1. Introduction

Any offshore renewable energy sources are still in their infancy. Offshore wind farms are currently the most prevalent of these technologies, and, with the introduction of low subsidy auctions enabling installations further offshore, the distance from shore at which these are situated continues to expand [

1,

2]. Proposed sites such as Dogger Bank will be up to 290 km offshore, which is substantially further offshore than most current offshore wind farms [

3]. With these increasing distances come new challenges in many fields. One such challenge is the reliability of the offshore transmission system.

The reliability of subsea transmission cables, especially those connected to offshore wind farms, is of some significance. Due to the intermittence of wind offshore, wind farms are not always producing electricity and as such, when they are, it is of high importance to transmit the electricity to consumers. This not only lowers the cost of energy but helps reduce emissions from coal or oil power stations. Due to the nature of the environment in which a subsea cable is situated, the offshore wind farm it is connected to will expect a higher wind resource than its onshore counterpart. However, these conditions can also increase the mean time to repair due to the sea conditions, potentially leading to large reductions in availability for significant lengths of time. With a greater understanding of the reliability of subsea cables, fewer instances of unexpected downtime should occur, ultimately reducing the need for fossil fuels and lowering the cost of energy.

The reliability performance of offshore cable connections in the field is currently not very well documented. This is due to the relatively recent introduction of the technology when compared with onshore transmission. It is because of this and the ever increasing distances offshore that a greater understanding of the reliability of offshore transmission is needed, not only for wind farms but for wave and tidal technologies too.

One of the methods being considered to combat the issues that would arise from any significant offshore wind transmission systems outages or failures is an energy island. The concept for such an island has been proposed by TenneT [

4]—this “North Sea Wind Power Hub” would be situated in the Dogger Bank region of the North Sea. The island would be artificially constructed and would be home to a series of solar panels and be surrounded by wind turbines. The island would act as both a power source and an interconnector between six European countries: United Kingdom, Netherlands, Germany, Norway, Denmark, and Belgium. With these connections in place, no energy would be wasted, and, in the instance of a transmission system failure, the energy could be rerouted to another country.

With 79 operational offshore wind farms across Europe, 62 of which are less than 10 years old, it can be seen why the information available is so sparse. Additionally, 24 wind farms currently range from pre-construction to partial generation. As such, the availability of failure rate statistics will not massively improve over the next few years. However, using the data currently available, it is possible to gain a better understanding of the reliability of the cables during early life.

Prior to the introduction of offshore wind farms, subsea cable information was drawn from onshore transmission systems and interconnectors [

5,

6]. With this information, it was clear that there would be some specific offshore risks such as trawling or anchors from ships. However, it is of note that, due to the nature of the seabed, these connections would not always be similar in length or in state of burial to those currently in place. As such, it is not enough to rely entirely upon the known failure rates of onshore transmission or large interconnectors.

1.1. Offshore Wind Transmission System Technology

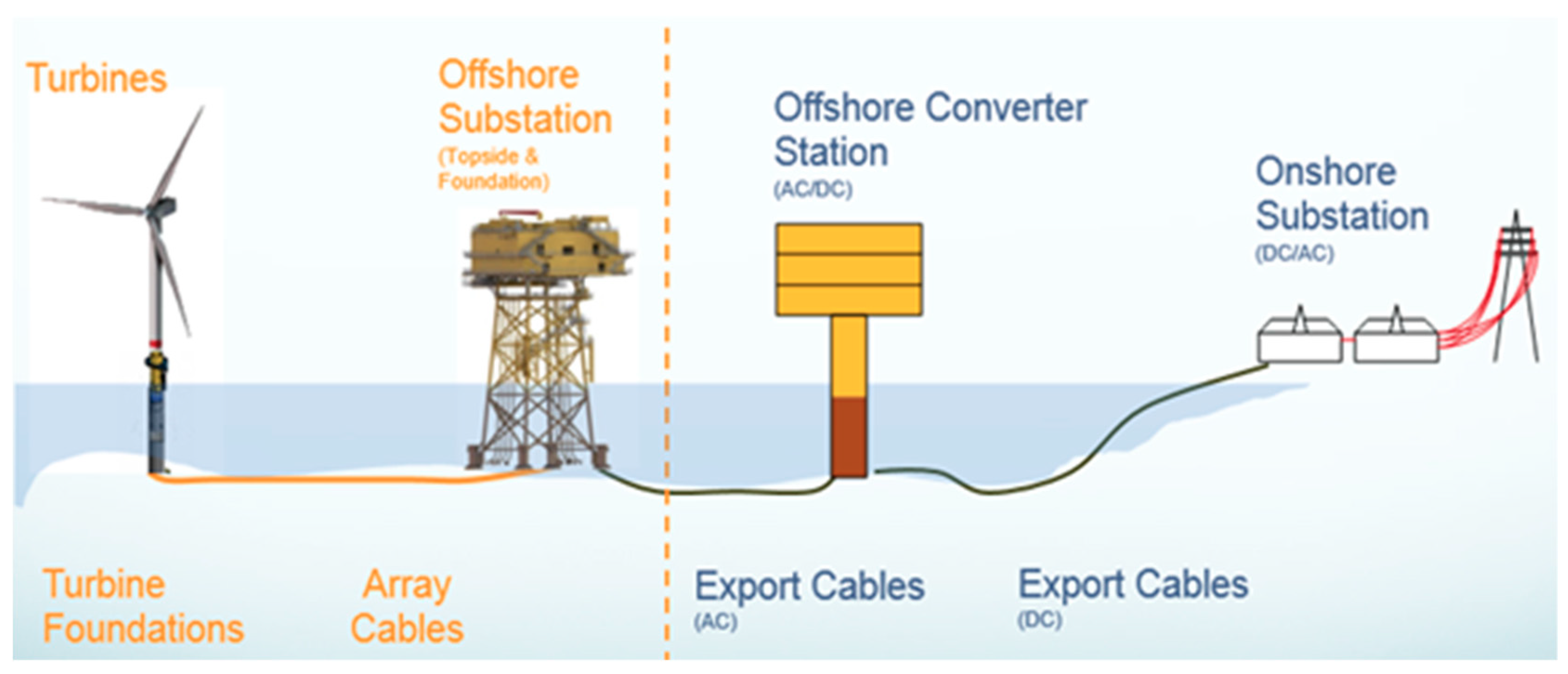

An offshore wind farm connection is comprised of several parts. This is dependent on the type of technology used both within the windfarm itself and in the cable connection to the grid, an example of which is visualized in

Figure 1. In some cases, such as the test sites found very close to shore, the connection is a short transmission cable which connects directly from the turbine to the transformer station.

When the wind farm is situated at a greater distance from the grid connection point, the developers must decide upon which technology will be used; the choices are medium voltage alternating current (MVAC), high voltage alternating current (HVAC), or high voltage direct current (HVDC). This decision can alter the transmission configuration [

5,

6].

When considering the alternating current (AC) options, a developer will need to account for possible reactive compensation at the remote ends. For long cables, it may be necessary to consider in-line reactive compensation for voltage and reactive power control.

Direct current (DC) cables are typically only used for greater cable lengths, as it is only at approximately 80 km that the cost–benefit associated with DC cables compared to AC cables becomes beneficial. A DC connection requires no substations along the length of the cable. However, it will require a converter station at either end of the cable to convert the AC power generated by the wind farm to DC and to convert the DC power back to AC at the grid side.

When planning a cable connection, another key design choice is that of the level of redundancy in a system. A number of sites will opt for a single cable, whereas others will choose three or four [

7].

The research carried out in this paper examined the transmission cables of all operational wind farms in Europe. The failure rates presented in the paper are related directly to the transmission cables themselves and do not account for failures associated with substations or array cables. It was found that the only DC connections currently being used are those owned and operated by the regional transmission system operator (TSO) [

8]. Unlike most other connections, these were constructed in order for a number of wind farms to connect to upon construction.

1.2. Cable Technology

AC cables are typically three phase cables, where each core is insulated individually, but the three cores are within a common armor. DC cables come in two types—mono-polar and bi-polar—and consist of two conductors again either laid as a bundle or separately [

9].

Each of the protective layers around a cable serves a particular purpose in preventing failures; the lead sheath contains the electric field and prevents water ingress into the cable. Due to the environment in which offshore cables are laid, and to protect them from installation forces, they are heavily armoured, normally with a layer of steel wires.

These cable technologies are insulated in order to reduce heat losses occurring in the conductors. Heat losses not only lead to lost energy but can also pose a threat to the integrity of the cable should the conductor overheat. Some of the insulators frequently used in offshore transmission are: Cross-linked polyethylene (XLPE), which is the technology used in offshore wind connections; self-contained oil filled (SCOF); and mineral insulated (MI) [

5,

6].

1.3. Data Resource

In the field of offshore wind transmission system reliability, published information is difficult to find. In the paper published by the authors [

1], a database of reported offshore failures in the field was created and compared to the assumed figures being used in the literature. It was found that failure rate statistics used in a number of published studies [

5,

6,

9,

10,

11,

12,

13,

14] conformed to those being experienced in offshore wind farms. However, it was established that most studies did not adequately consider the spread of potential reliability performance. This study draws from a larger pool of offshore wind farms, specifically all operational wind farms in Europe, and seeks to establish a benchmark for reliability performance based on operational performance.

1.4. Literature Review

An examination of literature [

5,

6,

9,

10,

11,

12,

13,

14] highlighted the lack of published failure rate information for offshore wind transmission systems. From a review of the available literature, it can be inferred that many publications estimate the failure statistics associated with several components of an offshore transmission system. A review of the literature would suggest that the key reference for offshore cable reliability failure rates are the reports published by CIGRE working groups B1.10 and B1.21 [

5,

6]. Not only does the industry heavily rely upon these statistics, it appears that other authors draw upon this information in their research [

9,

10,

11,

12,

13,

14]. Whilst previous publications by the authors [

1] suggested that these estimations conformed to the failure rate being experienced offshore, this research challenges that claim.

Research conducted by a number of parties also investigated failures by means of discussion with owners and operators of offshore wind components [

5,

6]. However, this research required further validation through discussion with cable manufacturers. Such reports have also drawn upon information from a number of transmission systems that are different to those used in offshore wind transmission systems. These reports rely on information from interconnectors, which are often longer and typically found in deeper water than offshore wind transmission lines.

According to the report by Ole Holmstrom called “Reliability of State of the Art Wind Farms” completed as part of Project Upwind [

15], if failures which occur during installation and commissioning are ignored, then current operational wind farms will not have experienced many cable failures. Whilst this statement is true for almost half of the wind farms currently operational across Europe, this is as a result of the infancy of many of these wind farms. The research completed in this paper aims to exhibit the number of failures being experienced by European wind farms.

Project Upwind also goes on to state that the reliability metrics currently being used could be reduced due to the conclusions drawn using HVDC links. However, this research also aimed to challenge this motion, as it was seen that failure rates being experienced by offshore transmission links have been, in many cases, higher than those published for interconnectors and other HVDC links.

Another issue highlighted in the Project Upwind report is a key cause of damage and failure being the entry to the wind turbines through J-tubes—the conduit which connects the cable from the sea to the platform. Reports suggested that at a number of sites the protection is sinking, which leaves cables bare and exposed to damage. Another key cause highlighted was the risk of cables becoming deburied and, as such, being exposed to seabed conditions such as strong currents and rocks. This paper, like previous work by the authors [

1] highlights other causes of failure.

A review of the available literature has highlighted a number of fields of research where the focus of this paper could be useful. Currently, there are a number of studies regarding optimizing the connections of offshore wind farms and other offshore generation technologies such as wave and tidal technologies [

16,

17]. Both of these technologies, like offshore wind, utilize offshore transmission systems and could benefit from the relative maturity of offshore wind cable connections, despite its lack of failure rate statistics.

Work which focusses on losses in offshore AC and DC transmission systems has also been completed [

18]. The work completed in this study looks at combining both AC and DC technologies to minimize losses across the length of the entire transmission system. This includes losses due to cable failures, which could potentially be reduced using the findings of this research through the application of accurate failure rate statistics to the AC portion of the combined technologies.

There is ongoing research within the field of offshore transmission systems regarding the viability of DC transmission systems [

19,

20,

21]. Whilst there had been much speculation that the industry would lean towards HVDC technology as wind farms moved further from shore, this has not been realized in practice yet. This drives the investigation and research for both AC and DC technologies.

2. Methodology

2.1. Database Population

Offshore transmission reliability information is not well publicized for a number of reasons. However, one of the key aspects is the small amount of offshore connections currently commissioned that have significant service experience.

Another key reason for the lack of published reliability information is related to commercial issues and the implications for manufacturers and insurers should failure information become public knowledge.

The population of the database began with listing the key details of all offshore transmission assets currently commissioned in Europe. Information that was deemed necessary is displayed in

Table 1:

This information could largely be drawn from online data sources such as 4C offshore [

22], as well as the governing body for each individual region.

Following up on information provided by industrial partners, it was then possible to search for news articles, governing body reports, notices to mariners, etc., containing evidence of cable failures. From these sources, a number of key facts could be extrapolated, such as the time of failure and the nature of the failure. In some cases, the time to repair was also provided.

The sources for all failures considered in this study are listed in the references section [

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50].

With this information, the total number of failures for each wind farm connection could be determined. Using this alongside the number of years the wind farm has been operational and the total cable length, the failure rate metric could be deduced:

In order to determine the total number of failures, a failure must be defined. In the reports produced by CIGRE in 2009 [

5,

6] a failure was defined as an “instantaneous failure leading to automatic disconnection” or an “occurrence requiring subsequent unplanned outage.” In this research, a failure follows this definition±—however, entries in the database such as exposed cable have been omitted from the overall failure rate calculation, as, in many cases, these have not yet lead to unplanned outages.

In order to obtain the total cable length for a given offshore wind connection, several online resources were accessed—primarily 4C offshore [

22]. In many cases, the information provided is the average cable length and the number of export cables, and the multiplication of these two figures resulted in the total cable length. The offshore cable length in this study was assumed to be from the wind farm substation to the onshore substation.

In this study, the decision was made to only use the year of commissioning. For a number of sites and failures, the information provided regarding exact dates of commissioning and failures is difficult to acquire, whilst the year of commissioning is easier to find. Removing the need for specific dates and months in the database allows for all sites and failures to be considered. The years operational were hence obtained through the calculation of the current year minus the year a site was commissioned.

2.2. Failure Metric Comparison

The results observed from Equation (1) were compared to the average values which were obtained by CIGRE in their reports [

5,

6]. The methodology used in this report is as follows.

A questionnaire was sent out to all countries with submarine cables regarding all cables installed between 1990 and 2005. The key questions regarded the total installed cable length and the number of faults experienced by the installed cables.

The working group received 32 replies from a total of 32 countries, and 14 of the replies claimed no faults had been experienced. This led to a supplementary questionnaire being sent to major cable manufacturers which received a positive response. The outcome of the supplementary questionnaire being that the data received can be assumed to be representative and sound [

5,

6].

The failure rates from this acquired data were estimated using the formula:

where

n = number of years,

Ni = number of failures of the component considered during the

i-th year of period concerned, and

Ai = quantity of the component in service at the end of the

i-th year.

The metrics derived in the CIGRE report using Equation (2) were compared to the metrics derived by the authors using Equation (1).

3. Results and Discussion

3.1. Site Analysis

Figure 2 displays the failure rate of AC transmission systems to offshore wind farms currently operational in Europe and compares these values to the average determined by CIGRE in their reports. Note that sites which have not experienced failures have been omitted from this graph and are listed in

Table 2 and

Table 3.

Excluded from the figure is Bard Offshore 1, which, due to its early life, short export cable connecting it to BorWin 1, and high number of failures, had a failure rate of around 0.0091 failures/km/year when considering all failures until March 2018. It can be seen that for those sites which have experienced any cable failures, the failure rate is higher than the figures published by CIGRE for XLPE cables. Additionally, it can be observed that the average failure rate across all offshore transmission systems connected to European wind farms—shown as the grey dotted line—was significantly higher than these published numbers.

3.2. HVAC

Considering the 50 operational offshore windfarm connections with a rating of greater than 100 kV, 19 have experienced failures. Proportionally, this is significantly higher than observed in the MVAC range, with 38% of all offshore transmission systems experiencing at least one failure. This is not unjustified when considering the factors that may lead to increased failure rate such as the maturity of the technology used. Other factors include the length of the cables since, as stated previously, the total cable lengths for these connections can be upwards of 400 km. Such long lengths bring their own difficulties with regards to cable burial and protection.

The increased capacity of the wind farms using these cable connections highlights the need for a greater understanding of the reliability of these cables. A majority of these connections are less than 10 years old, which has led to a lack of historical knowledge which most reliability analyses have been previously been based upon.

After examining the failure rates visualized in the graph, it can be seen that there was a significant difference in failure rate comparing site to site. An example of this can be seen in comparing the failures at Anholt, where several failures were experienced in early life—with a cable length of 24.5 km—to London Array, which has experienced a similar number of failures in the same lifetime but has a total cable length of 268.8 km due to the four cables connecting it to shore. This is significant, as if either of these sites were omitted from reliability analysis for future wind farm connections, the data could be misinterpreted.

Acquired data and previous studies by the authors has highlighted that a large number of failures occur as a result of manufacturing or installation faults which are not apparent until the cable is energized. Reports [

15] support this, suggesting that issues arising during cable installation are leading causes of in early life failures which then fall under the responsibility of the offshore transmission owners (OFTO) to repair, unless the damage leads to a fault prior to the OFTO transfer.

If the failure rate data is compared to those previously published throughout the literature, the results are similar to that observed for MVAC. It can be observed that if the failure rate for HVAC offshore wind connections were taken from the CIGRE statistics for XLPE subsea cables, then the failure rate would be underestimated.

3.3. MVAC

Assessing the connections within the MVAC range (10–66 kV), it can be observed that 19 of the 22 sites using this technology have no reported failures. This is significantly lower than the failures reported in the HVAC range, with only 14% of systems experiencing at least one failure. This could be due to several factors. These connections are typically short, and this is why they are able to use a lower voltage rating that the longer cables connected to larger capacity wind farms. It is of note that the longest total cable length in this region is 25.2 km compared to over 400 km when considering higher cable ratings.

From the graph in

Figure 2, it would appear that the failure rates experienced by cables in the medium voltage (10–66 kV) region is comparable to that experienced across HVAC (110–245 kV) ratings. However, it must be considered that many of these sites have been operational for a number of years more than those with higher capacities and higher cable ratings.

If the failure rates in the MVAC region are then compared to previously published failure rates, it can be observed that the XLPE figures from the CIGRE reports are significantly lower than those reported in this paper. This is assumed to be largely due to the nature of the cables this report has drawn its information from. These connections are listed simply as subsea transmission and, as such, will include large interconnectors which are upwards of 100 km in length.

3.4. Comparison of Average Failure Rates

The graph in

Figure 2 compares the average failure rates published by CIGRE in their reports to the failure rate for all European offshore wind farms. The methodology for calculating these figures is outlined in the Failure Metric Comparison section of the paper.

In order to more accurately compare these values, the average failure rate for offshore wind farm cable connections needs to be calculated. The overall mean is calculated using the standard equation:

In this instance, N is the total number of operational offshore wind farms and xn is the failure rate for the n-th wind farm cable connection.

The values presented in

Table 4 further confirm the analysis and discussion from the graph. Even when considering the sites which provide a failure rate of no failures per year, the metric observed is more than four times higher than the metric widely used throughout the industry.

This would suggest that using the figures published throughout literature, a failure analysis would yield results that would be incorrect. If a cable were to fail four times more than anticipated, the financial implications could be significant from both a repairs and lost revenue perspective.

3.5. Causes of Failure

Several reports and papers which have been published regarding submarine cable failures cite the leading causes of failure as trawling or anchors being dropped on cables. However, an investigation into the causes of failures of offshore wind connections suggests that this is not the case.

From 44 reported failures, only one can be directly linked to the fishing industry [

47]—at Thornton Bank Phases 2 and 3 (which share an export cable), the cable had to be repaired due to an underlying anchor. It is important to note that other failures recorded in this work could be linked to the fishing industry, even if not directly related to an anchor strike or a failure as a result of trawling. Considering the information explained above, it is clear that fishing continues to be a risk to submarine cables, especially when they become exposed.

Despite exposed cable not being considered a ‘failure’ in this study, information has been collated on cables which have become exposed and have and/or will require reburial. Three wind farm connections have reported an exposed cable between 2014 and 2018 [

25,

36,

37].

A large number of reported failures occur due to internal cable faults, with the rest of failures typically being as a result of poor installation. Several sites have experienced failures during the commissioning stage or shortly after the cable has been energized for the first time.

The cause of failures is not always apparent due to the nature of the sources from which the failure information has been drawn. For a number of the sites considered in this research, there was no recorded data available in the public domain other than that found in 4C offshore. Whilst this has proven to be a valuable data source, it is important to note that the information found within its database could be incorrect due to the nature in which it is entered into the database.

In some cases, the downtime may have been as a result of a proactive repair (following knowledge about other cables from the same source). Other recorded outages may not be failures at all, instead being a short downtime due the pro-active replacement of cable sections believed to be at risk or outages due to non-cable related issues. However, without transparency from windfarm owners and OFTOs, this is difficult to validate.

KIS-ORCA (the Kingfisher Information Service—Offshore Renewable and Cable Awareness) project says the following regarding cable failures [

51]:

“Cable faults are caused by many events, both man-made and natural. In water depths greater than 1000 m, faults are almost always caused by natural events such as underwater seismic activity, underwater landslides, current abrasion, etc. In water depths less than 200 m, faults are nearly always caused by man-made activities such as fishing and anchoring. Around 70% of all cable faults are caused by fishing and anchoring activities and about 12% are caused by natural hazards, e.g., current abrasion or earthquakes.”

It is of note that this information is likely based on long term historical data. Some of the older interconnectors are reported to have had in excess of 20 anchor strikes/trawler damages in their lifetime. This is vastly reduced in current cables due to better communication with fishermen and other sea vessels through publications from KIS-ORCA.

The information presented in this paper challenges this claim. However it should be noted that it is in a company’s best interests to report any failures and repairs to this organization so that they can alert fisherman and other sea vessels. As such, the information provided to an organization like this may be more accurate than that procured from publically available sources.

4. Conclusions

This paper has presented a review of offshore wind transmission system reliability. Through an analysis of the literature and sourcing failures from other publically available sources, a site by site analysis of offshore failure rates could be conducted. The findings of this analysis are compared to the widely used figures from literature. It was found that all sites which have experienced at least one failure appear to have experienced a higher failure rate than that currently being used in industrial practices. This was this case for all types of technology currently being used in offshore wind transmission systems.

When comparing the average failure rates of all offshore wind transmission systems, this research found that, as with the site by site analysis, the failure rate which appears to be being experienced offshore is higher than the figures being used in current industry practices.

These findings suggest that there is a need for changes in industry practices. Due to the lack of available failure data, the means for the industry to conduct accurate failure analysis is not available. This leads to out of date information being used from sources dissimilar to that being considered. There is also a need for the data which is used by the industry to be updated; however, it is expected that this will be updated in the coming years through CIGRE working group B1.57.

This research is being continued through the use of statistical models to further populate the database of failures. It is hoped that this future work will create a model with which early life failures of offshore transmission systems can be forecasted. This model should aid in due diligence and decision making when planning offshore energy generation in the future.

The authors also aim to follow up this research by investigating the link between transmission system ownership and the reliability of a transmission system. Case studies of transmission system ownership in European countries will be conducted, and this information will be used alongside the work presented in this paper to determine whether or not there is a link between different ownership schemes and reliability of a system.