The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Used in the Experiments

2.2. Technical and Chemical Analysis

2.3. Preparation of the Samples

- -

- Variant 1 (assumed as normal pellets): the reference sample was stored in the warehouse in the temperature of 20 °C at air humidity of 70% (the storage time was one month). The storage conditions (temperature and air humidity) inside the warehouse were controlled using a thermo hygrometer Kimo HD 50 (Kimo, Barcelona, Spain). All the pellets were packed in the 15 kg bags.

- -

- Variant 2 (assumed as frozen pellets): the pellets were stored in a laboratory freezer. The temperature inside the freezer was −28 °C. The storage time was 5 days. Hermetically packed 10 samples of each material were prepared for further tests. The mass of one sample was 500 g.

- -

- Variant 3 (assumed as defrosted pellets): after the storage of the pellets in the freezer, five samples of each investigated material were taken out and left for a period of 12 hours in the warehouse (in the temperature of 20 °C at air humidity of 70%) to enable the samples to have a natural defrosting process.

2.4. Mechanical Durability Test

3. Results and Discussion

3.1. Technical and Chemical Characteristics

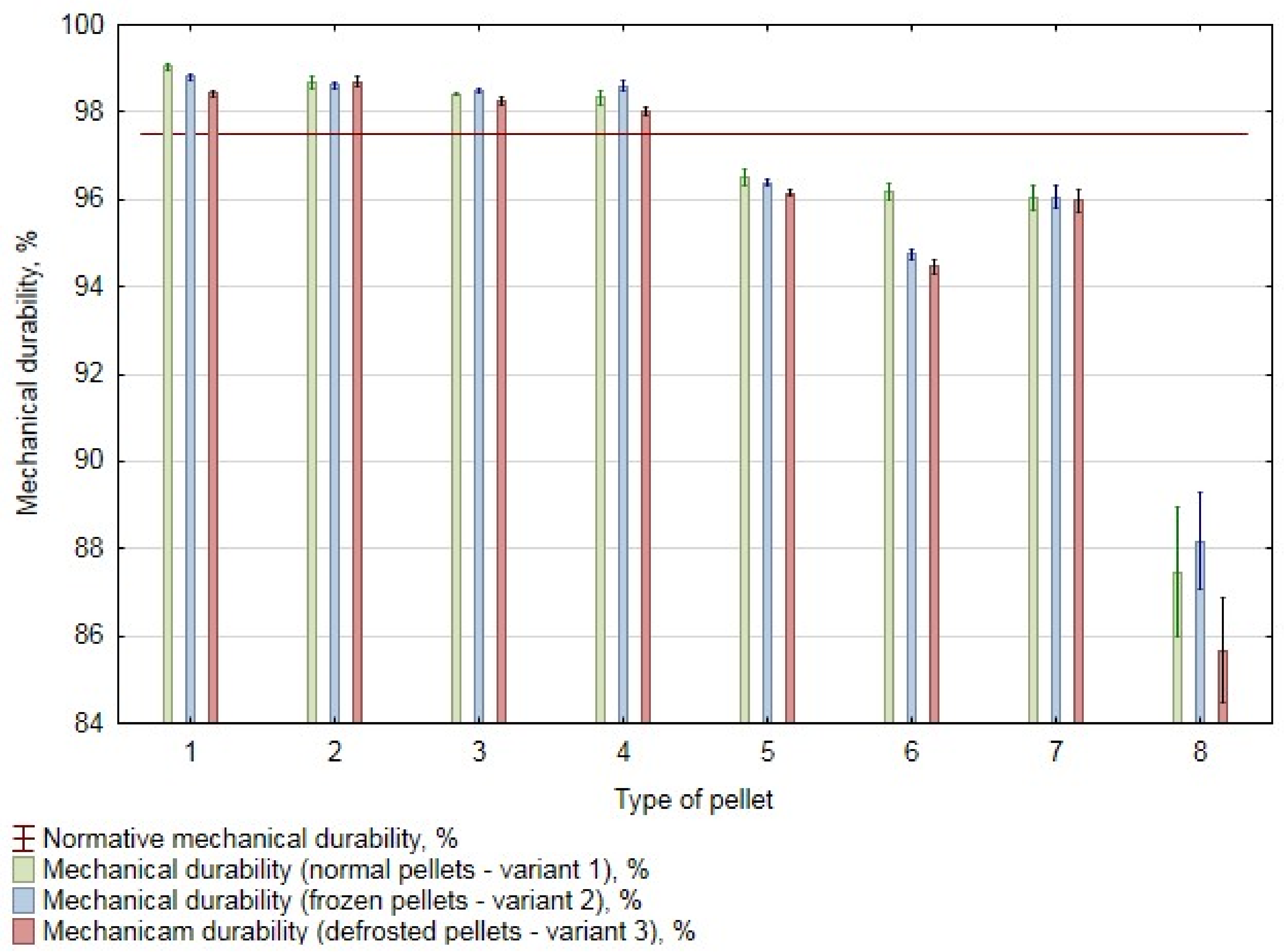

3.2. Mechanical Durability Index

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AC | ash content |

| EC | European Commission |

| EU | European Union |

| HHV | higher heating value |

| LHV | lower heating value |

| MC | moisture content |

| RES | renewable energy sources |

| VM | volatile matter content |

References

- EuroStat. Energy Consumption in Households. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Energy_consumption_in_households (accessed on 29 May 2019).

- European Commission. EUROPE 2020: A Strategy for Smart, Sustainable and Inclusive Growth; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- World Bioenergy Association. WBA Global Bioenergy Statistics 2018; World Bioenergy Association: Stockholm, Sweden, 2018. [Google Scholar]

- Karakashev, D.; Zhang, Y. BioEnergy and BioChemicals Production from Biomass and Residual Resources. Energies 2018, 11, 2125. [Google Scholar] [CrossRef]

- PN-EN. CEN-EN 303-5. In Heating Boilers. Part 5: Heating Boilers for Solid Fuels, Manually and Automatically Stoked, Nominal Heat Output of Up to 500 kW—Terminology, Requirements, Testing and Marking; European Committee for Standardization: Brussels, Belgium, 2012.

- Nilsson, D.; Bernesson, S.; Hansson, P.A. Pellet production from agricultural raw materials—A systems study. Biomass Bioenergy 2011, 35, 679–689. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Thek, G.; Obernberger, I. Wood pellet production costs under Austrian and in comparison to Swedish framework conditions. Biomass Bioenergy 2004, 27, 671–693. [Google Scholar] [CrossRef]

- Sahoo, K.; Hawkins, G.L.; Yao, X.A.; Samples, K.; Mani, S. GIS-based biomass assessment and supply logistics system for a sustainable biorafinery: A case study with cotton stalks in the Southeastern US. Appl. Energy 2016, 182, 260–273. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Shoenau, G. Grinding performance and physical properties of non-treated and steam exploded barley, canola, oat and wheat straw. Biomass Bioenergy 2011, 35, 549–561. [Google Scholar] [CrossRef]

- Obidziński, S. Influence of selected structure parameters of pellet mill on the quality of the final product. Pol. J. Food Nutr. Sci. 2007, 57, 121–124. [Google Scholar]

- Tumuluru, J.S. Effect of process variables on the density and durability of the pellets made from high moisture corn stover. Biosyst. Eng. 2014, 119, 44–57. [Google Scholar] [CrossRef] [Green Version]

- Kraszkiewicz, A.; Kachel-Jakubowska, M.; Szpryngiel, M.; Niedziółka, I. Analiza wybranych cech jakościowych peletów wytworzonych z surowców roślinnych. Inżynieria Rolnicza 2013, 2, 167–173. [Google Scholar]

- Novaes, E.; Kirst, M.; Chiang, V.; Winter-Sederoff, H.; Sederoff, R. Lignin and biomass: A negative Correlations for wood formation and lignin content in trees. Plant Physiol. 2010, 154, 555–561. [Google Scholar] [CrossRef]

- Lehmann, B.; Schroder, H.W.; Wollenberg, R.; Repke, J.U. Effect of miscanthus addition and different grinding processes on the quality of wood pellets. Biomass Bioenergy 2012, 44, 150–159. [Google Scholar] [CrossRef]

- Rynkiewicz, M.; Dobek, T.K. Wybrane właściwości fizyczne i mechaniczne pelletów w zależności od składu i temperatury ich przechowywania. Inżynieria Rolnicza 2013, 3, 321–330. [Google Scholar]

- Niedziółka, I.; Szpryngiel, M. Ocena cech jakościowych peletów wytworzonych z biomasy roślinnej. Inżynieria Rolnicza 2012, 2, 267–276. [Google Scholar]

- Graham, S.; Eastwick, C.; Snape, C.; Quick, W. Mechanical degradation of biomass wood pellets during long term stockpile storage. Fuel Process. Technol. 2017, 160, 143–151. [Google Scholar] [CrossRef]

- Kulig, R. Wpływ procesu kondycjonowania wybranych surowców strączkowych na właściwości fizyczne granulatu. Inżynieria Rolnicza 2009, 1, 147–155. [Google Scholar]

- Sahoo, K.; Bilek, E.M.; Mani, S. Techno-economic and environmental assessments of storing woodchips and pellets for bioenergy applications. Renew. Sustain. Energy Rev. 2018, 98, 27–39. [Google Scholar] [CrossRef]

- Noll, M.; Jirjis, R. Microbial communities in large-scale wood piles and their effects on wood quality and the environment. Appl. Microbiol. Biotechnol. 2012, 95, 551–563. [Google Scholar] [CrossRef]

- Jirjis, R.; Theander, O. The effect of seasonal storage on the chemical composition of forest residue chips. Scand. J. For. Res. 1990, 5, 437–438. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.L.; Poulsen, T.; Felby, C. Importance of temperature, moisture content, and species for the conversion process of wood residues into fuel pellets. Wood Fiber Sci. 2009, 41, 414–425. [Google Scholar]

- Arshadi, M.; Gref, R.; Geladi, P.; Dahlqvist, S.A.; Lestander, T.A. The influence of raw material characteristics on the industrial pelletizing process and pellet quality. Fuel Process. Technol. 2008, 89, 1442–1447. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef] [Green Version]

- Sultana, A.; Kumar, A. Development of energy and emission parameters for densiefied form of lignocellulosic biomass. Energy 2011, 36, 2716–2732. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef] [Green Version]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Ahn, B.J.; Chang, H.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.; Yang, I. Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Carroll, J.P.; Finnan, J. Physical and chemical properties of pellets from energy crops and cereal straws. Biosyst. Eng. 2012, 112, 151–159. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Shoenau, G.; Opoku, A. Pelleting characteristic of selected biomass with and without steam explosion pretreatment. Int. J. Agric. Biol. Eng. 2010, 3, 62–79. [Google Scholar]

- Kirsten, C.; Lenz, V.; Schroder, H.W.; Repke, J.U. Hay pellets—The influence of particle size reduction on their physical-mechanical quality and energy demand during production. Fuel Process. Technol. 2016, 148, 163–174. [Google Scholar] [CrossRef]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard, R.; McKinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw and big bluestem. Ind. Crops Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Lee, S.; Ahn, B.J.; Choi, D.H.; Han, G.S.; Jeong, H.S.; Ahn, S.M.; Yang, I. Effect on densification variables on the durability of wood pellets fabricated with Larix kaempferi C. and Liriodendron tulipifera L. sawdust. Biomass Bioenergy 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass palletization—A review. Bioresources 2012, 7, 4451–4490. [Google Scholar]

- Hansen, M.T.; Rosentoft-Jein, A.; Wach, E.; Bastian, M. Poradnik użytkowania pelet drzewnych; Bałtycka Agencja Poszanowania Energii S.A.: Gdańsk, Poland, 2009.

- PN-EN. ISO 18134-2:2017-03E. In Solid Biofuels. Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method; European Committee for Standardization: Brussels, Belgium, 2017.

- PN-EN. ISO 18125:2017-07. In Solid Biofuels-Determination of Calorific Value; European Committee for Standardization: Brussels, Belgium, 2017.

- Porowski, R. Analiza metod określania ciepła spalania i wartości opałowej paliw. Zeszyty Naukowe SGSP 2016, 59, 45–70. [Google Scholar]

- PN. ISO 1171:2010. In Solid Mineral Fuels. Determination of Ash; European Committee for Standardization: Brussels, Belgium, 2010.

- PN-EN. ISO 18123:2016-01. In Solid Fuels. Determination of Volatile Content by Gravimetric Method; European Committee for Standardization: Brussels, Belgium, 2016.

- PN-EN 1936:2010. In Metody badań kamienia naturalnego. Oznaczanie gęstości i gęstości objętościowej oraz całkowitej i otwartej porowatości; European Committee for Standardization: Brussels, Belgium, 2010.

- PN-EN 1237:2000. In Fertilizers—Determination of Bulk Density (Tapped); European Committee for Standardization: Brussels, Belgium, 2000.

- PN-EN. ISO 17831-1:2016-02. In Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets; European Committee for Standardization: Brussels, Belgium, 2016.

- Damirichi, H.; Najafi, G.; Alizadehnia, S.; Mamat, R.; Azwadi, N.; Sidik, C.; Azmi, W.H.; Noor, M.M. Micro Cimbined Heat and Power to provide heat and electrical power using biomass and Gamma-type Striling engine. Appl. Therm. Eng. 2016, 103, 1460–1469. [Google Scholar] [CrossRef]

- Bai, Z.; Liu, Q.; Lei, J.; Hong, H.; Jin, H. New-solar biomass power generation system integrated a two-stage gasifier. Appl. Energy 2017, 194, 310–319. [Google Scholar] [CrossRef]

- Gehring, M.; Wohler, M.; Pelz, S.; Steinbrink, J.; Thorwarth, H. Kaolin as additive in wood pellet combustion with several mixtures of spruce and short-rotation-coppice willow and it influence on emissions and ashes. Fuel 2019, 235, 610–616. [Google Scholar] [CrossRef]

- Lim, C.H.; Lam, H.L. Biomass supply chain optimisation via novel Biomass Element Life Cycle Analysis (BELCA). Appl. Energy 2016, 161, 733–745. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Pelleting of Pine and Switchgrass Blends: Effect of Process Variables and Blend Ratio on the Pellet Quality and Energy Consumption. Energies 2019, 12, 1198. [Google Scholar] [CrossRef]

- Ellis, N.; Masnadi, M.S.; Roberts, D.G.; Kochanek, M.A.; Ilyushechkin, A.Y. Mineral matter interactions during co-pyrolysis of coal and biomass and their impact in intrinsic char co-gasification reactivity. Chem. Eng. J. 2015, 279, 402–408. [Google Scholar] [CrossRef]

- Matali, S.; Rahman, N.A.; Idris, S.S.; Yaacob, N.; Alias, A.B. Lignocellulosic Biomass solid Fuel Properties Anhancement via Torrefaction. Procedia Eng. 2016, 148, 671–678. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Bańda, M.; Wiącek, J.; Parafiuk, P.; Gondek, E. Mechanical and combustion properties of sawdust—Straw pellets blended in different proportions. Fuel Process. Technol. 2017, 156, 366–375. [Google Scholar] [CrossRef]

- Welker, C.M.; Balasubramanian, V.K.; Petti, C.; Rai, K.M.; DeBolt, S.; Mendu, V. Enginnering Plant Biomass Lignin Content and composition for Biofuels and Bioproducts. Energies 2015, 8, 7654–7676. [Google Scholar] [CrossRef]

- Šavija, B. Smart Crack Control in Concrete through Use of Phase Change Materials (PCMs): A Review. Materials 2018, 11, 654. [Google Scholar]

| Type of Pellet | Proximate Analysis | Ultimate Analysis | Additional Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MC * | HHV * | LHV * | AC * | VM * | C | H | N | Relative Density | Bulk Density | Porosity | |

| % | kJ∙kg−1 | kJ∙kg−1 | % | % | % | kg∙m−3 | kg∙m−3 | % | |||

| Pine sawdust pellet | 3.01 5.07 ** | 19523 | 17887 | 0.66 | 77.84 | 47 | 6.7 | 0.11 | 1385.2 | 432.4 | 68.78 |

| Wheat straw pellet | 10.33 11.69 ** | 17574 | 15992 | 7.27 | 72.83 | 40 | 6.1 | 0.69 | 1429.3 | 358.3 | 74.93 |

| Digestate pellet | 16.45 16.99 ** | 19051 | 17224 | 7.10 | 67.28 | 40 | 6.5 | 1.5 | 1463.4 | 488.0 | 66.65 |

| Corn settlements pellet | 7.82 8.91 ** | 18797 | 17181 | 1.27 | 74.91 | 42 | 6.4 | 0.5 | 1431.3 | 651.5 | 54.49 |

| Agricultural residues pellet | 10.97 12.41 ** | 18129 | 16511 | 8.27 | 71.05 | 39 | 6.2 | 1.3 | 1461.8 | 467.5 | 68.02 |

| Post-hydrolytic wood pellet | 20.08 20.26 ** | 21532 | 19914 | 8.99 | 56.17 | 46 | 5.7 | 0.3 | 1665.5 | 822.1 | 50.64 |

| Sunflower husk pellet | 13.77 13.80 ** | 19946 | 18246 | 2.99 | 71.83 | 44 | 6.4 | 0.8 | 1409.4 | 533.4 | 62.15 |

| Fine coal (45%) and straw (55%) pellet | 8.89 9.18 ** | 23269 | 21880 | 9.43 | 44.15 | 54 | 5.3 | 2.1 | 1653.1 | 737.9 | 55.36 |

| Mechanical Durability and Its Variations * | |||

|---|---|---|---|

| Type of pellet | Variant 1 (normal pellets) | Variant 2 (frozen pellets) | Variant 3 (defrosted pellets) |

| % | Δ% | Δ% | |

| Digestate | 99.0 | −0.2 | −0.6 |

| Pine sawdust | 98.7 | −0.1 | 0.0 |

| Wheat straw | 98.4 | +0.1 | −0.2 |

| Post-hydrolytic wood | 98.3 | +0.3 | −0.3 |

| Agricultural residues | 96.5 | −0.1 | −0.3 |

| Fine coal (45%) and straw (55%) | 96.2 | −1.5 | −1.7 |

| Corn settlements | 96.0 | 0.0 | 0.0 |

| Sunflower husk | 87.4 | +0.8 | −1.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dyjakon, A.; Noszczyk, T. The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies 2019, 12, 2627. https://doi.org/10.3390/en12132627

Dyjakon A, Noszczyk T. The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies. 2019; 12(13):2627. https://doi.org/10.3390/en12132627

Chicago/Turabian StyleDyjakon, Arkadiusz, and Tomasz Noszczyk. 2019. "The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass" Energies 12, no. 13: 2627. https://doi.org/10.3390/en12132627

APA StyleDyjakon, A., & Noszczyk, T. (2019). The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies, 12(13), 2627. https://doi.org/10.3390/en12132627