Experimental Studies of Fuel Injection in a Diesel Engine with an Inclined Injector

Abstract

:1. Introduction

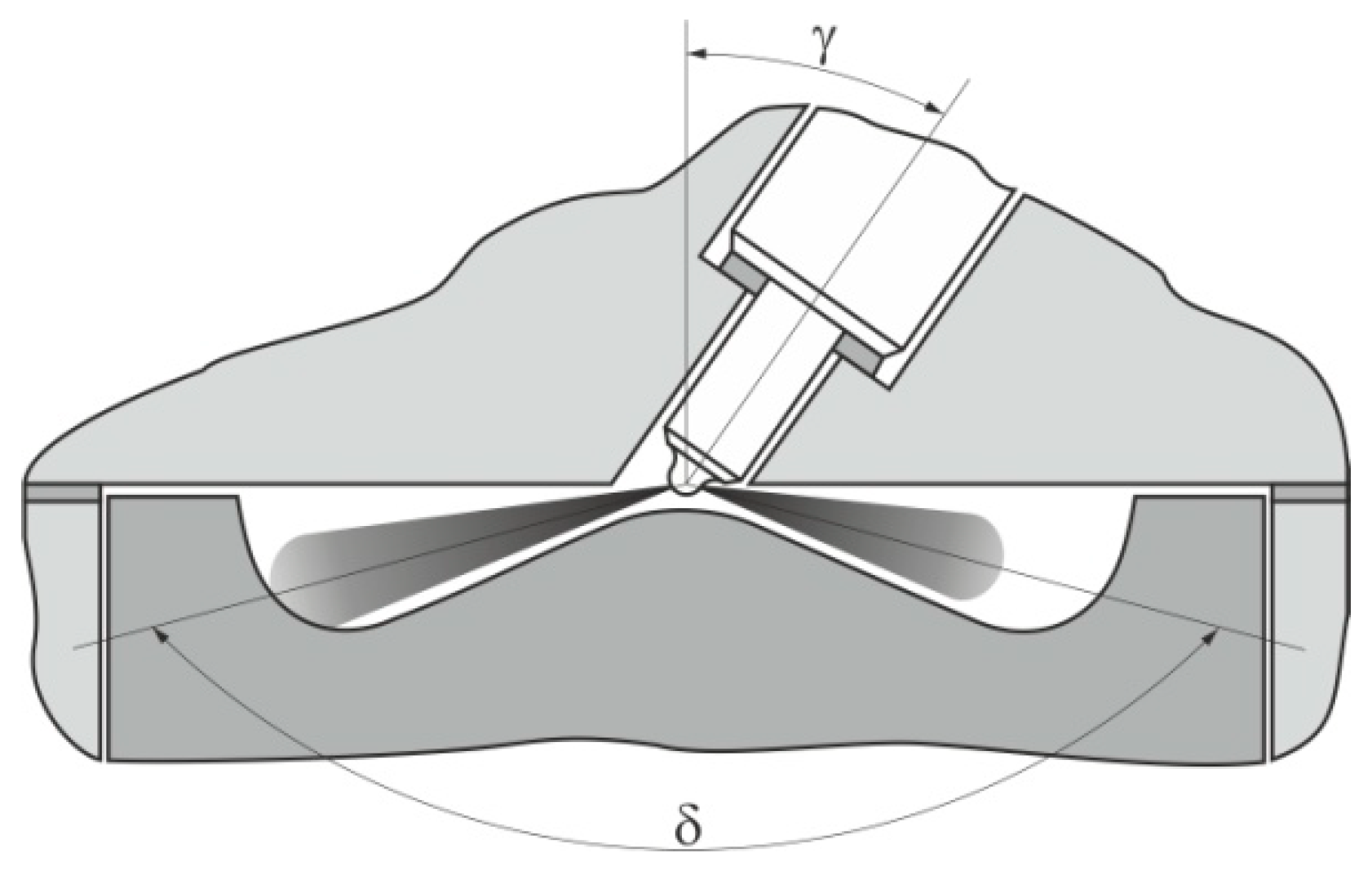

2. Materials and Methods

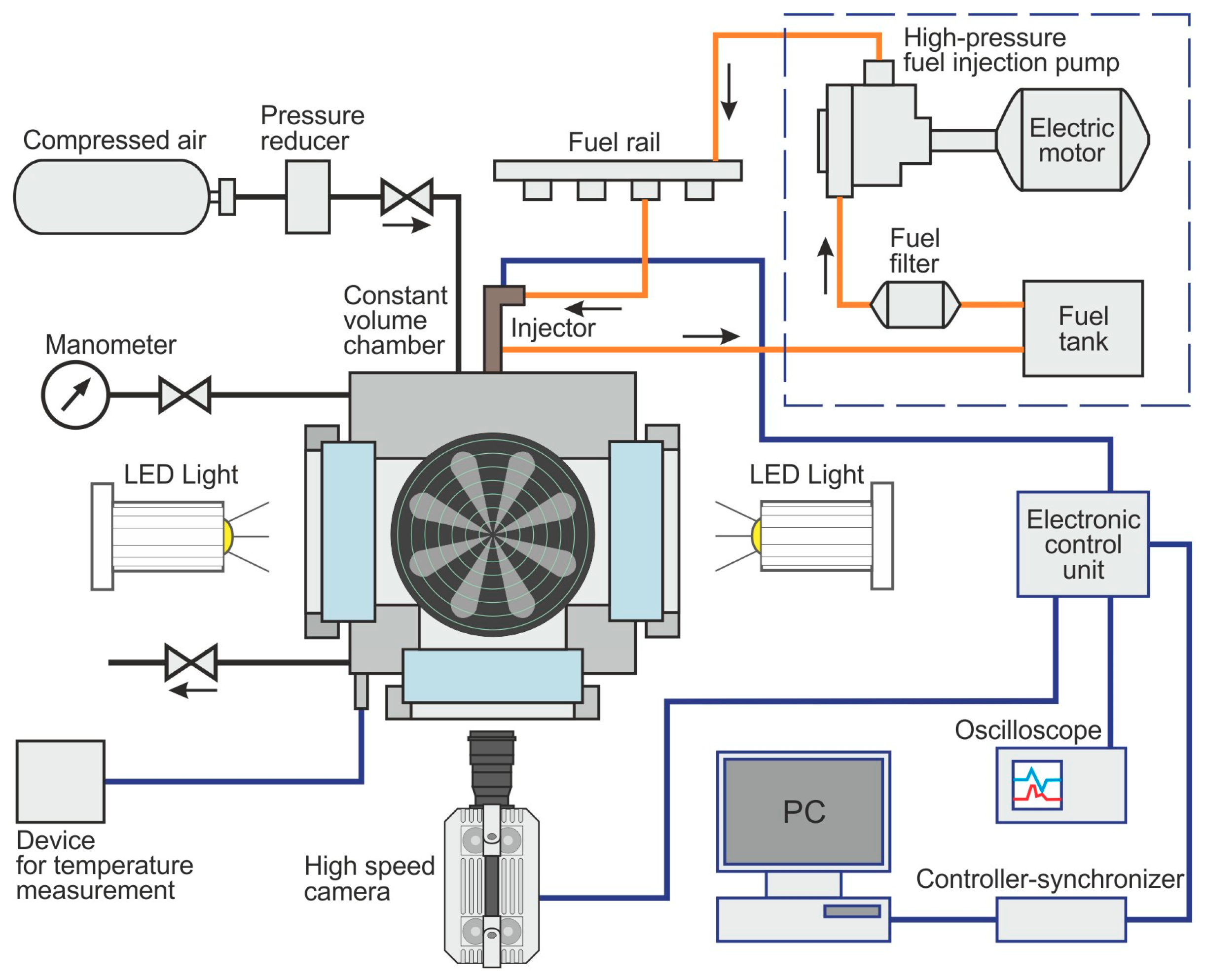

2.1. Experimental Setup.

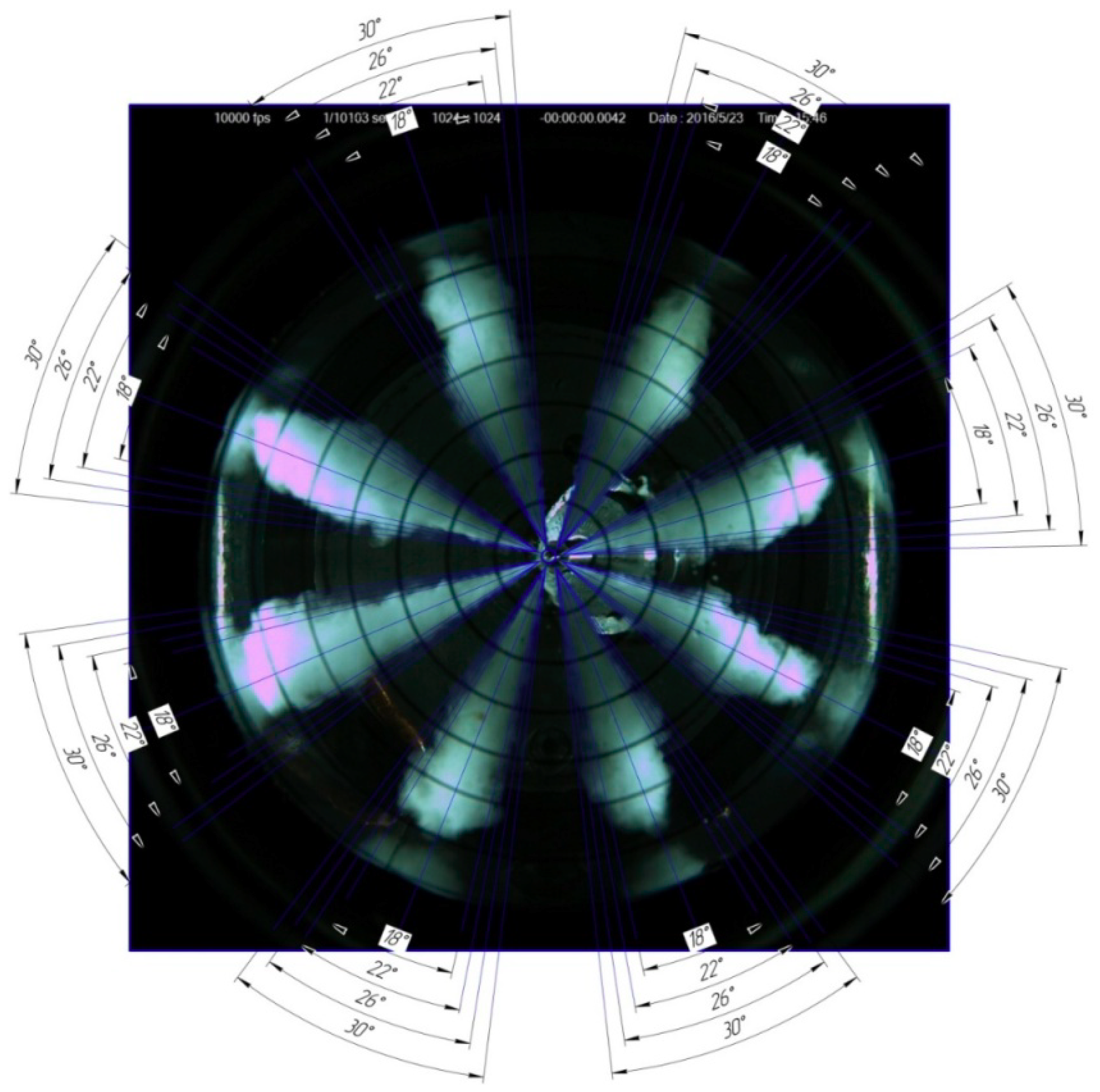

2.2. Experimental Research Methodology.

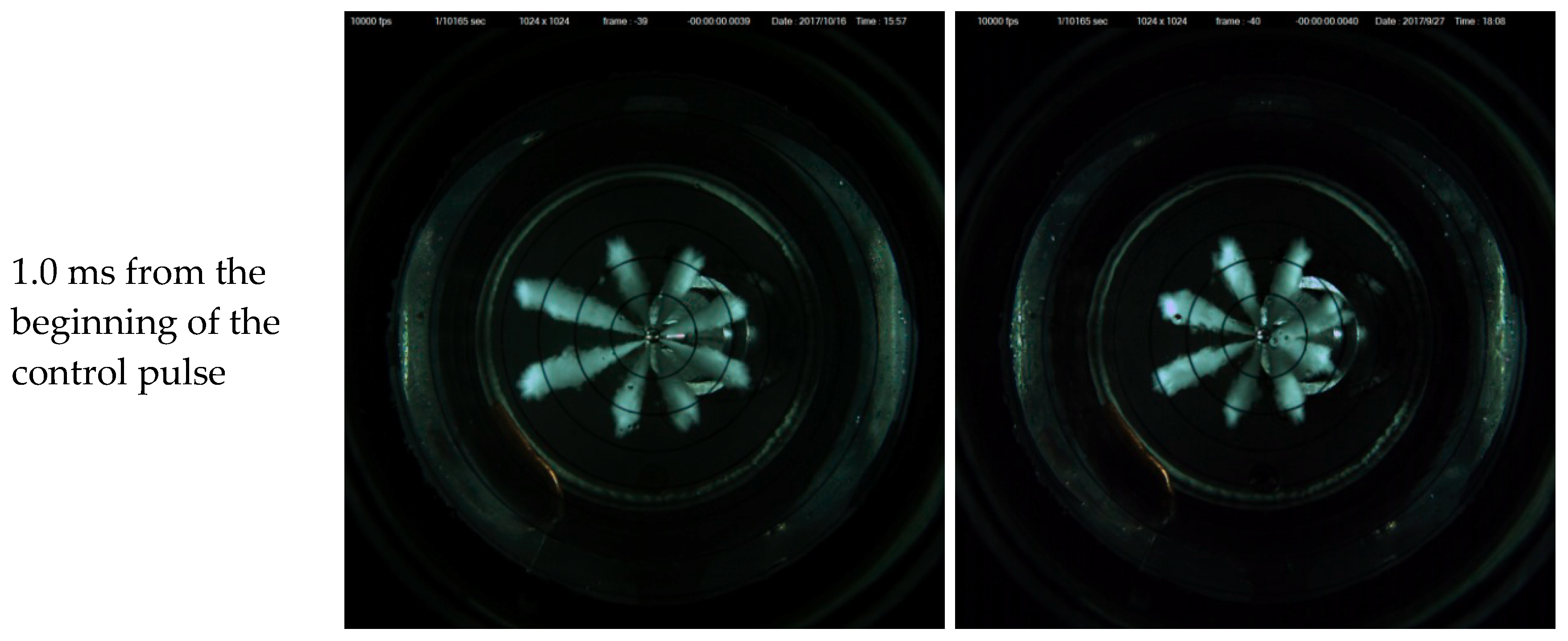

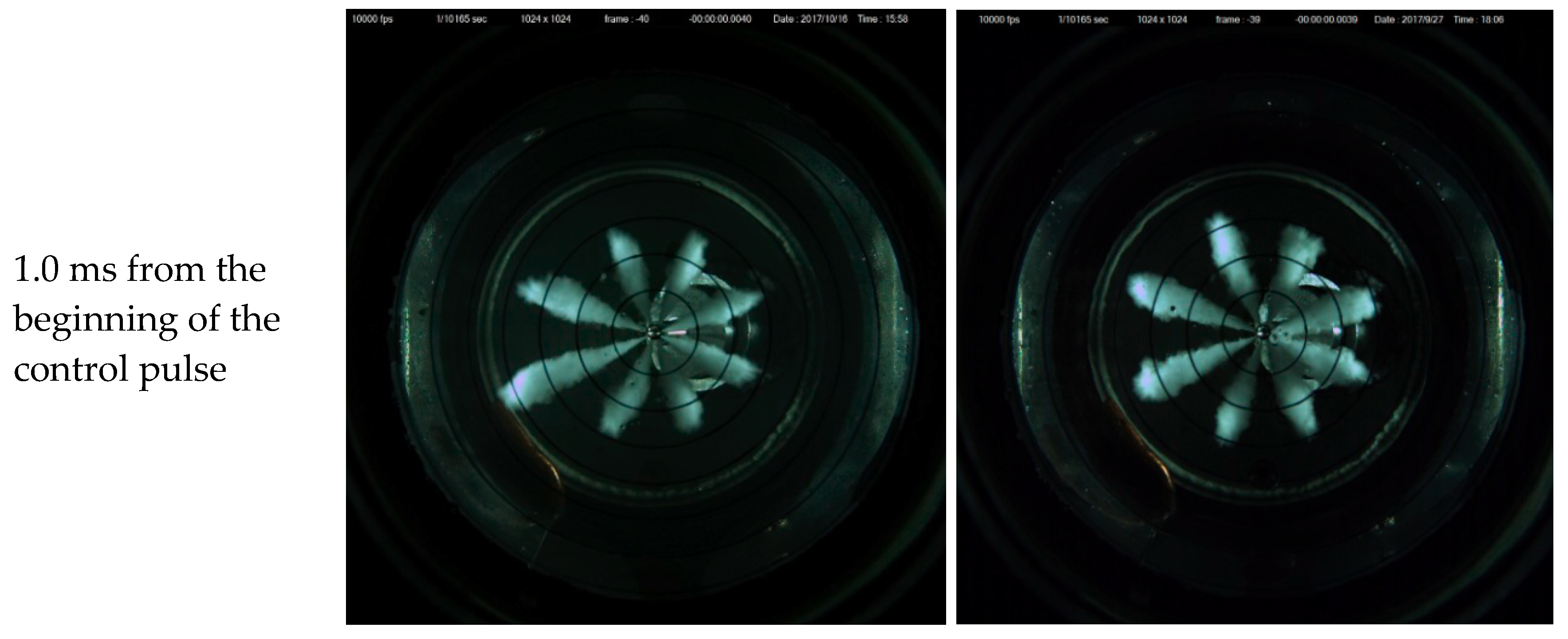

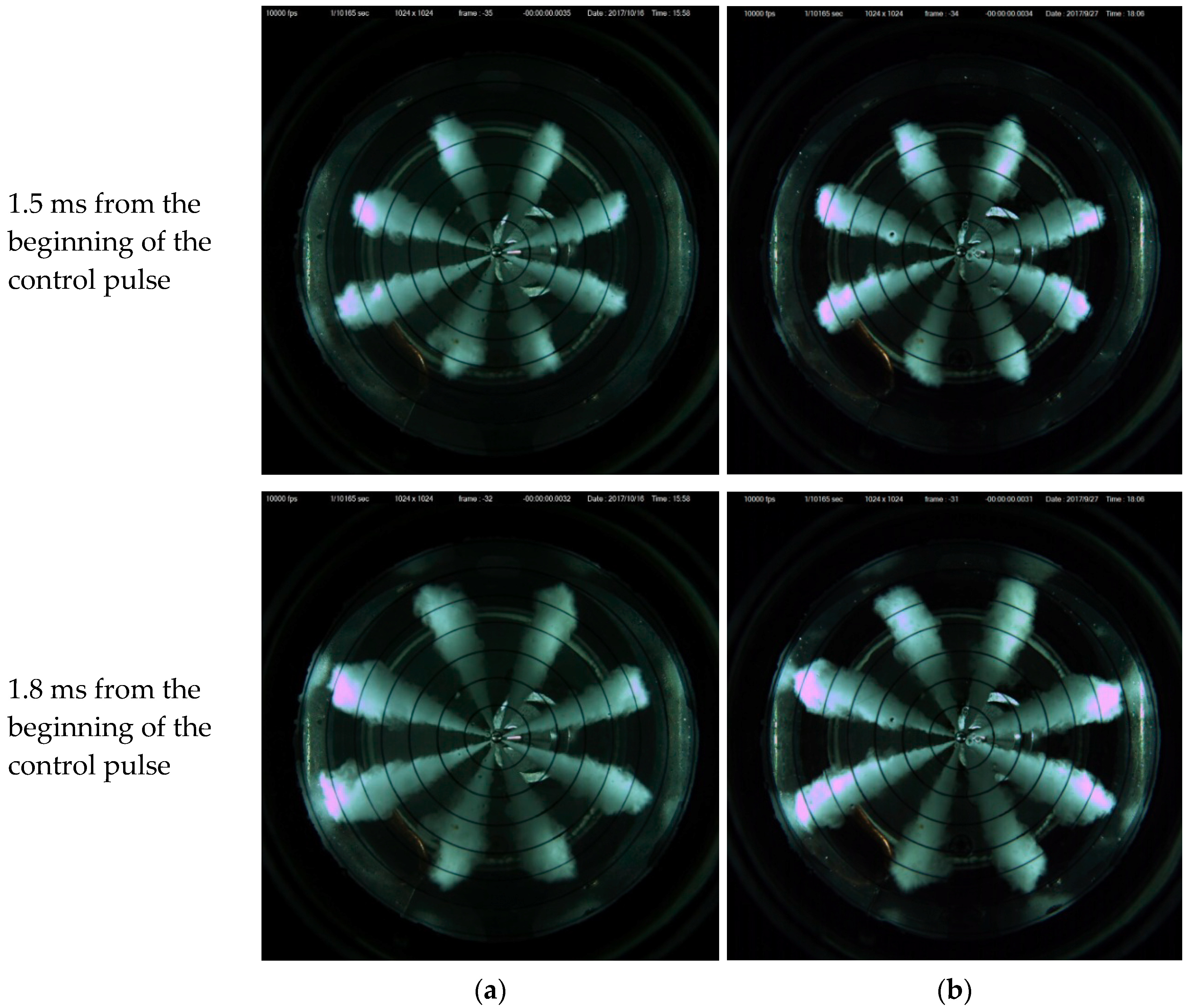

3. Results

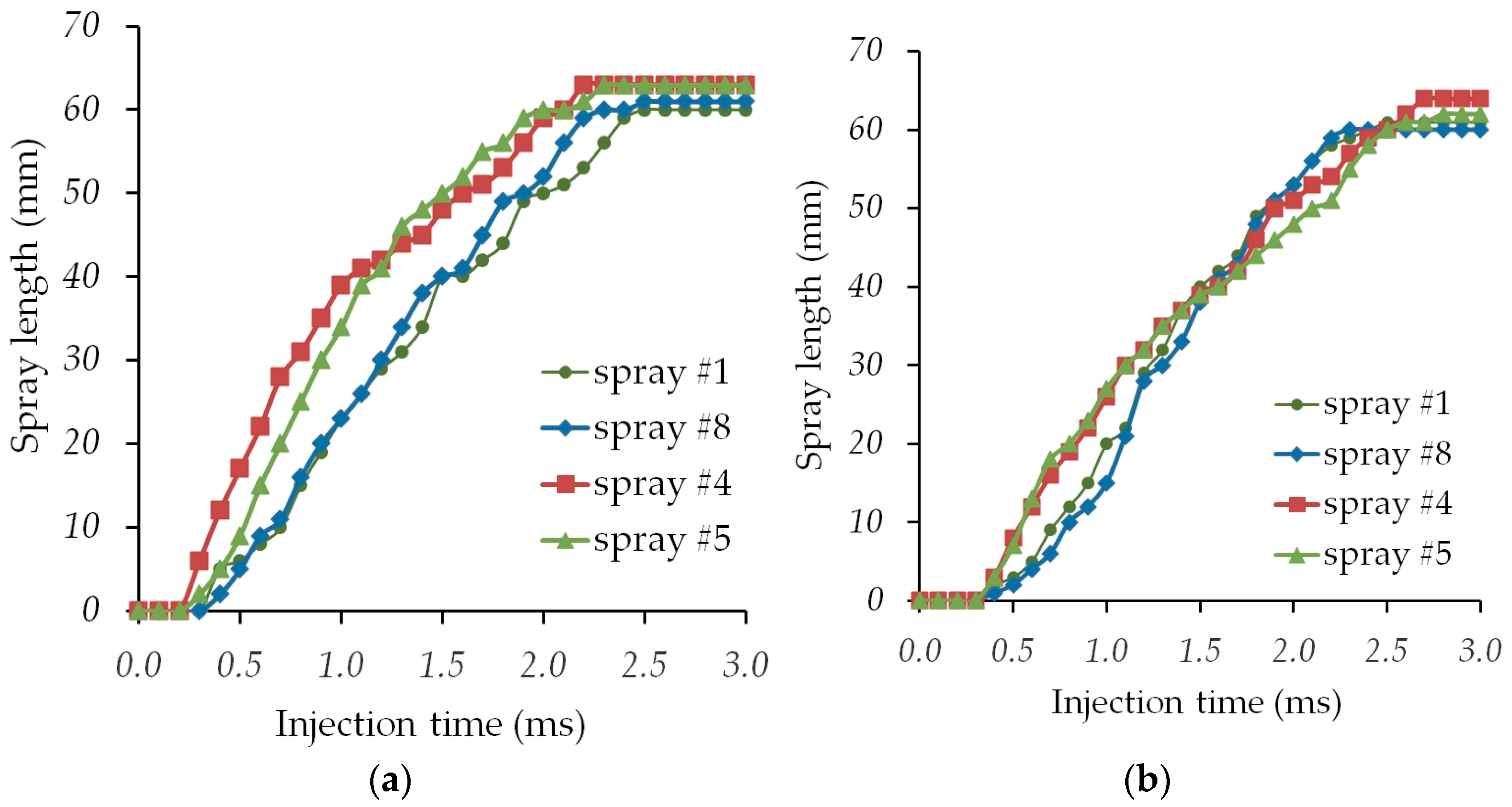

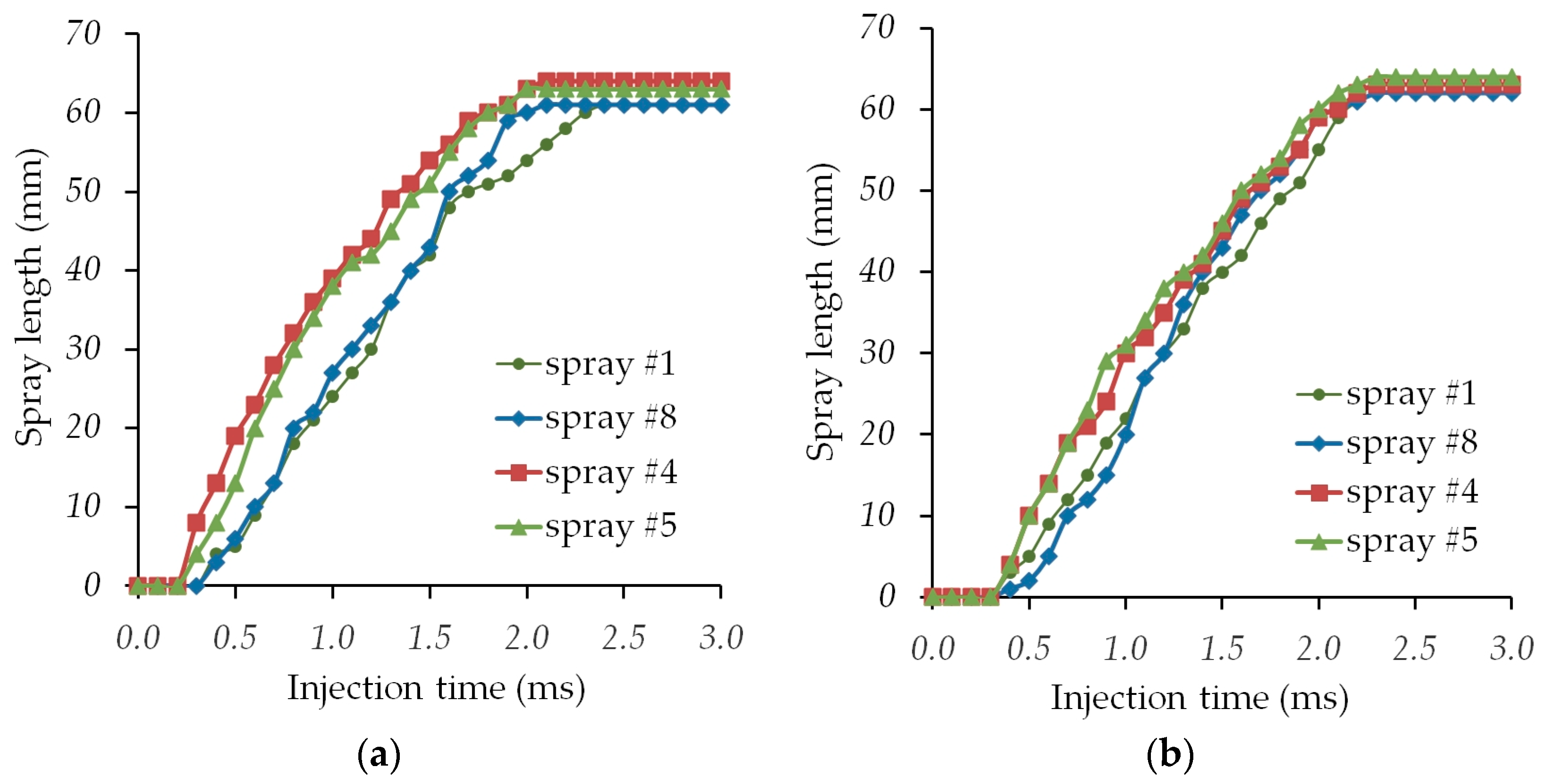

3.1. The Results of Measuring the Length of Fuel Sprays.

3.2. The Results of Measuring the Cone Angles of Fuel Sprays.

3.3. The Results of Measurement of the Cyclic Fuel Supply by the Electromagnetic Injector of Common Rail type with Nozzles 1 and 2

4. Discussion

5. Conclusions

- -

- Delay in the start of the fuel injection process from the initial moment of the electric impulse controlling the injector, regardless of rail pressure, was about 0.3 ms;

- -

- Delay in the end of the fuel injection process from the end of the electric impulse controlling the injector, regardless of rail pressure, was about 1.0 ms;

- -

- Duration of the fuel injection process is usually 0.7 ms longer than the duration of the electric impulse controlling the injector;

- -

- At nozzle 1, the fuel sprays develop differently: The sprays from nozzles 4 and 5 have the greatest penetration length; the difference of spray penetration length with other nozzles reaches 10–15 mm and persists until it touches the chamber wall;

- -

- At nozzle 2, the fuel sprays develop more evenly: The greatest difference in spray penetration length of nozzles 4 and 5 with others is no more than 3–5 mm;

- -

- Average development rate of the fuel sprays of the nozzle 2 at a rail pressure of 100 MPa is 3 m/s less than that of the nozzle 1 (31 and 34 m/s, respectively), but as the pressure rises to 165 MPa, the velocities equalize and are about 40 m/s;

- -

- The measured fuel spray cone angles from the nozzle orifices 1, 2, 7, and 8 are usually larger than the angles from the other orifices: For nozzle 1, this difference is from 0.5° to 1.5°, and for nozzle 2 it reaches 3.0–4.0°;

- -

- With increase in rail pressure from 100 to 165 MPa, the fuel spray cone angles of the nozzle 1 decrease from 20–22° to 18–18.5°, by an average of 13.6%. The fuel spray cone angles of the nozzle 2 are reduced from 20–24° to 19–22.5°, by an average of 5.7%.

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Payri, R.; Bracho, G.; Marti-Aldaravi, P.; Viera, A. Near field visualization of diesel spray for different nozzle inclination angles in non-vaporizing conditions. At. Sprays 2017, 27, 251–267. [Google Scholar] [CrossRef]

- Herfatmanesh, M.R.; Lu, P.; Attar, M.A.; Zhao, H. Experimental investigation into the effects of two-stage injection on fuel injection quantity, combustion and emissions in a high-speed optical common rail diesel engine. Fuel 2013, 109, 137–147. [Google Scholar] [CrossRef] [Green Version]

- Payri, R.; Salvador, F.J.; Bracho, G.; Viera, A. Differences between single and double-pass schlieren imaging on diesel vapor spray characteristics. Appl. Therm. Eng. 2017, 125, 220–231. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, H.; Jiang, C.; Wyszynski, M.L.W. Experimental study on microscopic and macroscopic characteristics of diesel spray with split injection. Fuel 2016, 174, 140–152. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.J.; Bracho, G.; Viera, A. Vapor phase penetration measurements with both single and double-pass Schlieren for the same injection event. In Proceedings of the ILASS–Europe 2017 28th Conference on Liquid Atomization and Spray Systems, Valencia, Spain, 6–8 September 2017; Payri, R., Margot, X., Eds.; Editorial Universitat Politecnica de Valencia: Valencia, Spain, 2017. [Google Scholar]

- Payri, R.; Viera, J.P.; Gopalakrishnan, V.; Szymkowicz, P.G. The effect of nozzle geometry over internal flow and spray formation for three different fuels. Fuel 2016, 183, 20–33. [Google Scholar] [CrossRef] [Green Version]

- Xue, F.; Luo, F.; Cui, H.; Moro, A.; Zhou, L. Numerical analyses of transient flow characteristics within each nozzle hole of an asymmetric diesel injector. Int. J. Heat Mass Transf. 2017, 104, 18–27. [Google Scholar] [CrossRef]

- Salvador, F.J.; Jaramillo, D.; Romero, J.-V.; Rosello, M.-D. Using a homogeneous equilibrium model for the study of the inner nozzle flow and cavitation pattern in convergent–divergent nozzles of diesel injectors. J. Comput. Appl. Math. 2017, 309, 630–641. [Google Scholar] [CrossRef]

- Hansen, H.; Jollet, S.; Niemeyer, D.; Thimm, L.; Dinkelacker, F. Influence of the spray hole geometries on cavitation formation inside diesel injector nozzles. In Proceedings of the 2nd Conference on Engine Processes, Berlin, Germany, 2–3 July 2015; Sens, M., Baar, R., Eds.; Universitätsverlag der TU Berlin: Berlin, Germany, 2015; pp. 158–168. [Google Scholar]

- Salvador, F.J.; Carreres, M.; Jaramillo, D.; Martinez-Lopez, J. Analysis of the combined effect of hydrogrinding process and inclination angle on hydraulic performance of diesel injection nozzles. Energy Convers. Manag. 2015, 105, 1352–1365. [Google Scholar] [CrossRef] [Green Version]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T. The Impact of Injector Hole Diameter on Spray Behaviour for Butanol-Diesel Blends. Energies 2018, 11, 1298. [Google Scholar] [CrossRef]

- Eagle, E.W.; Morris, S.B.; Wooldridge, M.S. High-speed imaging of transient diesel spray behavior during high pressure injection of a multi-hole fuel injector. Fuel 2014, 116, 299–309. [Google Scholar] [CrossRef]

- Payri, R.; Gimeno, J.; Bracho, G.; Vaquerizo, D. Study of liquid and vapor phase behavior on Diesel sprays for heavy duty engine nozzles. Appl. Therm. Eng. 2016, 107, 365–378. [Google Scholar] [CrossRef] [Green Version]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Experimental study on the spray characteristics discharging from elliptical diesel nozzle at typical diesel engine conditions. Fuel 2018, 221, 28–34. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Experimental study on the diesel and biodiesel spray characteristics emerging from equilateral triangular orifice under real diesel engine operation conditions. Fuel 2018, 224, 357–365. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. An experimental comparison of the elliptical and circular nozzles spray and mixing characteristics under different injection pressures. Fuel 2019, 236, 1474–1482. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Experimental study on the spray and mixing characteristics for equilateral triangular and circular nozzles with diesel and biodiesel under high injection pressures. Fuel 2019, 239, 97–107. [Google Scholar] [CrossRef]

- Desantes, J.M.; Pastor, J.V.; García-Oliver, J.M.; Briceño, F.J. An experimental analysis on the evolution of the transient tip penetration in reacting Diesel sprays. Combust. Flame 2014, 161, 2137–2150. [Google Scholar] [CrossRef]

- Du, W.; Lou, J.; Yan, Y.; Bao, W.; Liu, F. Effects of injection pressure on diesel sprays in constant injection mass condition. Appl. Therm. Eng. 2017, 121, 234–241. [Google Scholar] [CrossRef]

- Xia, J.; Huang, Z.; Xu, L.; Ju, D.; Lu, X. Experimental study on spray and atomization characteristics under subcritical, transcritical and supercritical conditions of marine diesel engine. Energy Convers. Manag. 2019, 195, 958–971. [Google Scholar] [CrossRef]

- Payri, R.; Giraldo, J.S.; Ayyapureddi, S.; Versey, Z. Experimental and analytical study on vapor phase and liquid penetration for a high pressure diesel injector. Appl. Therm. Eng. 2018, 137, 721–728. [Google Scholar] [CrossRef]

- Pinkert, F.; Najar, I.; Drescher, M.; Fink, C.; Harndorf, H. Nozzle geometry impact on spray, ignition and combustion of large fuel injection jets. In Proceedings of the 2nd Conference on Engine Processes, Berlin, Germany, 2–3 July 2015; Sens, M., Baar, R., Eds.; Universitätsverlag der TU Berlin: Berlin, Germany, 2015; pp. 140–157. [Google Scholar]

- Soid, S.N.; Zainal, Z.A. Spray and combustion characterization for internal combustion engines using optical measuring techniques—A review. Energy 2011, 36, 724–741. [Google Scholar] [CrossRef]

- Huang, H.; Liu, Q.; Shi, C.; Wang, Q.; Zhou, C. Experimental study on spray, combustion and emission characteristics of pine oil/diesel blends in a multi-cylinder diesel engine. Fuel Process. Technol. 2016, 153, 137–148. [Google Scholar] [CrossRef]

- Salvador, F.J.; Lopez, J.J.; De la Morena, J.; Crialesi-Esposito, M. Experimental investigation of the effect of orifices inclination angle in multihole diesel injector nozzles. Part 1–Hydraulic performance. Fuel 2018, 213, 207–214. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.J.; De la Morena, J.; Pagano, V. Experimental investigation of the effect of orifices inclination angle in multihole diesel injector nozzles. Part 2–Spray characteristics. Fuel 2018, 213, 215–221. [Google Scholar] [CrossRef]

- Payri, R.; Gimeno, J.; Bardi, M.; Plazas, A.H. Study liquid length penetration results obtained with a direct acting piezo electric injector. Appl. Energy 2013, 106, 152–162. [Google Scholar] [CrossRef] [Green Version]

- Kowalski, J. Influence of fuel injector holes diameter on parameters of combustion process in the cylinder of the marine 4-stroke Diesel engine. J. Pol. CIMEEAC 2016, 11, 95–102. [Google Scholar]

- “Injection”: Unique Research Installation. Available online: https://sites.susu.ru/inject/ (accessed on 1 June 2019).

- Musculus, M.P.B.; Miles, P.C.; Pickett, L.M. Conceptual models for partially premixed low-temperature diesel combustion. Prog. Energy Combust. Sci. 2013, 39, 246–283. [Google Scholar] [CrossRef]

- Seykens, X.L.J.; Somers, L.M.T.; Baert, R.S.G. Detailed modeling of common rail fuel injection process. MECCA 2005, 3, 30–39. [Google Scholar]

- Postrioti, L.; Buitoni, G.; Pesce, F.C.; Ciaravino, C. Zeuch method-based injection rate analysis of a common-rail system operated with advanced injection strategies. Fuel 2014, 128, 188–198. [Google Scholar] [CrossRef]

- Klein-Douwel, R.J.H.; Frijters, P.J.M.; Somers, L.M.T.; de Boer, W.A.; Baert, R.S.G. Macroscopic diesel fuel spray shadowgraphy using high speed digital imaging in a high-pressure cell. Fuel 2007, 86, 1994–2007. [Google Scholar] [CrossRef]

- Kamaltdinov, V.G.; Rozhdestvensky, Y.V.; Lysov, I.O.; Popov, A.Y.; Nikiforov, S.S. Experimental Investigations of the Effects of Electric Control Impulse on Injection Characteristics of Common Rail Type Injector. Indian J. Sci. Technol. 2016, 9, 104225. [Google Scholar] [CrossRef]

| Hole Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Nozzle 1 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 |

| Nozzle 2 | ~0.50 | ~0.40 | 0.30 | 0.30 | 0.30 | 0.30 | ~0.40 | ~0.50 |

| Rail Pressure (MPa) | Hole Number | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| 100 | 22° | 22° | 21° | 21° | 21.5° | 20.5° | 20° | 21° |

| 130 | 20° | 19.5° | 19° | 19° | 19° | 19° | 18.5° | 19.5° |

| 165 | 18.5° | 18.5° | 18° | 18° | 18° | 18° | 18.5° | 18.5° |

| Rail Pressure (MPa) | Hole Number | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| 100 | 22.5° | 20° | 22° | 22° | 20° | 21° | 24° | 22° |

| 130 | 23° | 21° | 20° | 19.5° | 19° | 19° | 21° | 22° |

| 165 | 21° | 22.5° | 19.5° | 19.5° | 19° | 20° | 21° | 21° |

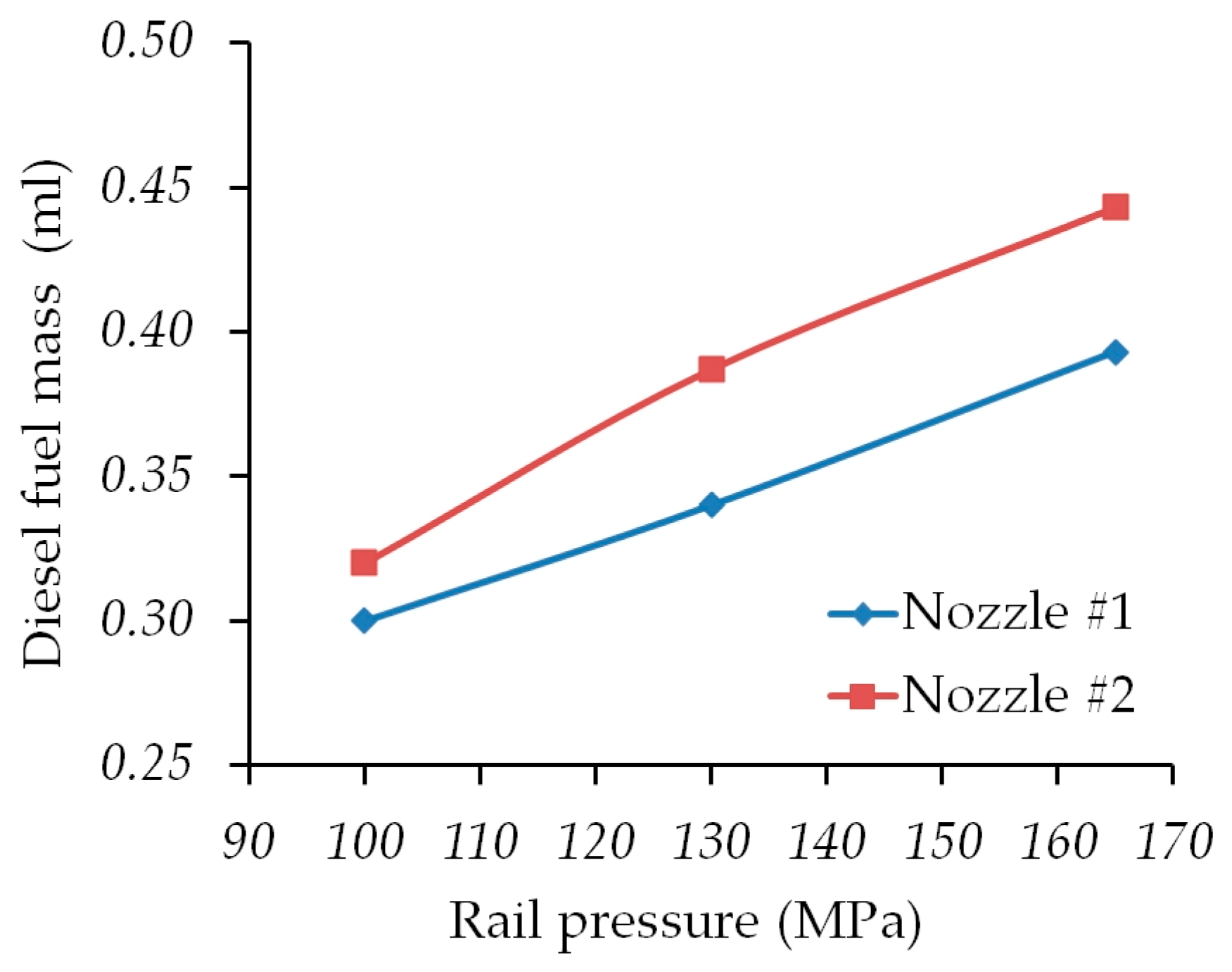

| Rail Pressure (MPa) | Injector with Nozzle 1 | Injector with Nozzle 2 | Δ (%) |

|---|---|---|---|

| 100 | 9 | 9.6 | 6.7 |

| 130 | 10.2 | 11.6 | 13.7 |

| 165 | 11.8 | 13.3 | 12.7 |

| Rail Pressure (MPa) | Injector with Nozzle 1 | Injector with Nozzle 2 | Δ (%) |

|---|---|---|---|

| 100 | 0.3 | 0.32 | 6.7 |

| 130 | 0.34 | 0.387 | 13.7 |

| 165 | 0.393 | 0.443 | 12.7 |

| Rail Pressure (MPa) | Injector with Nozzle 1 | Injector with Nozzle 2 | Δ (%) |

|---|---|---|---|

| 100 | 21.12° | 21.68° | 2.65 |

| 130 | 19.19° | 20.56° | 7.1 |

| 165 | 18.25° | 20.43° | 11.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamaltdinov, V.G.; Markov, V.A.; Lysov, I.O.; Zherdev, A.A.; Furman, V.V. Experimental Studies of Fuel Injection in a Diesel Engine with an Inclined Injector. Energies 2019, 12, 2643. https://doi.org/10.3390/en12142643

Kamaltdinov VG, Markov VA, Lysov IO, Zherdev AA, Furman VV. Experimental Studies of Fuel Injection in a Diesel Engine with an Inclined Injector. Energies. 2019; 12(14):2643. https://doi.org/10.3390/en12142643

Chicago/Turabian StyleKamaltdinov, V. G., V. A. Markov, I. O. Lysov, A. A. Zherdev, and V. V. Furman. 2019. "Experimental Studies of Fuel Injection in a Diesel Engine with an Inclined Injector" Energies 12, no. 14: 2643. https://doi.org/10.3390/en12142643

APA StyleKamaltdinov, V. G., Markov, V. A., Lysov, I. O., Zherdev, A. A., & Furman, V. V. (2019). Experimental Studies of Fuel Injection in a Diesel Engine with an Inclined Injector. Energies, 12(14), 2643. https://doi.org/10.3390/en12142643