations. The crossover operation is presented in Figure 4. After the completion of the variation of the computer programs, a new generation is obtained. Each result, obtained from an individual program from a generation, is compared with the experimental data. The process of changing and evaluating the organisms is repeated until the termination criterion of the process is fulfilled.

Figure 4.

Crossover operation (out of two parental organisms, the offspring with randomly distributed genetic material are evolved).

An in-house genetic programming system, coded in the AutoLISP programming language, which is integrated into AutoCAD (i.e., commercial computer-aided design software), was used [33,34,35]. Its settings included the size of the population of organisms: 500; the maximum number of generations: 100; reproduction probability: 40%; crossover probability: 60%; maximum permissible depth in the creation of the population: 6; maximum permissible depth after the operation of crossover of two organisms: 10, and the smallest permissible depth of organisms in generating new organisms: 2.

The genetic operations of the reproduction and the crossover were used. To select the organisms, the tournament method with a tournament size 7 was used.

The in-house genetic programming system was run 100 times in order to develop 100 models for the prediction of electric energy consumption. Each run lasted approximately two and a half hours on an I7 Intel processor and 8 GB of RAM.

It must be emphasized that during the random generation of the computer programs (models for electric energy consumption), the already developed linear regression model (Equation (2)) was employed. The population size was 500. Out of these 500 organisms (computer programs), 50 were the same linear regression model, and the remaining 450 organisms were randomly generated at the beginning of the simulated evolution. Afterward, the population was changed with the genetic operations (e.g., crossover) without introducing any additionally developed linear regression models.

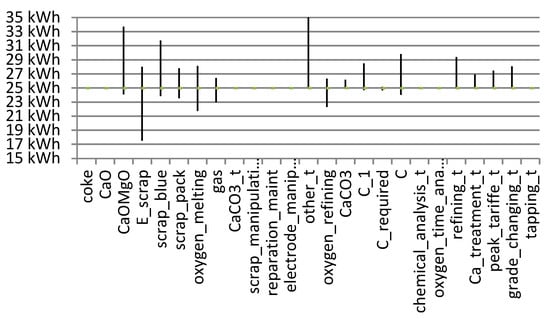

The best mathematical model obtained from 100 runs of genetic programming system was:

The average and the maximal relative deviation from the experimental data was 3.31% and 41.21%, respectively. The calculated influences of the individual parameters (individual variables) on the electric energy consumption are presented in Figure 5. It is possible to conclude that the dolomite, E-type scrap, low-alloyed steel (moderate content of Cr), other technological delays, and coke injection during refining were the most influential factors. Note that the coke, lime, limestone, scrap charging, reparation of the linings with the dolomite or magnesite, electrode settings, chemical analysis delay, oxygen and temperature analysis delay, and the delay during tapping were not considered in the model (Equation (3)). Additionally, based on the genetically developed model, it was possible to calculate that the average electric energy consumption could be reduced by up to 1.16% in the case of the maintenance and other technological delays.

Figure 5.

The calculated influences of the individual parameters on the electric energy consumption using a linear genetically developed model.

4. Validation of the Modeling Results

Additional data were gathered in January 2019 (278 batches) when the maintenance and technological delays were below 20 minutes. The average values and the standard deviation of the individual parameters are summarized in Table 2.

Table 2.

The average values and the standard deviation of individual parameters from 3248 consecutively produced batches at the Štore Steel Ltd. in 2018.

The average relative deviation between the experimental data and the linear regression model was 3.65%, and that between the experimental data and the genetic programming model was 3.49%. This is in accordance with the average relative deviation from the data obtained in 2018. Consequently, we can conclude that the represented approach can be used as a precise EAF energy consumption tool that also considers the maintenance and technological delays.

5. Conclusions

The prediction of the electric energy consumption of the EAF operation at the Štore Steel company was presented. Twenty-five selected parameters from the individual production process steps in 2018 (3248 consecutively produced batches) were used for modeling. Two models were considered: the first was based on linear regression, and the second was based on the more accurate genetic programming. The average relative deviation of the models from the experimental data was 3.60% with the linear regression model, and 3.31% with the genetic programming model, respectively.

Based on the linear regression results, it was possible to conclude that 63.60% of the total variances could be explained by the variances of the independent variables. Based on the linear regression model, it was possible to calculate that the average electric energy consumption could be reduced by up to 1.04% in the case of maintenance and other technological delays, while on the other hand the time savings represented 24.89% of the average tapping time. Out of the 25 independent parameters, only lime, dolomite, scrap charging, chemical analysis delay, temperature and oxygen analysis delay, and delay during tapping were not significantly influential (p > 0.05).

An in-house genetic programming system, coded in AutoLISP, which is integrated into AutoCAD, was used to obtain 100 independent models for the prediction of the electric energy consumption during the EAF operation. A population size of 500 organisms was chosen. Out of these 500 organisms (computer programs), 50 were from the same developed linear regression model, and the remaining 450 organisms were randomly generated at the beginning of the simulated evolution. Afterward, the population was changed with the genetic operations (e.g., crossover) without introducing additionally developed linear regression models. Only the best ones were used for analysis. The most influential parameters (based on calculation) were dolomite, E-type scrap, low- alloyed steel (moderate content of Cr), other technological delays, and coke injection during refining. It must be emphasized that coke, lime, limestone, scrap charging, reparation of the linings with the dolomite or magnesite, electrode settings, chemical analysis delay, oxygen and temperature analysis delay, and delay during tapping were not considered in the genetically developed model.

Both models were also validated by using the data from 278 batches produced in 2019, when the maintenance and the technological delays were below 20 minutes per batch. The average relative deviation of the linear regression and genetic programming model prediction from the experimental data were 3.56% and 3.49%, respectively. This was in accordance with the average relative deviations from the data obtained in 2018.

The following points represent the highlights of our work:

- -

- For modeling the EAF electric energy consumption, 25 parameters were used.

- -

- Parameters involved melting (e.g., coke, dolomite, quantity), refining and tapping (e.g., injected oxygen, carbon, and limestone quantity), maintenance, and technological delays.

- -

- The data from 3248 consecutively produced batches in 2018 were used.

- -

- For modeling, linear regression and genetic programming were used.

- -

- Both developed models were validated by using the data from 278 batches produced in 2019.

- -

- Both models showed that the electric energy consumption could be reduced by up to 1.16% with the reduction of the maintenance and other technological delays.

In the future, a detailed analysis of charging and melting operation steps will be conducted including the time-dependent electric energy, natural gas, oxygen, and coke consumption. The represented approach is, with only slight modifications, practically applicable in a spectra of different EAFs as well as in other steelmaking process steps.

Author Contributions

M.K.: conceptualization, methodology, investigation, data analysis, software, writing, visualization; K.S.: conceptualization, investigation, data analysis, writing, editing, visualization; R.V.: software, data mining, data analysis, review and editing; B.Š.: project management, data analysis, review and editing.

Funding

This research was funded by the Slovenian Grant Agency, grant numbers P2-0162 and J2-7197 and the Štore-Steel Company (www.store-steel.si).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Stopar, K.; Kovačič, M.; Kitak, P.; Pihler, J. Electric arc modeling of the EAF using differential evolution algorithm. Mater. Manuf. Process. 2017, 32, 1189–1200. [Google Scholar] [CrossRef]

- Toulouevski, Y.N.; Zinurov, I.Y. Modern Steelmaking in Electric Arc Furnaces: History and Development. In Innovation in Electric Arc Furnaces; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1–24. [Google Scholar]

- Toulouevski, Y.N.; Zinurov, I.Y. EAF in Global Steel Production. In Energy and Productivity Problems; Springer: Berlin, Germany, 2017; pp. 1–6. [Google Scholar]

- Tunc, M.; Camdali, U.; Arasil, G. Energy Analysis of the Operation of an Electric-Arc Furnace at a Steel Company in Turkey. Metallurgist 2015, 59, 489–497. [Google Scholar] [CrossRef]

- Damiani, L.; Revetria, R.; Giribone, P.; Schenone, M. Energy Requirements Estimation Models for Iron and Steel Industry Applied to Electric Steelworks. In Transactions on Engineering Technologies; Springer: Singapore, 2019; pp. 13–29. [Google Scholar]

- Shyamal, S.; Swartz, C.L.E. Real-time energy management for electric arc furnace operation. J. Process Control 2019, 74, 50–62. [Google Scholar] [CrossRef]

- Gajic, D.; Savic-Gajic, I.; Savic, I.; Georgieva, O.; Di Gennaro, S. Modelling of electrical energy consumption in an electric arc furnace using artificial neural networks. Energy 2016, 108, 132–139. [Google Scholar] [CrossRef]

- Zhao, S.; Grossmann, I.E.; Tang, L. Integrated scheduling of rolling sector in steel production with consideration of energy consumption under time-of-use electricity prices. Comput. Chem. Eng. 2018, 111, 55–65. [Google Scholar] [CrossRef]

- Klemen, S.; Kovačič, M.; Peter, K.; Jože, P. Electric-arc-furnace productivity optimization. Mater. Tehnol. 2014, 48, 3–7. [Google Scholar]

- Marchi, B.; Zanoni, S.; Mazzoldi, L.; Reboldi, R. Product-service System for Sustainable EAF Transformers: Real Operation Conditions and Maintenance Impacts on the Life-cycle Cost. Procedia CIRP 2016, 47, 72–77. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Mazzoldi, L.; Reboldi, R. Energy Efficient EAF Transformer—A Holistic Life Cycle Cost Approach. Procedia CIRP 2016, 48, 319–324. [Google Scholar] [CrossRef]

- Belkovskii, A.G.; Kats, Y.L. Effect of the Mass of the Liquid Residue on the Performance Characteristics of an Eaf. Metallurgist 2015, 58, 950–958. [Google Scholar] [CrossRef]

- Wei, G.; Zhu, R.; Dong, K.; Ma, G.; Cheng, T. Research and Analysis on the Physical and Chemical Properties of Molten Bath with Bottom-Blowing in EAF Steelmaking Process. Metall. Mater. Trans. B 2016, 47, 3066–3079. [Google Scholar] [CrossRef]

- Wieczorek, T.; Blachnik, M.; Ma̧czka, K. Building a Model for Time Reduction of Steel Scrap Meltdown in the Electric Arc Furnace (EAF): General Strategy with a Comparison of Feature Selection Methods. In Artificial Intelligence and Soft Computing—ICAISC 2008; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1149–1159. [Google Scholar]

- Malfa, E.; Nyssen, P.; Filippini, E.; Dettmer, B.; Unamuno, I.; Gustafsson, A.; Sandberg, E.; Kleimt, B. Cost and Energy Effective Management of EAF with Flexible Charge Material Mix. BHM Berg und Hüttenmännische Monatshefte 2013, 158, 3–12. [Google Scholar] [CrossRef]

- Sandberg, E.; Lennox, B.; Undvall, P. Scrap management by statistical evaluation of EAF process data. Control Eng. Pract. 2007, 15, 1063–1075. [Google Scholar] [CrossRef]

- Lee, B.; Sohn, I. Review of Innovative Energy Savings Technology for the Electric Arc Furnace. JOM 2014, 66, 1581–1594. [Google Scholar] [CrossRef]

- Hocine, L.; Yacine, D.; Kamel, B.; Samira, K.M. Improvement of electrical arc furnace operation with an appropriate model. Energy 2009, 34, 1207–1214. [Google Scholar] [CrossRef]

- Feng, L.; Mao, Z.; Yuan, P.; Zhang, B. Multi-objective particle swarm optimization with preference information and its application in electric arc furnace steelmaking process. Struct. Multidiscip. Optim. 2015, 52, 1013–1022. [Google Scholar] [CrossRef]

- Moghadasian, M.; Alenasser, E. Modelling and Artificial Intelligence-Based Control of Electrode System for an Electric Arc Furnace. J. Electromagn. Anal. Appl. 2011, 3, 47–55. [Google Scholar] [CrossRef]

- Mapelli, C.; Baragiola, S. Evaluation of energy and exergy performances in EAF during melting and refining period. Ironmak. Steelmak. 2006, 33, 379–388. [Google Scholar] [CrossRef]

- Kim, D.S.; Jung, H.J.; Kim, Y.H.; Yang, S.H.; You, B.D. Optimisation of oxygen injection in shaft EAF through fluid flow simulation and practical evaluation. Ironmak. Steelmak. 2014, 41, 321–328. [Google Scholar] [CrossRef]

- Cantacuzene, S.; Grant, M.; Boussard, P.; Devaux, M.; Carreno, R.; Laurence, O.; Dworatzek, C. Advanced EAF oxygen usage at Saint-Saulve steelworks. Ironmak. Steelmak. 2005, 32, 203–207. [Google Scholar] [CrossRef]

- Makarov, A.N. Change in Arc Efficiency During Melting in Steel-Melting Arc Furnaces. Metallurgist 2017, 61, 298–302. [Google Scholar] [CrossRef]

- Oda, J.; Akimoto, K.; Tomoda, T.; Nagashima, M.; Wada, K.; Sano, F. International comparisons of energy efficiency in power, steel, and cement industries. Energy Policy 2012, 44, 118–129. [Google Scholar] [CrossRef]

- Balan, R.; Hancu, O.; Lupu, E. Modeling and adaptive control of an electric arc furnace. IFAC Proc. Vol. 2007, 40, 163–168. [Google Scholar] [CrossRef]

- MacRosty, R.D.M.; Swartz, C.L.E. Dynamic Modeling of an Industrial Electric Arc Furnace. Ind. Eng. Chem. Res. 2005, 44, 8067–8083. [Google Scholar] [CrossRef]

- Coetzee, L.C.; Craig, I.K.; Rathaba, L.P. Mpc control of the refining stage of an electric arc furnace. IFAC Proc. Vol. 2005, 38, 151–156. [Google Scholar] [CrossRef]

- Mesa Fernández, J.M.; Cabal, V.Á.; Montequin, V.R.; Balsera, J.V. Online estimation of electric arc furnace tap temperature by using fuzzy neural networks. Eng. Appl. Artif. Intell. 2008, 21, 1001–1012. [Google Scholar] [CrossRef]

- Hanoglu, U.; Šarler, B. Multi-pass hot-rolling simulation using a meshless method. Comput. Struct. 2018, 194, 1–14. [Google Scholar] [CrossRef]

- Koza, J.R. The Genetic Programming Paradigm: Genetically Breeding Populations of Computer Programs to Solve Problems; MIT Press: Cambridge, MA, USA, 1992; pp. 203–321. [Google Scholar]

- Koza, J.R. Genetic Programming II: Automatic Discovery of Reusable Programs; MIT Press: Cambridge, MA, USA, 1994; ISBN 0-262-11189-6. [Google Scholar]

- Kovačič, M.; Jager, R. Modeling of occurrence of surface defects of C45 steel with genetic programming. Mater. Tehnol. 2015, 49, 857–863. [Google Scholar] [CrossRef]

- Kovačič, M.; Šarler, B. Genetic programming prediction of the natural gas consumption in a steel plant. Energy 2014, 66, 273–284. [Google Scholar] [CrossRef]

- Kovacic, M.; Brezocnik, M. Reduction of Surface Defects and Optimization of Continuous Casting of 70MnVS4 Steel. Int. J. Simul. Model. 2018, 17, 667–676. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).