Performance Analysis of a Combined Solar-Assisted Heat Pump Heating System in Xi’an, China

Abstract

1. Introduction

2. Methodology

2.1. System Descriptions

2.2. Design Parameters of the Serial Mode

2.3. Design Parameters of Parallel Mode

2.4. Measurement Instrumentation

3. Modelling

3.1. Models of the Two Modes

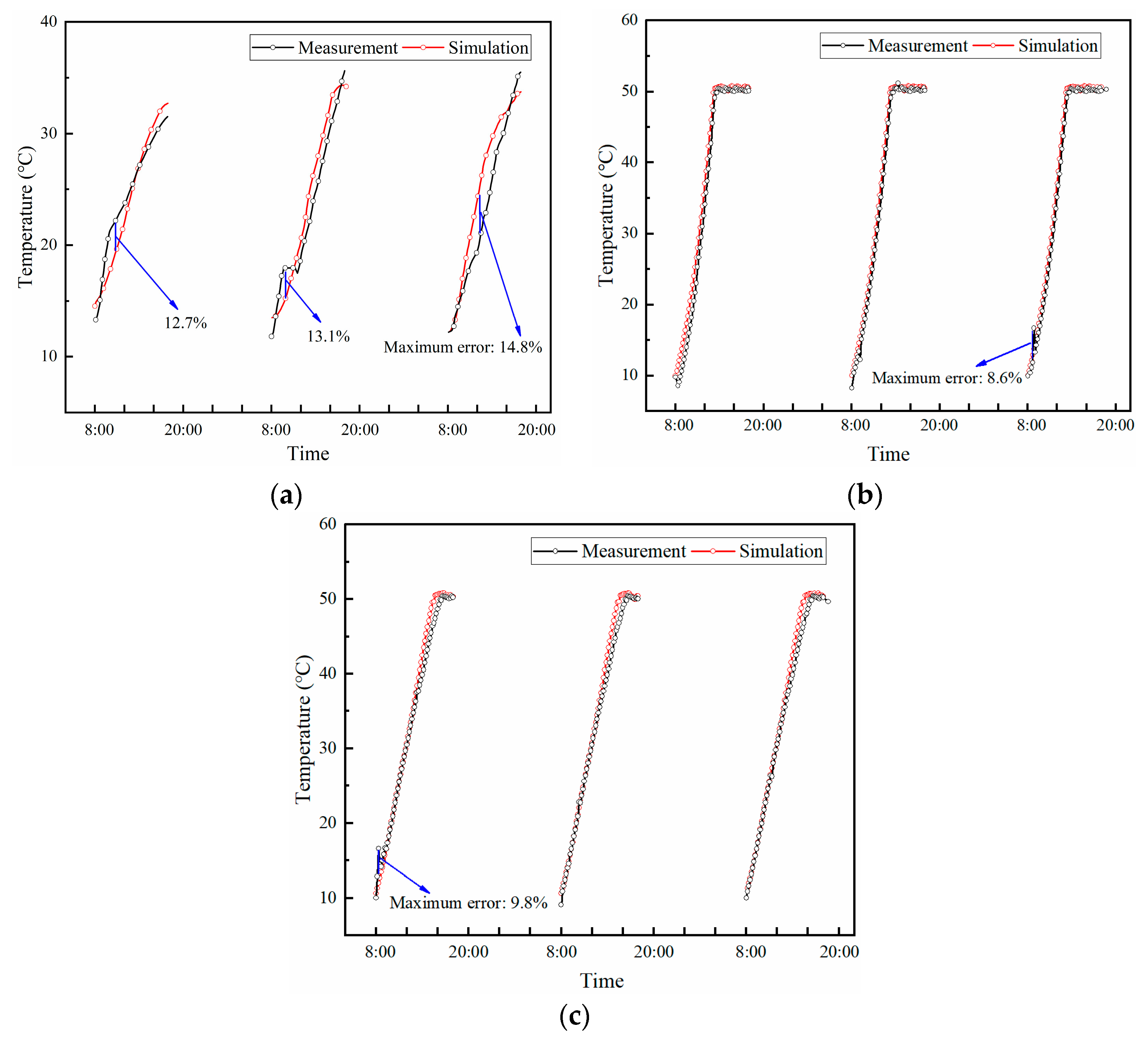

3.2. Model Validation

4. Results and Discussions

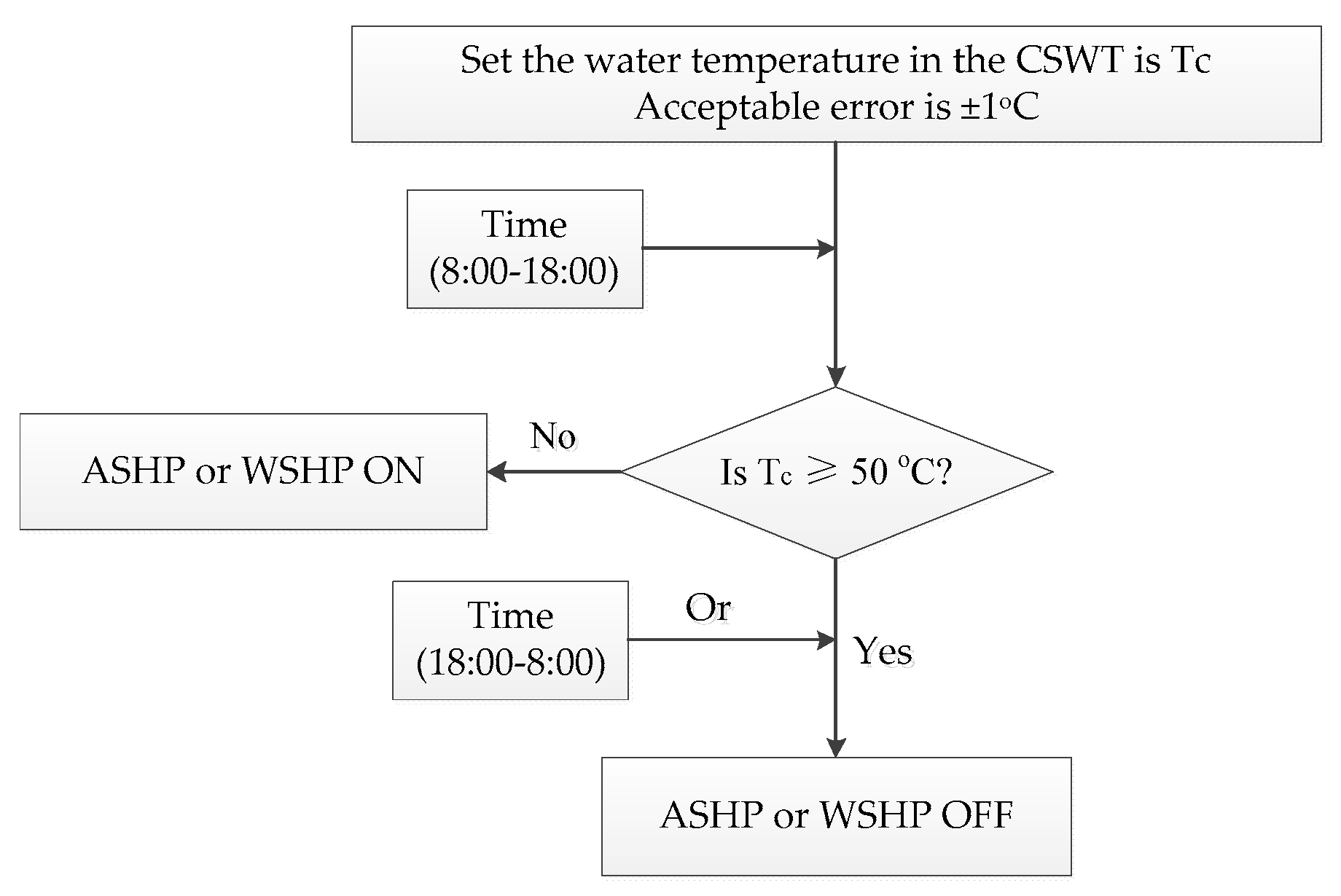

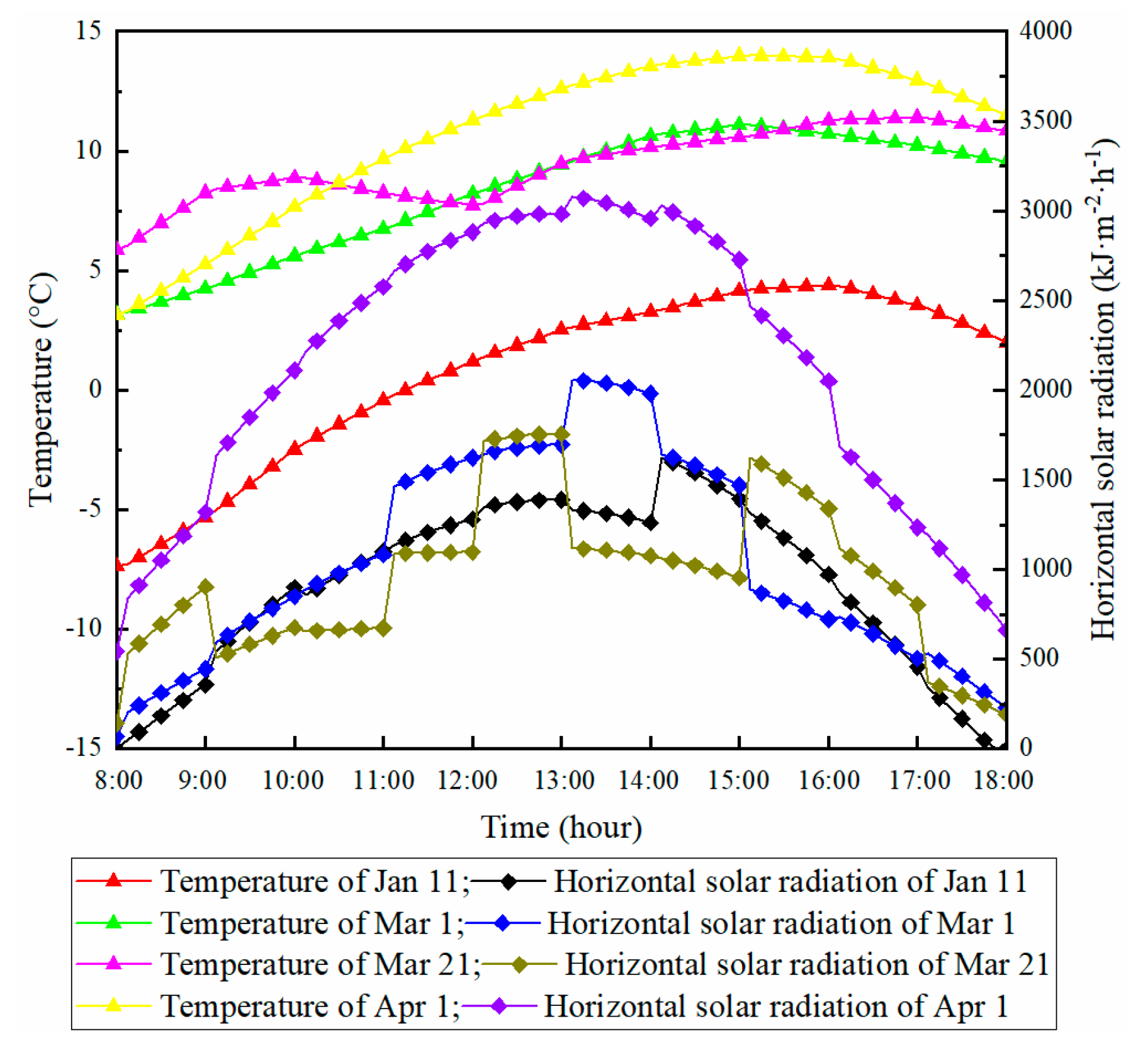

4.1. Switching Analysis

4.2. Heat Balance Equations of the SAHP System

- (1)

- Stable operation of the system.

- (2)

- Linear distribution of the temperatures in the solar collector and the heat exchanger.

- (3)

- Negligible heat loss of pipes and valves.

- (1)

- The compressor power consumption under the two modes was equal, which was described as follows:

- (2)

- The condensation temperatures of the ASHP and WSHP were approximately the same at the mode switching timing, thus it was supposed that the COPs of the heat pump systems were only influenced by the evaporation temperature.

- (3)

- The HSWT was insulated, thus the heat loss of the HSWT, e.g., KsAs(Tsm − Ta) could be ignored.

4.3. Switching Conditions

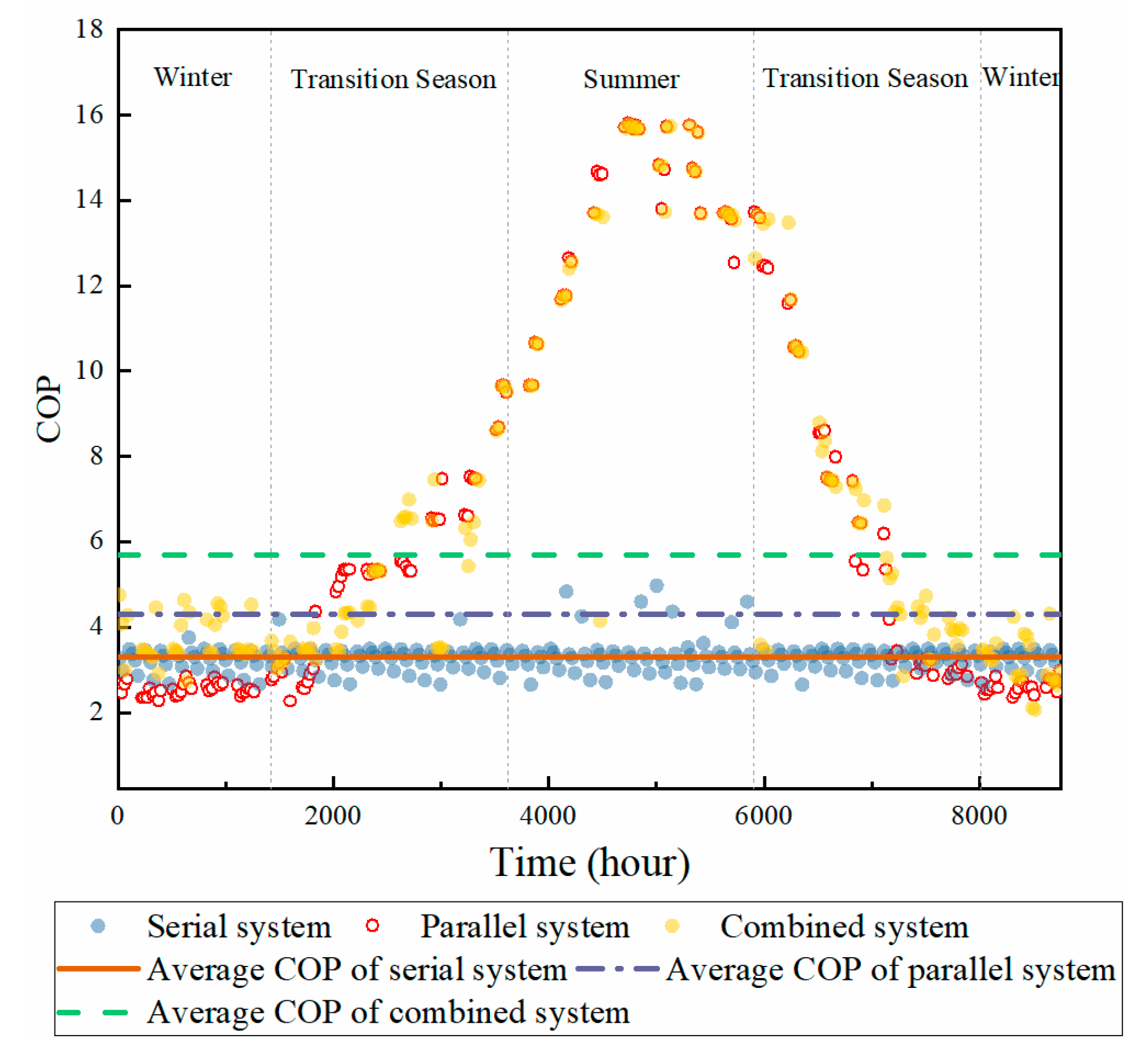

4.4. Annual Performance Analysis

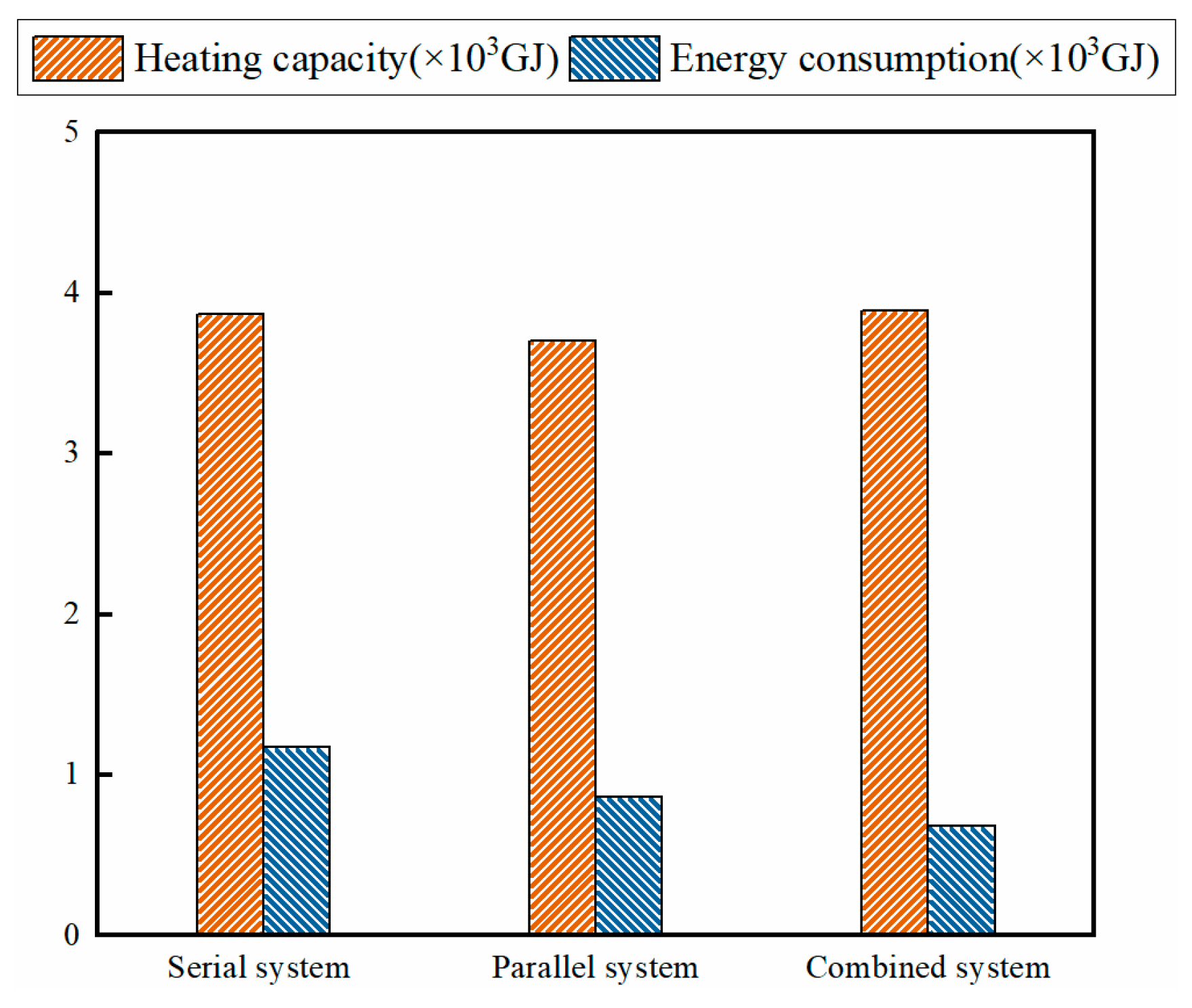

4.5. System Benefit Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ASHP | air source heat pump |

| CSWT | consumer side water tank |

| HSWT | heat storage water tank |

| SAHP | solar assisted heat pump |

| WSHP | water source heat pump |

| Ac | area of the solar collector, m2 |

| As | heat exchange area of HSWT, m2 |

| Aw | surface area of the exterior wall, m2 |

| Ci | conventional energy heating price in the year of system design, CNY/MJ |

| Ci’ | systematic assessment of conventional energy prices, CNY/kg |

| COPa | COP of ASHP |

| COPs | COP of WSHP |

| Eff | efficiency of conventional energy heating devices |

| Fr | heat removal factor |

| I | solar radiation, kJ·m−2·h−1 |

| Ic | average daily solar radiation in the coldest month, kJ·m−2·d−1 |

| Jt | annual solar radiation on the surface of solar collector, MJ/m2 |

| K1 | heat transfer coefficient of the plate to environment, kW·m−2·°C−1 |

| Ks | heat transfer coefficient of HSWT, kW·m−2·°C−1 |

| (mCp)s | heat capacity of water, kJ·°C−1·s−1 |

| mCp | heat capacity of the heating medium, kJ·°C−1·s−1 |

| Mi | simple annual energy saving cost, CNY |

| q | calorific value of conventional energy, MJ/kg |

| Q | heating capacity of CSWT for serial mode, kW |

| heating capacity of CSWT for parallel mode, kW | |

| QC | heat transfer rate of WSHP evaporator, kW |

| heat transfer rate of ASHP evaporator, kW | |

| Qk | heat transfer rate of WSHP condenser, kW |

| heat transfer capacity of ASHP condenser, kW | |

| Qs | daily heat capacity, kW |

| Qu | heat collection the solar collector, kW |

| collecting heat of the solar collector, kW | |

| ΔQ | annual energy-saving amount, MJ |

| Ta | ambient temperature, °C |

| Tca | average water temperature of the solar collector, °C |

| Tci | inlet water temperature of the collector, °C |

| Tco | outlet water temperature of the solar collector, °C |

| Tsm | average water temperature in HSWT, °C |

| V | volume of the HSWT, m3 |

| W | compressor power of WSHP, kW |

| compressor power of ASHP, kW | |

| (ρc)w | volumetric heat capacity of the heating medium, kJ·m−3·°C−1 |

| τα | product of the transmittance and absorption rates of the plate |

| ηc | collector efficiency |

| ηcd | heat loss rate of pipeline and water tank |

| ηs | heat loss rate of heating medium |

| Δt | temperature difference, °C |

| δTs/δτ | water temperature change rate, °C |

References

- Zeng, R.; Wang, X.; Di, H.; Jiang, F.; Zhang, Y. New concepts and approach for developing energy efficient buildings: Ideal specific heat for building internal thermal mass. Energy Build. 2011, 43, 1081–1090. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Moschos, K.; Antonopoulos, K.A. Energetic and financial evaluation of solar assisted heat pump space heating systems. Energy Convers. Manag. 2016, 120, 306–319. [Google Scholar] [CrossRef]

- Huang, Y.; Niu, J.; Chung, T. Study on performance of energy-efficient retrofitting measures on commercial building external walls in cooling-dominant cities. Appl. Energy 2013, 103, 97–108. [Google Scholar] [CrossRef]

- Tzivanidis, C.; Bellos, E.; Mitsopoulos, G.; Antonopoulos, K.A.; Delis, A. Energetic and financial evaluation of a solar assisted heat pump heating system with other usual heating systems in Athens. Appl. Therm. Eng. 2016, 106, 87–97. [Google Scholar] [CrossRef]

- Nozik, A.J. Photoelectrochemistry: Applications to Solar Energy Conversion. Ann. Rev. Phys. Chem. 2003, 29189–29222. [Google Scholar] [CrossRef]

- Lewis, N.S. Toward cost-effective solar energy use. Science 2007, 315, 798–801. [Google Scholar] [CrossRef] [PubMed]

- Li, B. Integration of Solar Systems with Heat Pumps and Other Technologies. In Handbook of Energy Systems in Green Buildings; Wang, R., Zhai, X., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1372–1407. [Google Scholar]

- Jordan, R.C.; Threlkeld, J.L. Design and economics of solar energy heat pump system. Heat. Piping Air Cond. 1954, 26, 122–130. [Google Scholar]

- Hawlader, M.N.A.; Chou, S.K.; Ullah, M.Z. The performance of a solar assisted heat pump water heating system. Appl. Therm. Eng. 2001, 21, 1049–1065. [Google Scholar] [CrossRef]

- Huang, B.J.; Lee, C.P. Long-term performance of solar-assisted heat pump water heater. Renew. Energy 2004, 29, 633–639. [Google Scholar] [CrossRef]

- Hepbasli, A.; Kalinci, Y. A review of heat pump water heating systems. Renew. Sustain. Energy Rev. 2009, 13, 1211–1229. [Google Scholar] [CrossRef]

- Sun, X.; Dai, Y.; Novakovic, V.; Wu, J.; Wang, R. Performance Comparison of Direct Expansion Solar-assisted Heat Pump and Conventional Air Source Heat Pump for Domestic Hot Water. Energy Procedia 2015, 70, 394–401. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, Y.; Yao, Y. The field test and optimization of a solar assisted heat pump system for space heating in extremely cold area. Sustain. Cities Soc. 2014, 13, 97–104. [Google Scholar] [CrossRef]

- Yang, W.; Zhu, J.; Shi, M.; Chen, Z. Numerical Simulation of the Performance of a Solar-Assisted Heat Pump Heating System. Procedia Environ. Sci. 2011, 11, 790–797. [Google Scholar] [CrossRef][Green Version]

- Cabrol, L.; Rowley, P. Towards low carbon homes—A simulation analysis of building-integrated air-source heat pump systems. Energy Build. 2012, 48, 127–136. [Google Scholar] [CrossRef]

- Molinaroli, L.; Joppolo, C.M.; De Antonellis, S. Numerical Analysis of the Use of R-407C in Direct Expansion Solar Assisted Heat Pump. Energy Procedia 2014, 48, 938–945. [Google Scholar] [CrossRef][Green Version]

- Wang, Z.; Guo, P.; Zhang, H.; Yang, W.; Mei, S. Comprehensive review on the development of SAHP for domestic hot water. Renew. Sustain. Energy Rev. 2017, 72, 871–881. [Google Scholar] [CrossRef]

- Morrison, G.L.; Anderson, T.; Behnia, M. Seasonal performance rating of heat pump water heaters. Sol. Energy 2004, 76, 147–152. [Google Scholar] [CrossRef]

- Lerch, W.; Heinz, A.; Heimrath, R. Direct use of solar energy as heat source for a heat pump in comparison to a conventional parallel solar air heat pump system. Energy Build. 2015, 100, 34–42. [Google Scholar] [CrossRef]

- Tagliafico, L.A.; Scarpa, F.; Valsuani, F. Direct expansion solar assisted heat pumps—A clean steady state approach for overall performance analysis. Appl. Therm. Eng. 2014, 66, 216–226. [Google Scholar] [CrossRef]

- Li, H.; Sun, L.; Zhang, Y. Performance investigation of a combined solar thermal heat pump heating system. Appl. Therm. Eng. 2014, 71, 460–468. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, Y.; Mi, H.; Zhou, Y.; Zhang, Y. Experimental Research of a Water-Source Heat Pump Water Heater System. Energies 2018, 11, 1205. [Google Scholar] [CrossRef]

- Ruschenburg, J.; Herkel, S.; Henning, H.-M. A statistical analysis on market-available solar thermal heat pump systems. Sol. Energy 2013, 95, 79–89. [Google Scholar] [CrossRef]

- Huan, C.; Wang, F.; Li, S.; Zhao, Y.; Liu, L.; Wang, Z.; Ji, C. A performance comparison of serial and parallel solar-assisted heat pump heating systems in Xi’an, China. Energy Sci. Eng. 2019, 00, 1–15. [Google Scholar] [CrossRef]

- Bakirci, K.; Yuksel, B. Experimental thermal performance of a solar source heat-pump system for residential heating in cold climate region. Appl. Therm. Eng. 2011, 31, 1508–1518. [Google Scholar] [CrossRef]

- Urchueguía, J.F.; Zacarés, M.; Corberán, J.M.; Montero, Á.; Martos, J.; Witte, H. Comparison between the energy performance of a ground coupled water to water heat pump system and an air to water heat pump system for heating and cooling in typical conditions of the European Mediterranean coast. Energy Convers. Manag. 2008, 49, 2917–2923. [Google Scholar] [CrossRef]

- Gao, L.; Dougal, R.A.; Liu, S.; Iotova, A.P. Parallel-Connected Solar PV System to Address Partial and Rapidly Fluctuating Shadow Conditions. IEEE Trans. Ind. Electron. 2009, 56, 1548–1556. [Google Scholar]

- Liang, C.; Zhang, X.; Li, X.; Zhu, X. Study on the performance of a solar assisted air source heat pump system for building heating. Energy Build. 2011, 43, 2188–2196. [Google Scholar] [CrossRef]

- Touchie, M.F.; Pressnail, K.D. Testing and simulation of a low-temperature air-source heat pump operating in a thermal buffer zone. Energy Build. 2014, 75, 149–159. [Google Scholar] [CrossRef]

- Dikici, A.; Akbulut, A. Performance characteristics and energy–exergy analysis of solar-assisted heat pump system. Build. Environ. 2008, 43, 1961–1972. [Google Scholar] [CrossRef]

- Li, H.; Yang, H. Study on performance of solar assisted air source heat pump systems for hot water production in Hong Kong. Appl. Energy 2010, 87, 2818–2825. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Energetic and financial sustainability of solar assisted heat pump heating systems in Europe. Sustain. Cities Soc. 2017, 33, 70–84. [Google Scholar] [CrossRef]

- Moreno-Rodríguez, A.; González-Gil, A.; Izquierdo, M.; Garcia-Hernando, N. Theoretical model and experimental validation of a direct-expansion solar assisted heat pump for domestic hot water applications. Energy 2012, 45, 704–715. [Google Scholar] [CrossRef]

- Banister, C.J.; Collins, M.R. Development and performance of a dual tank solar-assisted heat pump system. Appl. Energy 2015, 149, 125–132. [Google Scholar] [CrossRef]

- Aye, L.; Charters, W.W.S.; Chaichana, C. Solar heat pump systems for domestic hot water. Sol. Energy 2002, 73, 169–175. [Google Scholar] [CrossRef]

- Chaturvedi, S.K.; Gagrani, V.D.; Abdel-Salam, T.M. Solar-assisted heat pump—A sustainable system for low-temperature water heating applications. Energy Convers. Manag. 2014, 77, 550–557. [Google Scholar] [CrossRef]

- Shan, P.; Lai, X. Influence of CT scanning parameters on rock and soil images. J. Vis. Commun. Image Represent 2019, 58, 642–650. [Google Scholar] [CrossRef]

- Liu, L.; Xin, J.; Feng, Y.; Zhang, B.; Song, K. Effect of the cement-tailing ratio on the hydration products and microstructure characteristics of cemented paste backfill. Arab. J. Sci. Eng. 2019. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, C.; Qi, C.; Zhang, B.; Song, K. A microstructural hydration model for cemented paste backfill considering internal sulfate attacks. Constr. Build. Mater. 2019, 211, 99–108. [Google Scholar] [CrossRef]

- Qi, C.; Liu, L.; He, J.; Chen, Q.; Yu, L.; Liu, P. Understanding Cement Hydration of Cemented Paste Backfill: DFT Study of Water Adsorption on Tricalcium Silicate (111) Surface. Minerals 2019, 9, 202. [Google Scholar] [CrossRef]

- Sabiha, M.A.; Saidur, R.; Mekhilef, S.; Mahian, O. Progress and latest developments of evacuated tube solar collectors. Renew. Sustain. Energy Rev. 2015, 51, 1038–1054. [Google Scholar] [CrossRef]

- Qi, Q.M.; Wang, X.Z. Meteorological Data Set for China’s Building Thermal Environment Analysis, 1st ed.; China Building Industry Press: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Ito, S.; Miura, N.; Wang, K. Performance of a heat pump using direct expansion solar collectors/evaporators. Sol. Energy 1999, 65, 189–196. [Google Scholar] [CrossRef]

- Ito, S.; Miura, N.; Takano, Y. Studies of Heat Pumps Using Direct Expansion Type Solar Collectors. J. Sol. Energy Eng. 2005, 127, 60–64. [Google Scholar] [CrossRef]

- Kuang, Y.; Wang, R.; Yu, L. Experimental study of solar assisted heat pump(SAHP) system for heat supply. Acta Energiae Sol. Sin. 2002, 4, 408–413. (In Chinese) [Google Scholar]

- Zhang, X.; Yu, L.; Kuang, Y. Measurement Error Analysis of Solar Assisted Heat Pump System. Energy Conserv. Technol. 2006, 4, 316–320. (In Chinese) [Google Scholar]

- Li, S.; Wang, H.; Meng, X.; Wei, X. Comparative study on the performance of a new solar air collector with different surface shapes. Appl. Therm. Eng. 2017, 114, 639–644. [Google Scholar] [CrossRef]

- Suppiah, S.; Kutchcoskie, K.J.; Balakrishnan, P.V.; Chuang, K.T. Dissolved oxygen removal by combination with hydrogen using wetproofed catalysts. Can. J. Chem. Eng. 2010, 66, 849–857. [Google Scholar] [CrossRef]

- Schmidt, T.; Mangold, D.; Müller-Steinhagen, H. Central solar heating plants with seasonal storage in Germany. Sol. Energy 1997, 76, 165–174. [Google Scholar] [CrossRef]

- Badescu, V.; Staicovici, M.D. Renewable energy for passive house heating: Model of the active solar heating system. Energy Build. 2006, 38, 129–141. [Google Scholar] [CrossRef]

- Ji, Y.; Duan, M. Operation modes of solar-assisted ground-source heat pump system in transition season. Heat. Vent. Air Cond. 2017, 47, 127–131. (In Chinese) [Google Scholar]

- Shunroku, T. Solar Cooling and Heating, 1st ed.; China Building Industry Press: Beijing, China, 1982. [Google Scholar]

- Jiang, L.Q.; Lou, J.; Jiang, J.L. Study on the selection of the parallel pattern solar heat pumps in water heating system. Water Watstewater Eng. 2008, 9, 89–91. (In Chinese) [Google Scholar]

- Liu, L.; Yang, P.; Qi, C.; Zhang, B.; Guo, L.; Song, K. An experimental study on the early-age hydration kinetics of cemented paste backfill. Constr. Build. Mater. 2019, 212, 283–294. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Z.; Ji, C.; Liu, L.; Zhang, B.; Huan, C. Characterization of particulate matter from heating and cooling several edible oils. Build. Environ. 2019, 152, 204–213. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Duffy, A.; McCormack, S.J.; Conlon, M. Validated TRNSYS model for forced circulation solar water heating systems with flat plate and heat pipe evacuated tube collectors. Appl. Therm. Eng. 2011, 31, 1536–1542. [Google Scholar] [CrossRef]

- Haller, M.Y.; Bertram, E.; Dott, R.; Afjei, T.; Ochs, F.; Hadorn, J.-C. Review of Component Models for the Simulation of Combined Solar and Heat Pump Heating Systems. Energy Procedia 2012, 30, 611–622. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Delis, A.; Antonopoulos, K.A. Comparison of a Solar-Driven Heat Pump Heating System with Other Typical Heating Systems with TRNSYS. In Proceedings of the 28th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Pau, France, 30 June–3 July 2015. [Google Scholar]

- Rao, K. A method for obtaining correction coefficient of incidence angle of evacuated collector. Acta Energiae Sol. Sin. 2009, 30, 1163–1167. (In Chinese) [Google Scholar]

- Zhang, X.M.; Jia, L.M.; Liang, Y.F.; Liu, F.X. Principle characteristics and influence factors of ASHP. J. Hebei Inst. Archit. Sci. Technol. 2002, 1, 18–21. (In Chinese) [Google Scholar]

- Zhang, X.; Lan, G.; Du, Y.; Fei, X. Equipment Energy Balance in Solar Energy Heat Pump System. Build. Energy Environ. 2000, 19, 23–25. (In Chinese) [Google Scholar]

- China, Ministry of Housing and Urban-Rural Construction. Tecnical Code for Solar Heating System; China Architecture & Building Press: Beijing, China, 2009; Volume GB 50495-2009, p. 77. (In Chinese)

| Component | TRNSYS Type |

|---|---|

| Weather data reader | 109 |

| Evacuated collector | 538 |

| Controller | 2 |

| HSWT | 4 |

| CSWT | 4 |

| WSHP | 668 |

| Water pump | 114 |

| Load profile | 14 |

| Results | 24 |

| Printer | 25 |

| Graphic plotter | 65 |

| ASHP | 941 |

| Mixer | 11 |

| Performance Parameters | Jan 11 | Mar 1 | Mar 21 | Apr 1 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S Mode | S + P Mode | S Mode | S + P Mode | S Mode | S + P Mode | S Mode | S + P Mode | |||||

| C | A | C | A | C | A | C | A | |||||

| Heating capacity/106 kJ (C&A) | 4.08 | 1.55 | 2.70 | 5.22 | 2.14 | 3.17 | 5.34 | 2.36 | 3.71 | 5.46 | 4.45 | 1.93 |

| Energy consumption/106 kJ | 1.26 | 1.35 | 1.32 | 1.38 | 1.34 | 1.40 | 1.35 | 0.72 | ||||

| COP | 3.24 | 3.15 | 3.94 | 3.86 | 3.99 | 4.32 | 4.06 | 8.84 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huan, C.; Li, S.; Wang, F.; Liu, L.; Zhao, Y.; Wang, Z.; Tao, P. Performance Analysis of a Combined Solar-Assisted Heat Pump Heating System in Xi’an, China. Energies 2019, 12, 2515. https://doi.org/10.3390/en12132515

Huan C, Li S, Wang F, Liu L, Zhao Y, Wang Z, Tao P. Performance Analysis of a Combined Solar-Assisted Heat Pump Heating System in Xi’an, China. Energies. 2019; 12(13):2515. https://doi.org/10.3390/en12132515

Chicago/Turabian StyleHuan, Chao, Shengteng Li, Fenghao Wang, Lang Liu, Yujiao Zhao, Zhihua Wang, and Pengfei Tao. 2019. "Performance Analysis of a Combined Solar-Assisted Heat Pump Heating System in Xi’an, China" Energies 12, no. 13: 2515. https://doi.org/10.3390/en12132515

APA StyleHuan, C., Li, S., Wang, F., Liu, L., Zhao, Y., Wang, Z., & Tao, P. (2019). Performance Analysis of a Combined Solar-Assisted Heat Pump Heating System in Xi’an, China. Energies, 12(13), 2515. https://doi.org/10.3390/en12132515