A Photovoltaic Greenhouse with Variable Shading for the Optimization of Agricultural and Energy Production

Abstract

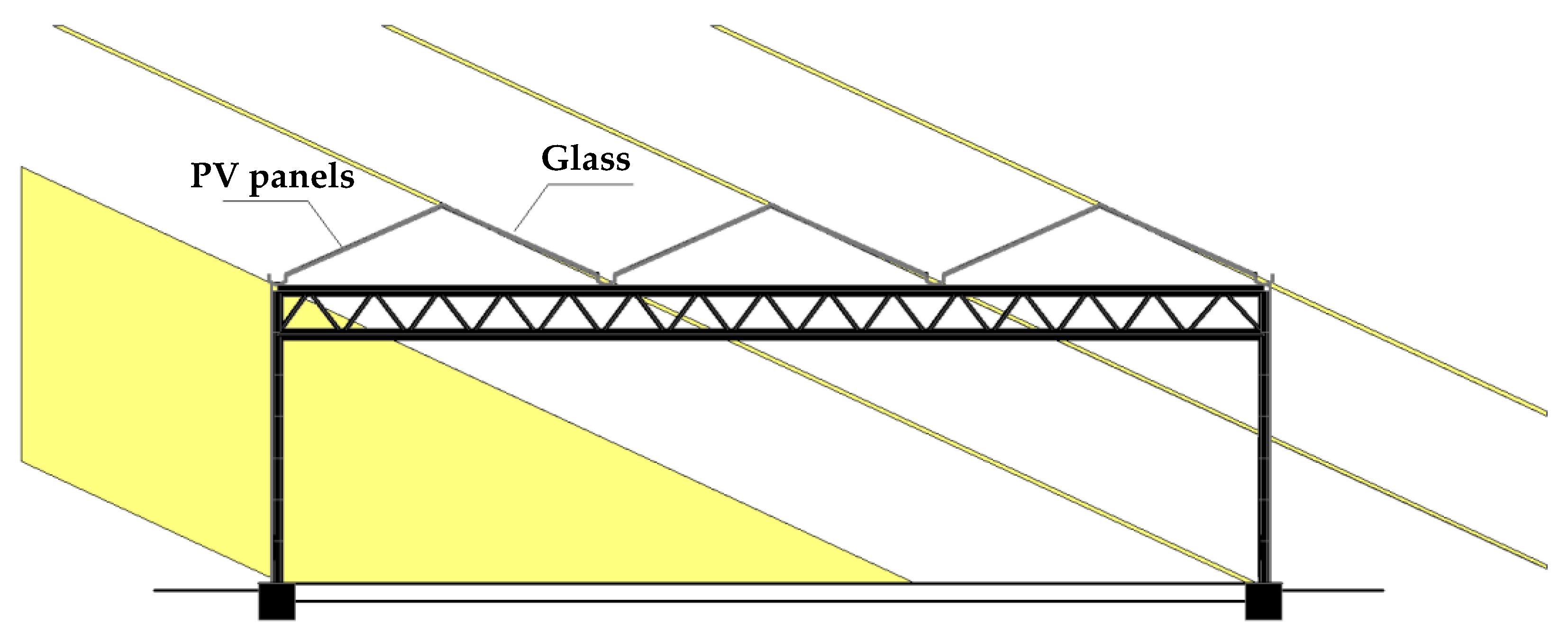

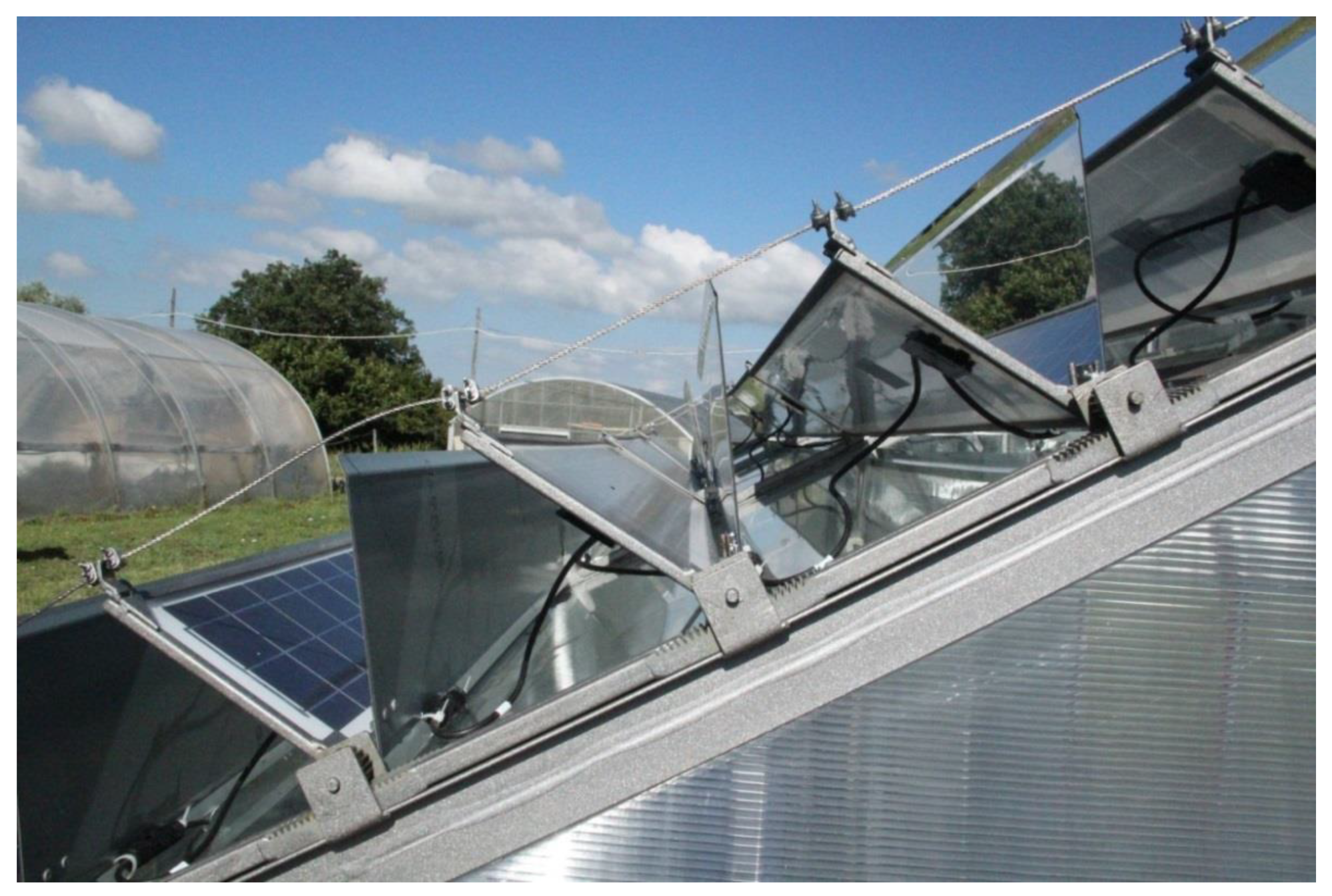

:1. Introduction

- (1)

- Continuously vary the shading according to the weather conditions, the period of the year, the time of day, and the type of harvest. The mobile system (panels and mirrors) makes the structure dynamic and flexible based on the needs of the situation;

- (2)

- Optimize energy and agricultural production consuming the same land unit, without filling areas adjacent to the greenhouse for the positioning of the panels at the expense of crops;

- (3)

- Totally recover the amount of energy lost by reflection when the inclination of the direct solar radiation moves away from the optimal one thanks to the use of aluminum mirrors constantly aligned with the sun’s rays;

- (4)

- Use a large part of the greenhouse roof for the installation of photovoltaic panels, leaving the crop protected from precipitation.

2. Materials and Methods

- (1)

- The kind of crop;

- (2)

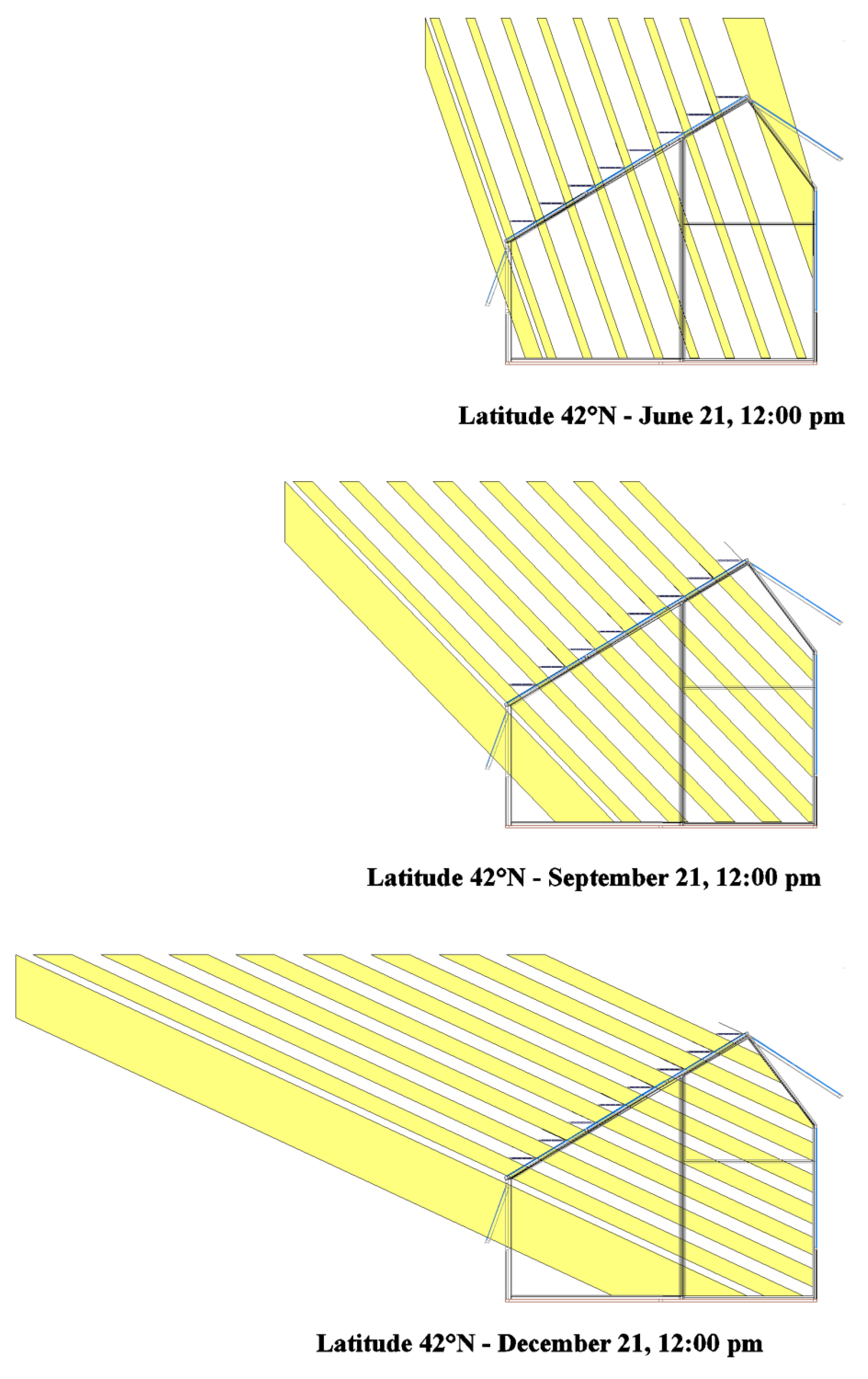

- Latitude;

- (3)

- The time of day; and

- (4)

- External weather conditions.

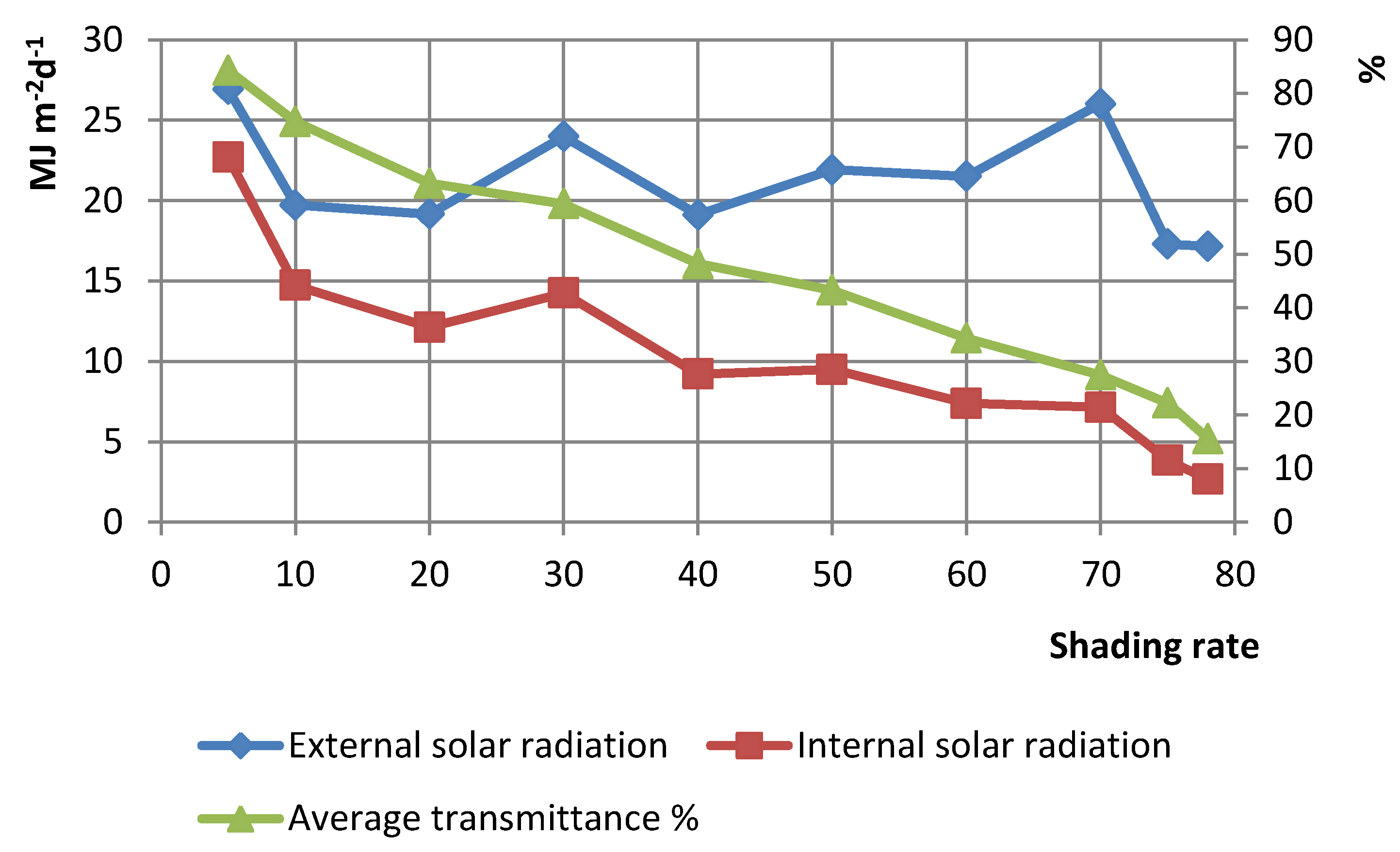

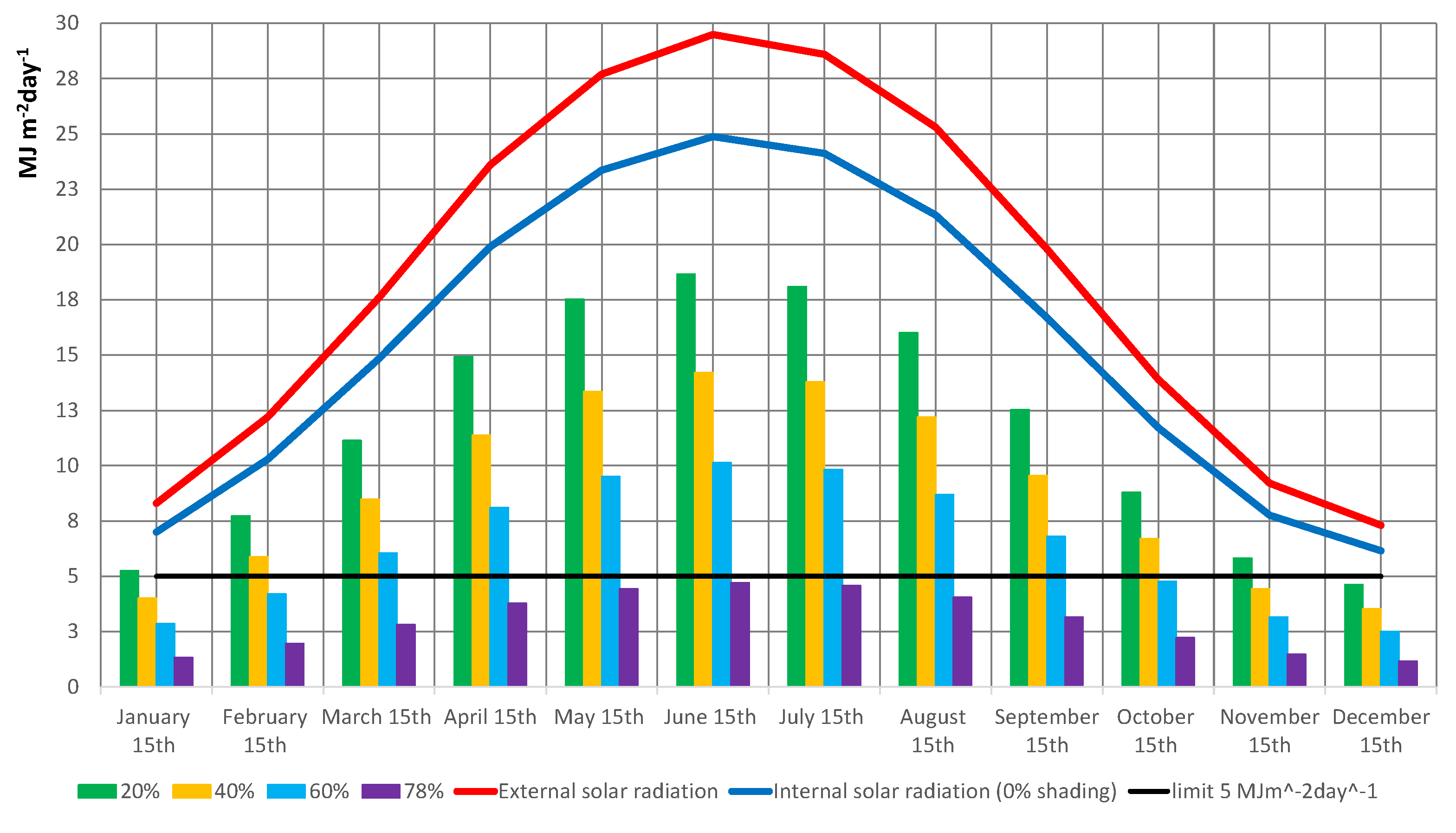

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dias, G.M.; Ayer, N.W.; Khosla, S.; Acker, R.V.; Young, S.B.; Whitney, S.; Hendricks, P. Life cycle perspectives on the sustainability of Ontario greenhouse tomato production: Benchmarking and improvement opportunities. J. Clean. Prod. 2017, 140, 831–839. [Google Scholar] [CrossRef]

- Sethi, V.P.; Sharma, S.K. Survey and evaluation of heating technologies for worldwide agricultural greenhouse applications. Sol. Energy 2008, 82, 832–859. [Google Scholar] [CrossRef]

- Kim, K.; Yoon, J.Y.; Kwon, H.J.; Han, J.H.; Son, J.E.; Nam, S.W. 3-D CFD analysis of relative humidity distribution in greenhouse with a fog cooling system and refrigerative dehumidifiers. Biosyst. Eng. 2008, 100, 245–255. [Google Scholar] [CrossRef]

- Islovich, I. Optimal control strategy for greenhouse lettuce: Incorporating supplemental lighting. Biosyst. Eng. 2009, 103, 57–67. [Google Scholar] [CrossRef]

- Korner, O.; Van’t Ooster, A.; Hulsbos, M. Design and performance of a measuring system for CO2 exchange of a greenhouse crop at different light levels. Biosyst. Eng. 2007, 97, 219–228. [Google Scholar] [CrossRef]

- Al-Helal, I.M.; Alhamdan, A.M. Effect of arid environment on radiative properties of greenhouse polyethylene cover. Sol. Energy 2009, 83, 790–798. [Google Scholar] [CrossRef]

- Yano, A.; Kadowaki, M.; Furue, A.; Tamaki, N.; Tanaka, T.; Hiraki, E. Shading and electrical features of a photovoltaic array mounted inside the roof of an east-west oriented greenhouse. Biosyst. Eng. 2010, 106, 367–377. [Google Scholar] [CrossRef]

- Mesmoudi, K.; Soudani, A.; Zitouni, B.; Bournet, PE.; Serir, L. Experimental study of the energy balance of unheated greenhouse under hot and arid climates: Study for the night period of winter season. J. Assoc. Arab. Univ. Basic. Appl. Sci. 2010, 9, 27–37. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Yano, A.; Cossu, M.; Yoshioka, H.; Kita, I.; Ibaraki, Y. Electrical energy producing greenhouse shading system with a semi-transparent photovoltaic blind based on micro-spherical solar cells. Energies 2018, 11, 1681. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Yin, F. The integration of semi-transparent photovoltaics on greenhouse roof for energy and plant production. Renew. Energy 2018, 121, 377–388. [Google Scholar] [CrossRef]

- Panwar, N.; Kaushik, S.; Kothari, S. Solar greenhouse an option for renewable and sustainable farming. Renew Sustain. Energy Rev. 2011, 15, 3934–3945. [Google Scholar] [CrossRef]

- Squatrito, R.; Sgroi, F.; Tudisca, S.; Trapani, A.M.D.; Testa, R. Post feed-in scheme photovoltaic system feasibility evaluation in Italy: Sicilian case studies. Energies 2014, 7, 7147–7165. [Google Scholar] [CrossRef]

- Blanco, I.; Anifantis, A.S.; Pascuzzi, S.; Mugnozza, G.S. Hydrogen and renewable energy sources integrated system for greenhouse heating. J. Agric. Eng. Res. 2013, 44, 226–230. [Google Scholar] [CrossRef]

- Russo, G.; Anifantis, A.S.; Verdiani, G.; Mugnozza, G.S. Environmental analysis of geothermal heat pump and LPG greenhouse heating systems. Biosyst. Eng. 2014, 127, 11–23. [Google Scholar] [CrossRef]

- Al-Shamiry, F.M.S.; Ahmad, D.; Sharif, A.R.M.; Aris, I.; Janius, R.; Kamaruddin, R. Design and development of a photovoltaic power system for tropical greenhouse cooling. Am. J. Appl. Sci. 2007, 4, 386–389. [Google Scholar] [CrossRef]

- Al-Ibrahim, A.; Al-Abbadi, N.; Al-Helal, I. PV greenhouse system—System description, performance and lesson learned. Acta Hortic. 2006, 710, 251–264. [Google Scholar] [CrossRef]

- Juang, P.; Kacira, M. System dynamics of a photovoltaic integrated greenhouse. Acta Hortic. 2014, 1037, 107–112. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Sonneveld, P.J.; Swinkels, G.L.A.M.; van Tuijl, B.A.J.; Janssen, H.J.J.; Campen, J.; Bot, G.P.A. Performance of a concentrated photovoltaic energy system with static linear fresnel lenses. Sol. Energy 2011, 85, 432–442. [Google Scholar] [CrossRef]

- Wang, T.; Wu, G.; Chen, J.; Cui, P.; Chen, Z.; Yan, Y.; Zhang, Y.; Li, M.; Niu, D.; Li, B.; et al. Integration of solar technology to modern greenhouse in China: Current status, challenges and prospect. Renew. Sustain. Energy Rev. 2017, 70, 1178–1188. [Google Scholar] [CrossRef]

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Li, Z.; Yano, A.; Cossu, M.; Yoshioka, H.; Kita, I.; Ibaraki, Y. Shading and electric performance of a prototype greenhouse blind system based on semi-transparent photovoltaic technology. J. Agric. Meteorol. 2018, 74, 114–122. [Google Scholar] [Green Version]

- Vadiee, A.; Yaghoubi, M. Exergy analysis of the solar blind system integrated with a commercial solar greenhouse. Int. J. Renew. Energy Res. 2016, 6, 1189–1199. [Google Scholar]

- Al Dakheel, J.; Aoul, K.T. Building applications, opportunities and challenges of active shading systems: A state-of-the-art review. Energies 2017, 10, 1672. [Google Scholar] [CrossRef]

- Aroca-Delgado, R.; Pérez-Alonso, J.; Callejón-Ferre, A.J.; Velázquez-Martí, B. Compatibility between crops and solar panels: An overview from shading systems. Sustainability 2018, 10, 743. [Google Scholar] [CrossRef]

- García, M.L.; Medrano, E.; Sánchez-Guerrero, M.C.; Lorenzo, P. Climatic effects of two cooling systems in greenhouses in the Mediterranean area: External mobile shading and fog system. Biosyst. Eng. 2011, 108, 133–143. [Google Scholar] [CrossRef]

- López-Marín, J.; Gálvez, A.; González, A.; Egea-Gilabert, C.; Fernández, J.A. Effect of shade on yield, quality and photosynthesis-related parameters of sweet pepper plants. Acta Hortic. 2012, 956, 545–552. [Google Scholar] [CrossRef]

- Mashonjowa, E.; Ronsse, F.; Mhizha, T.; Milford, J.R.; Lemeur, R.; Pieters, J.G. The effects of whitening and dust accumulation on the microclimate and canopy behaviour of rose plants (Rosa hybrida) in a greenhouse in Zimbabwe. Sol. Energy 2010, 84, 10–23. [Google Scholar] [CrossRef]

- Martínez, D.L.V.; Ureña, L.J.B.; Aiz, F.D.M.; Martínez, A.L. Greenhouse Agriculture in Almería. A Comprehensive Techno-Economic Analysis; Cajamar Caja Rural: Andalusia, Spain, 2016; ISBN 9788495531759. [Google Scholar]

- Abdel-Ghany, A.M.; Picuno, P.; Al-Helal, I.; Alsadon, A.; Ibrahim, A.; Shady, M. Radiometric characterization, solar and thermal radiation in a greenhouse as affected by shading configuration in an arid climate. Energies 2015, 8, 13928–13937. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M. Influences of greenhouse-integrated semi-transparent photovoltaics on microclimate and lettuce growth. Int. J. Agric. Biol. Eng. 2017, 10, 11–22. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Liu, L.; Guan, C.; Zhang, F.; Li, M.; Lv, H.; Yao, P.; Ingenhoff, J. A novel agricultural photovoltaic system based on solar spectrum separation. Sol. Energy 2018, 162, 84–94. [Google Scholar] [CrossRef]

- Ahemd, H.A.; Al-Faraj, A.A.; Abdel-Ghany, A.M. Shading greenhouses to improve the microclimate, energy and water saving in hot regions: A review. Sci. Hortic. 2016, 201, 36–45. [Google Scholar] [CrossRef]

- Lorenzo, P.; Sánchez-Guerrero, M.C.; Medrano, E.; García, M.L.; Caparrós, I.; Giménez, M. External greenhouse mobile shading: Effect on microclimate, water use efficiency and yield of a tomato crop grown under different salinity levels of the nutrient solution. Acta Hortic. 2003, 609, 181–186. [Google Scholar] [CrossRef]

- Yano, A.; Furue, A.; Moriyama, T.; Ide, O.; Tsuchiya, K. Development of a greenhouse shading screen controller driven by photovoltaic energy. J. Jpn. Soc. Agric. Mach. 2007, 69, 57–64. [Google Scholar]

- Marucci, A.; Cappuccini, A. Dynamic photovoltaic greenhouse: Energy balance in completely clear sky condition during the hot period. Energy 2016, 102, 302–312. [Google Scholar] [CrossRef]

- Kadowaki, M.; Yano, A.; Ishizu, F.; Tanaka, T.; Noda, S. Effects of greenhouse photovoltaic array shading on Welsh onion growth. Biosyst. Eng. 2012, 111, 290–297. [Google Scholar] [CrossRef]

- Ureña-Sánchez, R.; Callejón-Ferre, Á.J.; Pérez-Alonso, J.; Carreño-Ortega, Á. Greenhouse tomato production with electricity generation by roof-mounted flexible solar panels. Sci. Agric. 2012, 69, 233–239. [Google Scholar] [CrossRef]

- Colantoni, A.; Monarca, D.; Marucci, A.; Cecchini, M.; Zambon, I.; Battista, F.D.; Maccario, D.; Saporito, M.G.; Beruto, M. Solar radiation distribution inside a greenhouse prototypal with photovoltaic mobile plant and effects on flower growth. Sustainability 2018, 10, 855. [Google Scholar] [CrossRef]

- Marrou, H.; Dufour, L.; Guilioni, L.; Salles, J.M.; Loisel, P.; Nogier, A.; Wery, J. Designing farming systems combining food and electricity production. In Proceedings of the 4th International Symposium for Farming Systems Design, Ganus Science and Technology Press, Lanzhou, China, 19–22 August 2013. [Google Scholar]

- Marrou, H.; Wéry, J.; Dufour, L.; Dupraz, C. Productivity and radiation use efficiency of lettuces grown in the partial shade of photovoltaic panels. Eur. J. Agron. 2013, 44, 54–66. [Google Scholar] [CrossRef]

- Cantagallo, J.E.; Medan, D.; Hall, A.J. Grain number in sunflower as affected by shading during floret growth, anthesis and grain setting. Field Crop. Res. 2004, 85, 191–202. [Google Scholar] [CrossRef]

- Dinesh, H.; Pearce, J.M. The potential of agrivoltaic systems. Renew. Sust. Energy Rev. 2016, 54, 299–308. [Google Scholar] [CrossRef]

- Fu, J.; Li, C.H.; Zhao, J.-R.; Ma, L.; Liu, T.X. Shade-tolerance indices of maize: Selection and evaluation. Yingyong Shengtai Xuebao 2009, 20, 2705e9. [Google Scholar]

- Worku, W.; Skjelvåg, A.; Gislerød, H. Responses of common bean Phaseolus vulgaris L. to photosynthetic irradiance levels during three phenological phases. Agronomie 2004, 24, 267–274. [Google Scholar] [CrossRef]

- Kim, J.J.; Kang, M.; Kwak, O.K.; Yoon, Y.J.; Min, K.S.; Chu, M.J. Fabrication and characterization of dye-sensitized solar cells for greenhouse application. Int. J. Photoenergy 2014, 2014, 376315. [Google Scholar] [CrossRef]

- Allardyce, C.S.; Fankhauser, C.; Zakeeruddin, S.M.; Grätzel, M.; Dyson, P.J. The influence of greenhouse-integrated photovoltaics on crop production. Sol. Energy 2017, 155, 517–522. [Google Scholar] [CrossRef]

- Emmott, C.J.M.; Röhr, J.A.; Campoy-Quiles, M.; Kirchartz, T.; Urbina, A.; Ekins-Daukes, N.J.; Nelson, J. Organic photovoltaic greenhouses: A unique application for semi-transparent PV? Energy Environ. Sci. 2015, 8, 1317–1328. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, Y.; Hao, Y.; Cui, Y.; Wang, W.; Ji, T.; Shi, F.; Wei, B. Visibly transparent organic photovoltaic with improved transparency and absorption based on tandem photonic crystal for greenhouse application. Appl. Opt. 2015, 54, 10232–10239. [Google Scholar] [CrossRef]

- Dos Reis Benatto, G.A.; Corazza, M.; Roth, B.; Schütte, F.; Rengenstein, M.; Gevorgyan, S.A.; Krebs, F.C. Inside or outside? Linking outdoor and indoor lifetime tests of ITO-free organic photovoltaic devices for greenhouse applications. Energy Technol. 2017, 5, 338–344. [Google Scholar] [CrossRef]

- Tani, A.; Shiina, S.; Nakashima, K.; Hayashi, M. Improvement in lettuce growth by light diffusion under solar panels. J. Agric. Meteorol. 2014, 70, 139–149. [Google Scholar] [CrossRef] [Green Version]

- Kavga, A.; Trypanagnostopoulos, G.; Zervoudakis, G.; Tripanagnostopoulos, Y. Growth and physiological characteristics of lettuce (Lactuca sativa L.) and rocket (Eruca sativa Mill.) plants cultivated under photovoltaic panels. Not. Bot. Horti Agrobot. 2018, 46, 206–212. [Google Scholar] [CrossRef]

- Buttaro, D.; Renna, M.; Gerardi, C.; Blando, F.; Santamaria, P.; Serio, F. Soilless production of wild rocket as affected by greenhouse coverage with photovoltaic module. Acta Sci. Pol. Hortorum Cultus 2016, 15, 129–142. [Google Scholar]

- Pérez-Alonso, J.; Pérez-García, M.; Pasamontes-Romera, M.; Callejón-Ferre, A.J. Performance analysis and neural modelling of a greenhouse integrated photovoltaic system. Renew. Sustain. Energy Rev. 2012, 16, 4675–4685. [Google Scholar] [CrossRef]

- Fatnassi, H.; Poncet, C.; Bazzano, M.M.; Brun, R.; Bertin, N. A numerical simulation of the photovoltaic greenhouse microclimate. Sol. Energy 2015, 120, 575–584. [Google Scholar] [CrossRef]

- Marucci, A.; Monarca, D.; Colantoni, A.; Campiglia, E.; Cappuccini, A. Analysis of the internal shading in a photovoltaic greenhouse tunnel. J. Agric. Eng. 2017, 48, 154–160. [Google Scholar] [CrossRef]

- Marucci, A.; Zambon, I.; Colantoni, A.; Monarca, D. A combination of agricultural and energy purposes: Evaluation of a prototype of photovoltaic greenhouse tunnel. Renew. Sustain. Energy Rev. 2018, 82, 1178–1186. [Google Scholar] [CrossRef]

- Yano, A.; Onoe, M.; Nakata, J. Prototype semi-transparent photovoltaic modules for greenhouse roof applications. Biosyst. Eng. 2014, 122, 62–73. [Google Scholar] [CrossRef] [Green Version]

- Cossu, M.; Yano, A.; Li, Z.; Onoe, M.; Nakamura, H.; Matsumoto, T.; Nakata, J. Advances on the semi-transparent modules based on micro solar cells: First integration in a greenhouse system. Appl. Energy 2016, 162, 1042–1051. [Google Scholar] [CrossRef] [Green Version]

- Marucci, A.; Monarca, D.; Cecchini, M.; Colantoni, A.; Cappuccini, A. Analysis of internal shading degree to a prototype of dynamics photovoltaic greenhouse through simulation software. J. Agric. Eng. 2015, 46, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Marrou, H.; Guilioni, L.; Dufour Dupraz, C.; Wery, J. Microclimate under agrivoltaic systems: Is crop growth rate affected in the partial shade of solar panels? Agric. For. Meteor. 2013, 177, 117–132. [Google Scholar] [CrossRef]

- Marucci, A.; Cappuccini, A. Dynamic photovoltaic greenhouse: Energy efficiency in clear sky conditions. Appl. Energy 2016, 170, 362–376. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; Wiley: New York, NY, USA, 1991. [Google Scholar]

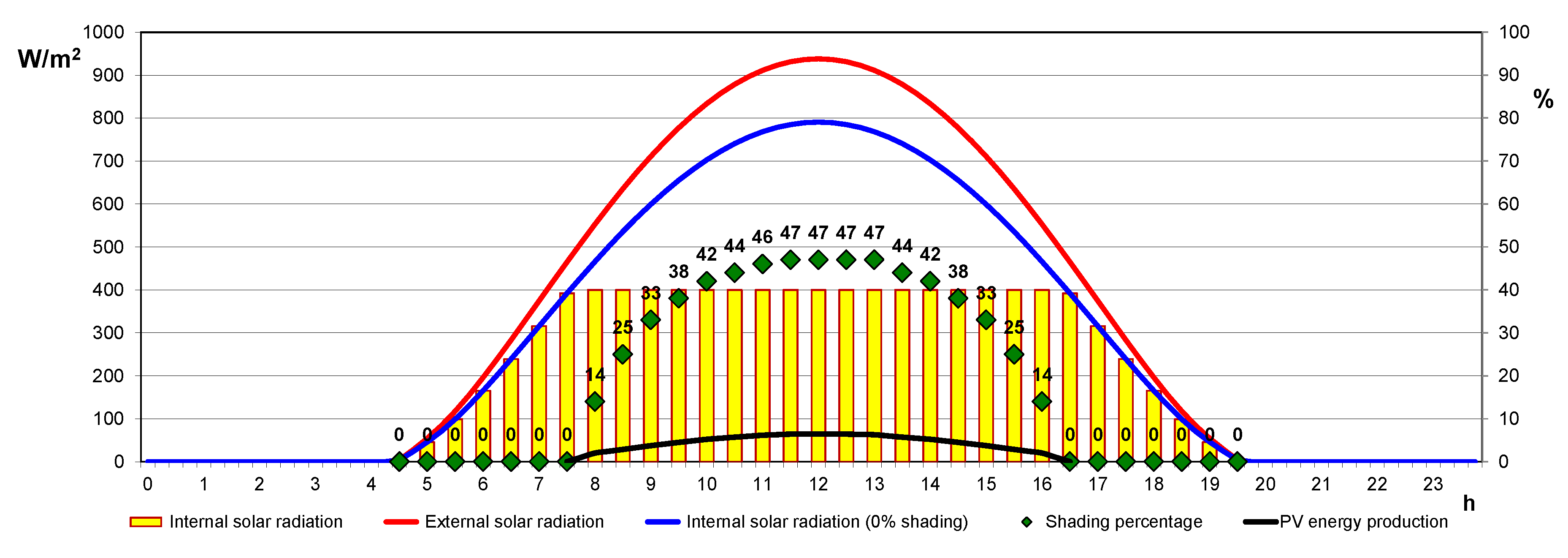

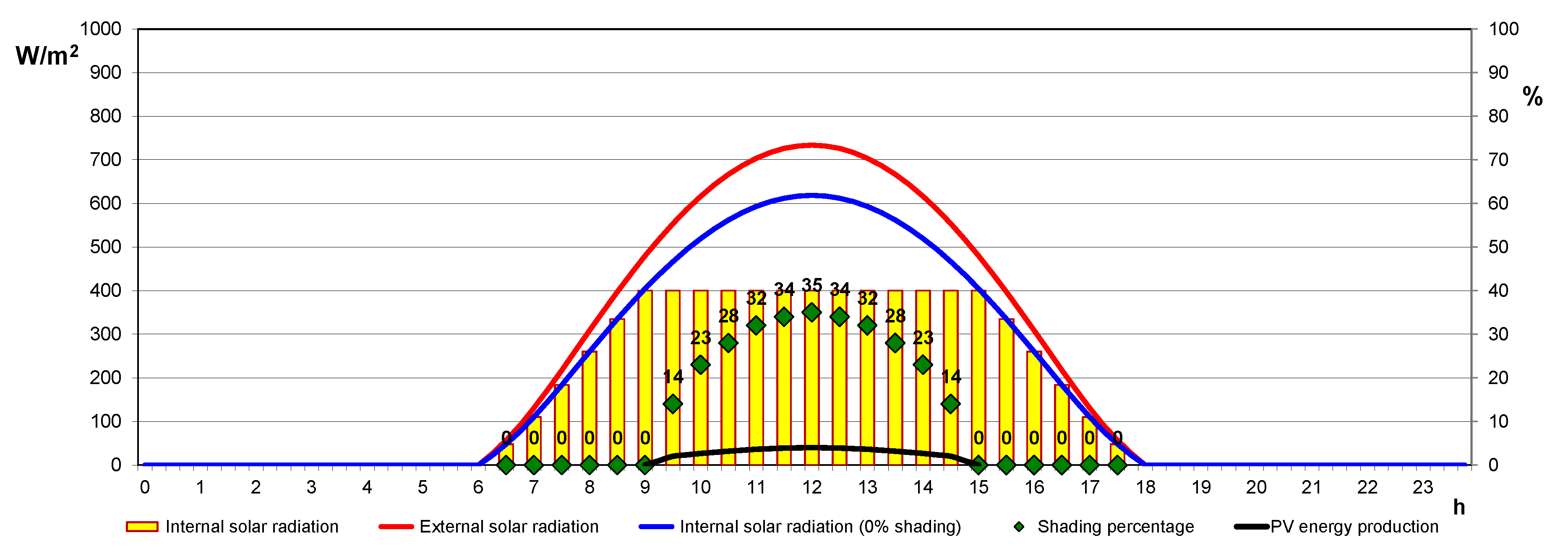

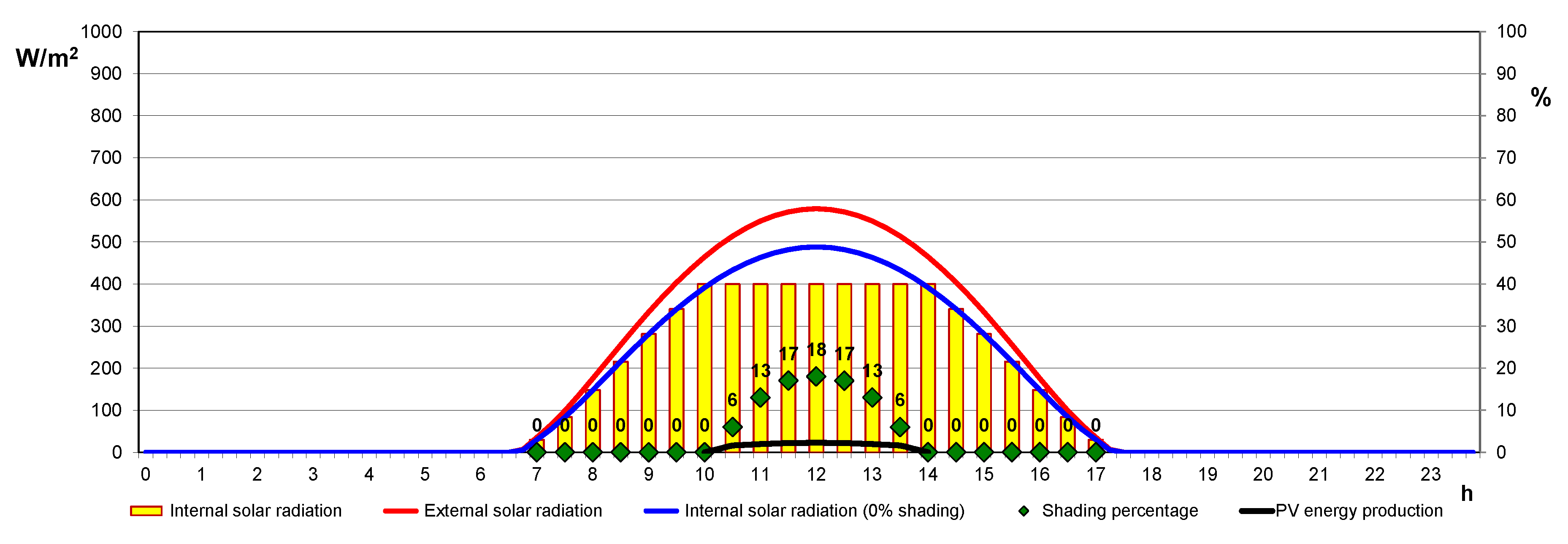

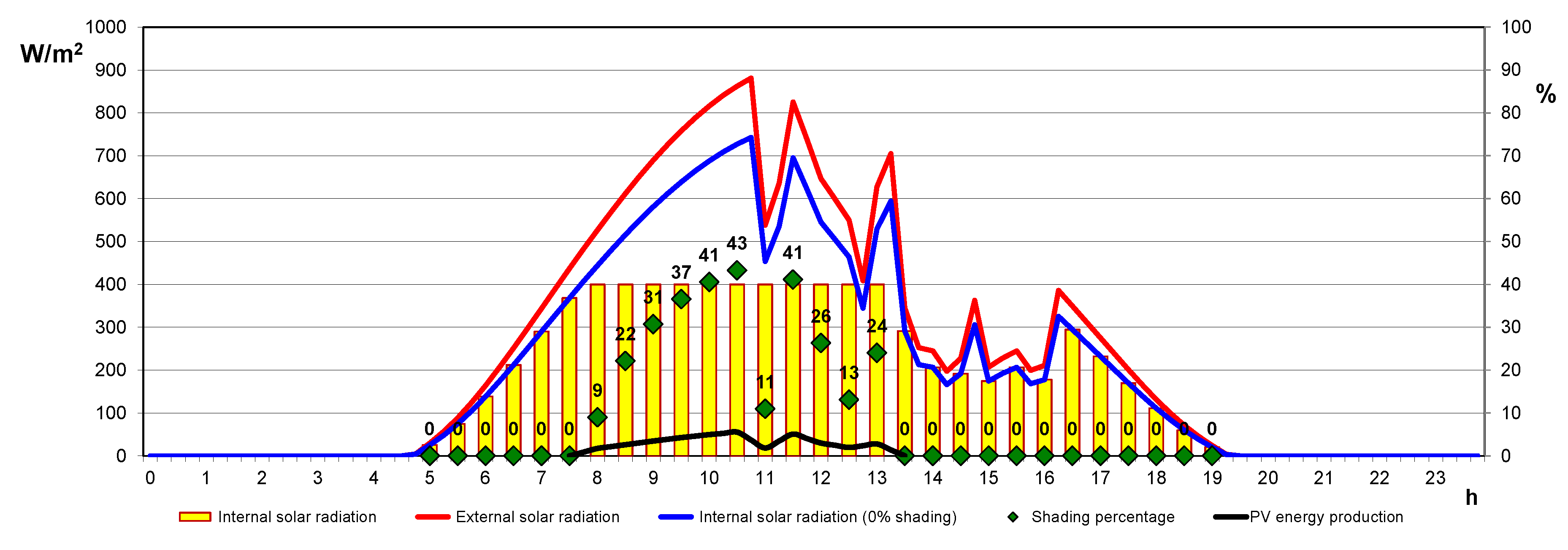

| Day | External Solar Radiation (MJ m−2d−1) | Internal Solar Radiation (MJ m−2d−1) | PV Energy Production (MJ m−2d−1) | PV Energy Efficiency (%) |

|---|---|---|---|---|

| June 21, clear sky | 29.5 | 16.8 | 1.44 | 4.9 |

| March 21, clear sky | 18.8 | 12.7 | 0.63 | 3.3 |

| February 21, clear sky | 13.3 | 10.4 | 0.25 | 1.9 |

| May 23, partly cloudy sky | 20.6 | 13.8 | 0.67 | 3.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moretti, S.; Marucci, A. A Photovoltaic Greenhouse with Variable Shading for the Optimization of Agricultural and Energy Production. Energies 2019, 12, 2589. https://doi.org/10.3390/en12132589

Moretti S, Marucci A. A Photovoltaic Greenhouse with Variable Shading for the Optimization of Agricultural and Energy Production. Energies. 2019; 12(13):2589. https://doi.org/10.3390/en12132589

Chicago/Turabian StyleMoretti, Simona, and Alvaro Marucci. 2019. "A Photovoltaic Greenhouse with Variable Shading for the Optimization of Agricultural and Energy Production" Energies 12, no. 13: 2589. https://doi.org/10.3390/en12132589